Tackifier of cement-base material and its preparation method and application

A technology of cement-based materials and tackifiers, applied in the field of building materials, can solve the problems of high price and unfavorable promotion and application, and achieve the effects of strong practicability, cost reduction, and solution to segregation and bleeding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

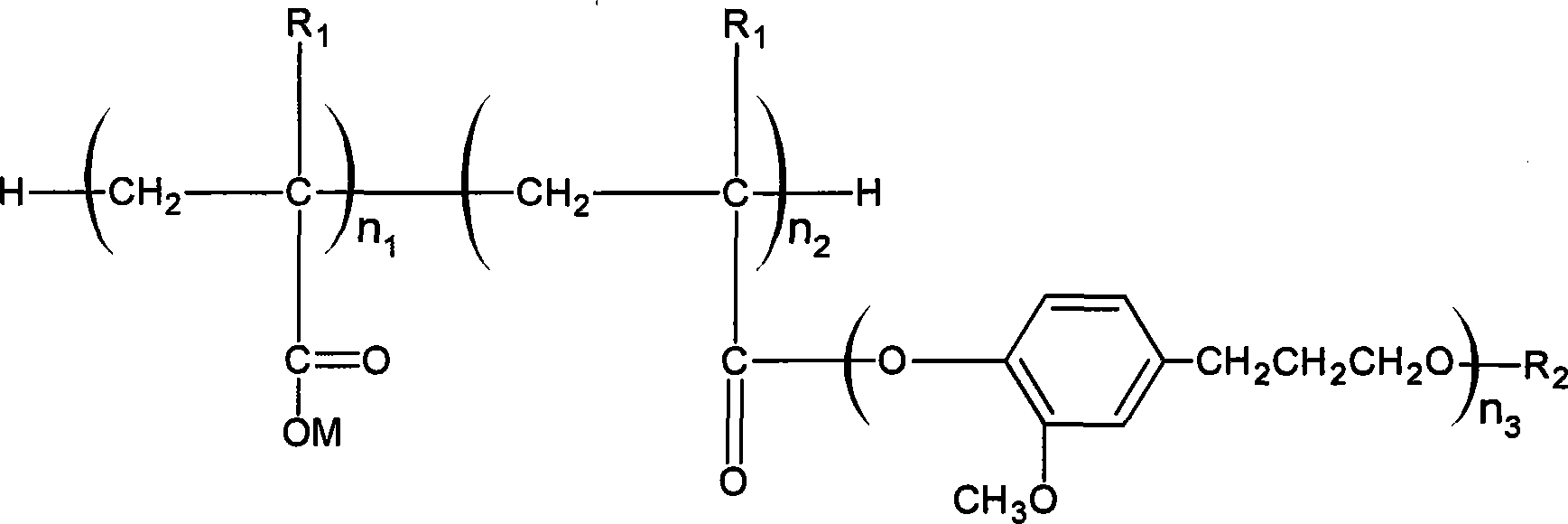

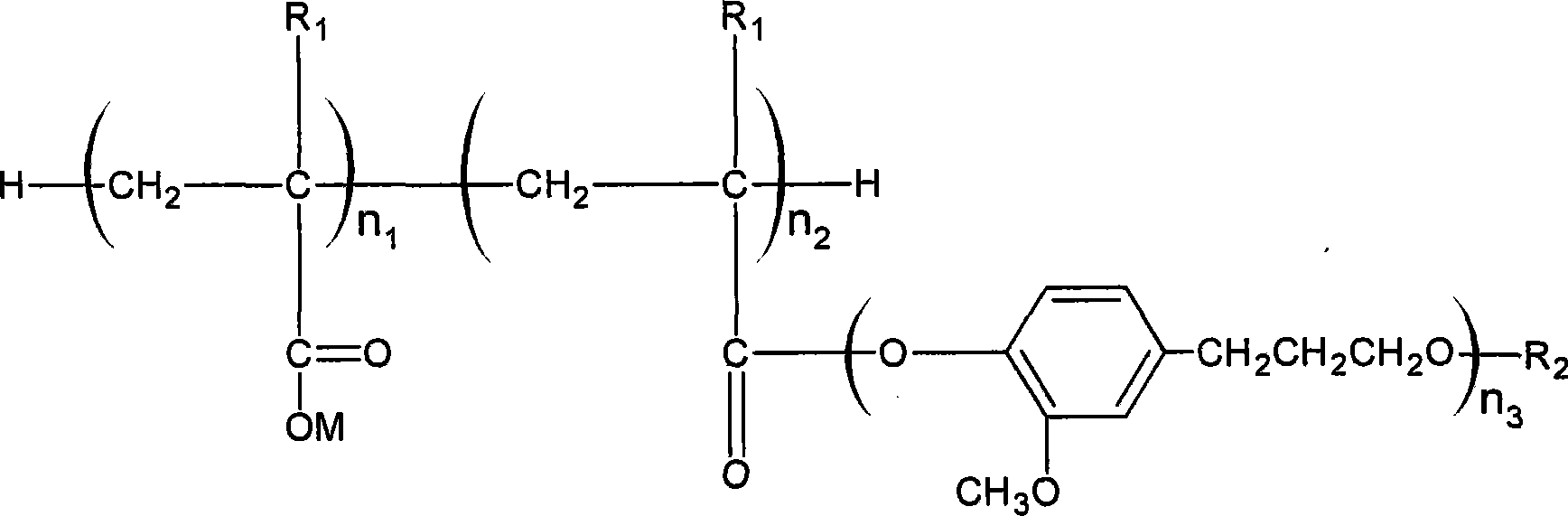

Image

Examples

Embodiment 1

[0015] Embodiment 1, the preparation method of the tackifier of cement-based material.

[0016] (1) Add 10 parts of acrylic acid, 50 parts of methylphenylpropane containing phenolic hydroxyl groups and concentrated sulfuric acid as a catalyst into a four-necked flask, heat up to 90±2°C while stirring, and perform an esterification reaction for 6 hours; Add 3 parts of acrylic acid and catalyst potassium persulfate, the reaction temperature is 85±2°C, react for 3 hours, then add dropwise 20 parts of formaldehyde solution with a concentration of 37%, and react for 1 hour; after the reaction is completed, adjust the pH of the reaction mixture with NaOH 6-7.

[0017] (2) Add 10 parts of maleic acid, 50 parts of methylphenylpropane containing phenolic hydroxyl groups and catalyst p-toluenesulfonic acid into a four-necked flask, heat up to 90±2°C while stirring, and perform esterification for 6 hours; Add 1.7 parts of maleic acid and catalyst ammonium persulfate after the reaction i...

Embodiment 2

[0018] Embodiment 2, the application example of tackifier

[0019] Application example of the present invention in large-volume fly ash self-compacting concrete: 230kg of cement, 230kg of fly ash, 900kg of sand, 800kg of 5-20mm stones, 170kg of water, 1.5kg of high-efficiency water reducer, and the tackifier of the present invention 138g. The indicators of the concrete after mixing are as follows: slump expansion degree 700mm, J-ring expansion degree 660mm, L-shaped box height ratio 0.87, U-shaped box flow height 330mm, concrete viscosity 65Pa·S, water retention and viscosity increase effect is obvious, no obvious Segregation and bleeding phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump spread | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com