Viscosity-increasable profile control agent and preparation method thereof

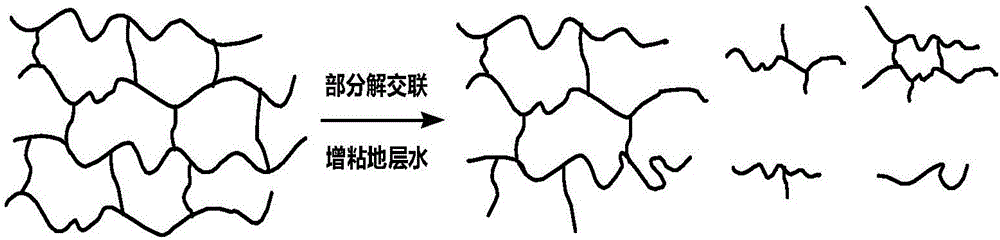

A profile control agent and initiator technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that the profile control agent has no viscosity-increasing ability and cannot play a displacing effect, etc., to ensure the strength and expansion performance, The effect of uniform cross-linking structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]

[0038] Dissolve 30.00g of acrylamide in 94.00g of water, add 3.00g of the main crosslinking agent N,N-dimethylacrylamide and 0.52g of lithium magnesium silicate to the aqueous solution of acrylamide monomer in sequence, stir until clarified, then add 0.12 g of the secondary crosslinking agent polyethylene glycol diacrylate, mixed evenly to obtain a monomer solution; while uniformly stirring, nitrogen was passed through the polymerization system to remove oxygen for 30 minutes;

[0039] Take by weighing 0.06g potassium persulfate and dissolve in 6.00g water to prepare initiator solution;

[0040]Mix the monomer solution and the initiator solution, and put the mixed reaction solution in a water bath at 40°C for 10.0 hours, then raise the temperature to 60°C for 8.0 hours to increase the conversion rate;

[0041] The product obtained in the above steps was pulverized and dried in an oven at 60°C until constant weight;

[0042] Use a 12000r / min universal pulverizer to...

Embodiment 2

[0044]

[0045] Dissolve 30.00g of acrylamide in 94.00g of water, add 1.80g of the main crosslinking agent N,N-dimethylacrylamide and 2.60g of lithium magnesium silicate to the aqueous solution of acrylamide monomer in sequence, stir until clarified, then add 0.30 The secondary cross-linking agent polyethylene glycol diacrylate of g is mixed uniformly to obtain a monomer solution;

[0046] Take by weighing 0.06g potassium persulfate and dissolve in 6.00g water to prepare initiator solution;

[0047] Mix the monomer solution and the initiator solution, and deoxygenate with nitrogen for 30 minutes;

[0048] Put the mixed reaction solution after deoxygenation into a water bath at 40°C for 10.0 hours, then raise the temperature to 60°C for 8.0 hours to increase the conversion rate;

[0049] The product obtained in the above steps was pulverized and dried in an oven at 60°C until constant weight;

[0050] The dried product is pulverized by a 12000r / min universal pulverizer, an...

Embodiment 3

[0065] Take Example 3 as an example:

[0066] Dissolve 30.00g of acrylamide in 94.00g of water, add 0.90g of the main crosslinking agent N,N-dimethylacrylamide and 1.12g of lithium magnesium silicate to the aqueous solution of acrylamide monomer in sequence, stir until clarified, then add 0.21 The secondary cross-linking agent polyethylene glycol diacrylate of g is mixed uniformly to obtain a monomer solution;

[0067] Take by weighing 0.06g potassium persulfate and dissolve in 6.00g water to prepare initiator solution;

[0068] Mix the monomer solution and the initiator solution, and deoxygenate with nitrogen for 30 minutes;

[0069] Put the mixed reaction solution after deoxygenation into a water bath at 40°C for 10.0 hours, then raise the temperature to 60°C for 8.0 hours to increase the conversion rate;

[0070] The product obtained in the above steps was pulverized and dried in an oven at 60°C until constant weight;

[0071] Use a 12000r / min universal pulverizer to pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com