Thickener for self-compacting concrete, preparation method thereof and self-compacting concrete using the thickener

A technology of self-compacting concrete and thickener, which is applied in the fields of concrete admixture, concrete structure and concrete engineering, can solve the problems of unable to obtain qualified products, complex emulsification system, difficult emulsification, etc. Good, good thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

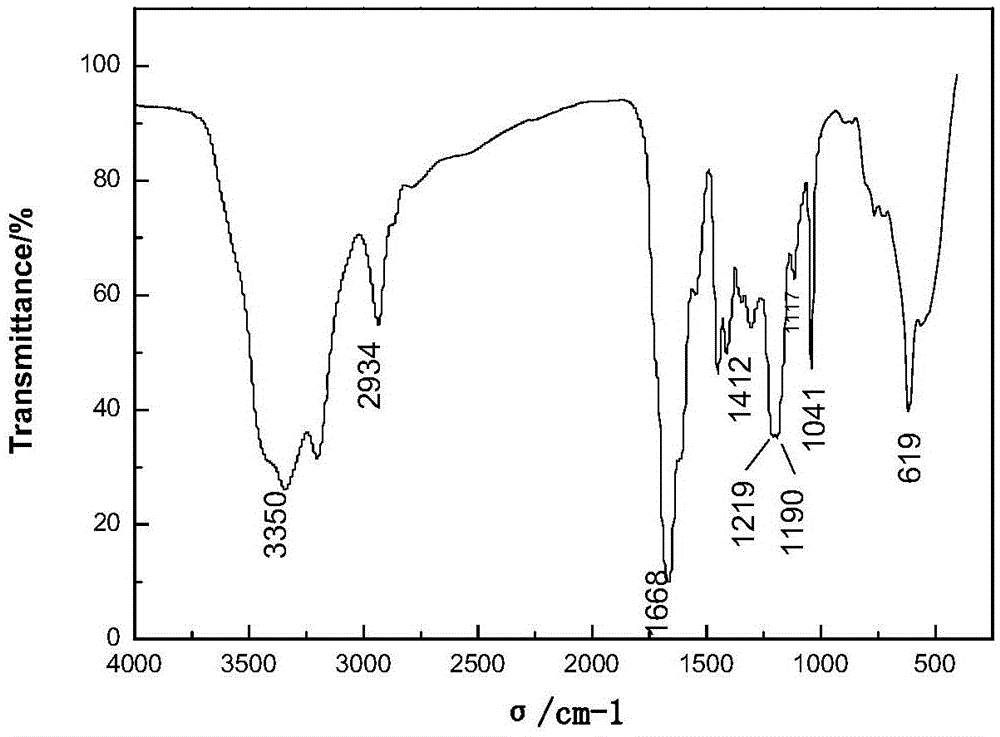

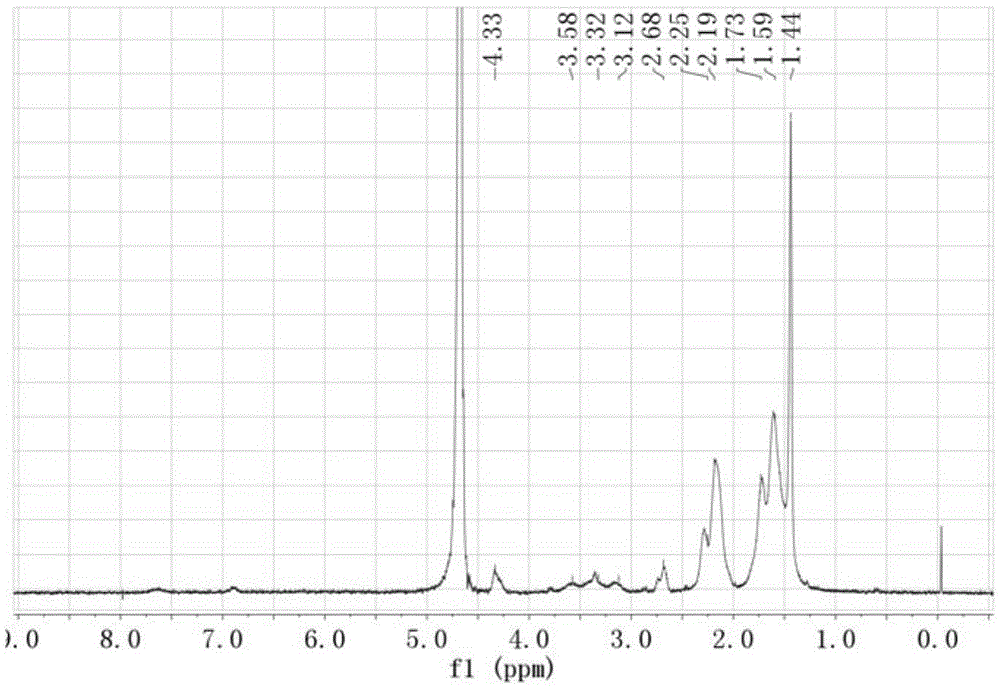

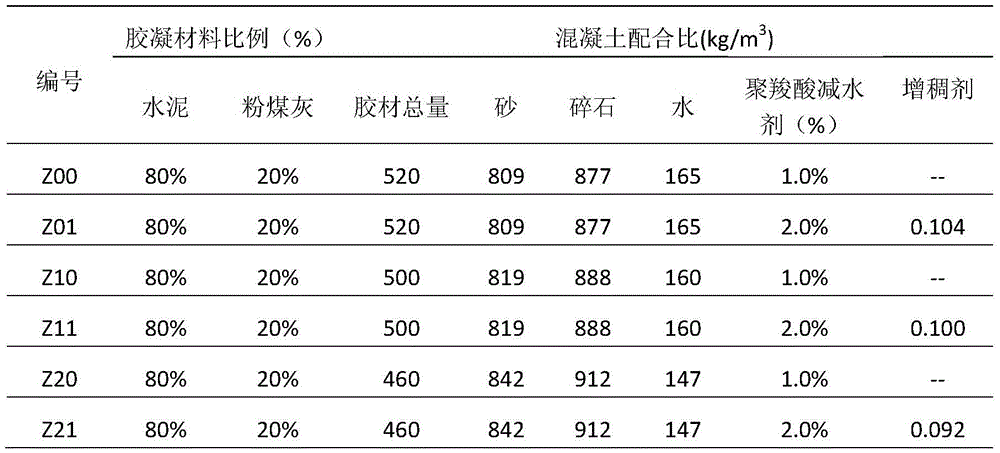

[0027] This example is a preparation example for self-compacting concrete thickener.

[0028] Weigh 5.0g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 15.0g of acrylic acid (AA), neutralize with 35mL of 20% NaOH solution until the pH of the mixture is 7; add 2.0g while stirring g of acrylamide (AM) solution, so that the total monomer concentration is 20%, after stirring evenly, pour the prepared solution into a 250mL three-necked flask, put it in a constant temperature water bath, pass nitrogen protection, and set the stirring speed to 1100 rpm / min; when the reaction temperature rises to 40°C, add 0.05g ammonium persulfate (40% aqueous solution) and 0.05g sodium bisulfite mixture initiator drop by drop, keep warm, stir and react for 2 hours, when the reactant is viscous liquid When the nitrogen is stopped, the constant temperature is matured for about 2 hours to obtain a colorless transparent colloid, which is a thickener for self-compacting concrete.

[0029] See ...

Embodiment 2

[0032] This example is a preparation example for self-compacting concrete thickener.

