Patents

Literature

57results about How to "Guaranteed expansion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

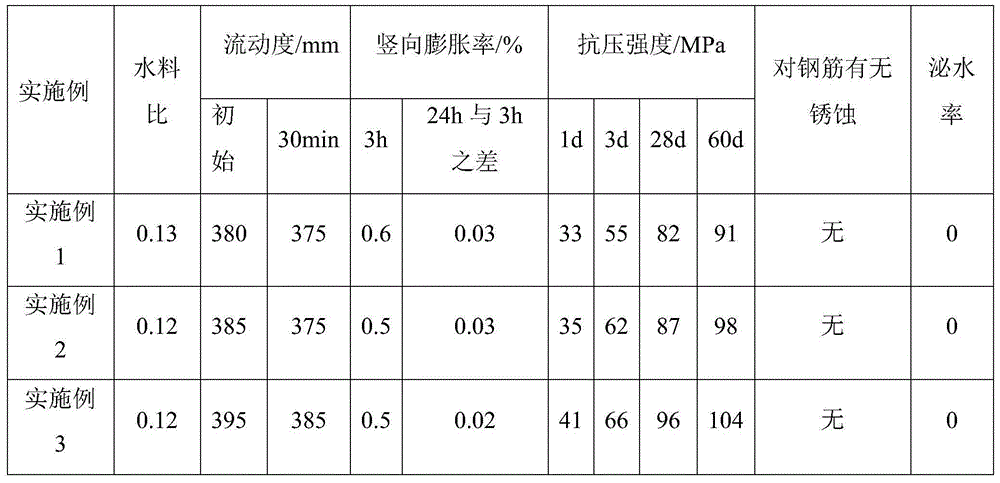

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

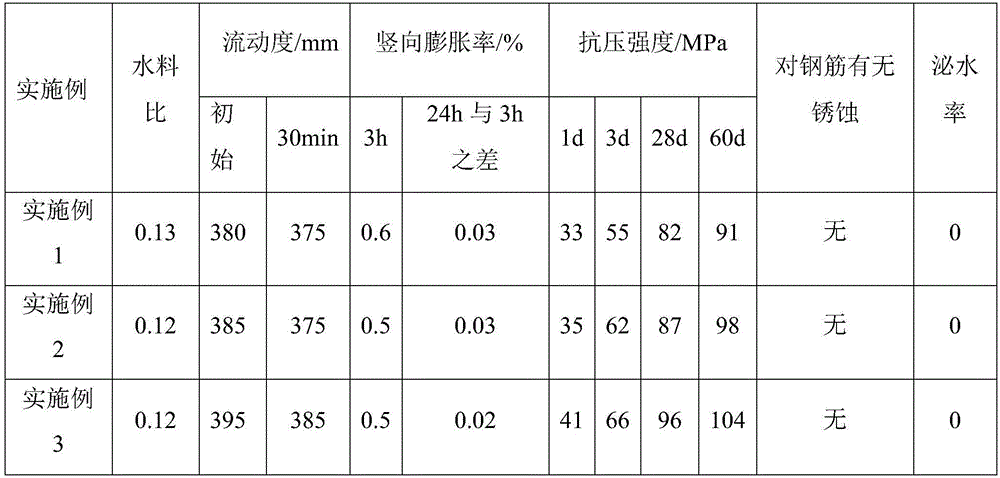

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

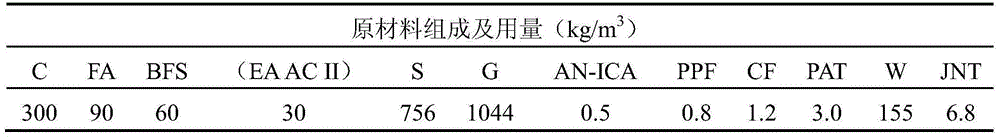

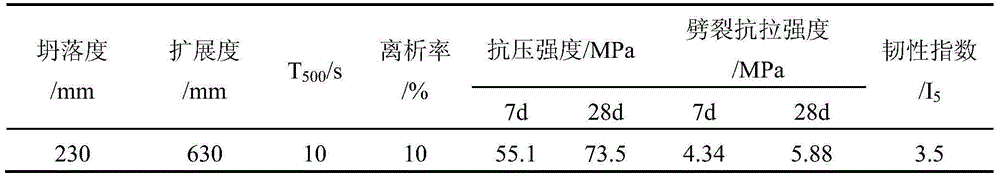

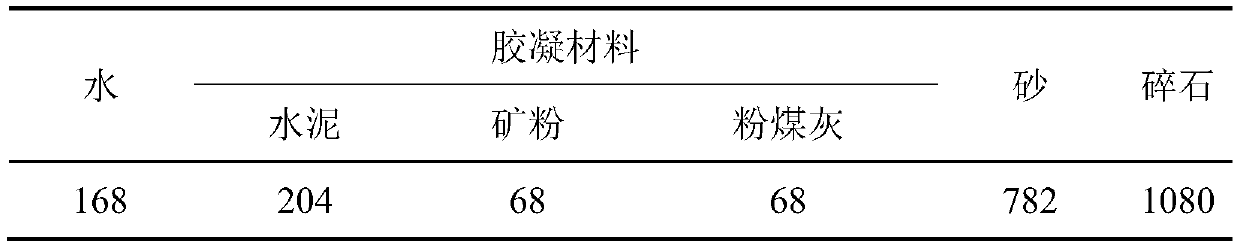

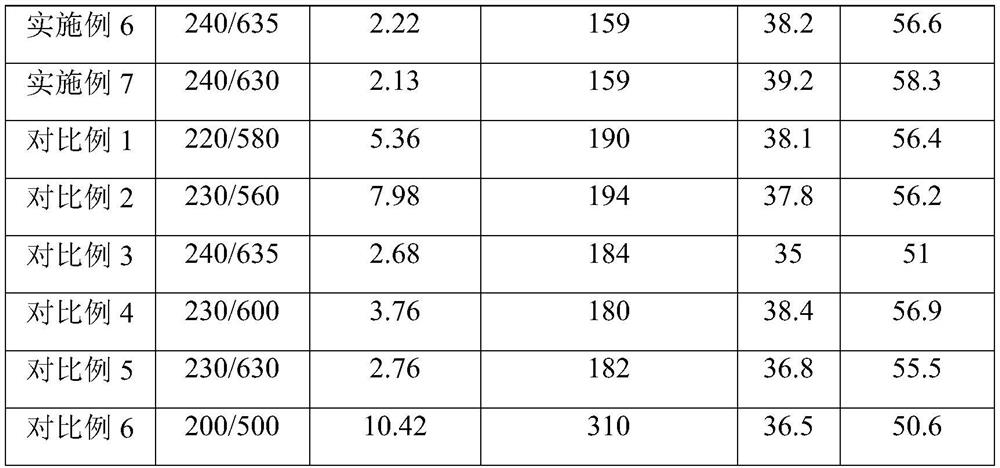

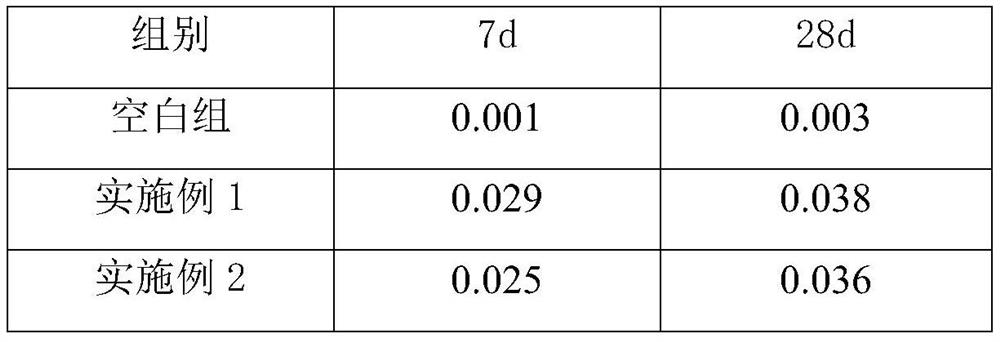

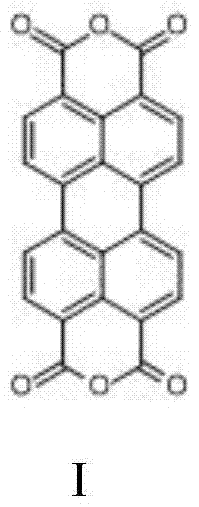

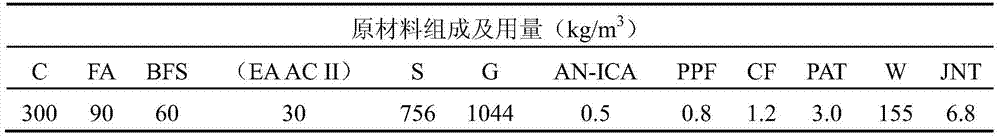

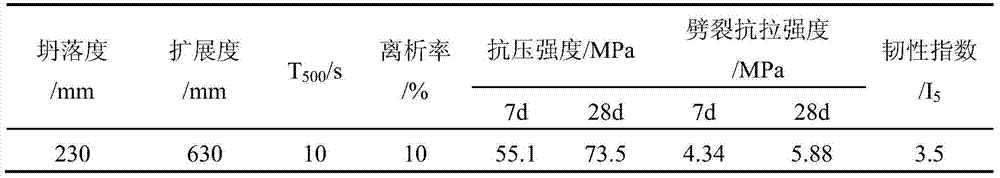

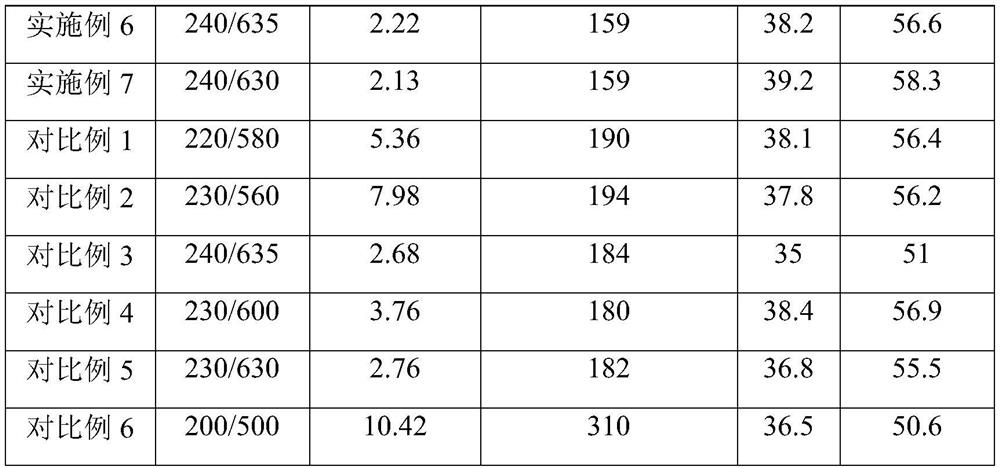

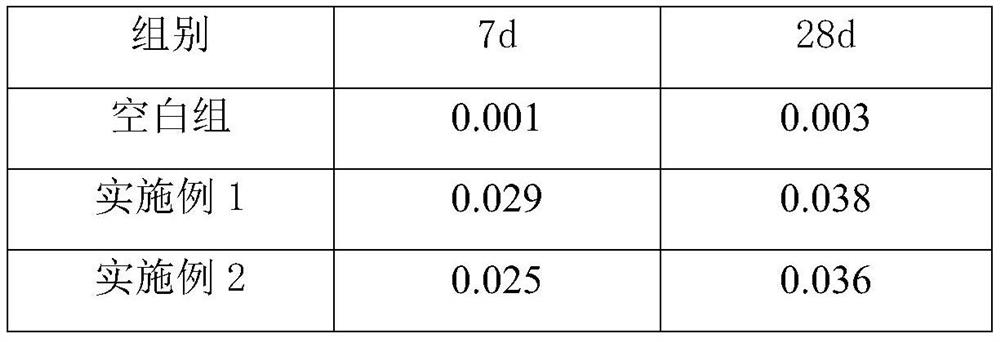

Low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, and preparation method thereof

The present invention discloses a low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, wherein the low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete is prepared from the following raw materials: cement, fly ash, mine powder, an expander, an AN-ICA internal curing agent, crushed stone, river sand, polyacrylonitrile fibers, micro-scale modified degreasing cotton cellulose, a cement slurry microstructure regulation agent, water and an ultra-dispersed water-reducing and shrinkage-reducing superplastic admixture. According to the present invention, the initial slump is more than or equal to 230 mm, the expansion degree is more than or equal to 630 mm, the 28 d compressive strength is more than or equal to 70 MPa, the 28 d splitting tensile strength is more than or equal to 5.8 MPa, the toughness index I5 is more than or equal to 3.0, the 28 d self-shrinkage is less than 100*10<-6>, the 28 d dry shrinkage rate is less than 150*10<-6>, the carbonization grade achieves T-IV, the anti-cracking grade achieves L-V, the product has characteristics of excellent mechanical property, excellent cracking resistance and excellent durability, and the difficult problems of high cement and cementing material material consumption, large shrinkage and easy cracking of the bridge tower concrete at the current stage can be solved.

