Gradient release type long-acting slump-retaining polycarboxylic water reducer, and preparation method and application thereof

A technology of slump-preserving polycarboxylic acid and water-reducing agent, applied in the field of building materials, can solve the problems of easy fluctuation of concrete working performance, loss of concrete fluidity, and segregation of concrete bleeding, so as to meet the requirement of fluidity retention time and solve the Slump loss, effect of reducing temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

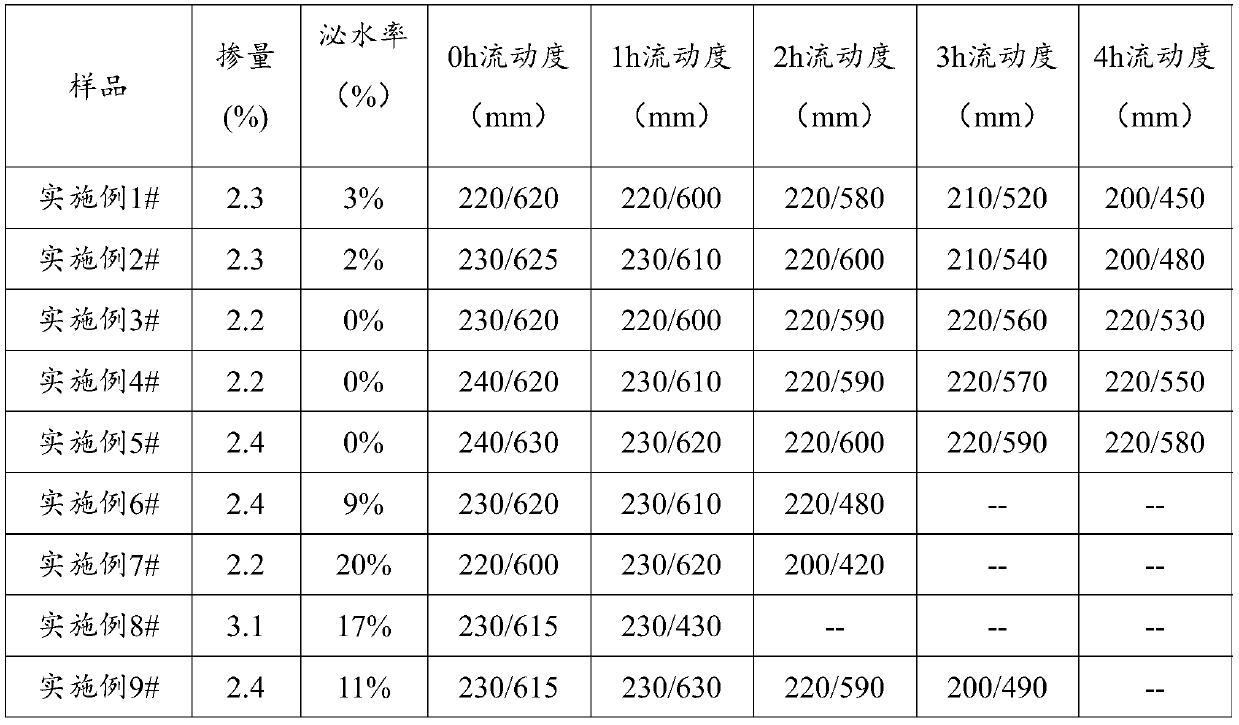

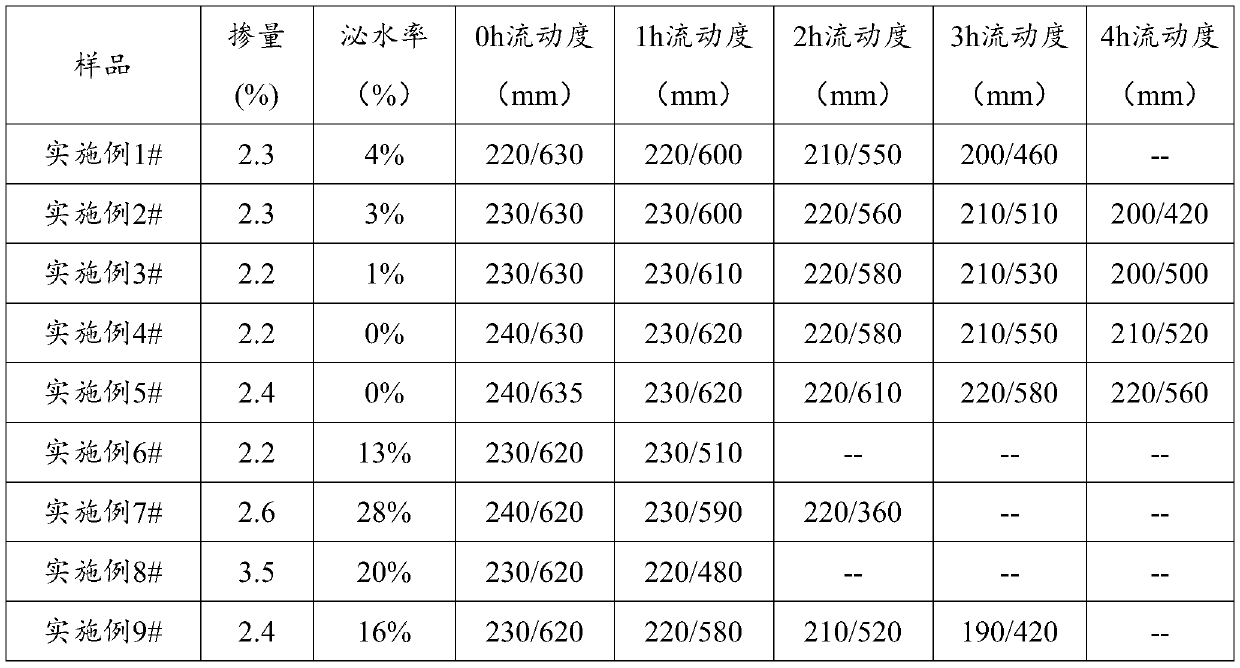

Examples

Embodiment 1

[0030] The preparation process of the long-acting slump-retaining polycarboxylate superplasticizer of the gradient release type in this embodiment is as follows:

[0031] 1) In a glass reactor equipped with a thermometer and a stirrer, add 20g of acrylic acid and 1g of cellulose ether, stir and mix well, then slowly add 10g of concentrated sulfuric acid, raise the temperature to 30°C, continue stirring for 180min, then add 30g of Ionized water, that is, to obtain a mixed solution of crosslinking monomer D containing unsaturated cellulose carboxylate;

[0032] 2) In a glass reactor equipped with a thermometer and a stirrer, sequentially add 200g of prenol polyoxyethylene ether and 270g of deionized water, stir and dissolve, then slowly add 5g of the mixed solution prepared in step 1), and stir for 30min , and then add 1g of ammonium persulfate to obtain the reactant solution;

[0033] 3) In the state of stirring, heat up or cold water to cool down to 10° C., respectively dropwis...

Embodiment 2

[0035] The preparation process of the long-acting slump-retaining polycarboxylate superplasticizer of the gradient release type in this embodiment is as follows:

[0036] 1) In a glass reactor equipped with a thermometer and a stirrer, add 10g of acrylic acid, 10g of methacrylic acid and 2g of cellulose ether, stir and mix well, then slowly add 15g of concentrated sulfuric acid, raise the temperature to 45°C, and continue stirring for 180min Finally, add 35g deionized water to obtain the crosslinking monomer D mixed solution containing unsaturated cellulose carboxylate;

[0037] 2) In a glass reactor equipped with a thermometer and a stirrer, sequentially add 200g of isobutenol polyoxyethylene ether and 270g of deionized water, after stirring and dissolving, slowly add 7g of the mixed solution prepared in step 1), stir for 30min, and then Add 1.5g of sodium persulfate to obtain the reactant solution;

[0038] 3) In the state of stirring, heat up or cool down to 20°C with cold...

Embodiment 3

[0040] The preparation process of the long-acting slump-retaining polycarboxylate superplasticizer of the gradient release type in this embodiment is as follows:

[0041] 1) In a glass reactor equipped with a thermometer and a stirrer, add 10g of methacrylic acid, 10g of maleic anhydride and 3g of cellulose ether, stir and mix well, then slowly add 5g of concentrated sulfuric acid, raise the temperature to 60°C, and continue After stirring for 120 min, add 40 g of deionized water to obtain a mixed solution of crosslinking monomer D containing unsaturated cellulose carboxylate;

[0042] 2) In a glass reactor equipped with a thermometer and a stirrer, sequentially add 200g of methallyl alcohol polyoxyethylene ether and 270g of deionized water, after stirring and dissolving, slowly add 10g of the mixed solution prepared in step 1), and stir 30min, then add 2g of potassium persulfate to obtain the reactant solution;

[0043] 3) In the state of stirring, heat up or cool down to 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com