Modified calcium sulfoaluminate-calcium oxide concrete expansion agent and preparation method therefor

A kind of calcium sulfoaluminate, concrete-like technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

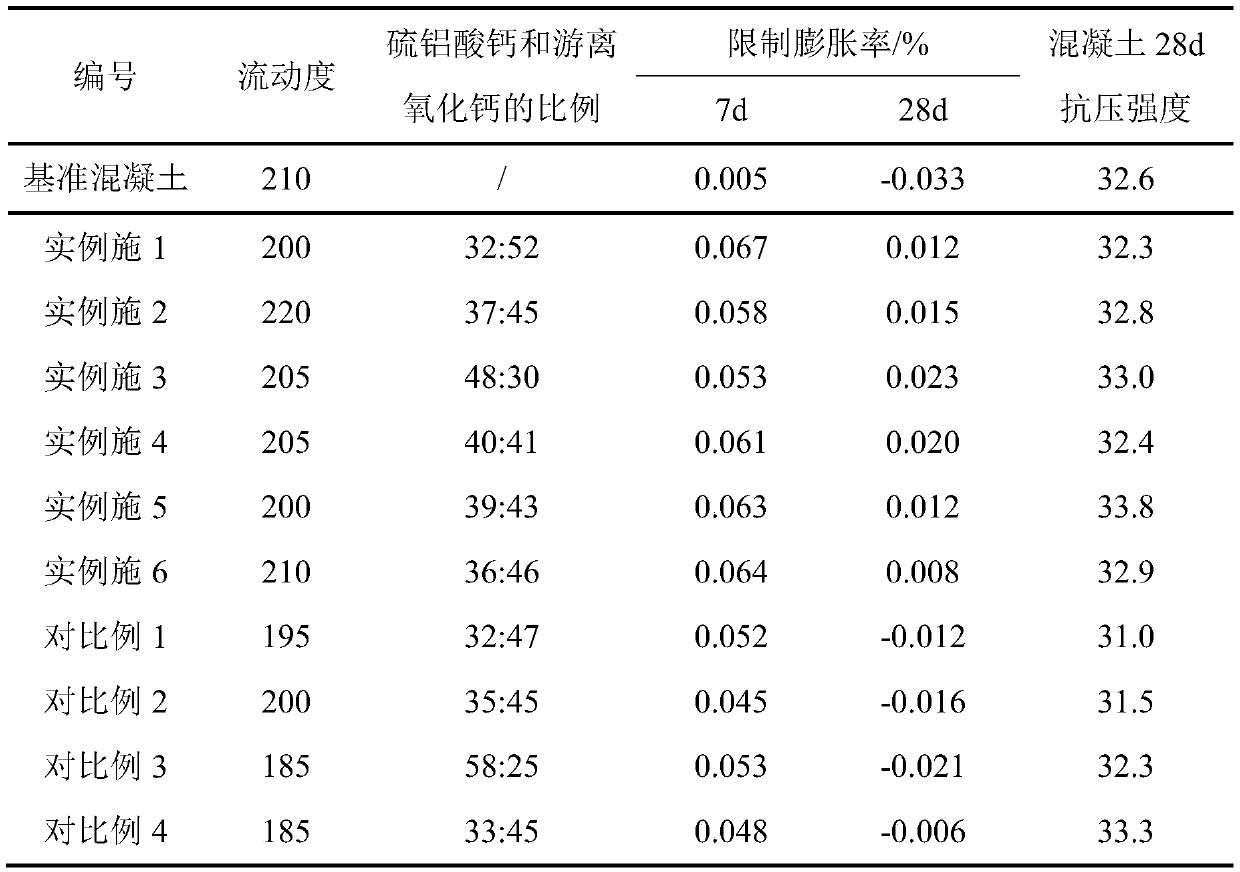

Embodiment 1

[0030] A modified calcium sulfoaluminate-calcium oxide concrete expansion agent, comprising calcium sulfoaluminate-calcium oxide expansion clinker and a modifier added in a weight ratio of 80:20;

[0031] The modifier is made of the following components in parts by weight: 30 parts of sodium silicate, 15 parts of silane coupling agent, 15 parts of carboxymethyl cellulose, 10 parts of nano-calcium carbonate and 20 parts of absolute ethanol .

[0032] The calcium sulfoaluminate-calcium oxide expansion clinker is made of the following components in parts by weight: 7 parts of calcined phosphogypsum, 15 parts of sulfur-fixing ash, 10 parts of aluminum slag, 15 parts of bauxite and 50 limestone.

[0033] The preparation method of the above-mentioned modified calcium sulfoaluminate-calcium oxide concrete expansion agent comprises the following steps:

[0034] S1, preparing calcium sulfoaluminate-calcium oxide expansion clinker;

Embodiment 2

[0041] A modified calcium sulfoaluminate-calcium oxide concrete expansion agent, comprising calcium sulfoaluminate-calcium oxide expansion clinker and a modifier added in a weight ratio of 90:10;

[0042] The modifier is made of the following components in parts by weight: 40 parts of sodium silicate, 10 parts of silane coupling agent, 10 parts of carboxymethyl cellulose, 5 parts of nano-calcium carbonate and 45 parts of absolute ethanol .

[0043] The calcium sulfoaluminate-calcium oxide expansion clinker is made of the following components in parts by weight: 10 parts of calcined phosphogypsum, 10 parts of sulfur-fixing ash, 5 parts of aluminum slag, 10 parts of bauxite and 55 limestone.

[0044] The preparation method of embodiment 2 is the same as that of embodiment 1, the difference is that the composition ratio is different.

Embodiment 3

[0046]A modified calcium sulfoaluminate-calcium oxide concrete expansion agent, comprising calcium sulfoaluminate-calcium oxide expansion clinker and a modifier added in a weight ratio of 85:15;

[0047] The modifying agent is made of the following components in parts by weight: 35 parts of sodium silicate, 12.5 parts of silane coupling agent, 12.5 parts of carboxymethyl cellulose, 7.5 parts of nano-calcium carbonate and 35 parts of absolute ethanol .

[0048] The calcium sulfoaluminate-calcium oxide expansion clinker is made of the following components in parts by weight: 8.5 parts of calcined phosphogypsum, 12.5 parts of sulfur-fixing ash, 7.5 parts of aluminum slag, 12.5 parts of bauxite and 53 parts limestone.

[0049] The preparation method of embodiment 3 is the same as that of embodiment 1, the difference is that the composition ratio is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com