Owner:WUHAN UNIV OF TECH +2

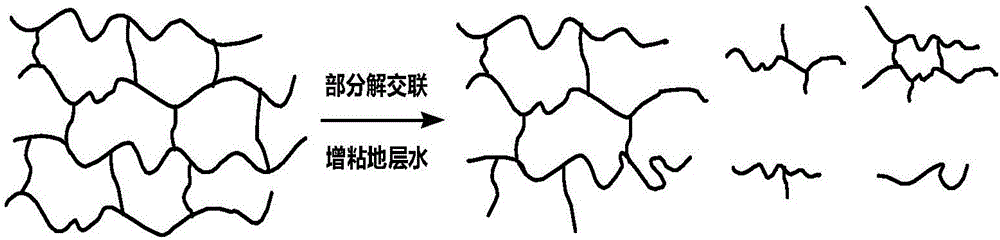

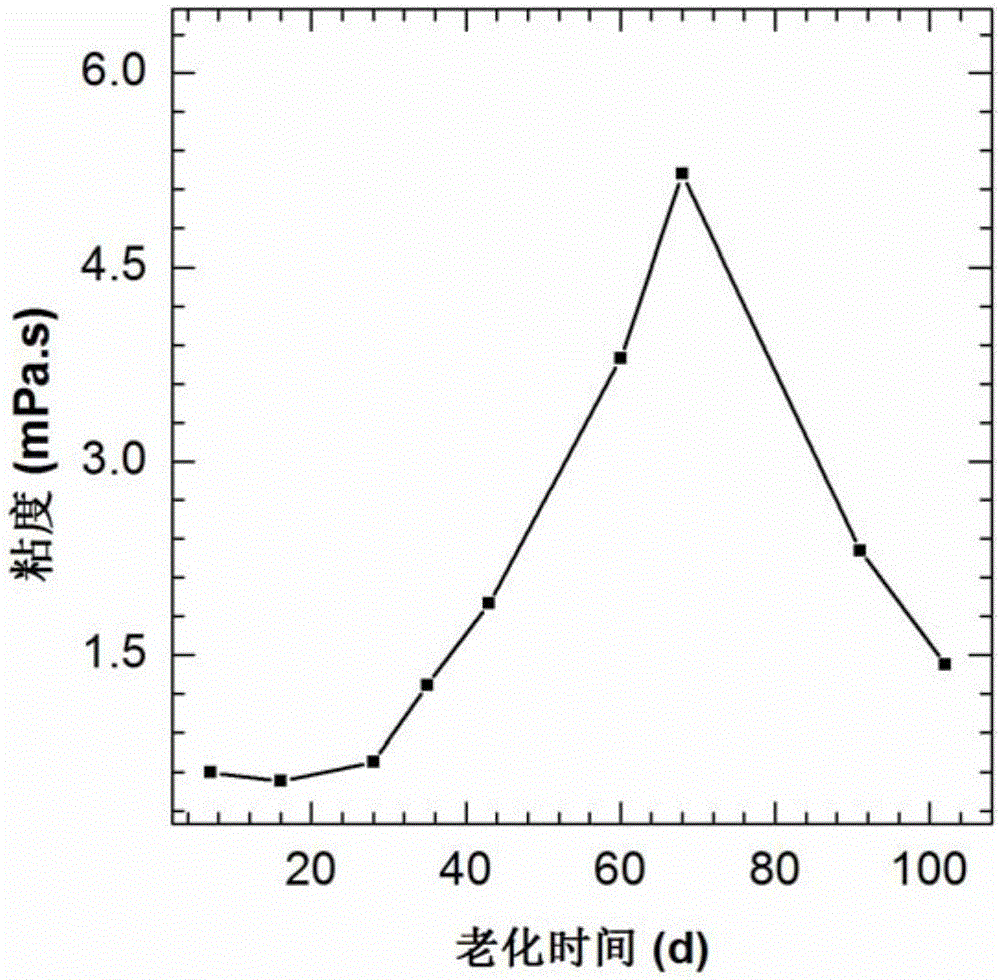

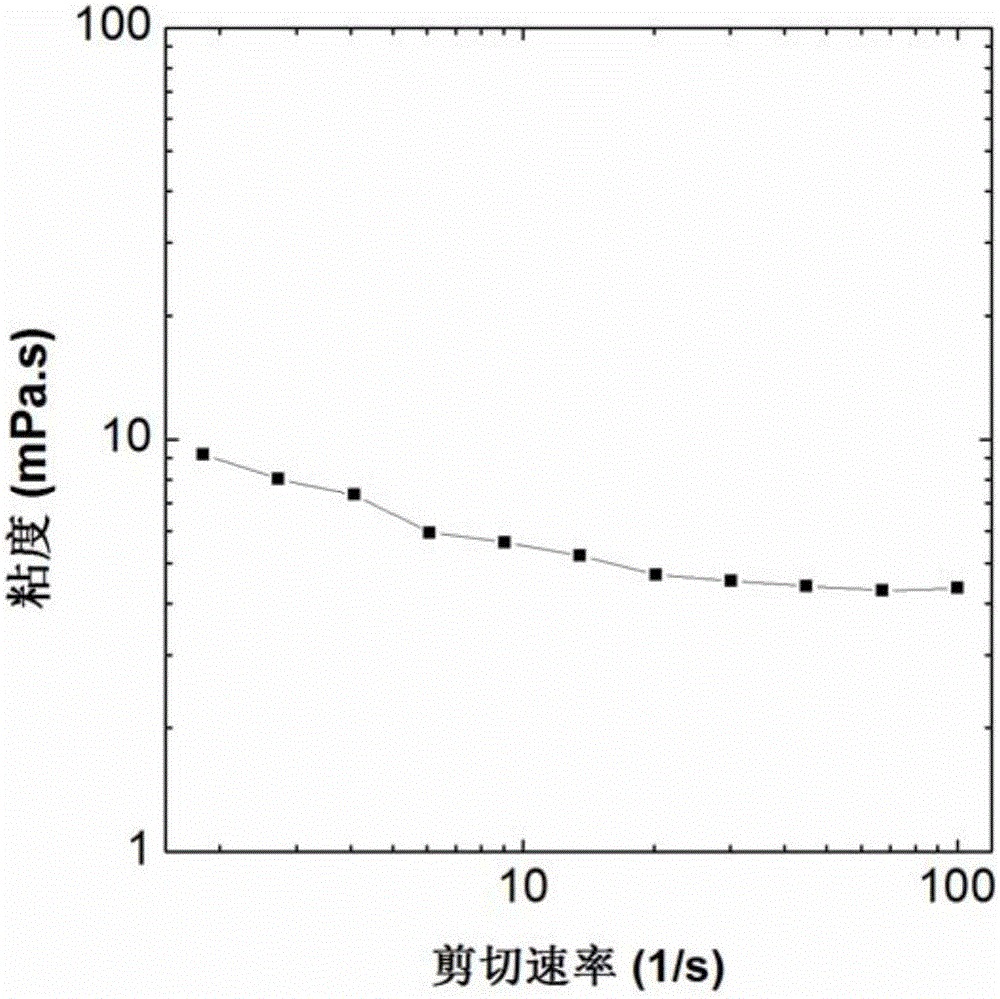

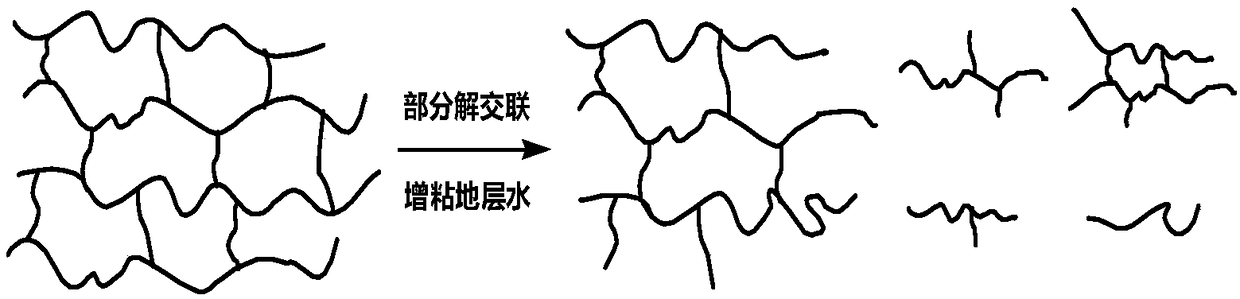

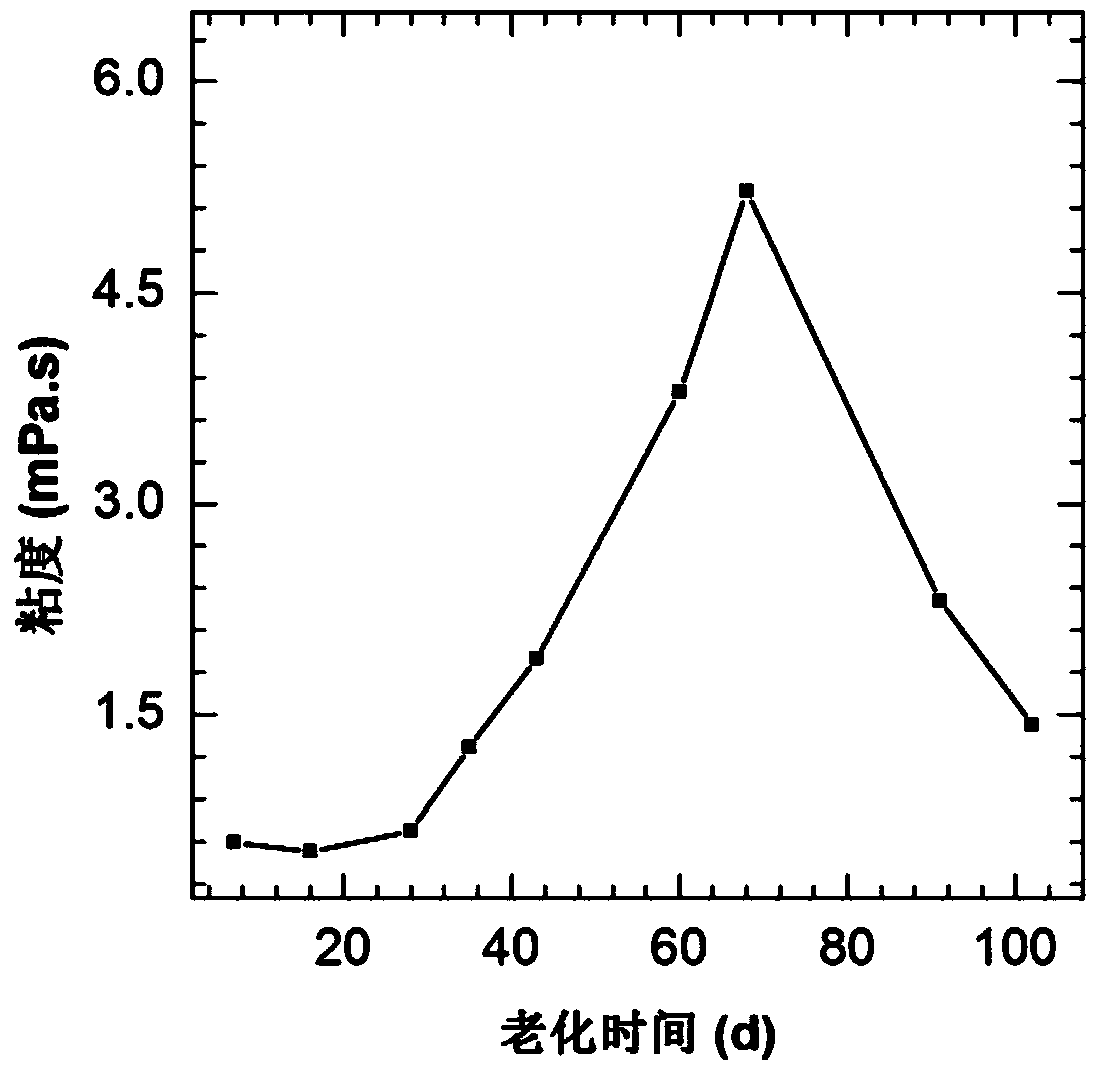

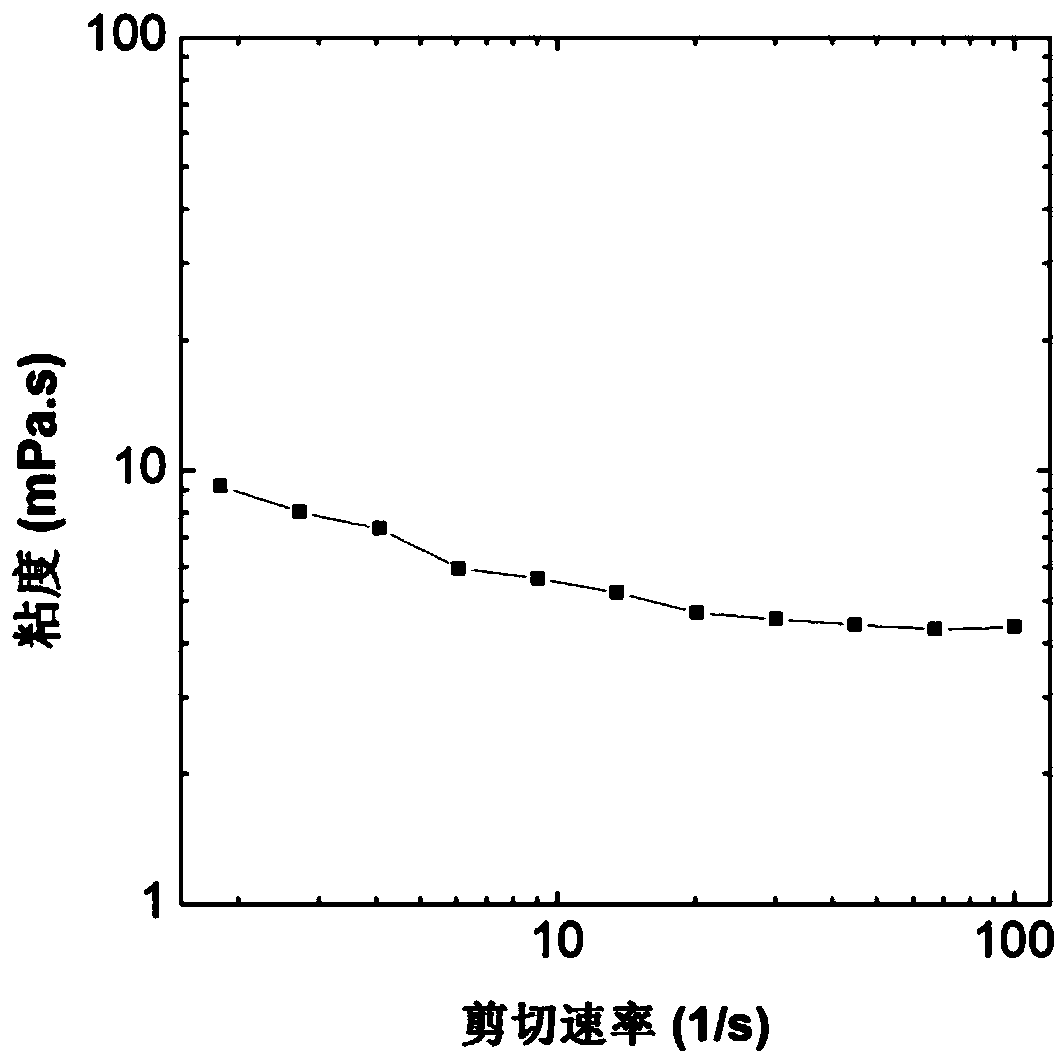

Viscosity-increasable profile control agent and preparation method thereof

ActiveCN106832146AUniform cross-linked structureGuaranteed strength and expansion propertiesDrilling compositionFunctional monomerOil production

The invention belongs to the technical field of a chemical reagent for oil production, and discloses a viscosity-increasable profile control agent and a preparation method thereof. The profile control agent is obtained through adding functional monomers, inorganic nanometer particles, main crosslinking agents and auxiliary crosslinking agents into an acrylamide monomer water solution, introducing nitrogen gas to remove dissolved oxygen and adding initiators under the water bath condition of 40 to 60 DEG C for polymerization; after the polymerization is completed, pelleting, drying and crushing are performed; a final product is obtained. The prepared profile control agent can realize the continuous viscosity increase on formation water to achieve a certain displacement effect; meanwhile, good anti-salt performance is realized; the water absorption swelling can be generated in the high-concentration salt brine; after the expansion, high intensity is still realized, so that the high seepage layer in an oil deposit can be effectively sealed and plugged; the profile control effect is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

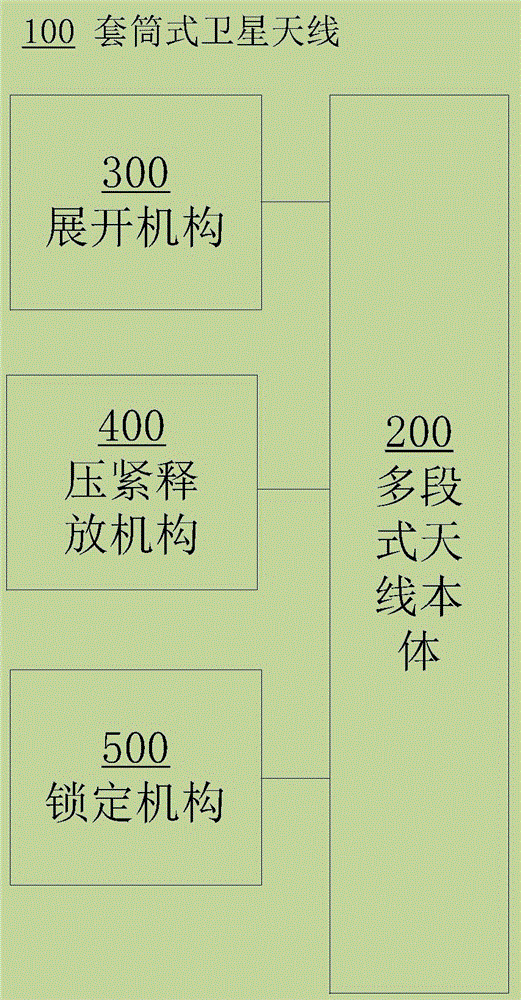

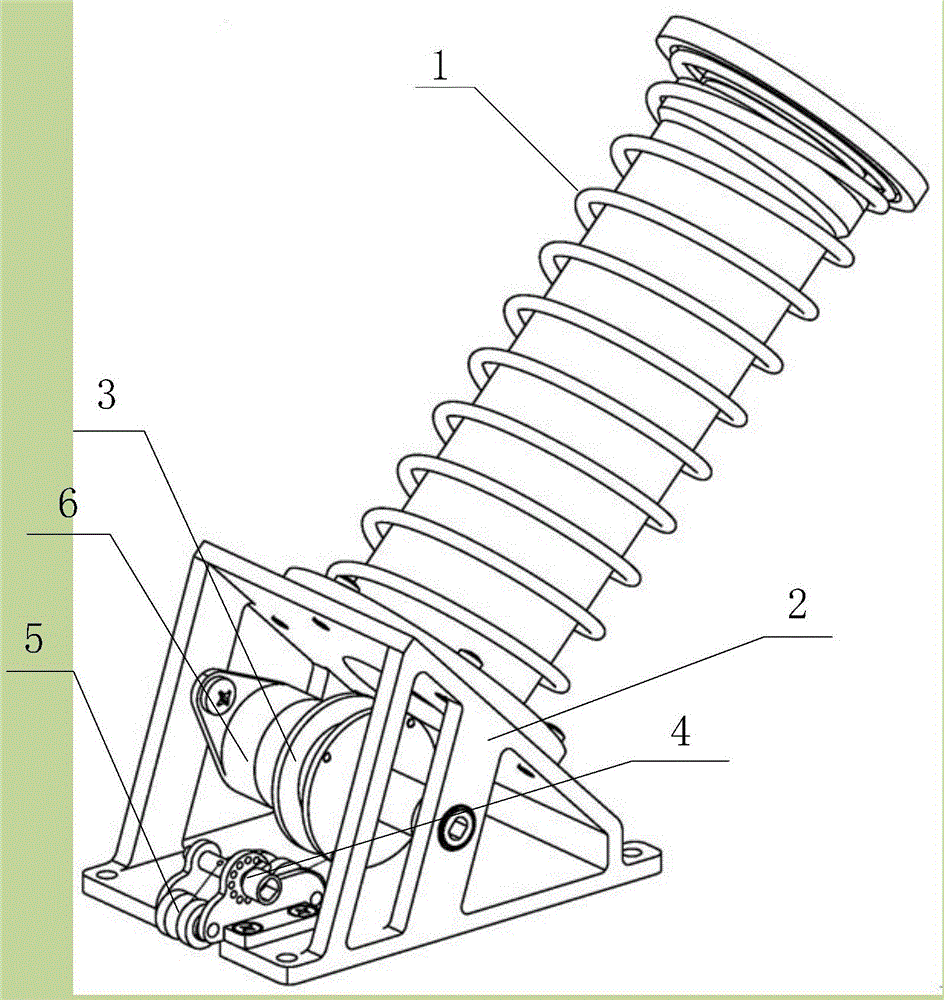

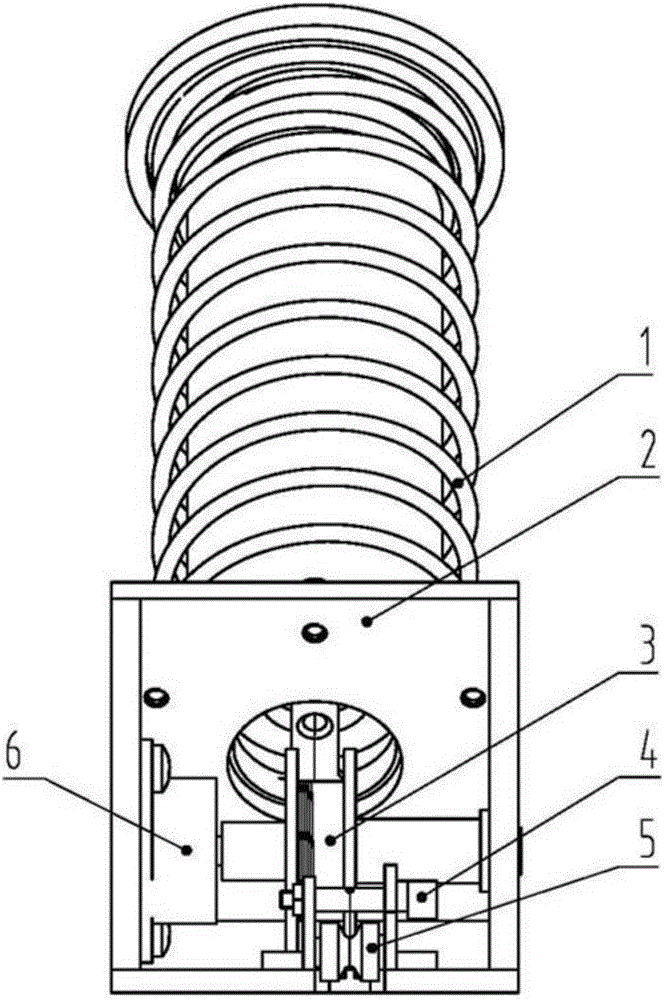

Telescopic satellite antenna

ActiveCN106602204AWon't pop upWon't pop up for no reasonRadiating elements structural formsTelescopic elementsLocking mechanismMulti segment

The invention discloses a telescopic satellite antenna. The telescopic satellite antenna comprises a multi-segment antenna body, an expansion mechanism used for expanding the multi-segment antenna body, a compaction releasing mechanism used for locking the multi-segment antenna body before expansion and unlocking and releasing the multi-segment antenna body during expansion action, and a locking mechanism used for carrying out position locking of the multi-segment antenna body after expansion. The telescopic satellite antenna is advantaged in that the structure is compact, and reliable expansion is realized.

