Patents

Literature

88results about How to "Control clotting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance fire-resistant abrasion-proof composite material

The present invention discloses a high-performance flame-proof abrasion-resisting composite material which is prepared mainly by the components of particle material alumina or / and corundum or / and mullite 50-70 parts; hard particle 5-25 parts; binding agent 8-25 parts; aluminum oxide micro powder or / and silicon micronized quartz powder 8-15 parts and surfactant 0.1 parts. The composite material is developed according to the scientific knowledge obtained in the long-term researching and producing for the flame-proof abrasion-resisting composite material in our company and absorbing the latest accomplishment of the present material science, the material has the advantages of increasing the high-temperature bonding strength and toughness of the composite material, increasing the binding ability of the interface between the composite material and the equipment, facilitating the two sides forming a compact and high-strength whole body, optimizing the capability of the composite material in the high-temperature state, prolonging the service lifetime of the equipment, reducing the number of the breakdown maintenance, reducing the material consumption and the labor intensity of the worker thereby obtaining the purpose of increasing the economic benefit of the enterprise.

Owner:郑州市鑫磊冶金材料有限公司

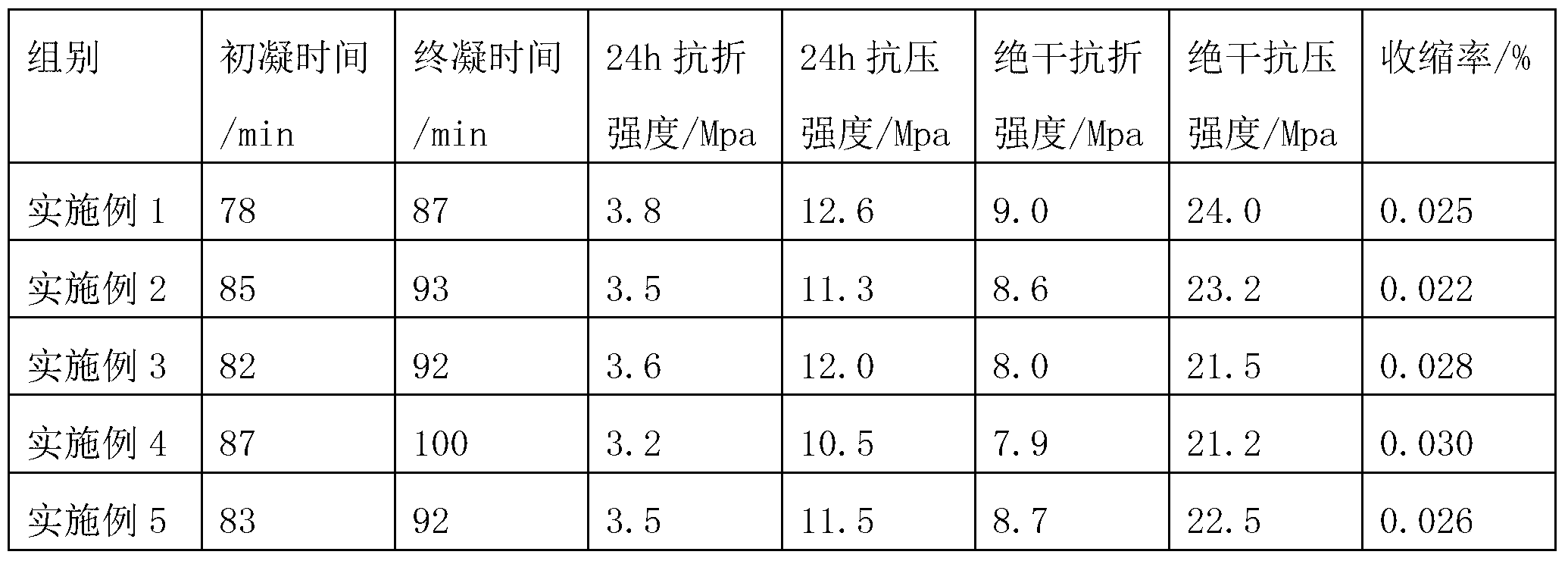

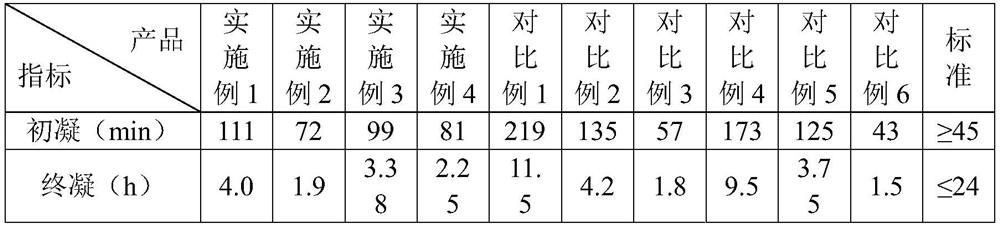

Alpha high-strength gypsum based self-leveling material prepared by adopting phosphogypsum and production process thereof

