A large fluid micro-expansion high-strength grouting material

A grouting material and micro-expansion technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of surface cavity, small effective bearing surface of the matrix, slow strength development, etc., to reduce pore water, Improve work performance and later mechanical properties, improve the effect of early and late strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

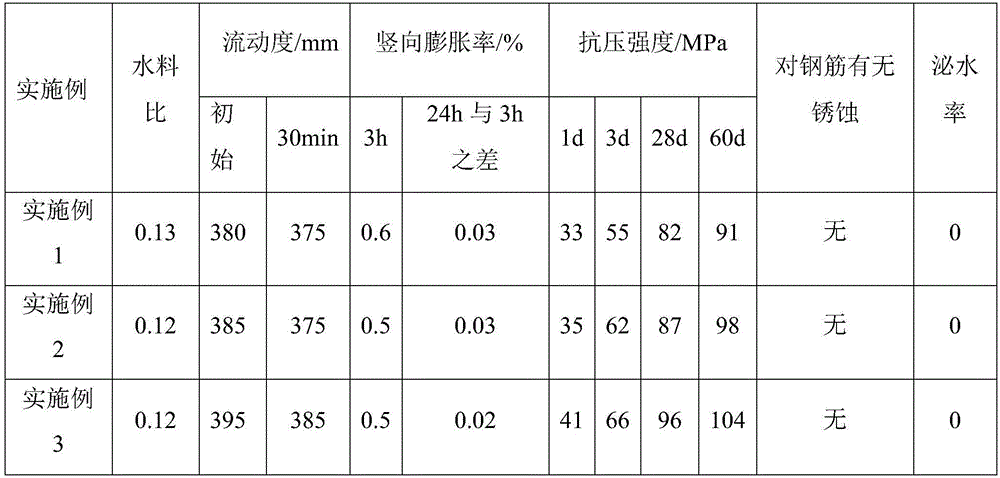

Embodiment 1

[0028] A large fluid micro-expansion high-strength grouting material, its raw materials are calculated by mass percentage: ordinary portland cement 23%, silica fume 3%, microbeads 5%, phosphorus slag composite powder 7%, quartz powder 3%, fine Aggregate 54.79%, water reducer 0.7%, defoamer 0.01%, expansion agent 3%, early strength agent 0.5%.

[0029] In this example, the content of active silica in silica fume is 92%, and the specific surface area is 20000m 2 / kg; the specific surface area of microbeads is 850m 2 / kg; the mass percentage of phosphorus slag powder in phosphorus slag composite powder is 70%, the mass percentage of limestone powder is 30%, and the specific surface area of phosphorus slag composite powder is 610m 2 / kg; the quartz powder of each particle size in the quartz powder is calculated as 15% of the 120-200 mesh quartz powder, 20% of the 200-260 mesh quartz powder, 30% of the 260-325 mesh quartz powder, and 35% of the 325-600 mesh quartz powder. %. ...

Embodiment 2

[0031] A large fluid micro-expansion high-strength grouting material, the components of which are calculated by mass percentage: 33% of ordinary Portland cement, 3.5% of encrypted silica fume, 3% of microbeads, 6% of phosphorus slag composite powder, and 3% of quartz powder %, fine aggregate 47.08%, water reducer 0.9%, defoamer 0.02%, expansion agent 2.5%, early strength agent 1%.

[0032] In this example, the content of active silica in silica fume is 92%, and the specific surface area is 22000m 2 / kg; the specific surface area of microbeads is 950m 2 / kg; the mass percentage of phosphorus slag powder in phosphorus slag composite powder is 80%, the mass percentage of limestone powder is 20%, and the specific surface area of phosphorus slag composite powder is 630m 2 / kg; the quartz powder of each particle size in the quartz powder is calculated as 20% of the 120-200 mesh quartz powder, 25% of the 200-260 mesh quartz powder, 20% of the 260-325 mesh quartz powder, and 35% o...

Embodiment 3

[0034] A large fluid micro-expansion high-strength grouting material, its components are calculated by mass percentage: ordinary Portland cement 34%, encrypted silica fume 3.5%, microbeads 3%, phosphorus slag composite powder 5%, quartz powder 3.5% %, fine aggregate 46.47%, water reducer 1%, defoamer 0.03%, expansion agent 2.5%, early strength agent 1%.

[0035] In this example, the content of active silica in silica fume is 94%, and the specific surface area is 25000m 2 / kg; the specific surface area of microbeads is 1000m 2 / kg; the mass percentage of phosphorus slag powder in phosphorus slag composite powder is 90%, the mass percentage of limestone powder is 10%, and the specific surface area of phosphorus slag composite powder is 650m 2 / kg; Quartz powder of each particle size in quartz powder is calculated as 10% of 120-200 mesh quartz powder, 20% of 200-260 mesh quartz powder, 20% of 260-325 mesh quartz powder, and 50% of 325-600 mesh quartz powder. %; the mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com