Owner:SPACE STAR TECH CO LTD

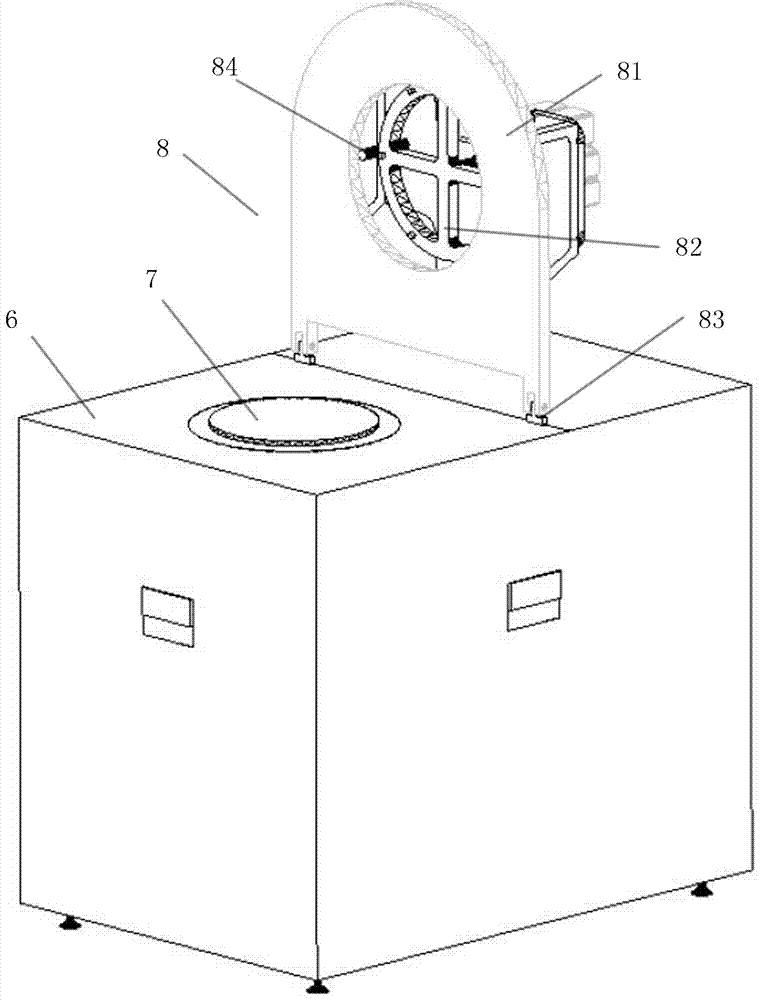

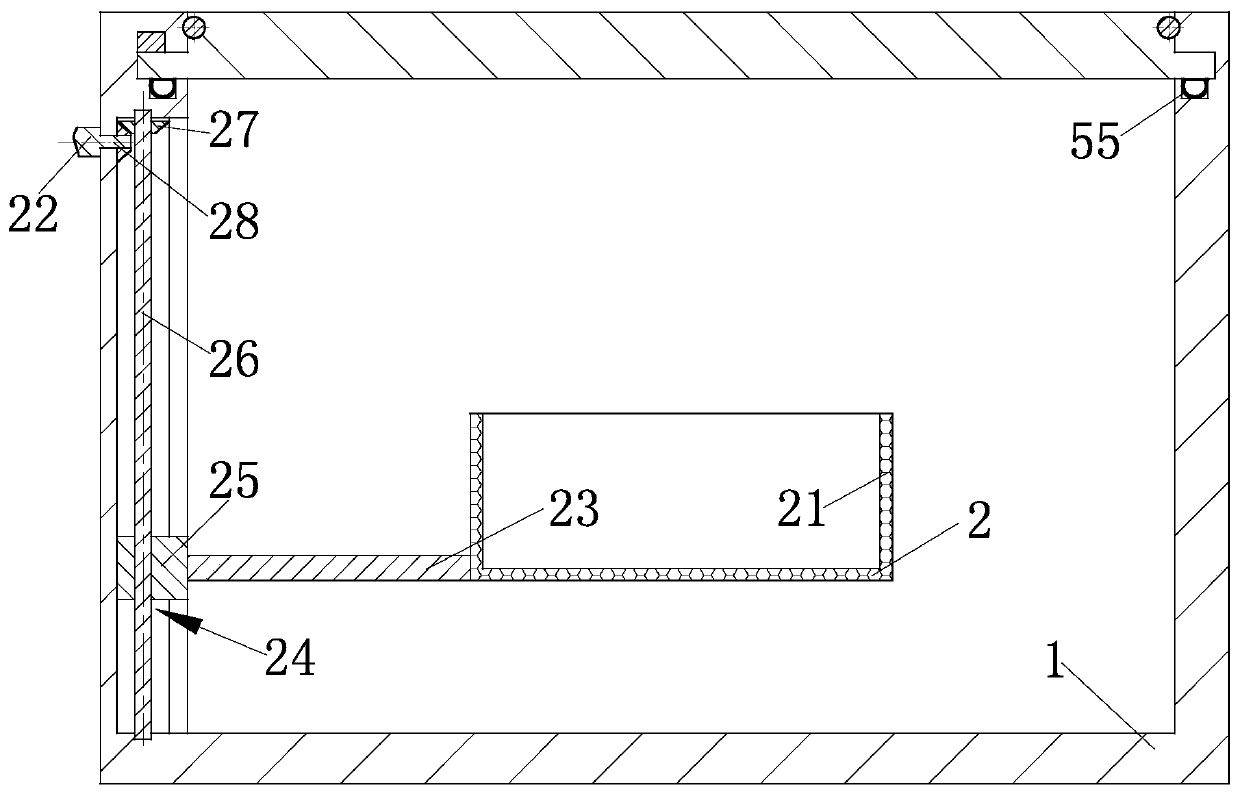

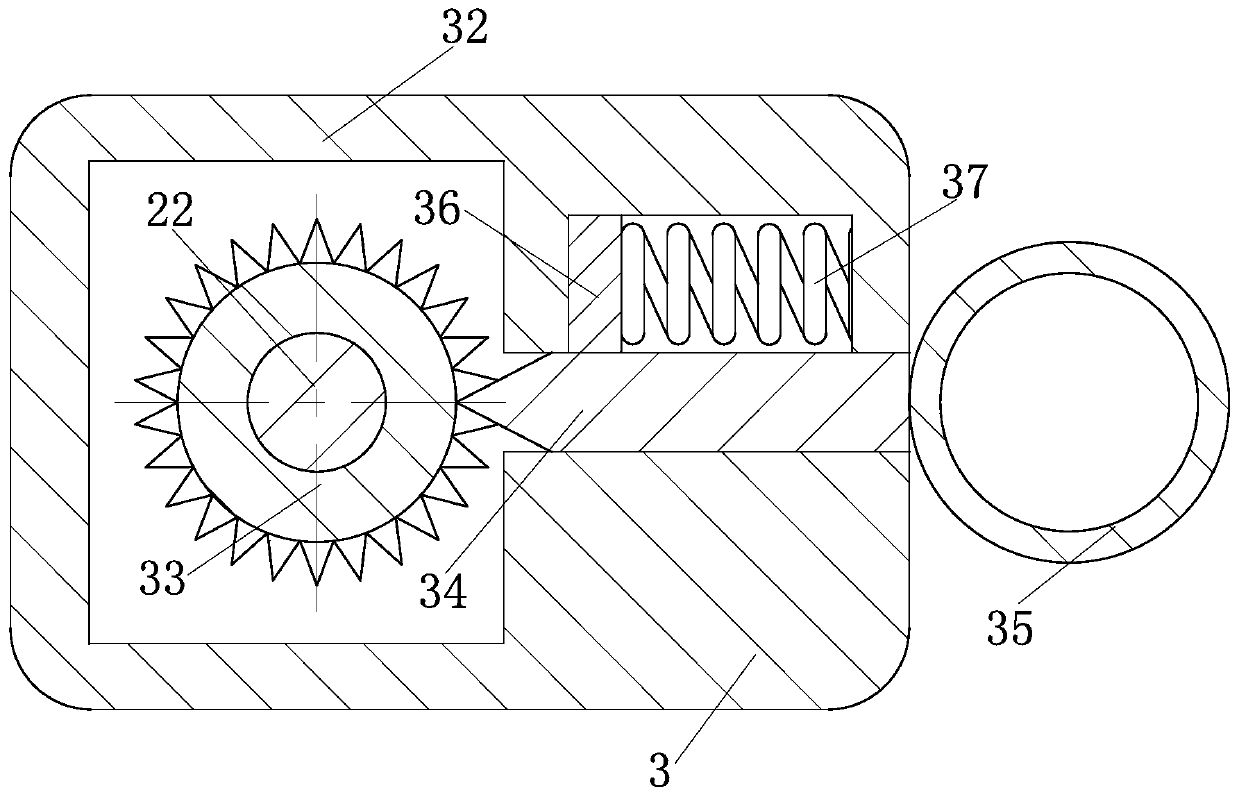

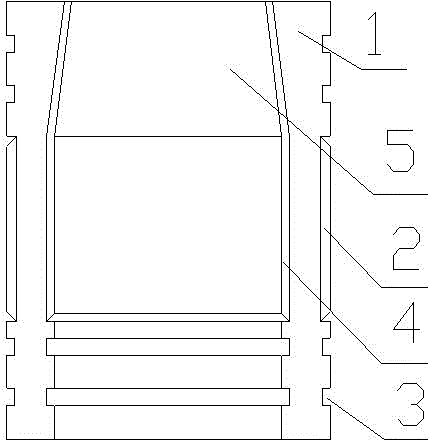

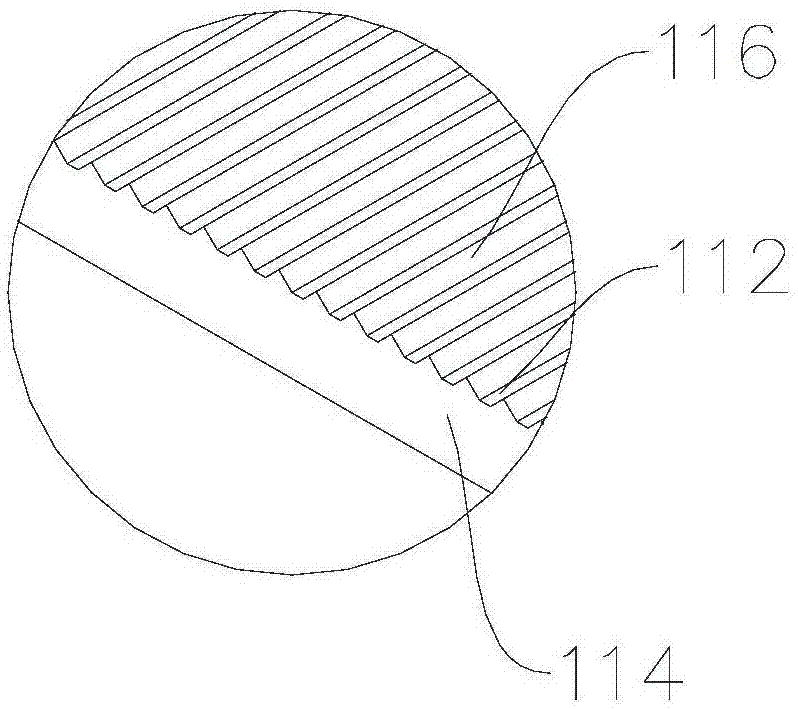

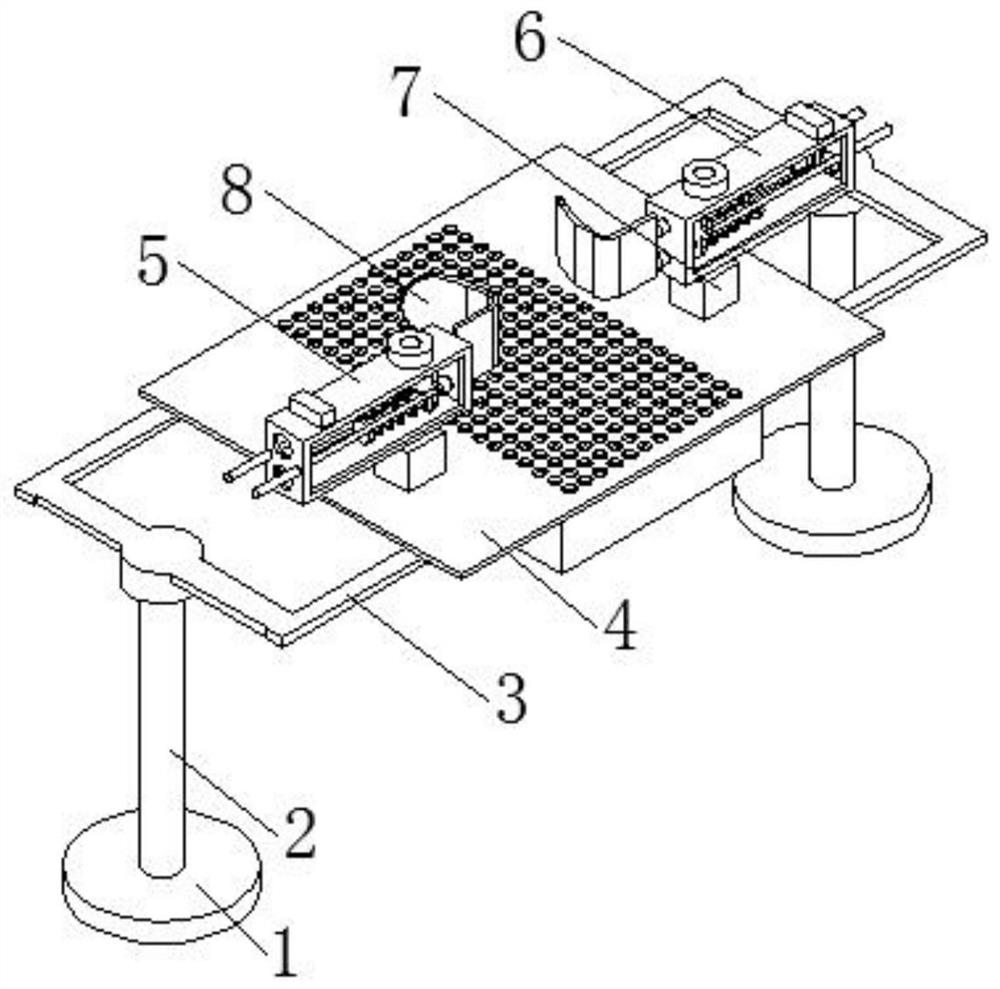

Film expansion machine and process for laser cutting by employing same

InactiveCN106952845APrevent shrinkageGuaranteed expansion effectSemiconductor/solid-state device manufacturingLaser beam welding apparatusClose relativesLaser cutting

The invention discloses a film expansion machine and a process for laser cutting by employing same. The film expansion machine comprises a working platform, a cover body, a son ring and a mother ring, wherein a film expansion base is arranged on the working platform and can lift relative to the working platform, the cover body is opened and closed relative to the film expansion base and comprises a cover body and a sub-cover body, the cover body is provided with a through hole opened relative to the film expansion base, the sub-cover body is arranged relative to the film expansion base, the sub-cover body can penetrate through the through hole to be in contact with the film expansion base, the son ring is arranged on the film expansion base, the mother ring is arranged on the sub-cover body, and the son ring and the mother ring can be buckled together during contact. During cutting, a sheet assembly is formed from an intermediate sheet by a lamination film, and cutting and film expansion are sequentially performed. The film expansion machine has the advantages of high film expansion efficiency, good film expansion quality and simple structure, and is convenient to use. The cutting process is reasonable in step, and compared with the prior art, the cutting efficiency and the cutting quality are both improved.

Owner:苏州五方光电材料有限公司

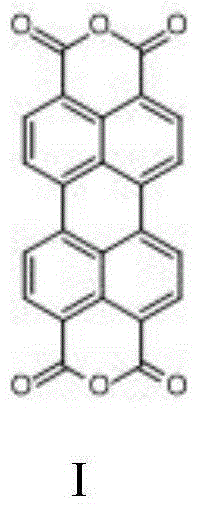

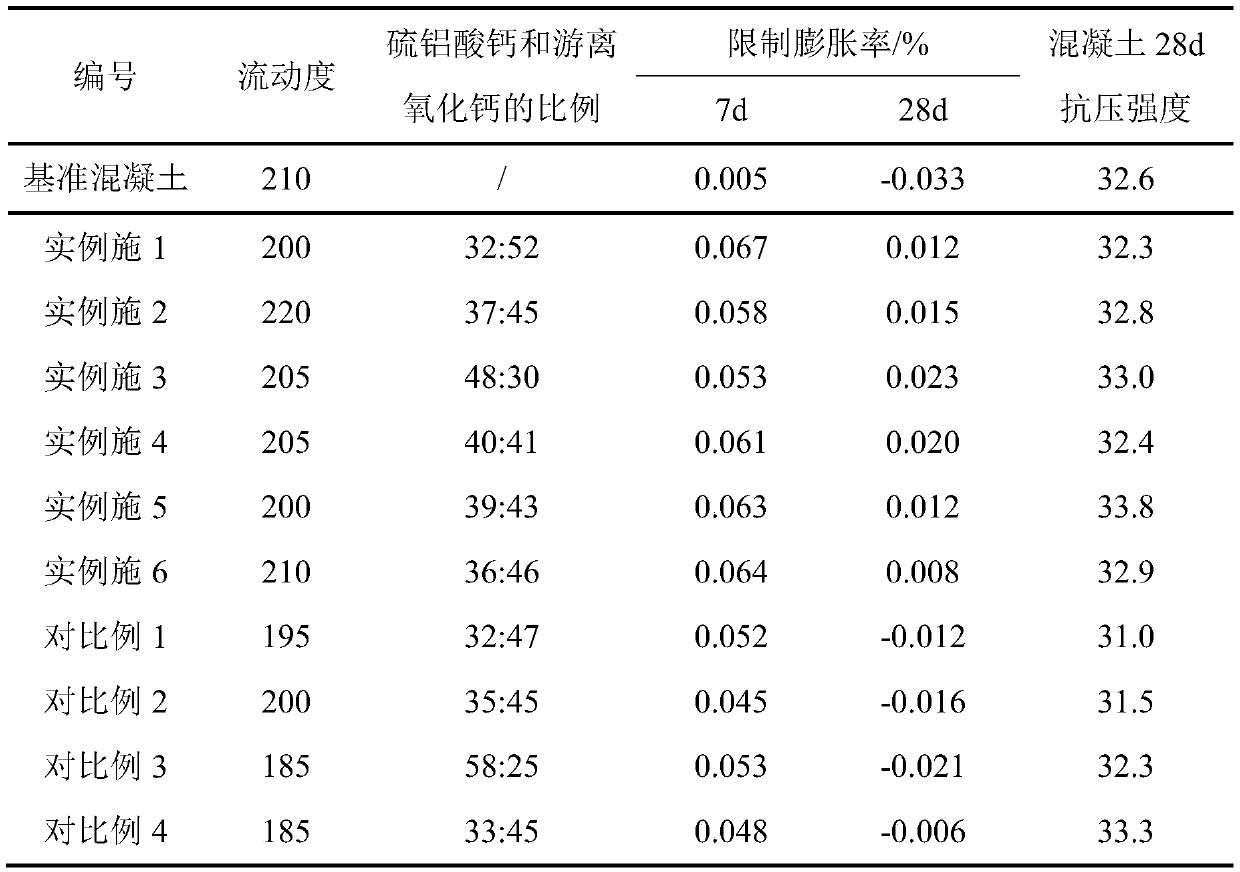

Modified calcium sulfoaluminate-calcium oxide concrete expansion agent and preparation method therefor

The invention discloses a modified calcium sulfoaluminate-calcium oxide concrete expansion agent and a preparation method therefor and belongs to the technical field of production of compound concreteexpansion agents. The modified calcium sulfoaluminate-calcium oxide concrete expansion agent specifically comprises a calcium sulfoaluminate-calcium oxide expansion clinker and a modifier which are in a weight-ratio addition level of (80 to 90): (10 to 20), wherein the modifier is prepared from the following ingredients in parts by weight: 30-40 parts of sodium silicate, 10-15 parts of silane coupler, 10-15 parts of carboxymethyl cellulose, 5-10 parts of nano calcium carbonate and 20-45 parts of anhydrous ethanol. According to the modified calcium sulfoaluminate-calcium oxide concrete expansion agent and the preparation method therefor, through optimizing a proportioning ratio of green stock, the ratio of calcium sulfoaluminate to free calcium oxide in the expansion clinker can be in therange of (30: 50) to (50: 30); meanwhile, through modifying the expansion clinker with the modifier, the hydrating speed of the calcium oxide is lowered; and volume expansion resulting from hydrationof the calcium sulfoaluminate also plays a certain role in compensating later-stage contraction deformation of concrete, the volume of the concrete can be continuously and uniformly expanded, early-stage and later-stage contraction of the concrete can be effectively compensated, and thus, the strength of a concrete structure is guaranteed.

