Thickener copolymer as well as preparation method and application thereof

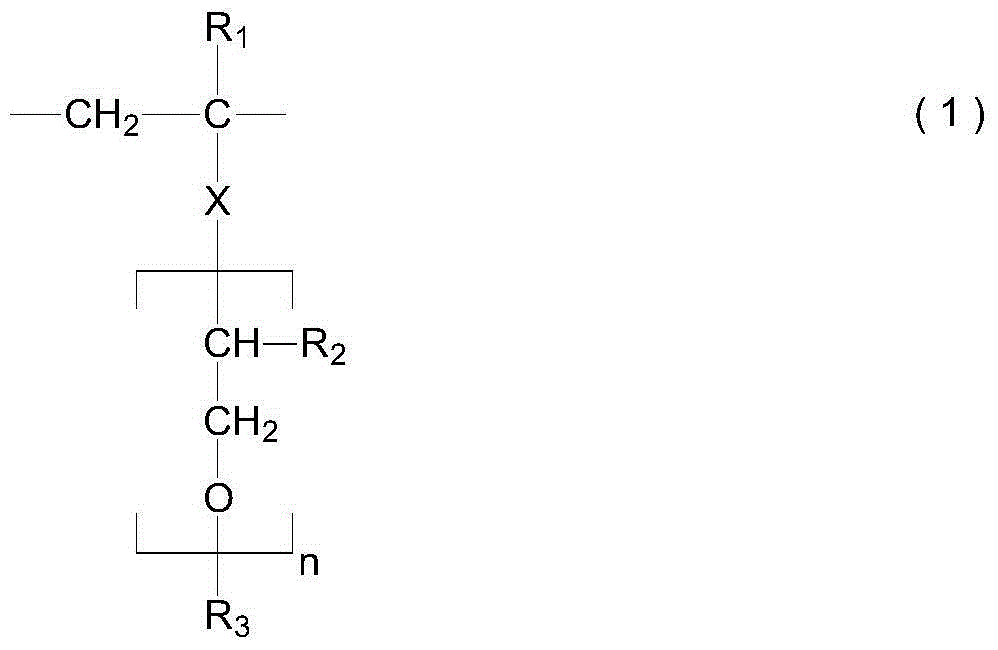

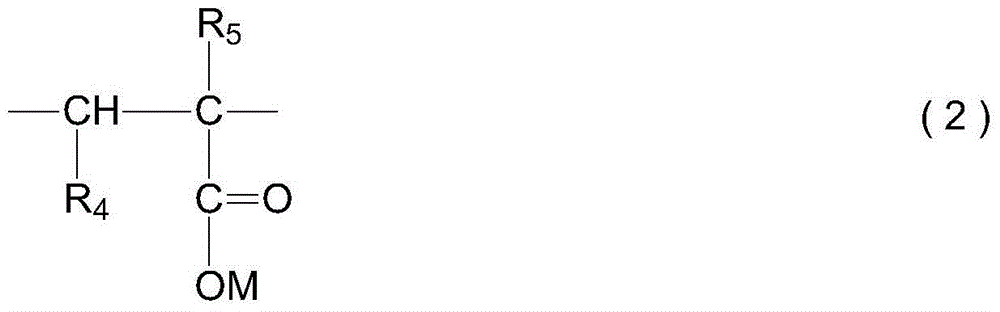

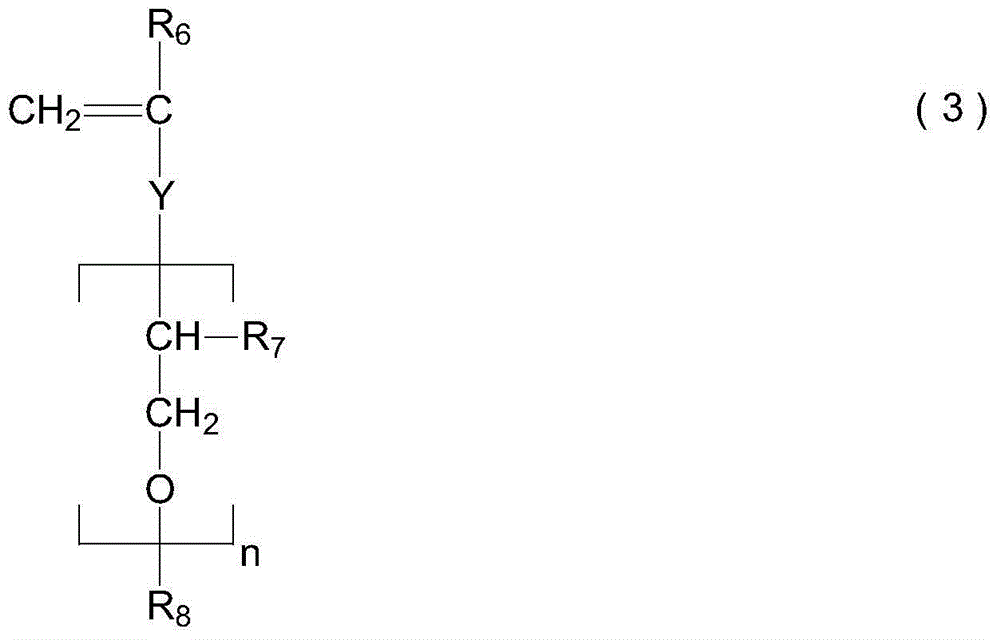

A technology for copolymers and thickeners, applied in the field of new thickeners containing polyether structural units and their preparation, can solve the problems of poor thickening and water retention, incompatibility, etc., and achieve initial fluidity and flow over time The effect of small size, controllable quality and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 500.0g of A-1 and 837.0g of water into a 2000ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, stir and heat up to 40°C, and add 12.0g of 35% hydrogen peroxide. At the same time, 101.0g vitamin C aqueous solution (obtained by dissolving 1.0g vitamin C in 100.0g water) and 400.0g monomer aqueous solution (obtained by dissolving 100.0g B-1 in 300.0g water) were added dropwise, and the dropping time was controlled at 20 minutes. The reaction temperature is controlled at 40-60°C. After the dropwise addition, the stirring was stopped, and the temperature was kept at 40-60° C. for 240 minutes to complete the polymerization reaction. After the heat preservation, 150.0g of 30% NaOH aqueous solution was added to obtain the thickener PA-1 with a solid content of about 31.0% and a weight average molecular weight of 850,000.

Embodiment 2