[0033] Weigh 4.05g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 9.75g of acrylic acid (AA), neutralize with 45mL of 20% NaOH solution until the pH of the mixture is 6.8; add 1.5g while stirring g of acrylamide (AM) solution, so that the total concentration of the three monomers is 20%, after stirring evenly, pour the prepared solution into a 250mL three-necked flask, put it in a constant temperature water bath, pass nitrogen protection, and set the stirring speed 1000 rpm; when the reaction temperature rises to 40°C, add 0.025g ammonium persulfate (40% aqueous solution) and 0.025g sodium bisulfite mixture initiator dropwise, keep warm, and stir for 2 hours. When it is a viscous liquid, stop nitrogen, and cure it at a constant temperature for about 2 hours to obtain a colorless and transparent colloid, which is a thickener for self-compacting concrete.

Embodiment 3

[0035] This example is a preparation example for self-compacting concrete thickener.

[0036] Weigh 7.5g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 19.5g of acrylic acid (AA), neutralize with 60mL of 20% NaOH solution until the pH of the mixture is 6.7; add 3.0g of Acrylamide (AM) solution, so that the total monomer concentration is 20%. After stirring evenly, pour the prepared solution into a 250mL three-necked flask, put it in a constant temperature water bath, and protect it with nitrogen. Set the stirring speed to 1300 rpm When the reaction temperature rises to 40°C, add 0.075g ammonium persulfate (40% aqueous solution) and 0.075g sodium bisulfite mixture initiator drop by drop, keep warm, stir and react for 2 hours, when the reactant is viscous liquid Stop the nitrogen flow, and cure at constant temperature for a period of about 2 hours to obtain a colorless transparent colloid, which is a thickener for self-compacting concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com