Owner:西安建祥建材科技有限公司

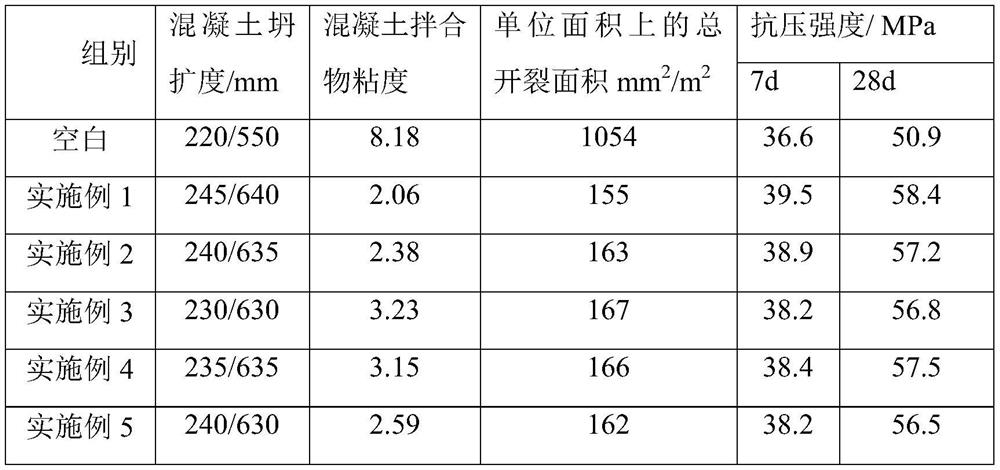

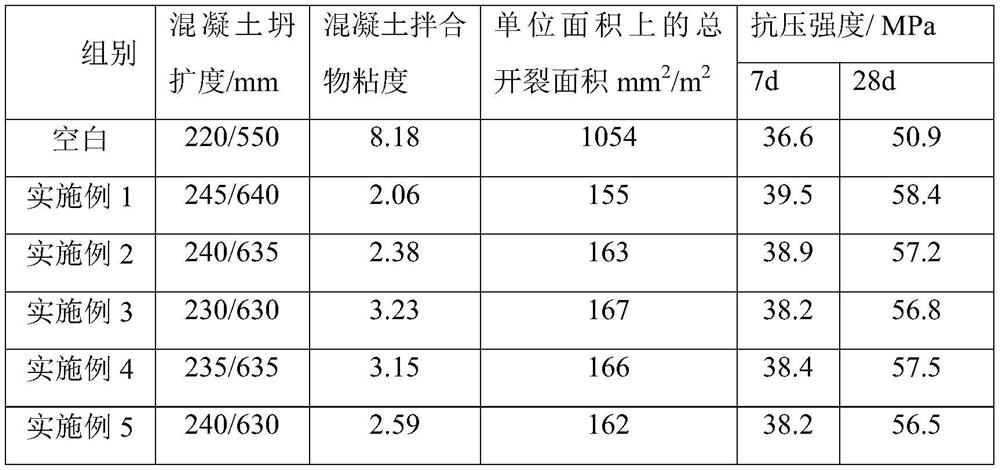

Viscosity-reducing enhanced anti-cracking agent and preparation method thereof

ActiveCN113387612AOvercoming the problem of increased viscosityLow viscosityCelluloseSilicon dioxide

The invention discloses a viscosity-reducing enhanced anti-cracking agent and a preparation method thereof. The viscosity-reducing enhanced anti-cracking agent is prepared from the following raw materials in percentage by mass: 30-60% of a modified magnesium oxide expanding agent, 5-20% of synthetic fiber, 10-40% of a viscosity-reducing component and 20-50% of an enhancing component, wherein the viscosity-reducing component comprises microbead powder, cellulose ether, a powder water reducing agent and sepiolite, and the enhancing component comprises a superfine mineral admixture, silica fume, nano silicon dioxide, sodium gluconate and urea. According to the invention, a viscosity-reducing component and an enhancing component are compounded on the basis of shrinkage compensation of an expanding agent and early crack resistance of fibers, the components have a synergistic effect under a proper ratio so as to effectively reduce the viscosity of concrete and improve the strength of the concrete, and the viscosity-reducing component and the enhancing component have a promoting effect on the expanding agent so as to synergistically improve the expansion effect of the expanding agent.

Owner:武汉三源特种建材有限责任公司

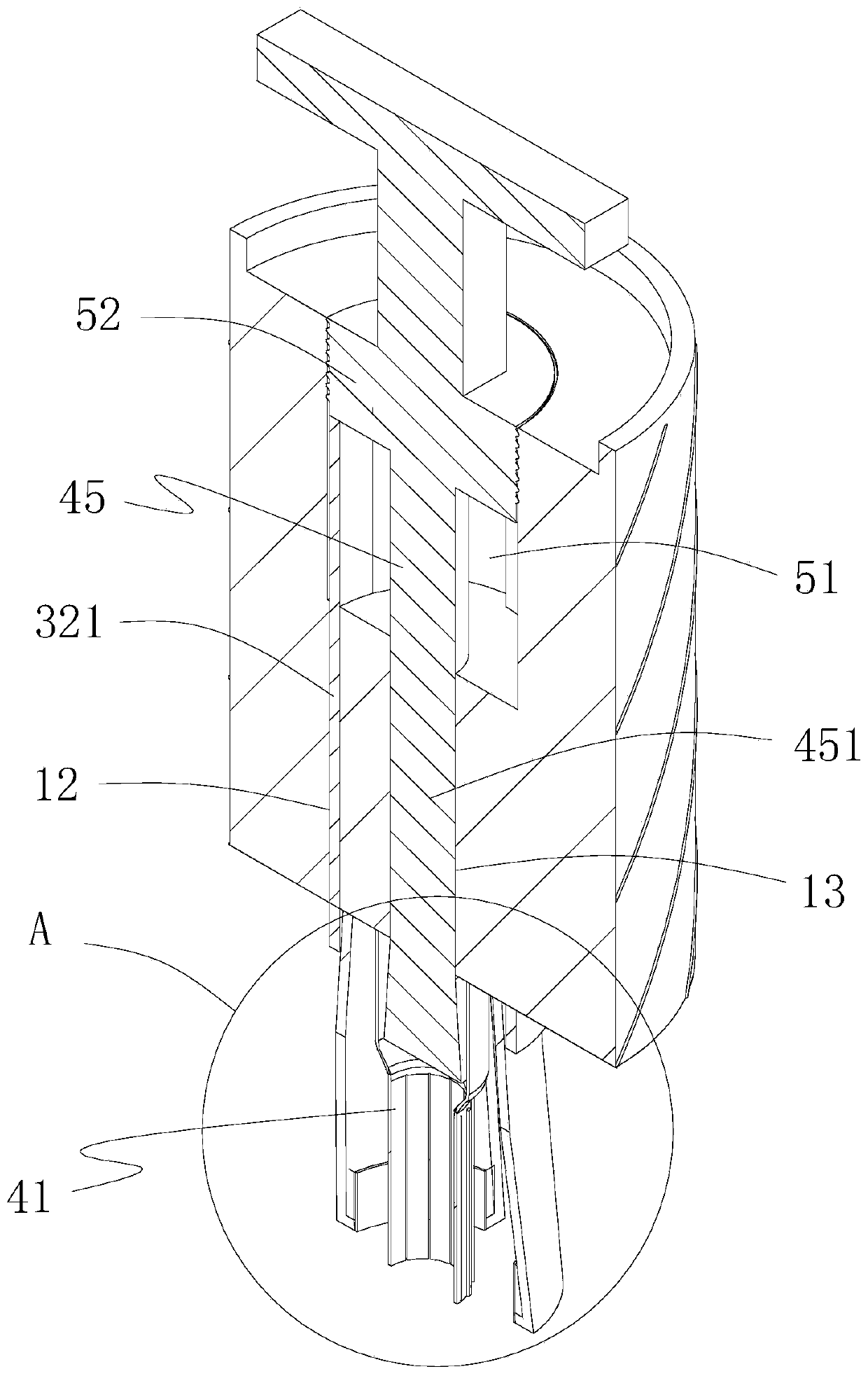

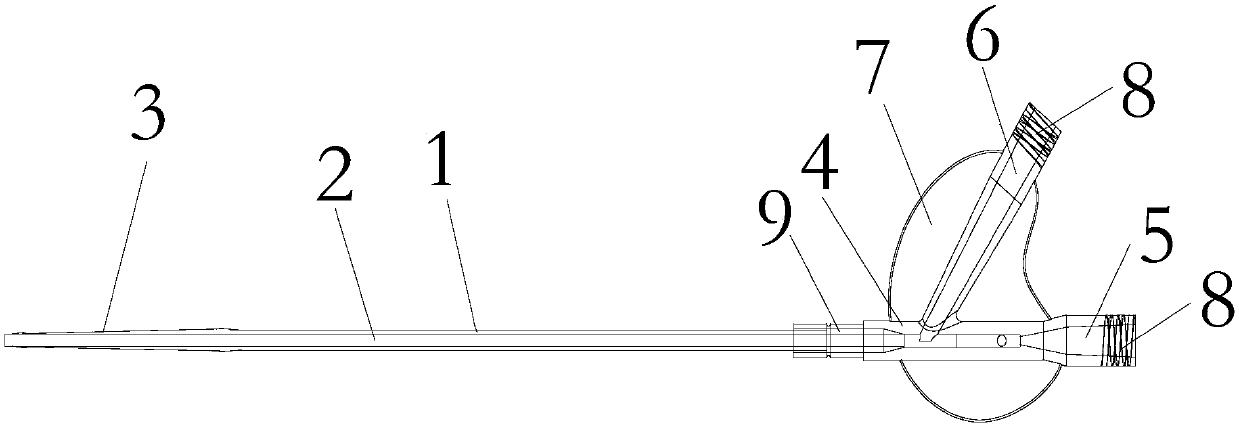

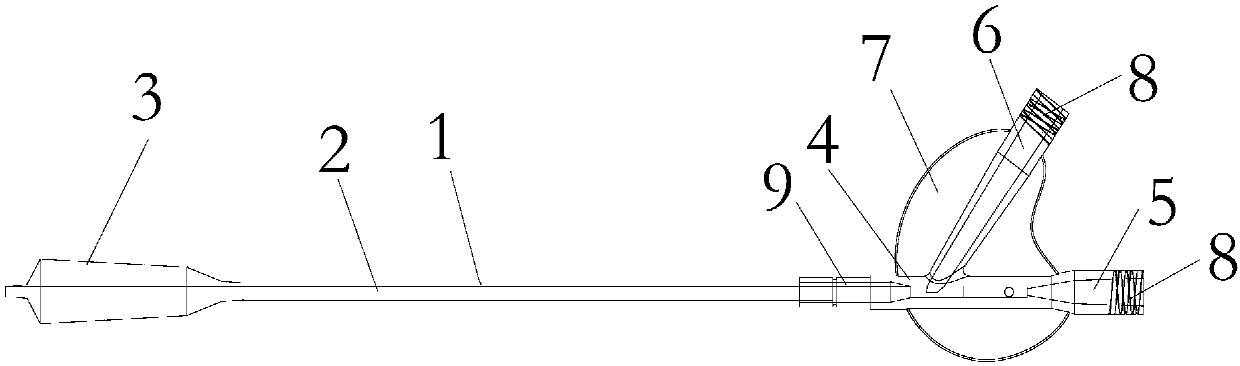

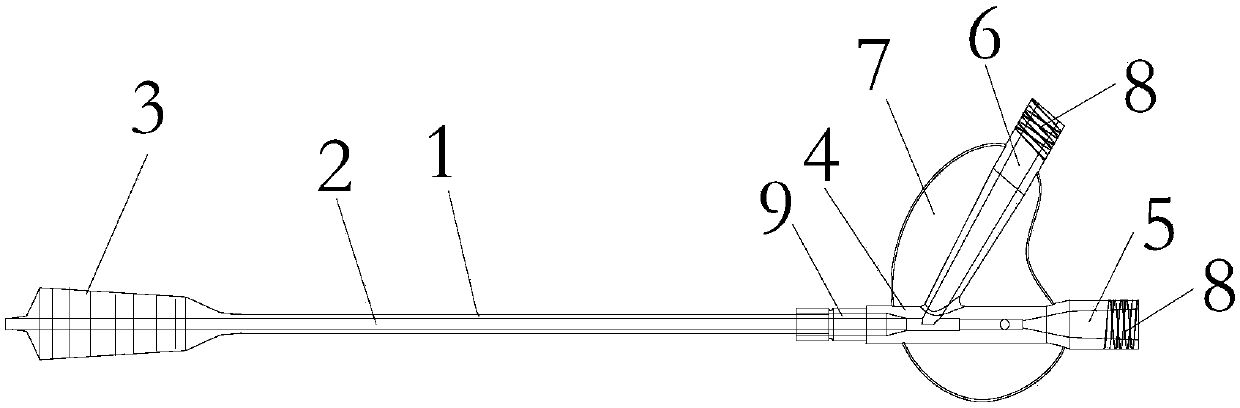

Broken nail removal device for orthopedics

ActiveCN110200692AGuaranteed expansion effectLabor-saving operationOsteosynthesis devicesBreaking nailsBone staple

The invention discloses a broken nail removal device for orthopedics. The device includes a holding member, a clamping part fixedly arranged at the lower part of the holding member and a nail removingpart fixedly arranged at the lower part of the holding member; the surface of the holding member is provided with multiple anti-skid lines; the clamping part is used for compressing the outer surfaceof a bone nail to fix the bone nail when the broken bone nail is removed and includes multiple clamping arms and a fastening ring which can move up and down relative to the clamping arms; the clamping arms are in outer expansion structure arrangement and have first ends connected to the holding member and second ends swinging relative to the first ends; and the fastening ring can drive the secondends to swing inwards so as to compress the bone nail during moving. The bone nail can be compressed through the cooperation of the clamping part and the outer wall of the bone nail, the cooperationof stopping and rotating can be performed through the nail removing part and the inner wall of the bone nail, and therefore, situations of slipping between the device and the bone nail can be guaranteed to not happen, and good nail removing effects can be achieved.

Owner:LISHUI PEOPLES HOSPITAL

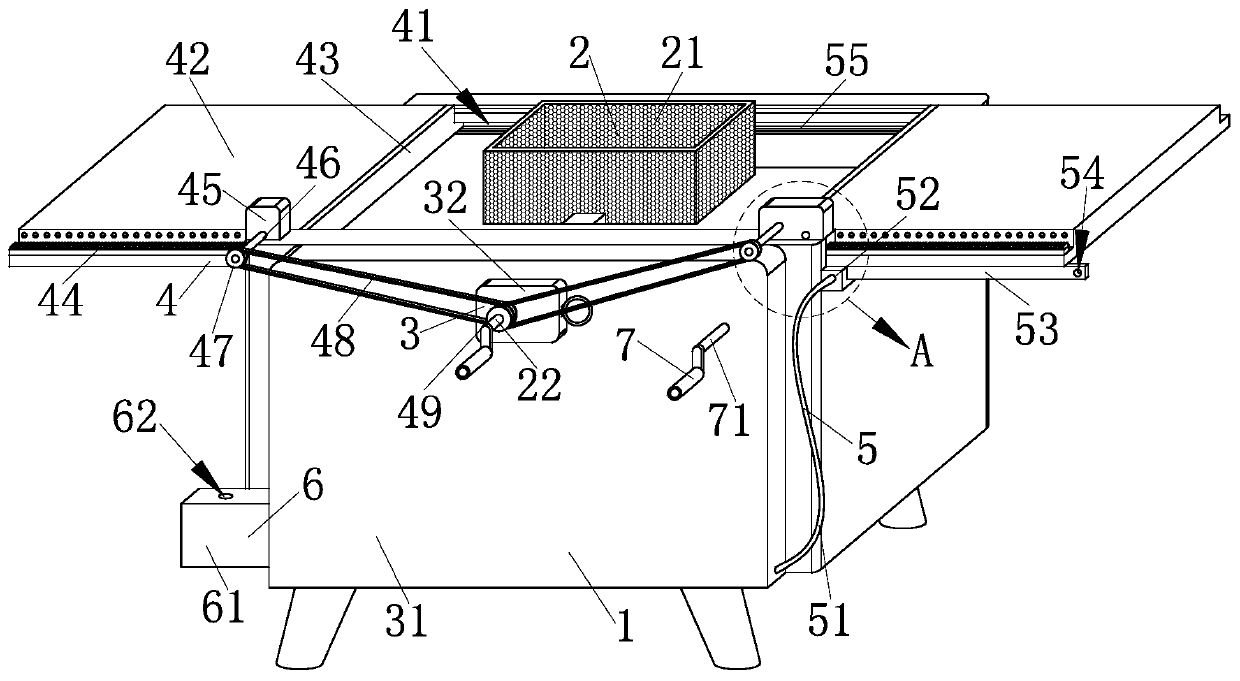

Hair follicle stem cell induced differentiation culture device and using method

ActiveCN111467072AAvoid auto-landing situationsAvoid harmVeterinary instrumentsGrooming devicesAlcoholHair follicle stem

The invention relates to the field of hair follicle stem cell induced differentiation culture devices, in particular to a hair follicle stem cell induced differentiation culture device and a using method. The hair follicle stem cell induced differentiation culture device comprises a cleaning tank, a draining structure, a limiting structure, an opening and closing structure, a sealing structure, apressure relief structure and a stirring structure; by arranging the draining structure capable of ascending and descending in the cleaning tank, newly born SD rats of one week old to be sampled can be taken out to be drained after being cleaned and disinfected, so that the situation that the fur of the rat directly fished out from alcohol further contains a large amount of alcohol, and the next procedure is not facilitated can be avoided, and the rat does not need to make contact with the hand of an operator from cleaning and disinfection to taking out, so that the harm of disinfection alcohol to the skin of the operator can be avoided, the draining structure can be limited through the arrangement of the limiting structure, and the situation that the draining structure falls automaticallywhen the rat drains can be avoided.

Owner:JINAN SHENGFATANG

A large fluid micro-expansion high-strength grouting material

ActiveCN104402345BReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

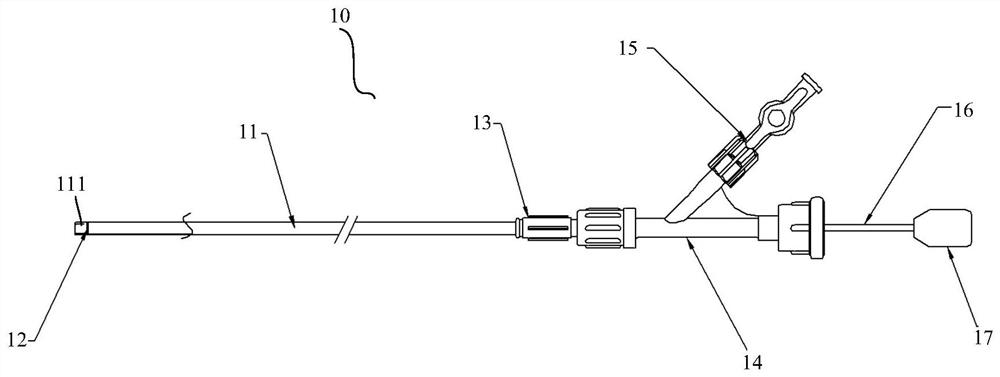

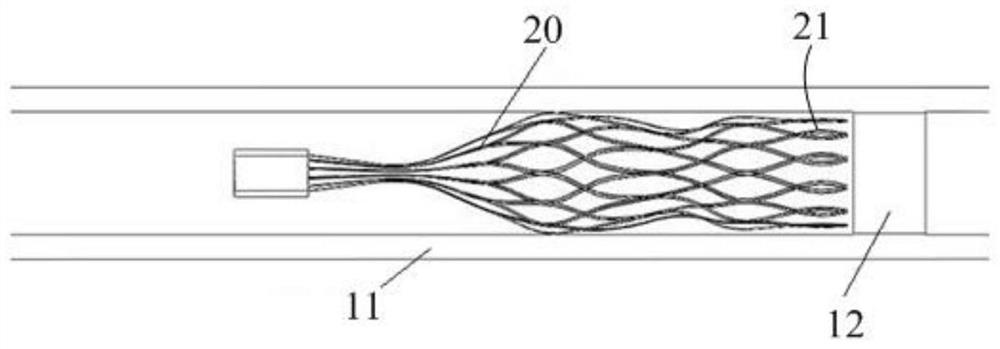

Medical inflatable balloon

The invention discloses a medical inflatable balloon. The medical inflatable balloon comprises a pushing tube, an inner tube and an inflatable balloon, wherein the balloon is arranged at a far end ofthe pushing tube; the inner tube is arranged in the pushing tube and passes through the balloon; the pushing tube is of a hollow structure; a connector is arranged at a near end of the pushing tube; one end which is far away from the pushing tube of the balloon is welded together with the inner tube; one end which is close to the pushing tube of the balloon is welded together with a push rod; theballoon is conical after being inflated; the balloon has a rectangular sheet structure when being not inflated, and can be folded in order to be inserted into a diseased lumen easily. By adopting themedical inflatable balloon, the defect that the stenosis lesion of a conical lumen cannot be treated with the conventional balloon is overcome; meanwhile, the lumen can be supported, so that the operation quality is ensured.

