Method for improving physical dimension precision of pipe body and pipe ends of longitudinally welded pipe

A technology of geometric size, straight seam welded pipe, applied in the field of pipeline steel pipe manufacturing, can solve problems such as difficulty in adapting to the rapid development of pipeline construction, high geometrical accuracy requirements of welded pipes, and large resilience of thick-walled straight seam welded pipes, etc. Error avoidance and excellent precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

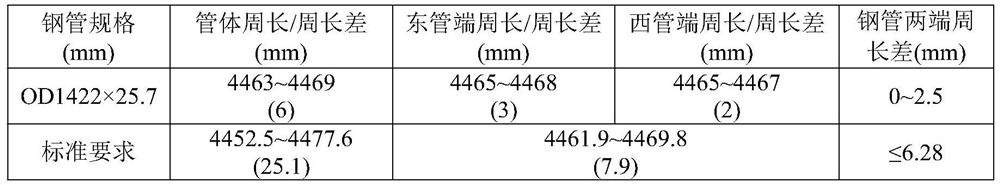

[0018] Example 1: Control of geometric dimension accuracy of X80 OD1422×25.7mm longitudinal welded pipe.

[0019] (1) Select the X80 thick-walled pipeline steel plate with a wall thickness of 25.7mm. The unevenness of the steel plate is required to be less than 10mm / 2000mm.

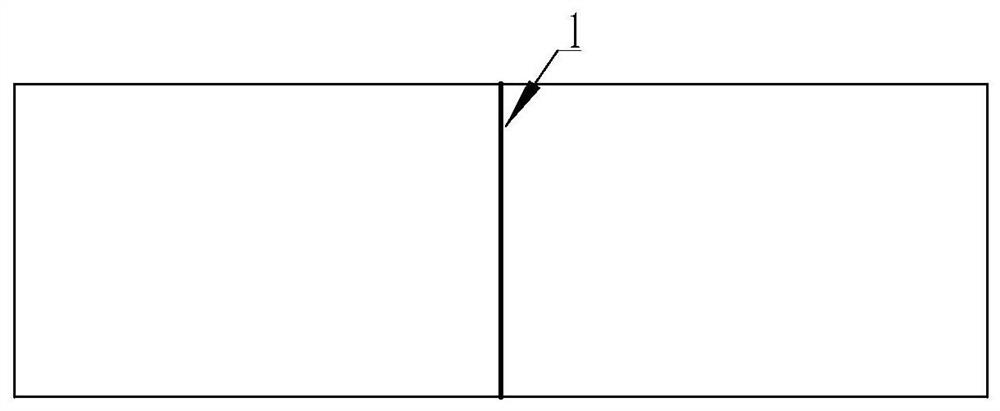

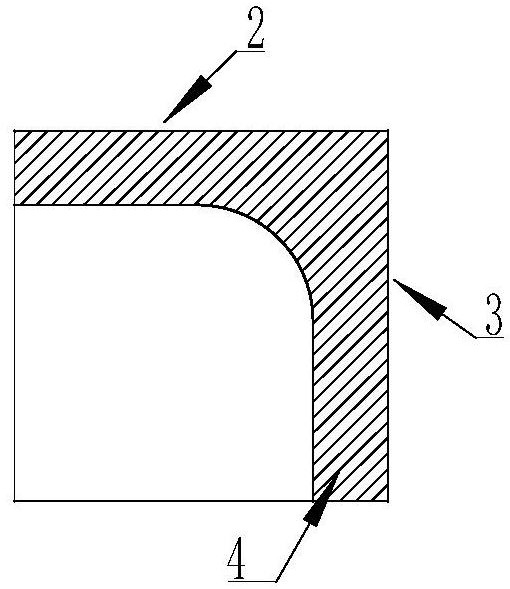

[0020] (2) When JCO is formed, use such as figure 1 and figure 2 The molded centering block shown is a hollow structure with a figure 2 Medium polyurethane material 4, placed in figure 1 At position 1 of the center line, during the process of pressing the steel plate from the J type to the C type and O type, after each pressing, the centering block is used to push the welded pipe to the center of the forming machine, and the centering block is used to push the welded pipe to the center of the forming machine. figure 2 Multi-angle centering is carried out on the center line 2 and the front centering position 3 on the middle and upper surface to ensure that the welded pipe is always in the center of t...

Embodiment 2

[0029] Example 2: Control of geometric dimension accuracy of X80 OD1422×30.8mm longitudinal welded pipe.

[0030] (1) Select the X80 thick-walled pipeline steel plate with a wall thickness of 30.8mm. The unevenness of the steel plate is required to be less than 10mm / 2000mm.

[0031] (2) When JCO is formed, it is used as shown in the attached drawing of the specification figure 1 and figure 2 The molded centering block shown is a hollow structure with a figure 2 Medium polyurethane material 4, placed in figure 1 At position 1 of the center line, during the process of pressing the steel plate from the J type to the C type and O type, after each pressing, the centering block is used to push the welded pipe to the center of the forming machine, and the centering block is used to push the welded pipe to the center of the forming machine. figure 2 Multi-angle centering is carried out on the center line 2 and the front centering position 3 on the middle and upper surface to ens...

Embodiment 3

[0040] Example 3: Control of geometric dimension accuracy of X80 OD1422×32.1mm longitudinal welded pipe.

[0041] (1) Select the X80 thick-walled pipeline steel plate with a wall thickness of 32.1mm. The unevenness of the steel plate is required to be less than 10mm / 2000mm.

[0042] (2) When JCO is formed, it is used as shown in the attached drawing of the specification figure 1 and figure 2 The molded centering block shown is a hollow structure with a figure 2 Medium polyurethane material 4, placed in figure 1 At position 1 of the center line, during the process of pressing the steel plate from the J type to the C type and O type, after each pressing, the centering block is used to push the welded pipe to the center of the forming machine, and the centering block is used to push the welded pipe to the center of the forming machine. figure 2 Multi-angle centering is carried out on the center line 2 and the front centering position 3 on the middle and upper surface to ens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Eccentricity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com