The invention relates to an alpha high-strength gypsum based self-leveling material prepared by adopting phosphogypsum and a production process thereof. The material comprises the following components in percentage by weight: 40-60% of alpha high-strength gypsum powder, 30-50% of aggregates, 1-4% of cement, 1-4% of fly ash, 2-4% of re-dispersible rubber powder, 0.1-0.3% of retarder, 0.2-0.75% of water reducing agent, 0.1-0.25% of water-retaining agent, 0.1-0.4% of air entraining agent and 0.05-0.15% of antifoaming agent. The production process comprises the steps of uniformly mixing the components and obtaining the alpha high-strength gypsum based self-leveling material. The alpha high-strength gypsum based self-leveling material disclosed by the invention has the advantages that the requirements of JC / T1023-2007 Gypsum based Self-leveling Mortar are met and the requirements on the 30min fluidity loss, the initial setting time, the final setting time, the breaking strength, the compressive strength and the shrinking rate are met.

Owner:WUHAN UNIV OF TECH

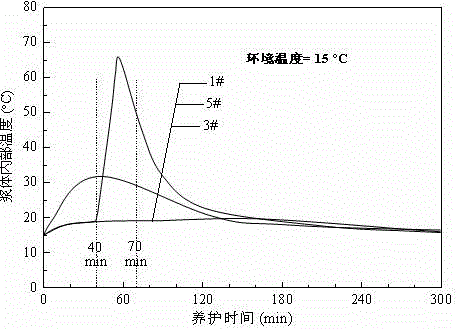

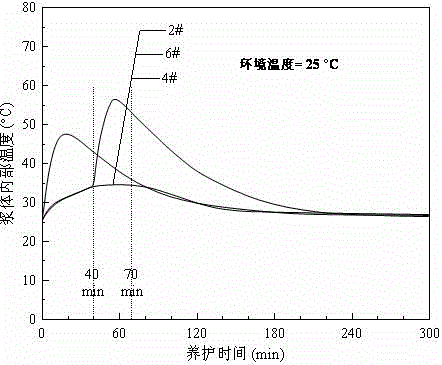

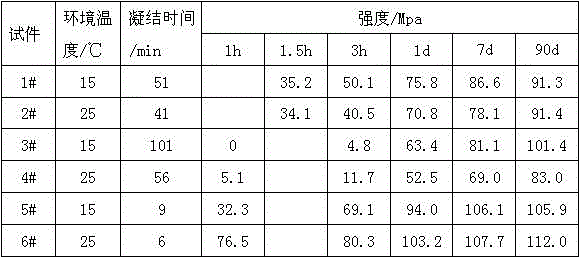

Method for controlling setting and hardening processes of magnesium phosphate cement

ActiveCN103332960APromotes hardening and early strength developmentLong term strength noMagnesium orthophosphateMagnesium phosphate

The invention relates to a method for controlling setting and hardening processes of magnesium phosphate cement. According to the method, the heat releasing speed of the magnesium phosphate cement is reduced by increasing addition of borax retarder to delay setting of magnesium phosphate cement mortar and adjust the setting time of the mortar within 20-150 minutes effectively, then a heat-transfer process between the mortar and an environment and the setting and hardening processes of the mortar are accelerated by increasing early environmental temperature of the mortar, and the early strength is form quickly and reaches 20-30MPa in an hour. The method solves the problem that the early strength of a magnesium phosphate cement system develops slowly due to the short setting time and a larger mixing amount of the borax retarder when the magnesium phosphate cement serves as a quick repairing material for a repairing project to some extent. Available test results indicate that the method can control the setting and hardening processes of the cement conveniently and effectively.