Owner:BIOVENTION LLC

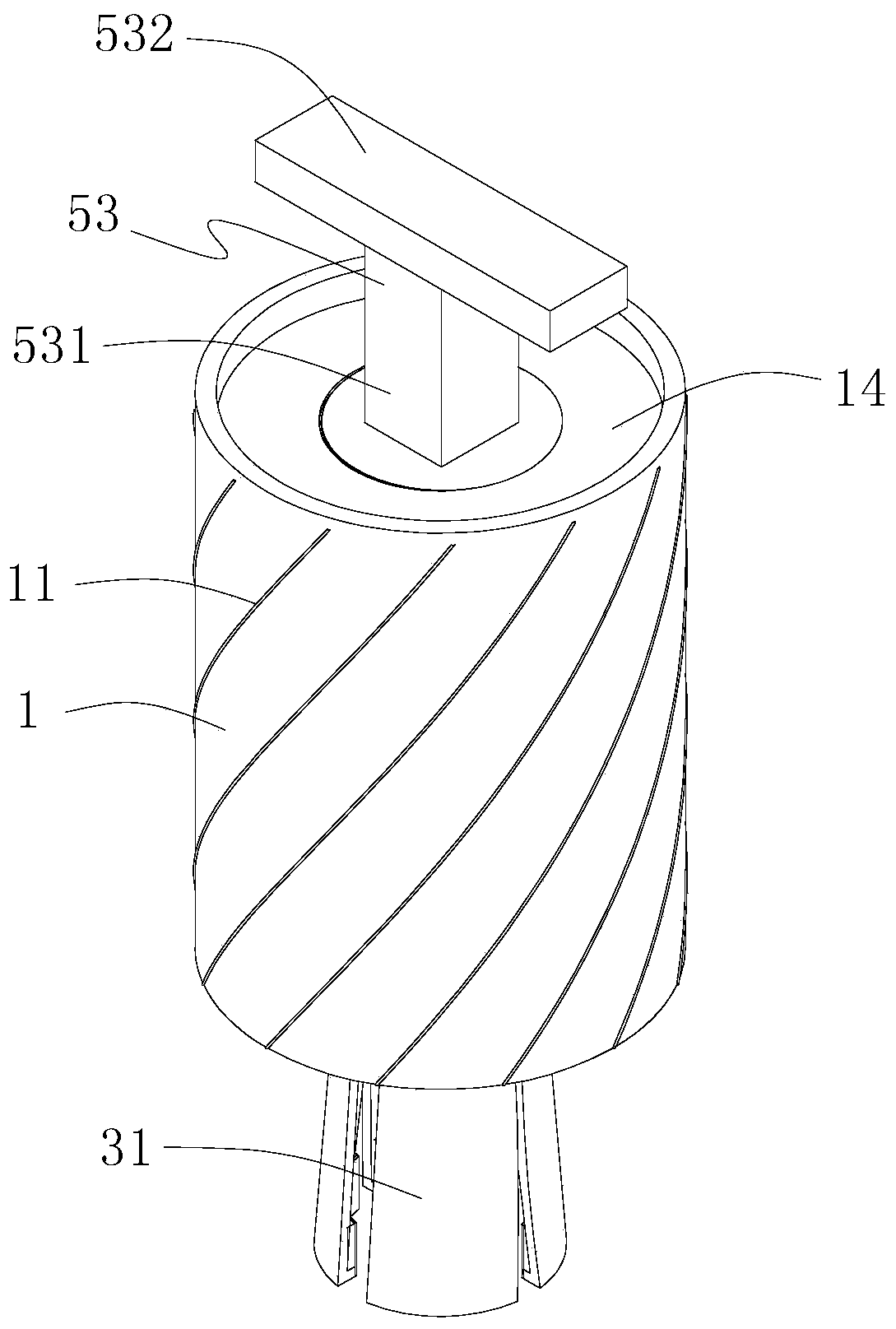

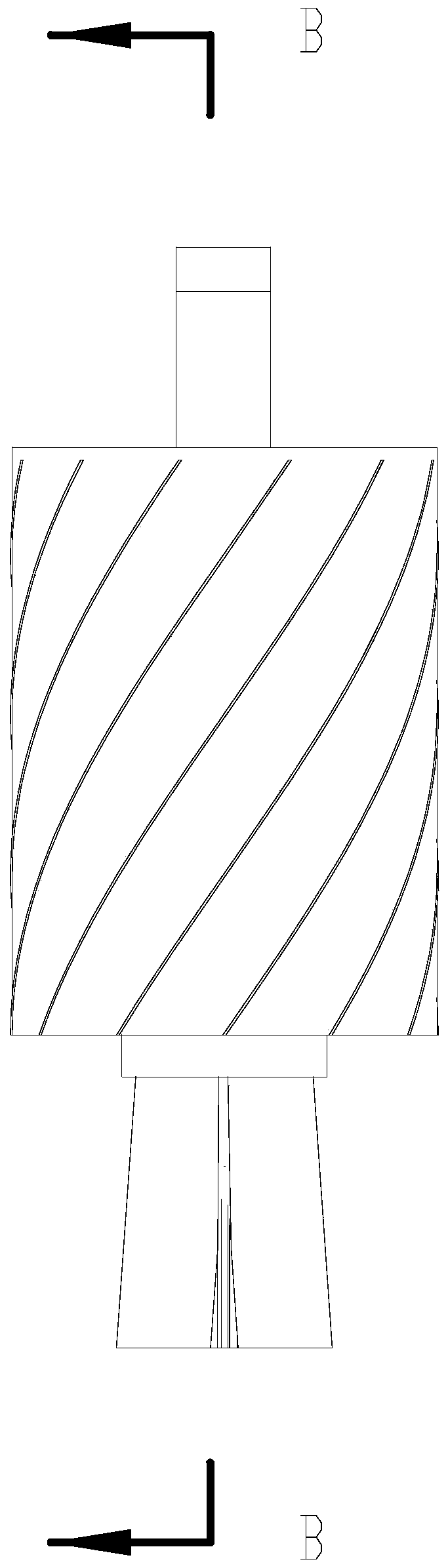

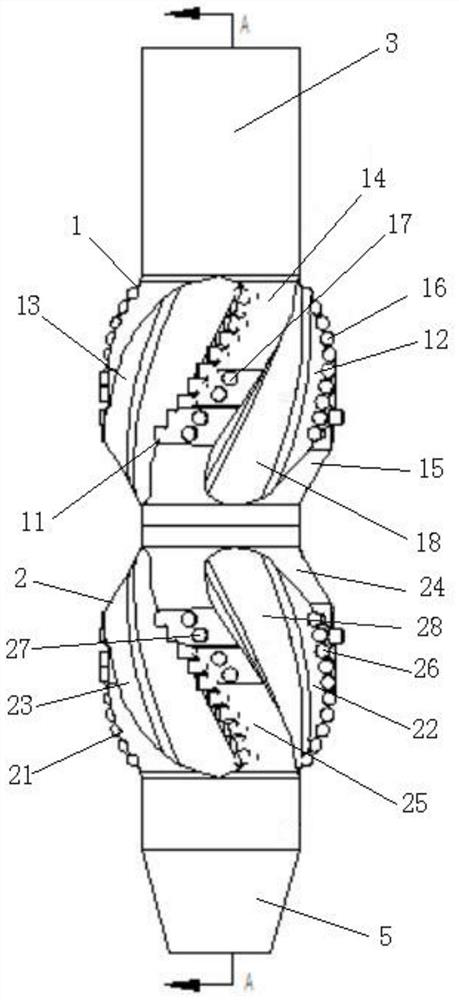

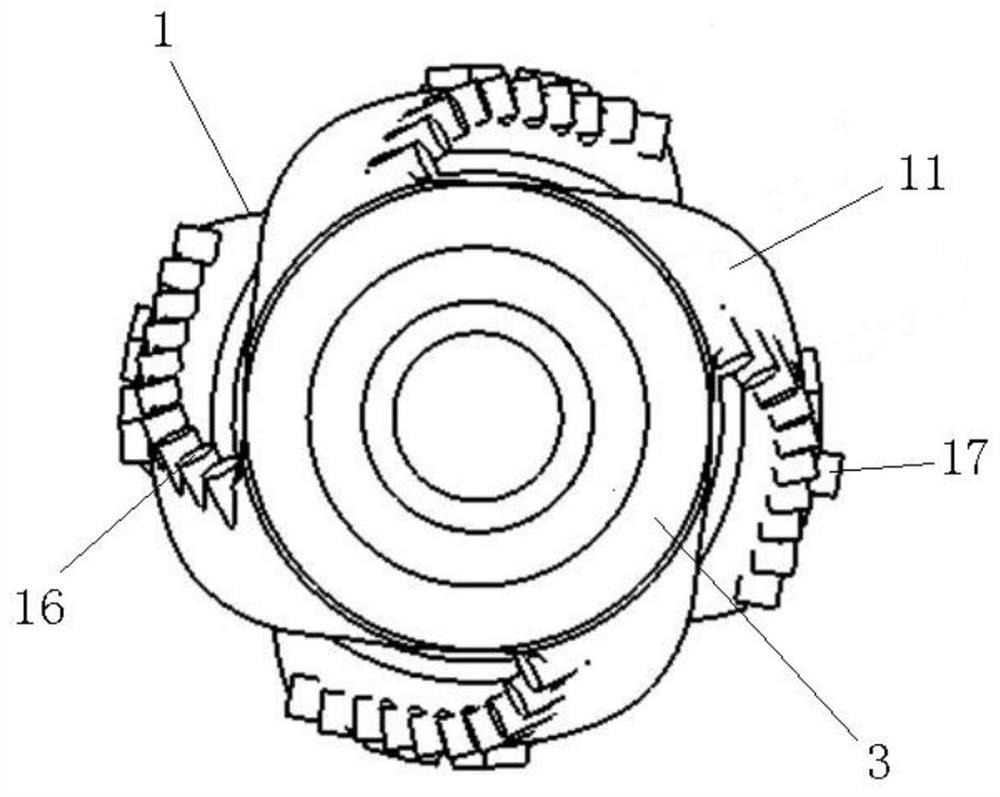

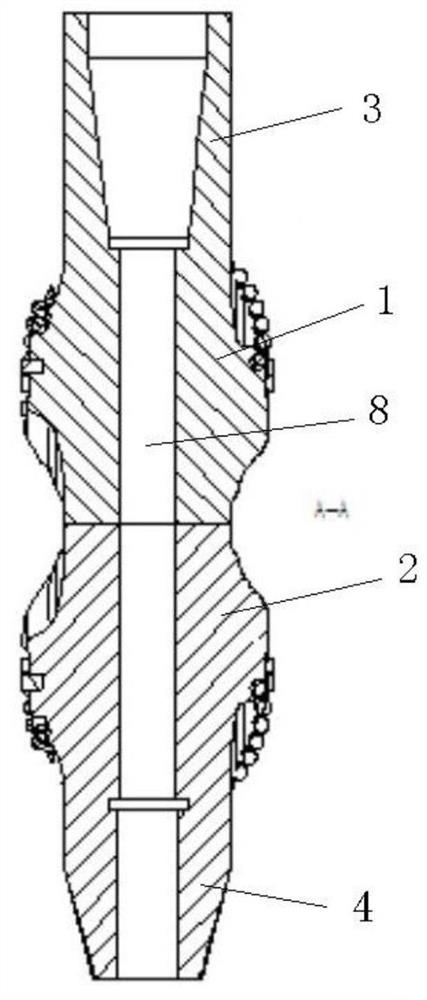

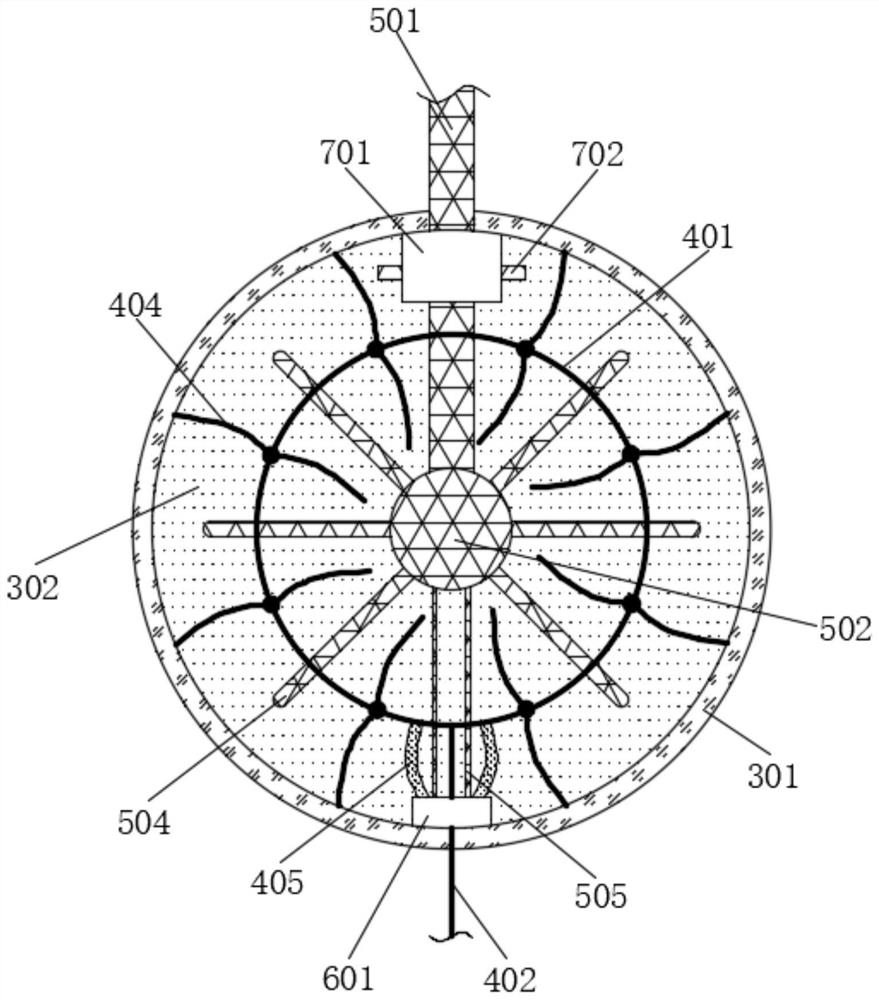

Corrugated pipe expansion tool

The invention provides a corrugated pipe expansion tool, and belongs to the field of petroleum drilling. The corrugated pipe expansion tool comprises an upper spiral reaming body and a lower spiral reaming body; a plurality of spiral upper reaming body side wings are uniformly arranged in the circumferential direction of the upper spiral reaming body; a lower spiral reaming body is connected to the lower portion of the upper spiral reaming body, and a plurality of spiral lower reaming body side wings are evenly arranged in the circumferential direction of the lower spiral reaming body; coaxialcenter holes are formed in the middle parts of the upper spiral reaming body and the lower spiral reaming body; and the spiral directions of the upper reaming body side wings and the lower reaming body side wings are opposite. According to the corrugated pipe expansion tool, a shaft can be reamed before the expansion corrugated pipe is tripped in, the expansion corrugated pipe is mechanically expanded after the expansion corrugated pipe is tripped in, and the corrugated pipe expansion tool has cutting capacity and cuts the excess weld metal of a welding seam of the expansion corrugated pipe.

Owner:CHINA PETROLEUM & CHEM CORP +1

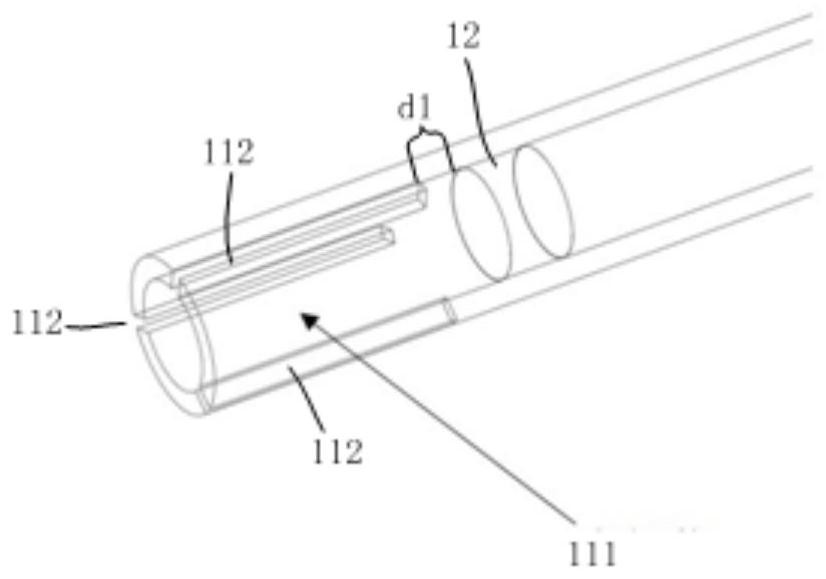

Medical implant delivery sheath and medical implant delivery system

PendingCN112773447AGuaranteed resistanceReduce resistanceOcculdersSurgical operationSurgical Manipulation

The invention relates to a medical implant delivery sheath and a medical implant delivery system. The delivery system comprises a delivery sheath, a pushing rod and a medical implant, the pushing rod is used for delivering the medical implant to a target position through a cavity of a catheter, the delivery sheath comprises a catheter and a skirt portion, the skirt portion is located at the far end of the catheter and is configured to have a folded state and an unfolded state, the skirt portion in the unfolded state forms a containing space, and the containing space is used for guiding or containing the medical implant. According to the invention, the resistance of recycling a medical implant back to a sheath can be reduced, and the surgical operation difficulty is reduced.

Owner:SHANGHAI ZUOXIN MEDICAL TECH CO LTD

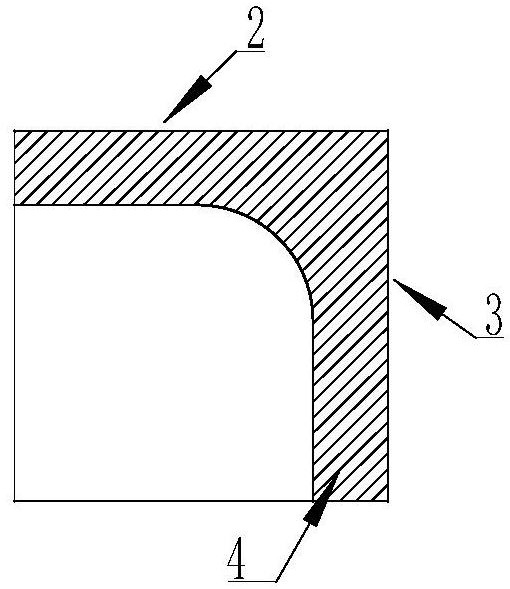

Expansion type sealing ring

InactiveCN104358869AGuaranteed expansion effectImprove sealingEngine sealsElectrical and Electronics engineeringEngineering

Owner:苏州瑞邦塑胶有限公司

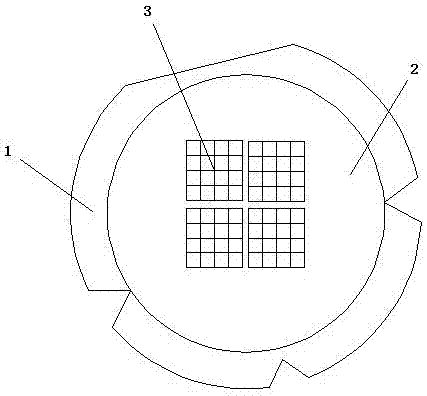

Thin layer expansion groove and thin layer expansion device

InactiveCN107315063AGrow fastGuaranteed expansion effectComponent separationOrganic solventThin layer

The invention provides a thin layer expansion groove and a thin layer expansion device, and relates to the field of biology, wherein the thin layer expansion groove comprises a bottom plate, a first side plate, a second side plate, a third side plate and a fourth side plate, the first side plate, the second side plate, the third side plate and the fourth side plate are all connected with the bottom plate, the first side plate and the second side plate are oppositely arranged, the third side plate and the fourth side plate are oppositely arranged, the bottom plate is provided with a plurality of first clamping grooves, and the first side plate and the second side plate are provided with a plurality of second clamping grooves. According to the thin layer expansion groove and the thin layer expansion device, an organic solvent is rapidly expanded, the speed is accelerated, meanwhile, the expansion effect of the organic solvent is guaranteed, and the condition of uneven expansion is avoided.