[0052] Add 570.0g of A-2, 30.0g of B-3, and 1148.2g of water into a 2000ml four-neck flask equipped with a stirrer, a thermometer, and a dropping device, stir and control the temperature at 20°C, and add 1.2g of ammonium persulfate. 100.6g vitamin C aqueous solution (obtained by dissolving 0.6g vitamin C in 100.0g water) was added dropwise, the dropping time was controlled at 10 minutes, and the reaction temperature was controlled at 20-30°C. After the dropwise addition, the stirring was stopped, and the temperature was kept at 20-30° C. for 300 minutes to complete the polymerization reaction. After the heat preservation is over, add 150.0g of 30% KOH aqueous solution to obtain thickener PA-2 with a solid content of about 31.3% and a weight average molecular weight of 280,000.

Embodiment 3

[0054] Add 100.0 g of A-3 and 1194.0 g of water into a 2000 ml four-necked flask equipped with a stirrer, a thermometer and a dropping device, stir and control the temperature at 50°C. At the same time, 106.0g aqueous initiator solution (obtained by dissolving 6.0g 2,2'-azobis(2-amidinopropane) hydrochloride in 100.0g water) and 600.0g monomer aqueous solution (obtained by dissolving 250.0g B-1, 50.0g of B-2 dissolved in 300.0g of water), the dropping time is controlled at 30 minutes, and the reaction temperature is controlled at 40-60°C. After the dropwise addition, stop stirring and keep warm at 40-60°C for 300 minutes to complete the polymerization reaction to obtain thickener PA-3 with a solid content of about 20.3% and a weight-average molecular weight of 625,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com