Owner:CHONGQING UNIV

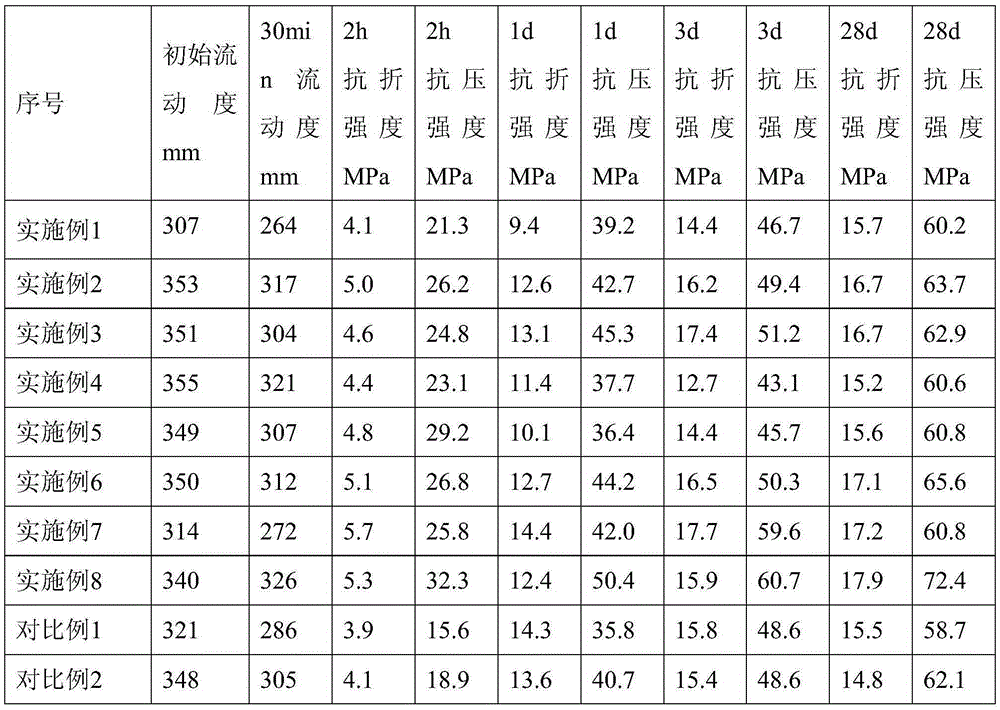

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

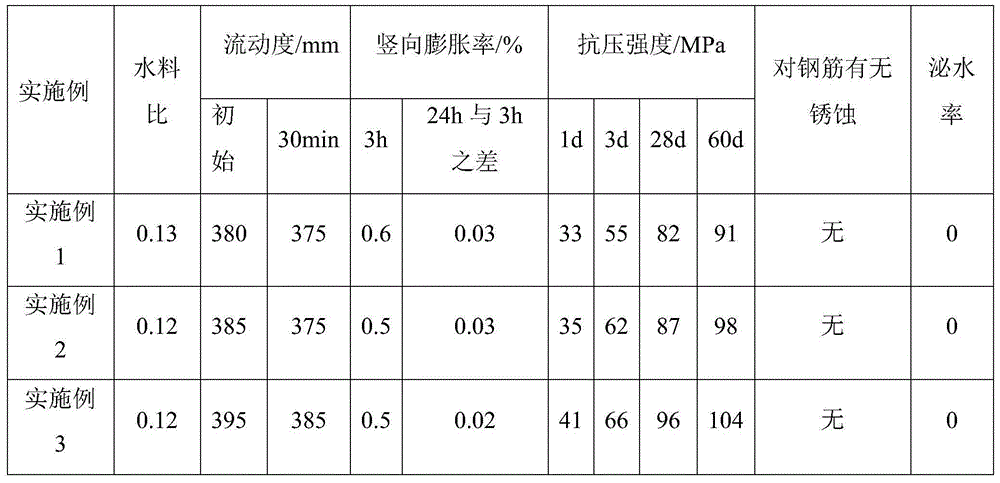

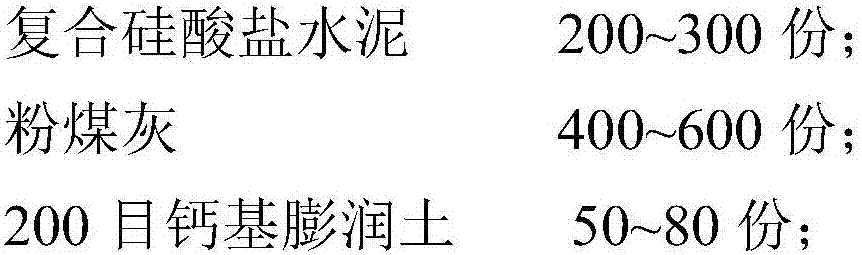

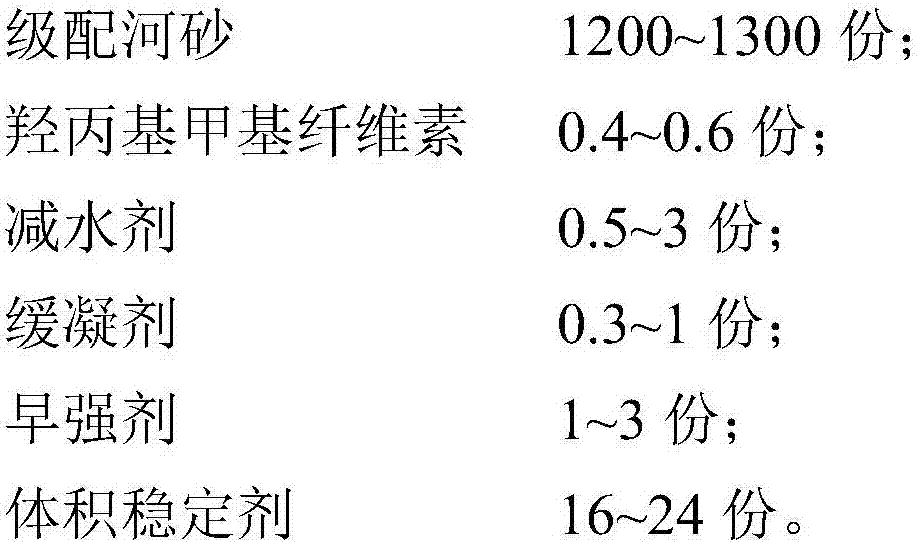

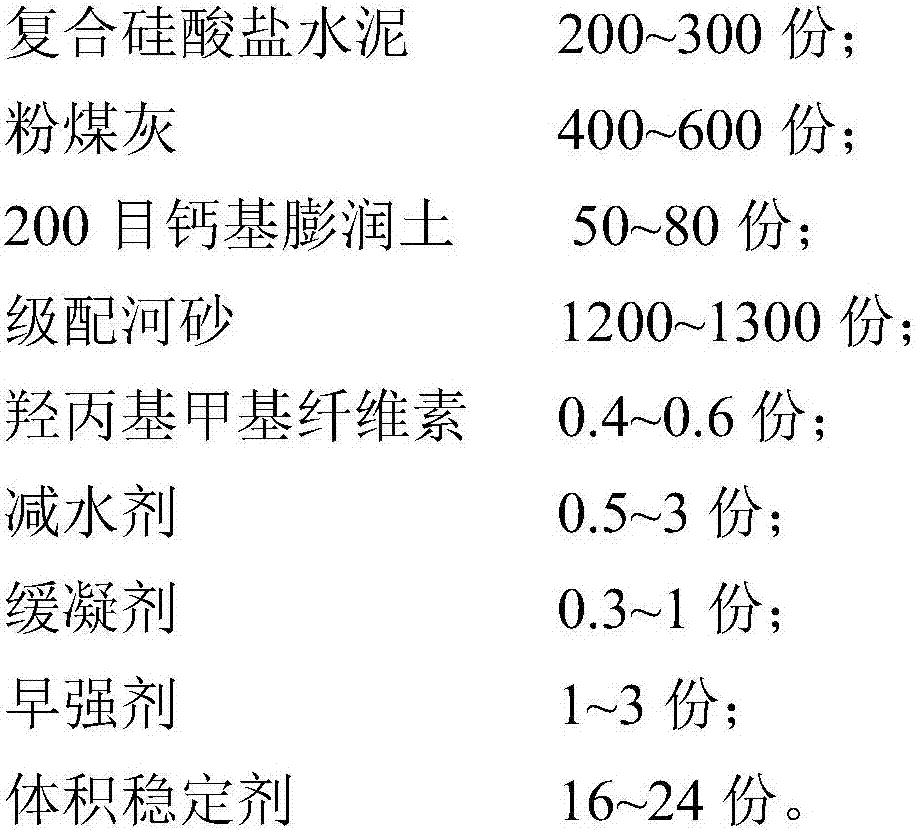

Shield synchronous grouting construction material

ActiveCN106946522AControl the compressive strengthControl bleeding rateSodium BentonitePortland cement

The invention discloses a shield synchronous grouting construction material including, by weight, 200-300 parts of composite Portland cement, 400-600 parts of fly ash, 50-80 parts of 200-mesh calcium based bentonite, 1200-1300 parts of grading river sand, 0.4-0.6 parts of hydroxypropylmethyl cellulose, 0.5-3 parts of a water reducer, 0.3-1 part of a retarder, 1-3 parts of an early strength agent and 16-24 parts of a volume stabilizing agent. Through reasonable adjustment of composition and content of the components, the compressive strength, bleeding ratio, setting time and flowability of the construction material are controlled, so that the construction material has long initial setting time, is quick in early strength development, is not liable to dissociation, has good volume stability, can effectively fill in gaps in buildings and prevent floatation and deformation of tunnel segments, has good flowability and anti-dispersing property, and is easy to transport and to store for a long period.