Owner:SHANDONG UNIV OF TRADITIONAL CHINESE MEDICINE

Automatic push-pull fluff adsorption device for textile wastewater treatment

InactiveCN112093843AGuaranteed expansion effectAccelerate evaporationWater/sewage treatment by sorptionThermodynamicsProcess engineering

The invention discloses an automatic push-pull fluff adsorption device for textile wastewater treatment, belongs to the technical field of wastewater treatment, and can realize that an elastic balloonfilled with an expanding agent I is arranged, a water guide net and a heat conduction assembly are arranged in a matching manner, and the water guide net can guide water to the expanding agent I, sothat the elastic balloon is expanded; the heat conduction assembly can absorb solar energy for heating and conduct heat to the first swelling agent, evaporation of water in the expanding agent I is accelerated, the elastic balloon is contracted, meanwhile, under the combined action of a specially-made water blocking mechanism and a heat conduction mechanism, the elastic balloon can be smoothly andrepeatedly expanded and contracted, and then a push-pull plate is repeatedly pushed away and pulled back, in the process that the push-pull plate is pulled back, fluff at the far position can be pulled to the position near the adsorption plate to be adsorbed by an adsorption plate, meanwhile, water can be driven to flow, fluff at the farther position can flow to the position near the adsorption plate to be gathered, the action range of the adsorption plate is greatly enlarged, and the treatment efficiency is improved.

Owner:王伟

A kind of thickening profile control agent and preparation method thereof

ActiveCN106832146BGuaranteed StrengthGuaranteed expansion effectDrilling compositionWater bathsHigh concentration

The invention belongs to the technical field of a chemical reagent for oil production, and discloses a viscosity-increasable profile control agent and a preparation method thereof. The profile control agent is obtained through adding functional monomers, inorganic nanometer particles, main crosslinking agents and auxiliary crosslinking agents into an acrylamide monomer water solution, introducing nitrogen gas to remove dissolved oxygen and adding initiators under the water bath condition of 40 to 60 DEG C for polymerization; after the polymerization is completed, pelleting, drying and crushing are performed; a final product is obtained. The prepared profile control agent can realize the continuous viscosity increase on formation water to achieve a certain displacement effect; meanwhile, good anti-salt performance is realized; the water absorption swelling can be generated in the high-concentration salt brine; after the expansion, high intensity is still realized, so that the high seepage layer in an oil deposit can be effectively sealed and plugged; the profile control effect is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

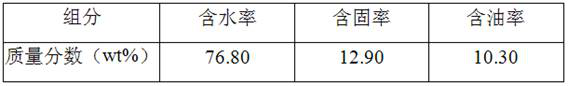

Method for preparing ceramsite from oily sludge

ActiveCN113121203AHigh degree of resource utilizationReduce salt contentCeramic materials productionClaywaresSludgeDistillation

The invention relates to a method for preparing ceramsite from oily sludge, which comprises the following steps: carrying out solid separation on the oily sludge to remove large-particle solids in the oily sludge; carrying out dehydration treatment until the water content is less than or equal to 70wt%, carrying out steam heating, adding distillate oil with the distillation range of 100-400 DEG C as a treating agent, carrying out a reaction, carrying out solid-liquid separation, drying the obtained solid, adding a cleaning agent, performing standing, separating out the solid, granulating, drying and roasting to obtain the ceramsite finished product. Under the synergistic effect of the distillate oil treating agent and the cleaning agent, the purpose of recovering the distillate oil in the oily sludge is achieved. The whole operation process is a closed loop, generated sump oil is recycled, generated solids are prepared into ceramsite with a high additional value, the recycling degree of the oily sludge is greatly improved, the added medicament is environment-friendly, the generated wastewater is low in salt content and simple to treat, and environmental pollution is not caused; the whole method does not involve high-temperature and high-pressure operation, and is economical and safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of high-strength rivet nuts

The invention provides a production process of high-strength rivet nuts, belongs to the technical field of rivet nut machining, and solves the technical problem that the strength of existing rivet nuts cannot be improved. The production process of the high-strength rivet nuts comprises the following steps that (1), raw material spheroidizing annealing is conducted, specifically, raw materials are selected and spheroidizing annealing treatment is carried out on the raw materials; (2), upsetting forming is conducted, specifically, the raw materials subjected to spheroidizing annealing are subjected to cold upsetting to form a blank; (3), oil is removed; (4), zone annealing is conducted, specifically, zone annealing is carried out on a designated position of the blank subjected to oil removal; (5), acid pickling is conducted, specifically, acid pickling is carried out on the blank obtained after zone annealing through an acid pickling solution; (6), tapping is conducted, specifically, tapping and tapping are carried out on the interior of the blank through a part machine to form rivet nuts; (7), surface treatment is conducted, specifically, treatment is carried out on the surfaces of the rivet nuts; (8), screening is conducted, specifically, testing is carried out on the rivet nuts, and the rivet nuts with qualified strength are screened out; and (9), packaging is carried out. The production process of the high-strength rivet nuts has the advantages that the overall strength of the rivet nuts is improved, and the production efficiency is high.

Owner:浙江坤厚汽车零部件股份有限公司

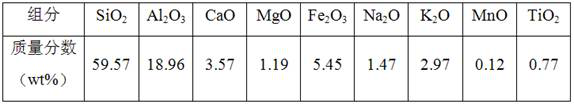

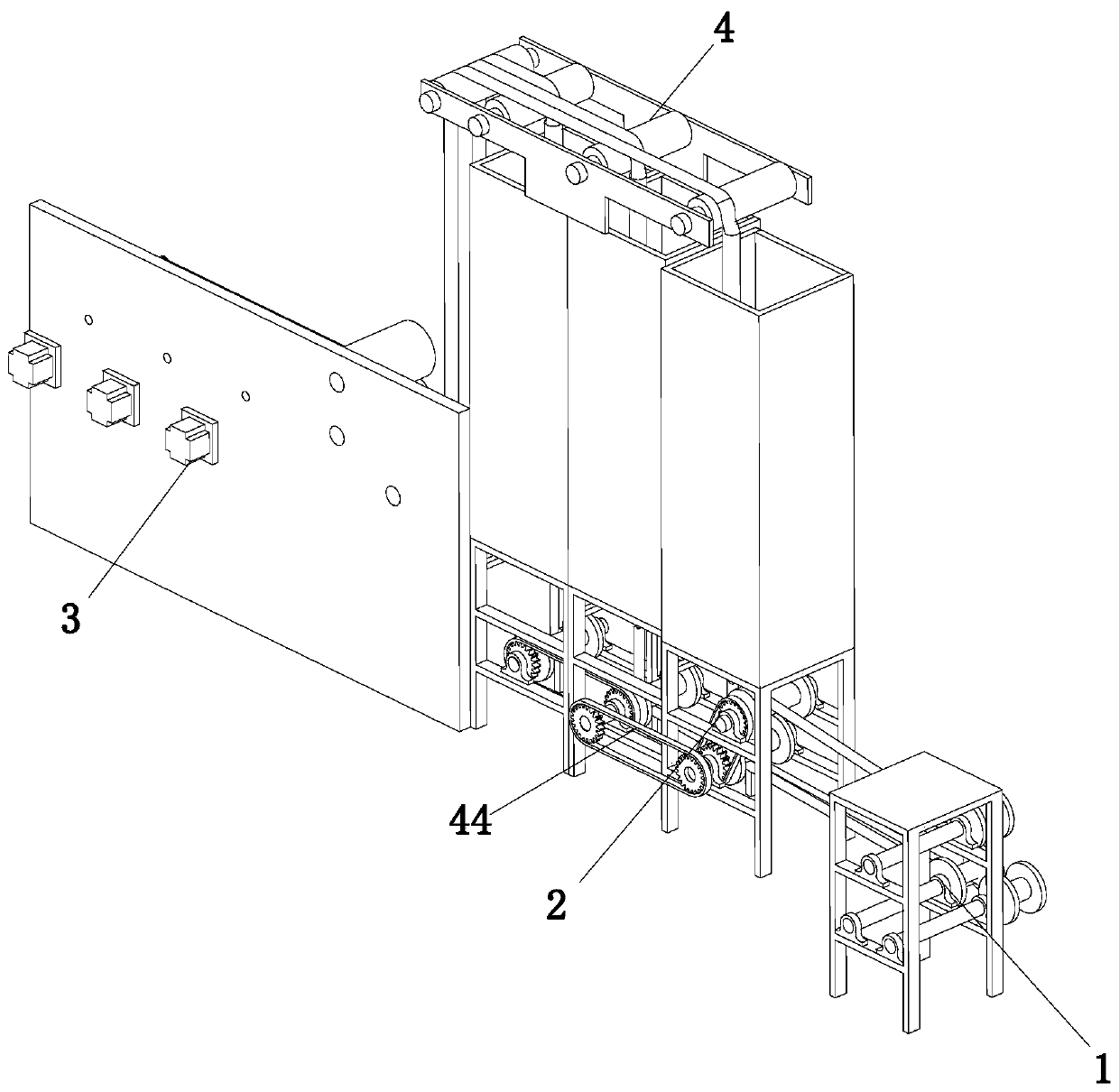

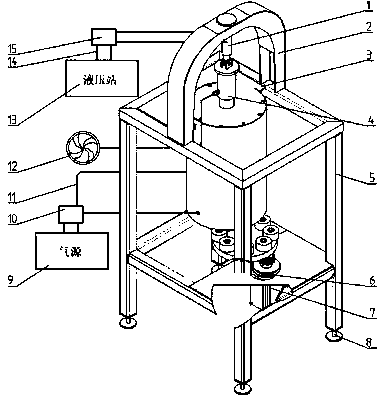

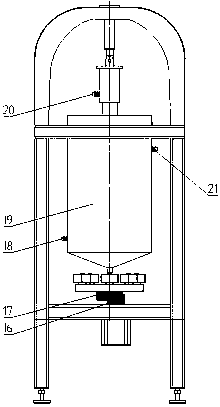

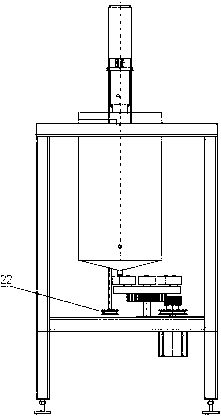

Production device and processing method for expansive glass hoses

PendingCN110193959AGuaranteed full impregnationAchieve full impregnationFilament handlingGlass fiberFiber

The invention belongs to the technical field of fiber pipes, and particularly relates to a production device and a processing method for expansive glass hoses. The production device comprises a feeding roller set, a plurality of parallel dipping mechanisms and a winding mechanism. The feeding roller set comprises a plurality of rotating shafts horizontally arranged at intervals. Each dipping mechanism comprises a guide mechanism, a strutting mechanism, a dipping assembly and a drying box, wherein the guide mechanism comprises a first guide assembly and a second guide assembly. The winding mechanism comprises an oriented roller set and a plurality of winding assemblies arranged at intervals. Each strutting mechanism comprises a center through cone and a limiting ring for the fiber hoses topass through. Each dipping assembly comprises a rubber paint box and a paint scraping plate arranged over the rubber paint box, and each paint scraping plate is provided with a through hole through which the fiber hoses pass. It is ensured that the thicknesses of rubber paint of the fiber hoses are the same, comprehensive dipping of the fiber hoses is realized, the defective rate of the glass fiber pipes is reduced, and the waste of production cost is reduced.

Owner:池州普胜电工材料科技有限公司

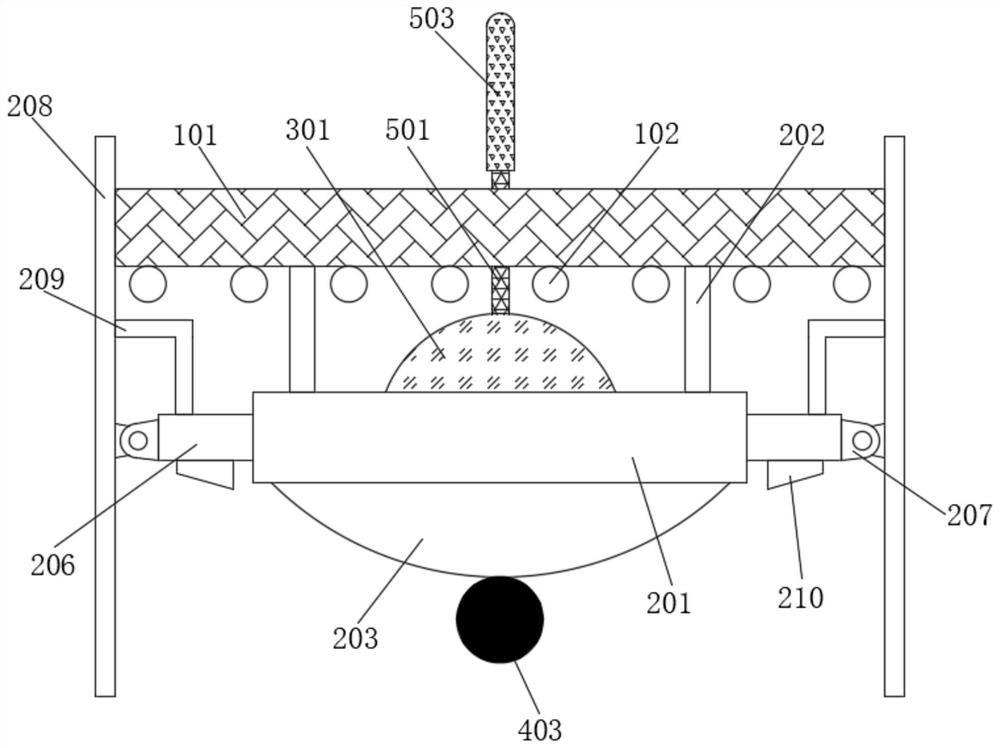

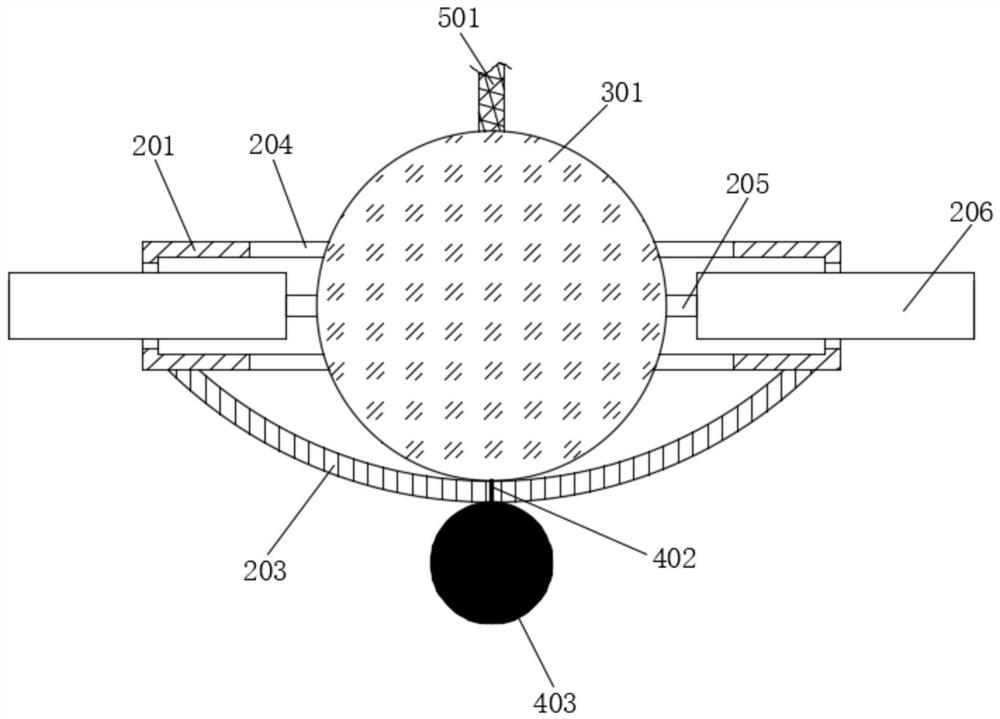

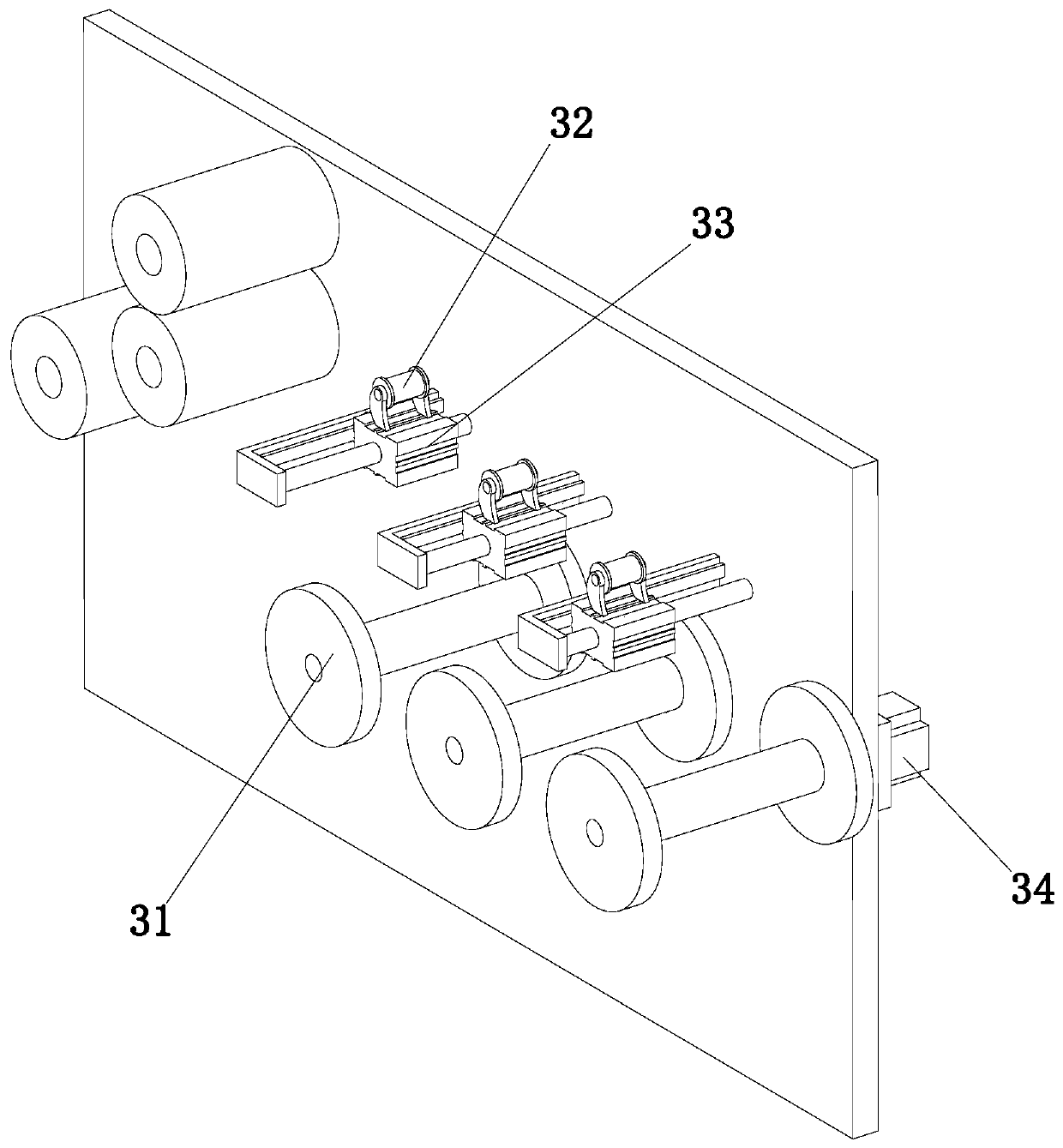

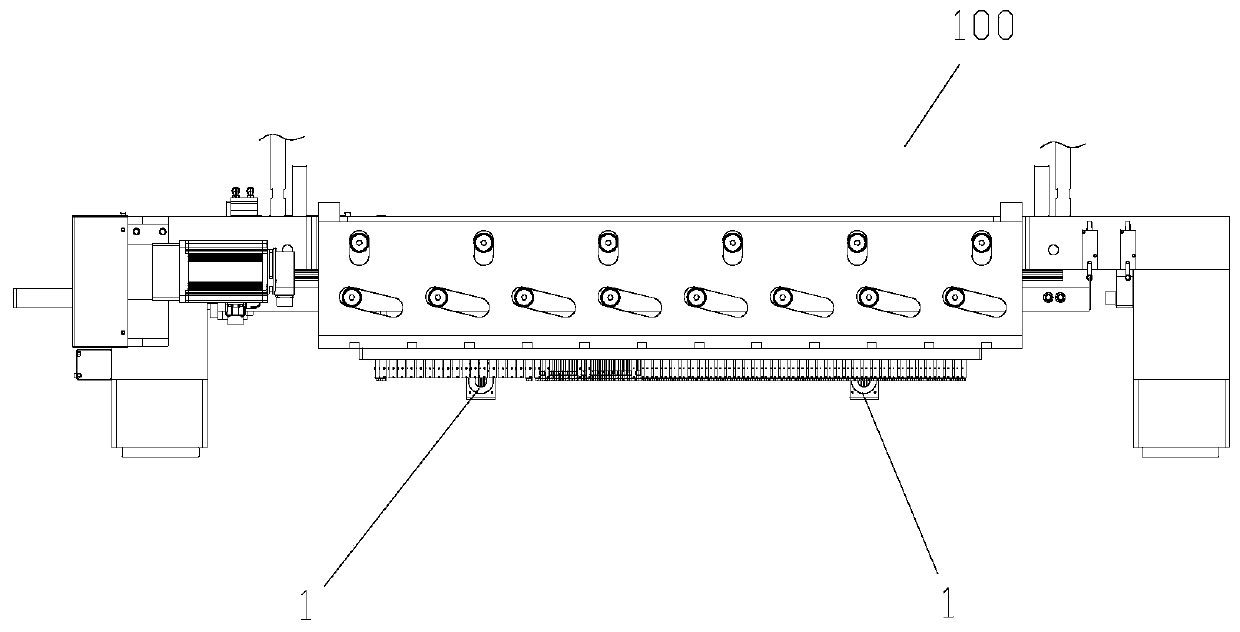

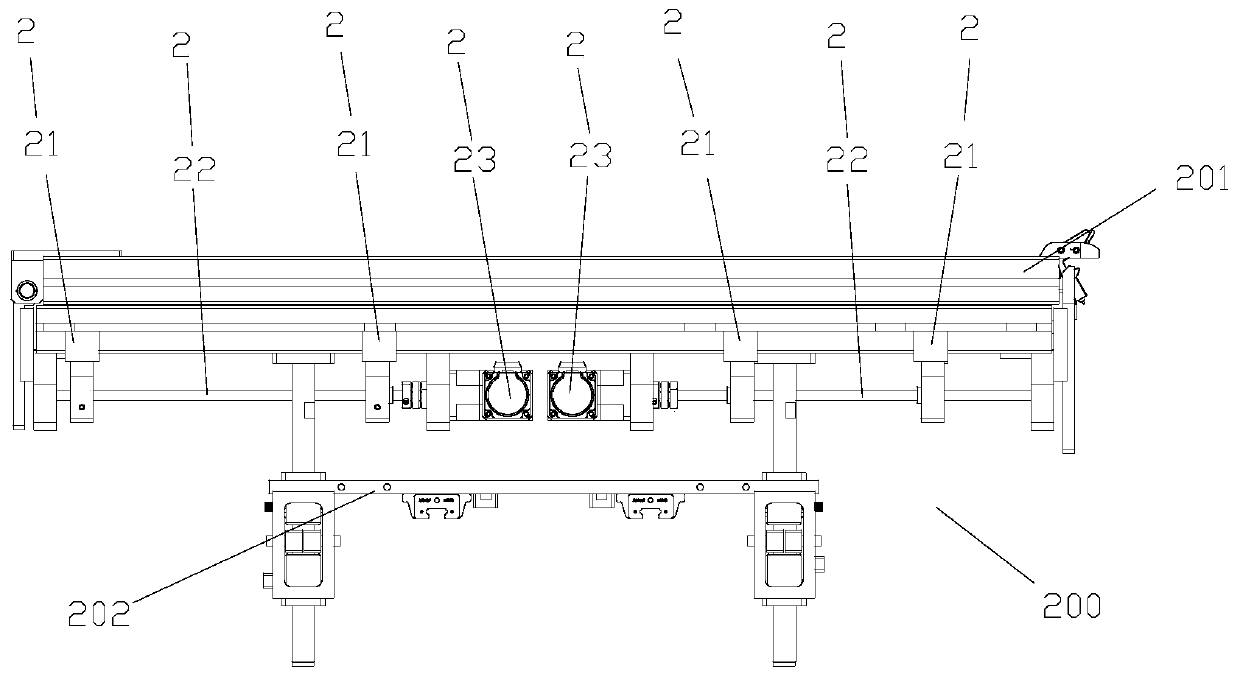

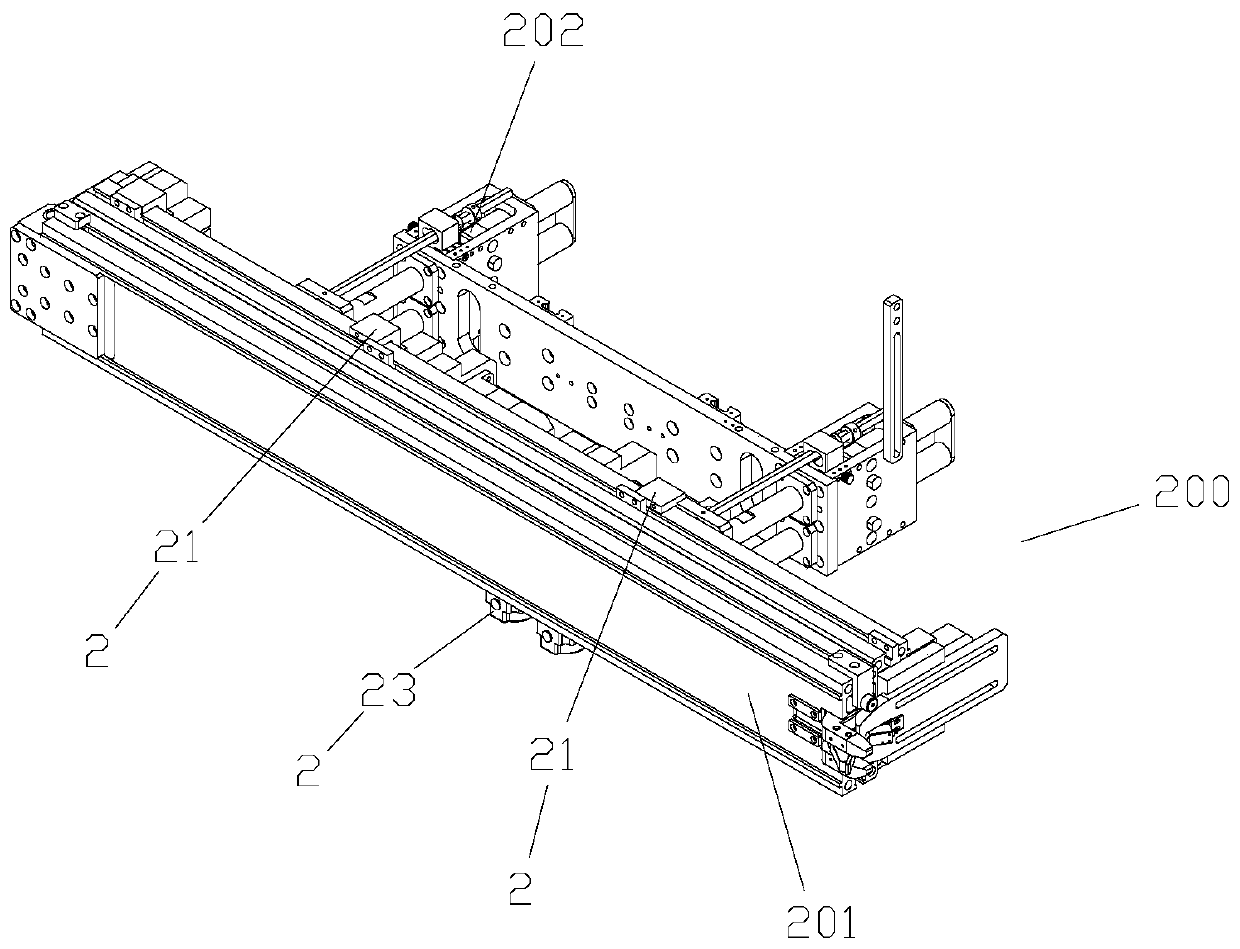

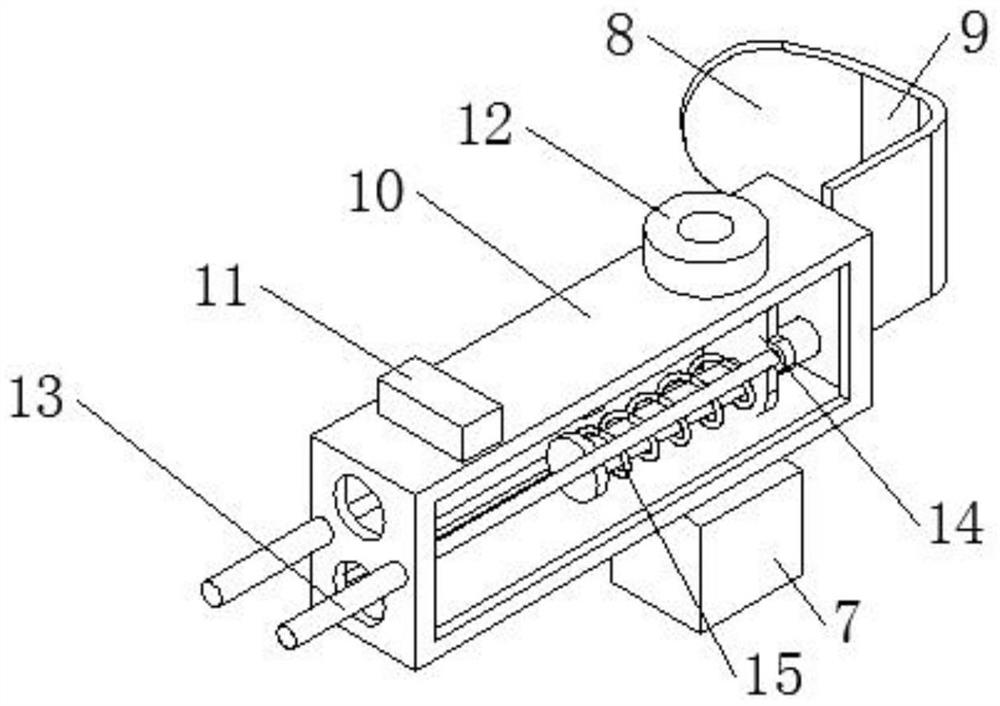

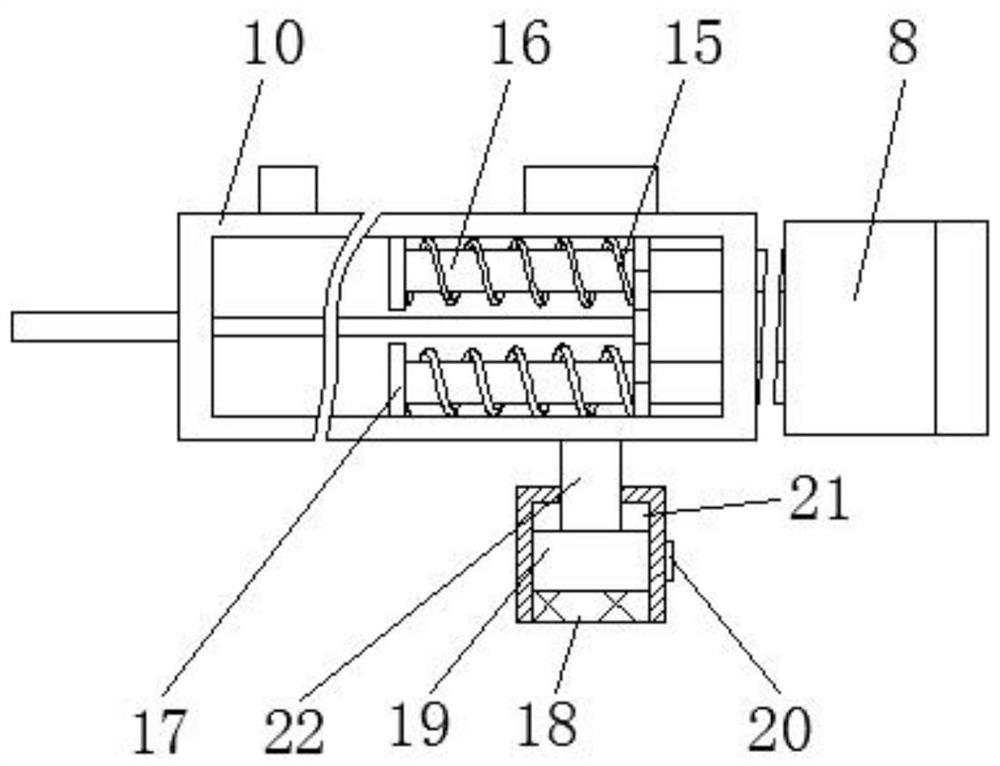

Nozzle aligning device and pipe expander with nozzle aligning device

ActiveCN111570641ASolve the problem of inconvenient alignmentAchieve alignmentMetal-working feeding devicesMetal working apparatusVisual inspectionVisual perception

The invention provides a nozzle aligning device and a pipe expander with the nozzle aligning device. The nozzle aligning device comprises a visual inspection mechanism, a position adjustment mechanismand a controller, wherein the visual inspection mechanism is used for obtaining images of a nozzle of a workpiece to be subjected to pipe expanding and an expanding ball of an expanding rod of the pipe expander; the position adjustment mechanism is provided with a moving part which is movably arranged in the first preset direction to drive the workpiece to be subjected to pipe expanding to move in the first preset direction; the controller are electrically connected to the visual inspection mechanism and the position adjustment mechanism to receive the images from the visual inspection mechanism and control the action of the position adjustment mechanism according to the positional relationship between the nozzle and the expanding ball on the images. The nozzle aligning device solves theproblem of inconvenient aligning of nozzles in the pipe expanding process in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

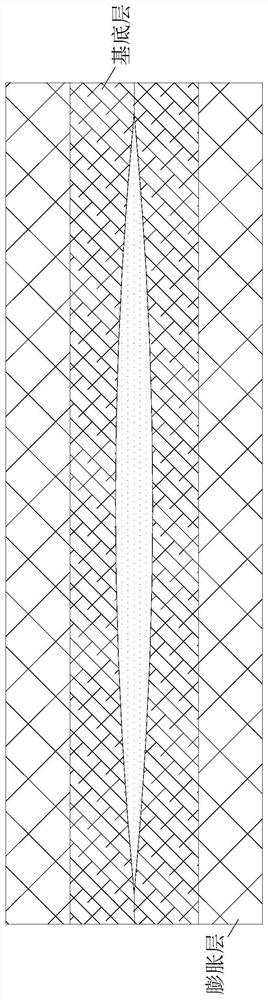

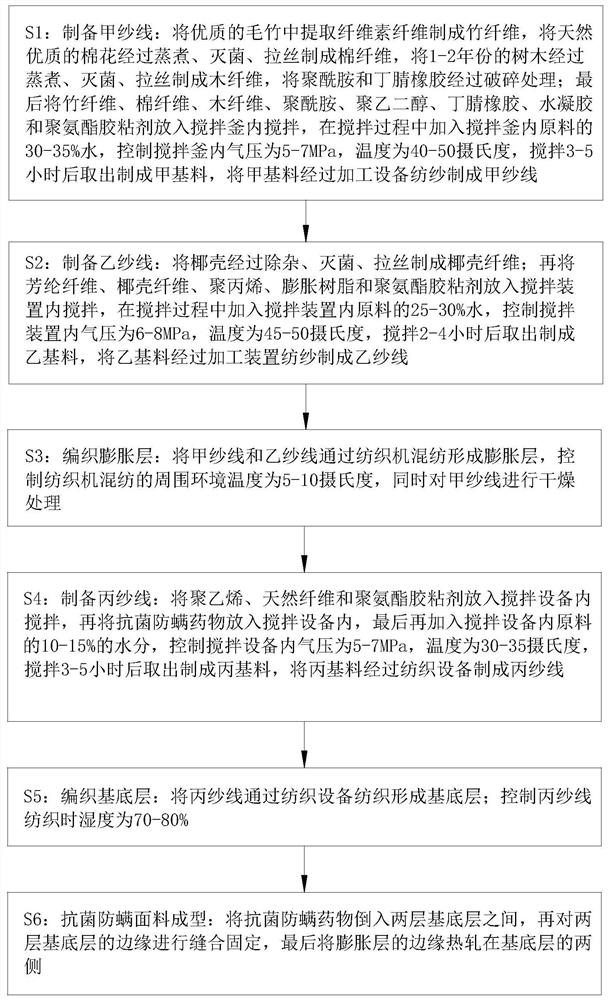

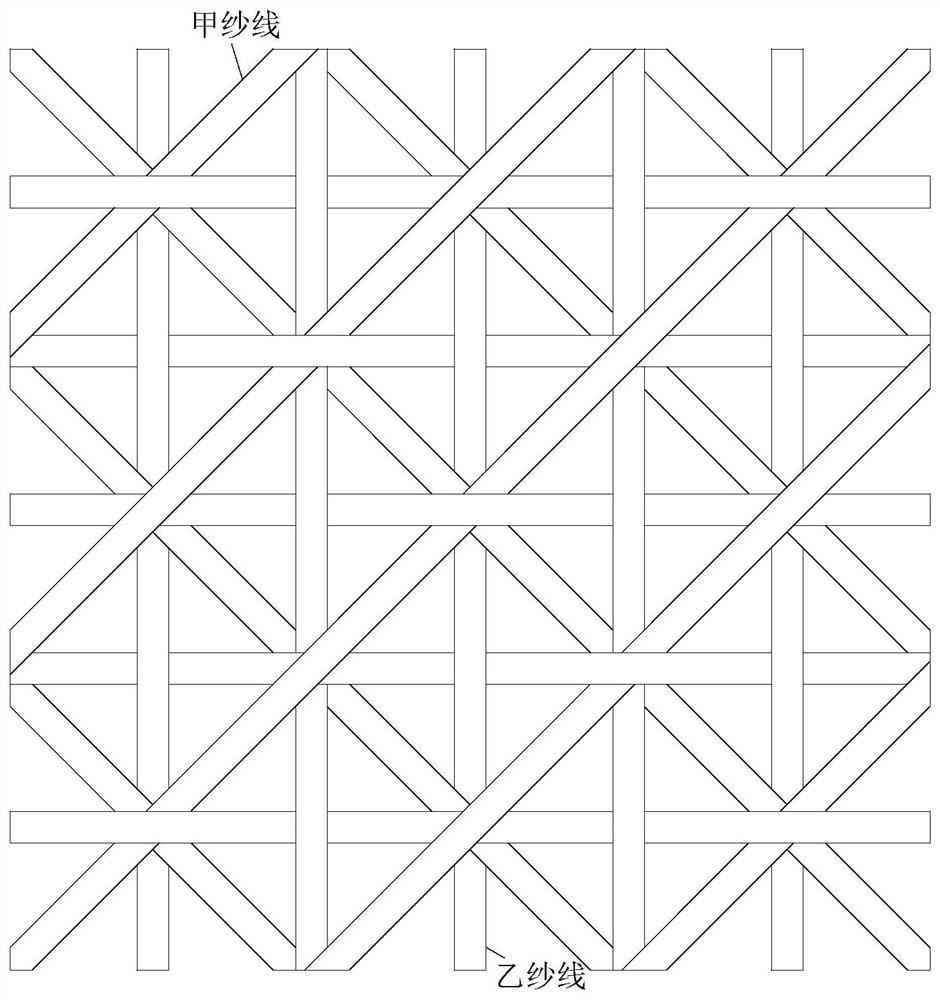

Preparation method of antibacterial and anti-mite fabric

ActiveCN112144175APrevent disappearingIncrease the gapBiochemical fibre treatmentSynthetic resin layered productsYarnThermal dilatation

The invention relates to the technical field of preparation of antibacterial and anti-mite fabrics, in particular to a preparation method of an antibacterial and anti-mite fabric. The antibacterial and anti-mite fabric comprises two layers of base layers and two layers of expansion layers; the base layers are located between the two expansion layers, and the space between the two base layers is filled with antibacterial and anti-mite medicine; the antibacterial and anti-mite medicine is powdery; the expansion layers are formed by weaving yarns A and yarns B; the yarns A have the effect of water absorption and expansion; and the yarns B have the effect of thermal expansion. According to the preparation method of the antibacterial and anti-mite fabric, the yarns A absorbing water and expanding in the expansion layers are matched with the yarns B expanding when being heated in the expansion layers, so that gaps between the yarns of the expansion layers are reduced, and therefore the antibacterial and anti-mite medicine between the base layers is protected against flowing away under the driving of water to the maximum extent; and therefore, the antibacterial and anti-mite effects of the antibacterial and anti-mite fabric are guaranteed, and the service life of the antibacterial and anti-mite fabric is prolonged.