Owner:北京艺高世纪科技股份有限公司

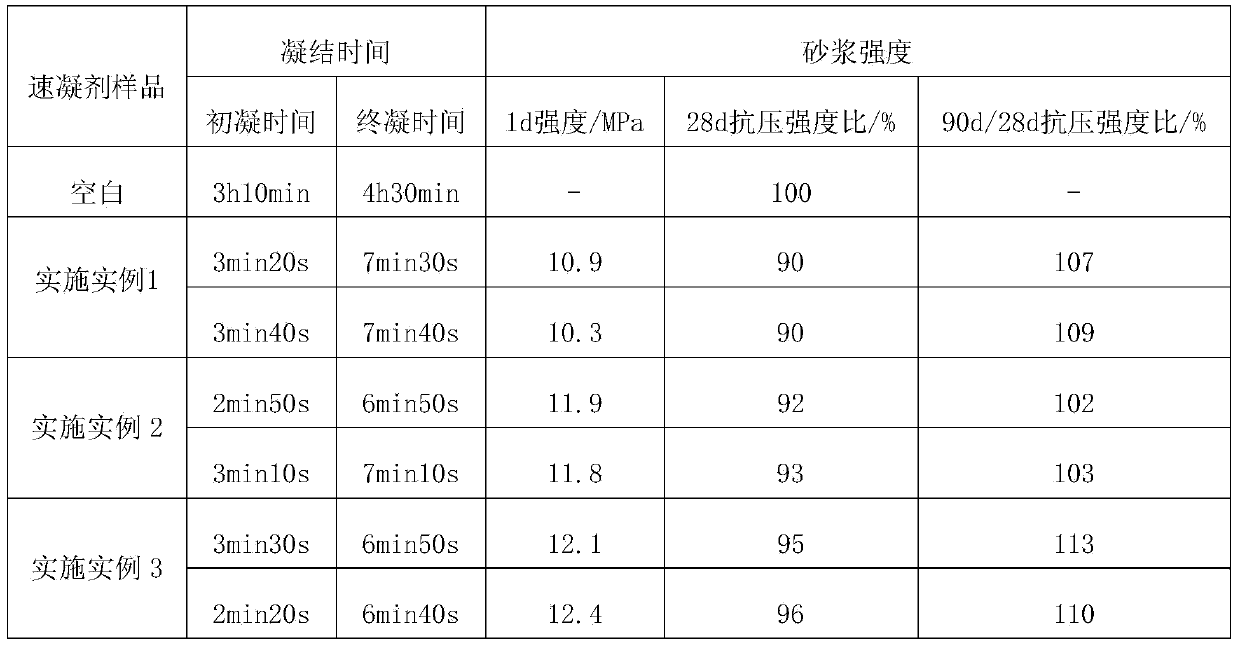

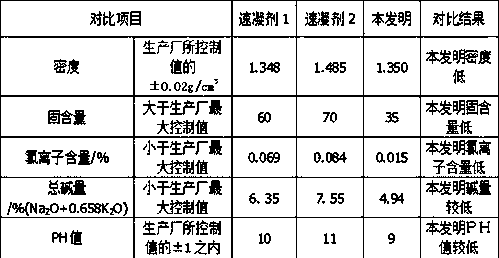

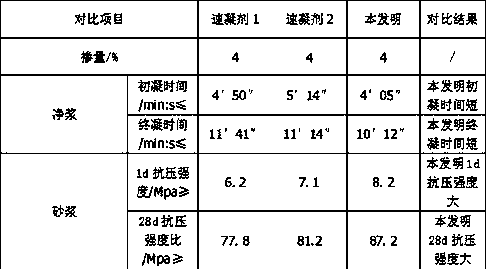

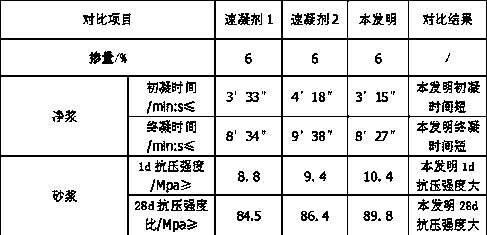

Low-resilience and low-alkaline liquid accelerator for sprayed concrete and preparation method thereof

The invention relates to a low-resilience and low-alkaline liquid accelerator for sprayed concrete and a preparation method thereof. The accelerator is prepared from the following raw materials: an aluminate mother liquid, a modifier, hydramine and a stabilizer, wherein the mass ratio of the modifier and the aluminate mother liquid is 1: (1-5), the dosage of hydramine is 0.5-2.5% of the sum of the modifier and the aluminate mother liquid in mass, the dosage of the stabilizer is 0.3-2% of the sum of the modifier and the aluminate mother liquid in mass; the stabilizer is one of vinylon glue, EDTA (Ethylene Diamine Tetraacetic Acid) and xanthan gum. The preparation method comprises the following steps: preparing the aluminate mother liquid; preparing the modifier; and preparing the low-alkaline liquid accelerator. The adulterate amount of the accelerator provided by the invention is 3-6% mass of cement, the initial setting time is 3 minutes and the final setting time is 8 minutes, and the requirements of JC477-2005 accelerator for sprayed concrete are satisfied. The accelerator is uniform and stable and strong in adaptability with cement, can be used for effectively reducing resilience and dust amount in construction of prayed concrete, and is short in setting time and less in loss of long-term strength.

Owner:刘翠芬

Cement grouting material

The invention provides a cement grouting material with self-compaction and high fluidity. The cement grouting material comprises anti-cracking mortar, flow promoting components, a plasticizer, coagulation delaying components and a coagulation accelerating component. The anti-cracking mortar comprises, by mass, 4-8% of Portland cement, 38-47% of sulfate aluminum cement, 42-52% of quartz sand, 4.6-4.9% of swelling agents and 0.1-0.4% of polypropylene fibers. The flow promoting components include water reducing agents and defoaming agents. The plasticizer is cellulose ether. The coagulation delaying components include one or more of tartaric acid, sodium gluconate and citric acid. The coagulation accelerating component contains calcium hydroxide. The cement grouting material can complete grouting on the condition of self-gravity and can be grouted successfully one time during high-altitude operation of a support and an inhaul cable pipeline of a bridge with no need for vibrating or secondary grouting; construction of the material is simple since it is only required to add water; the grouting material can be used in construction at a low temperature.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

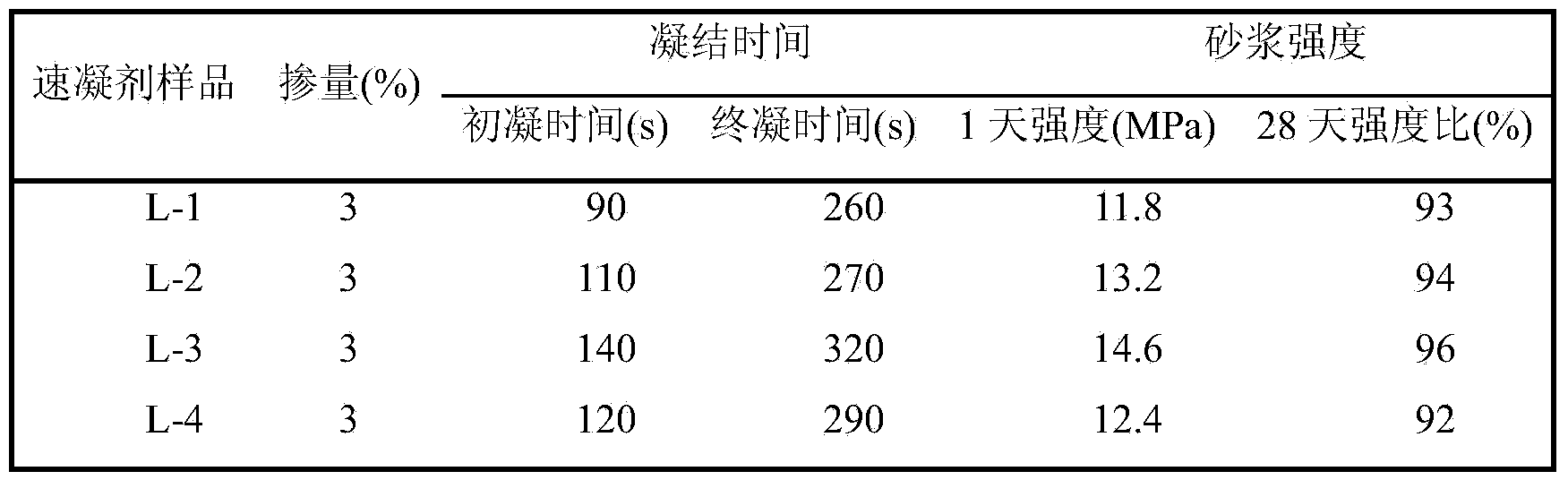

Preparation method of low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete

The invention discloses a preparation method of a low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete. The preparation method comprises the following steps: (1) preparing an aluminate mother solution; (2) preparing a modifying agent; (3) preparing a low-alkali polymer high-efficient liquid setting-accelerator. The disclosed low-alkali polymer high-efficient liquid setting-accelerator has a uniform and stable property and strong adaptability; the mixing amount is 2 to 4% of the cement mass, the initial setting time is within 2 minutes, the final setting time is within 5 minutes, the strength loss in the later stage of concrete is within 10%; furthermore, the liquid setting-accelerator can efficiently reduce the dust amount and resilience value during the sprayed concrete construction and improves the strength of sprayed concrete.

Owner:SHANDONG UNIV

Adhesive applicator with polymerization agent and/or bioactive material

A method of applying a bioactive agent and / or a polymerization or cross-linking rate modifier and / or a polymerization initiator to an applicator tip includes dissolving or dispersing the rate modifier, the initiator, and / or the bioactive agent in a low boiling point solvent, applying the resulting solution or dispersion to the applicator tip, and drying the applicator tip. The initiator and / or rate modifier is preferably applied in a methanol solvent and distributed along a concentration gradient on the applicator tip.