Owner:杭州卓涛实业有限公司

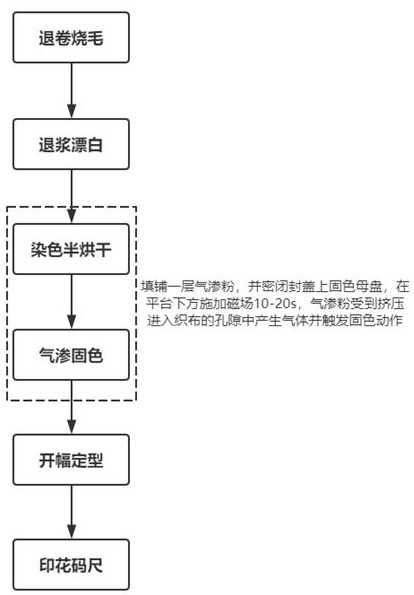

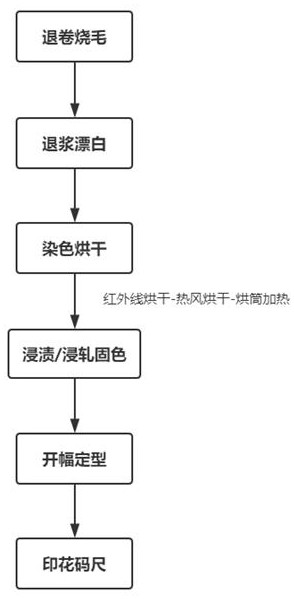

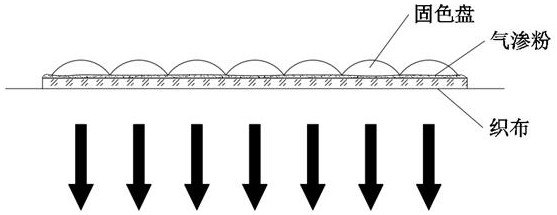

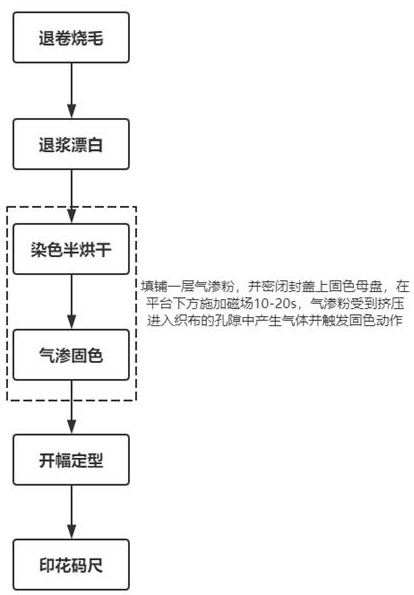

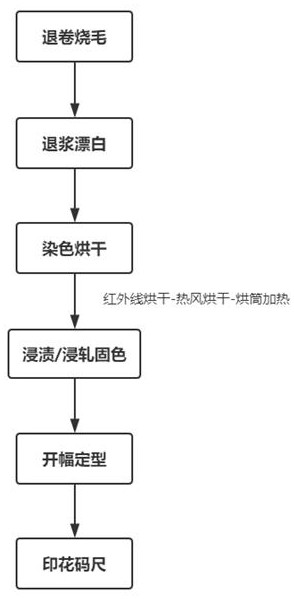

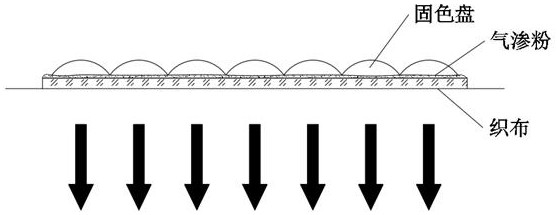

Gas permeation type textile printing and dyeing process

ActiveCN112941929ASimplify the drying and color fixing processImprove dyeing effectLiquid/gas/vapor removalTextile treatment machine arrangementsWoven fabricPolymer chemistry

The invention discloses a gas permeation type textile printing and dyeing process, and belongs to the technical field of textile. By simplifying an existing drying process, after infrared preliminary drying is conducted, gas permeation powder is filled and laid on the surface of woven cloth, and then a color fixing mother disc is sealed and covered; then a magnetic field is applied to force the color fixing mother disc to extrude the gas permeation powder into pores of the woven fabric, so that the gas permeation powder is dissolved in residual water in the woven fabric, the gas permeation powder releases a large amount of gas after chemical reaction, the gas rapidly permeates and expands in the woven fabric, and the water only provides a carrier for the chemical reaction and does not participate in the chemical reaction, so that the dye is not prone to migration; the color fixing mother disc is reversely extruded to release a color fixing liquid for exchange after the gas is expanded to a certain degree, the color fixing liquid enters the woven fabric along a gas permeation track, and the non-migrated dye is fully and uniformly subjected to color fixing treatment. Compared with the prior art, the drying and color fixing procedures are simplified; and meanwhile, the dyeing effect of the woven fabric is remarkably improved.

Owner:南通隆彩纺织科技有限公司

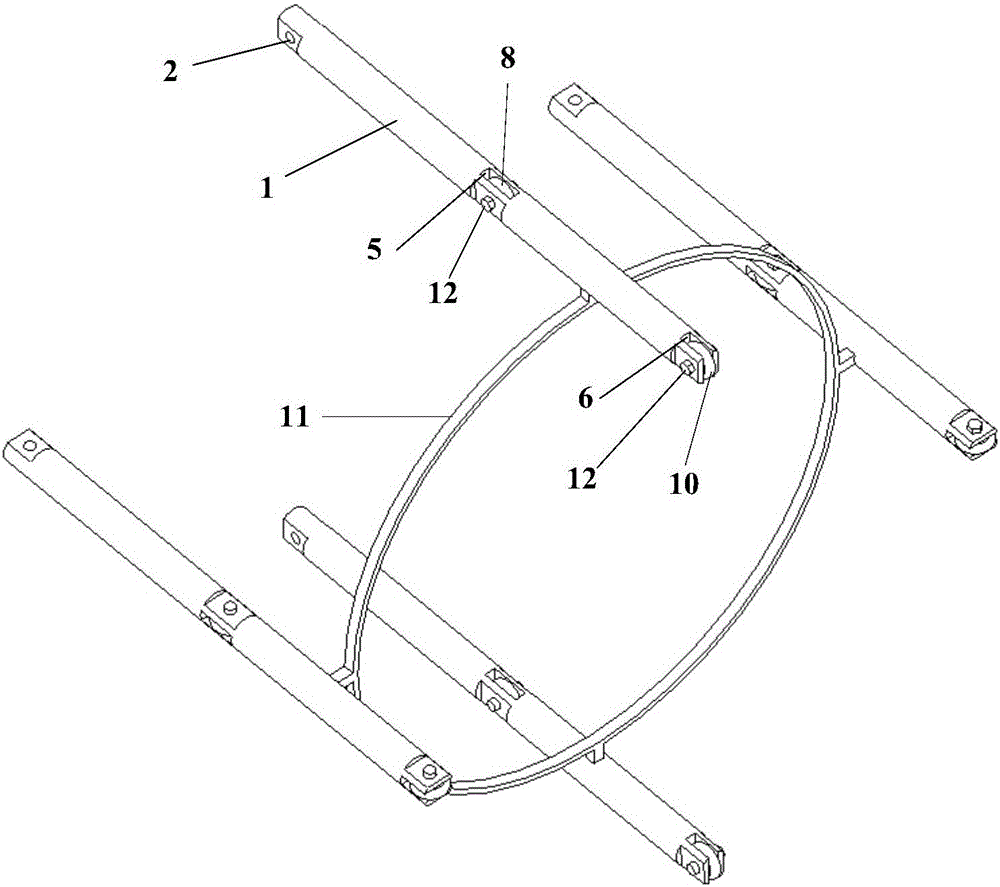

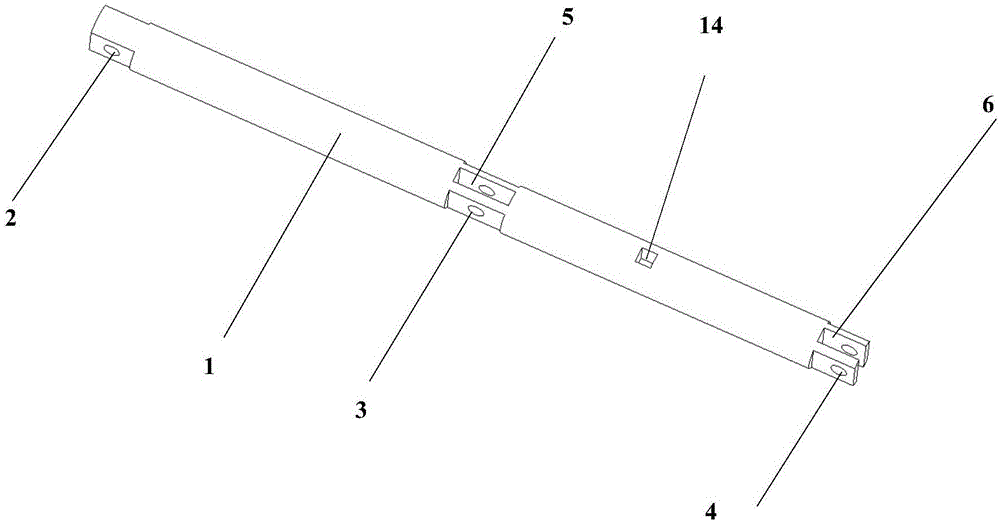

Guide rod device for stage separation of guided missile

ActiveCN106767197ASimple structureLow processing technology requirementsSelf-propelled projectilesRubber ringInterference fit

The invention discloses a guide rod device for stage separation of a guided missile. The guide rod device comprises cylindrical guide rods, first circular pulleys, second circular pulleys, first circular rubber rings, second circular rubber rings, a supporting ring, bolts, nuts and the like, wherein the cylindrical guide rods are fixed at the tail of a previous-stage guide missile through first circular through holes, the bolts and the nuts; the corresponding circular rubber rings can be directly sleeved with grooves in the outer ends of the circular pulleys; each first circular pulley is fixed in a first rectangular through hole in the middle of the corresponding cylindrical guide rod through a second circular through hole, the bolts and the nuts; each second circular pulley is fixed in a second rectangular through hole in the tail end of the corresponding cylindrical guide rod through a third circular through hole, the bolts and the nuts; the supporting ring is in interference fit and fixation with cuboid grooves in the lower surfaces of the four cylindrical guide rods through cuboid bosses which are uniformly distributed at the periphery. According to the guide rod device disclosed by the invention, the negative mass can be removed, the structure is simple, the stability in the separation process is guaranteed, the separation is enabled to quicker and the production cost is effectively reduced.

Owner:BEIHANG UNIV

A new type of obstetrics and gynecology clinical production assistance device

ActiveCN108210029BAvoid tearingOvercome deficienciesDiagnosticsObstetrical instrumentsDilatorEngineering

The invention discloses a novel clinical parturition assistance device for gynaecology and obstetrics. The device comprises a base, wherein the upper end of the base is fixedly provided with a telescopic rod, the upper end of the telescopic rod is fixedly provided with a supporting frame, the upper end of the supporting frame is fixedly provided with a tray, the upper surface of the tray is provided with a left side expander and a right side expander, the structure of the left side expander is the same as that of the right side expander, the left side expander comprises a mounting frame, the mounting frame is internally provided with a light rod, the light rod penetrates through a mounting hole at the side of the mounting frame, one end of the light rod is provided with a baffle, the otherend of the light rod is fixedly provided with an expansion hook, and the inner side of the expansion hook is fixedly provided with a pressure sensor. The novel clinical parturition assistance devicefor gynaecology and obstetrics can automatically adjust the expansionary force according to different stages of parturition, and avoid the problems of insufficient expansionary force and muscle tearing.

Owner:王丽

A low-shrinkage, crack-resistant C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensation and toughening and its preparation method

ActiveCN105130335BImprove cementing performanceGuaranteed mechanical propertiesCelluloseCrack resistance

The present invention discloses a low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, wherein the low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete is prepared from the following raw materials: cement, fly ash, mine powder, an expander, an AN-ICA internal curing agent, crushed stone, river sand, polyacrylonitrile fibers, micro-scale modified degreasing cotton cellulose, a cement slurry microstructure regulation agent, water and an ultra-dispersed water-reducing and shrinkage-reducing superplastic admixture. According to the present invention, the initial slump is more than or equal to 230 mm, the expansion degree is more than or equal to 630 mm, the 28 d compressive strength is more than or equal to 70 MPa, the 28 d splitting tensile strength is more than or equal to 5.8 MPa, the toughness index I5 is more than or equal to 3.0, the 28 d self-shrinkage is less than 100*10<-6>, the 28 d dry shrinkage rate is less than 150*10<-6>, the carbonization grade achieves T-IV, the anti-cracking grade achieves L-V, the product has characteristics of excellent mechanical property, excellent cracking resistance and excellent durability, and the difficult problems of high cement and cementing material material consumption, large shrinkage and easy cracking of the bridge tower concrete at the current stage can be solved.

Owner:WUHAN UNIV OF TECH +2

A kind of viscosity-reducing enhanced anti-cracking agent and preparation method thereof

The invention discloses a viscosity-reducing enhanced anti-cracking agent and a preparation method thereof. The raw materials include the following components in mass percentage: 30-60% of modified magnesium oxide expansion agent, 5-20% of synthetic fiber, and viscosity-reducing component 10-40%, reinforcement component 20-50%; the viscosity-reducing component includes microbead powder, cellulose ether, powder water reducer, sepiolite; the reinforcement component includes ultra-fine mineral admixture, silica fume , Nano silicon dioxide, sodium gluconate, urea. The present invention combines the viscosity-reducing component and the strengthening component on the basis of the expansion agent compensating for shrinkage and early crack resistance of the fiber. Each component has a synergistic effect under a suitable ratio, effectively reducing the viscosity of the concrete and improving the strength of the concrete. At the same time, the viscosity-reducing component and the strengthening component have a promoting effect on the expansion agent, and can synergistically improve the expansion effect of the expansion agent.

Owner:武汉三源特种建材有限责任公司

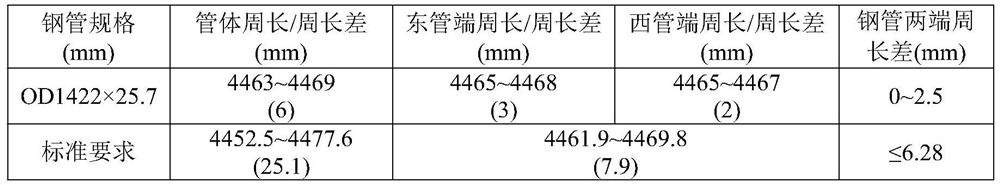

Method for improving physical dimension precision of pipe body and pipe ends of longitudinally welded pipe

InactiveCN111842673AEasy to observeSolve the problem of inaccurate positioning of the pressing positionMetal working apparatusPipeMechanical engineering

The invention discloses a method for improving the physical dimension precision of the pipe body and pipe ends of a longitudinally welded pipe. The method comprises the steps that modular subdivisioncontrol is adopted during mechanical diameter expanding, different diameter expanding rates are adopted for the pipe ends and the pipe body, the diameter expanding length of each subsection is about 2.5-3.0 m during pipe body diameter expanding, it is guaranteed that the overlapping amount of last and next subsection diameter expanding is larger than 0.5 m, and the straightness deviation of the steel pipe within the overall length range is optimally controlled to be smaller than or equal to 0.15% of the pipe length. According to the method, different diameter expanding rates are adopted according to the diameter expanding requirements of different positions, difference control over the physical dimension of the pipe ends and the pipe body can be achieved, and the diameter expanding effectand quality of the whole pipe are guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Installation technology method of rolling steel ball based on metal cold and hot deformation

PendingCN111360485AStable outputGuaranteed expansion effectMetal working apparatusGear wheelEngineering

The invention discloses an installation technology method of a rolling steel ball based on metal cold and hot deformation. The rolling steel ball comprises a tank bracket, a circulating cooling tank,a power system, a circulating cooling system, a negative pressure suction system, a rotary negative pressure absorbing tight device, a driving gear assembly, a disc lowering rotating assembly, a driving gear assembly and a composite gear shaft. The tank bracket is used as a structural support, the circulating cooling tank is used as a steel ball low-temperature treatment reaction chamber, and thedisc lowering rotating assembly is used as a tool head warming device. The installation technology method of the rolling steel ball based on the metal cold and hot deformation is compact in structureand reasonable in layout, has the advantages of high efficiency and good flexibility, and greatly reduces the labor strength.

Owner:HENAN POLYTECHNIC UNIV

An air-permeable textile printing and dyeing process

ActiveCN112941929BImprove dyeing effectDifficult to swimLiquid/gas/vapor removalTextile treatment machine arrangementsTextile printerTextile technology

The invention discloses an air-permeable textile printing and dyeing process, which belongs to the technical field of textiles. The present invention can simplify the existing drying process and fill the surface of the woven fabric with air-permeable powder after preliminary infrared drying. , and then seal the color-fixing master plate on the airtight cover, and then apply a magnetic field to force the color-fixing master plate to squeeze the air-permeable powder into the pores of the woven fabric, thereby dissolving in the residual moisture in the woven fabric. After the chemical reaction of the air-permeable powder occurs A large amount of gas is released, and the gas penetrates and expands rapidly in the fabric. Since the water only provides the carrier of the chemical reaction and does not participate in the chemical reaction, the dye is not easy to migrate. The color master disk releases the color-fixing liquid for exchange, and the color-fixing liquid enters the fabric along the gas permeation track, and performs color-fixing treatment on the non-migrated dye fully and uniformly. Compared with the existing technology, it not only simplifies Eliminates the drying and color fixing process, and at the same time significantly improves the dyeing effect of the woven fabric.

Owner:南通隆彩纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com