Owner:CLOSURE MEDICAL CORP (US)

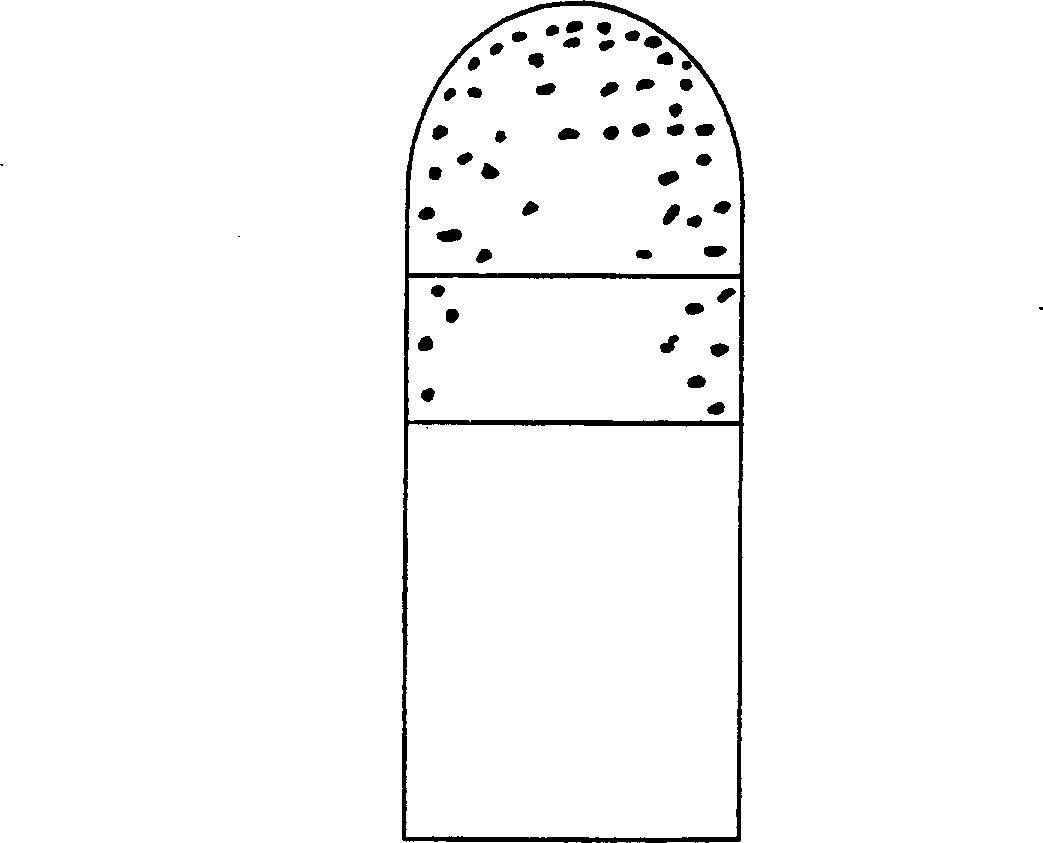

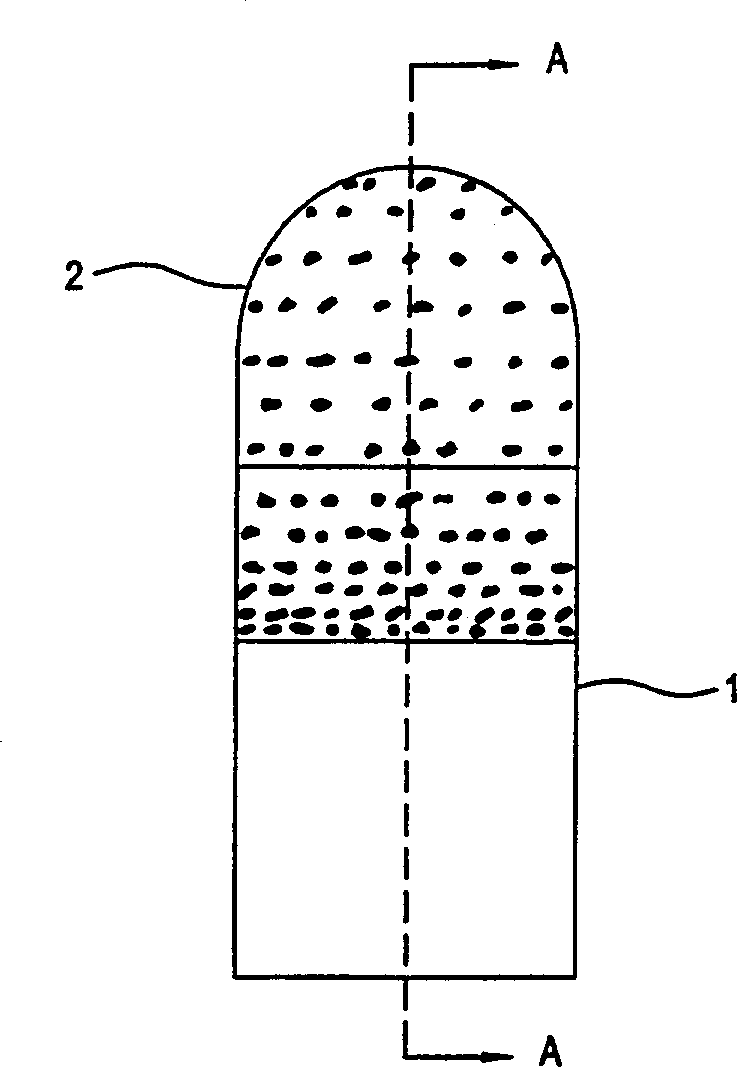

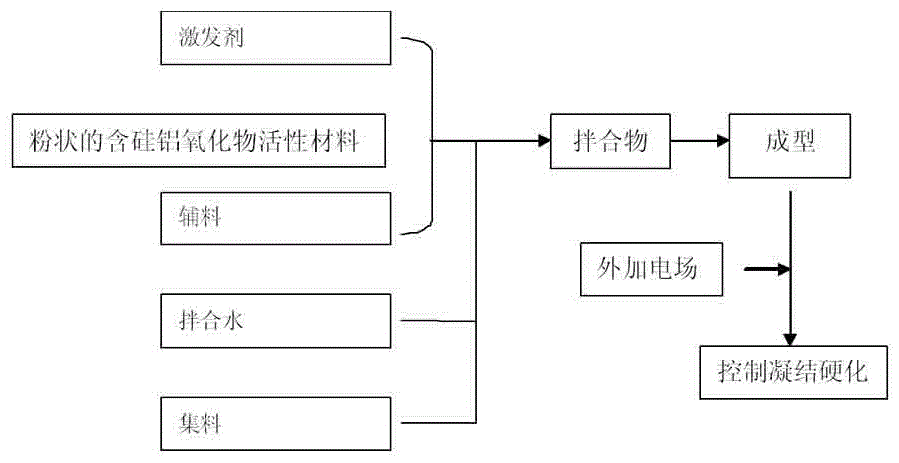

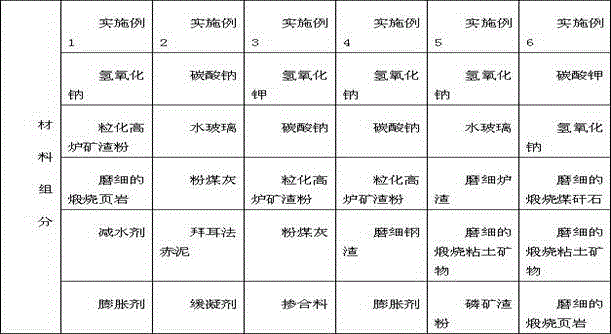

Alkali-activated cementing material capable of controlling setting time as well as control method and application thereof

InactiveCN105731947ASolve the problem of improper hydrationProlong clotting timeSolid waste managementCement productionThermodynamicsProcess engineering

The invention relates to a cementing material capable of controlling setting time as well as a setting time control method thereof and application of the cementing material in concrete, comprising the adopted cementing material, a method for controlling the setting time of an alkali-activated cementing material by virtue of an external electric field as well as a product and a method which apply the material and the method to the concrete. By adopting the material and method of the technical scheme, hydration process of the concrete can be sped up according to requirements after the concrete is moulded, setting and hardening time is controlled, and the prepared concrete has long setting time, so that construction performance requirements are met; meanwhile, the setting and hardening time can be shortened and early strength can be improved according to requirements; besides, environmental temperature during hydration can be guaranteed by utilizing concentrated and rapidly released hydration thermal produced by controlling the setting time, and the problem that normal hydration can not be carried out in negative temperature environment is solved.

Owner:胡晓霞

Self-flowing castable with waste blast furnace main runner material as main raw material and making method of self-flowing castable

The invention discloses a self-flowing castable with a waste blast furnace main runner material as a main raw material and a making method of the self-flowing castable. The making method sequentially comprises the steps: 1, selecting the materials; 2, crushing; 3, sieving; 4, mixing, and 5, packaging and storing. The self-flowing castable comprises: 20-30 parts of main runner waste material, 10-15 parts of electric smelting compact corundum, 20-30 parts of brown aluminum oxide, 5-15 parts of tabular corundum, 10-20 parts of silicon carbide, 3-8 parts of silicon powder, 2-4 parts of spherical asphalt, 1-2 parts of active aluminum oxide micro powder, 3-8 parts of aluminate cement, 2-5 parts of water reducing agent, 1-2 parts of detonation inhibitor and 1-2 parts of expanding agent. According to the self-flowing castable, the waste blast furnace main runner material is recycled, thus the resource waste is prevented, the environment pollution is reduced, and a very positive meaning is achieved for reducing the cost of the iron runner material and realizing the circular economy.

Owner:ZHEJIANG CHANGXING BAOSHENG FURNACE CHARGE CO LTD

Storage iron runner castable produced by adopting waste iron runner material

The invention discloses a storage iron runner castbale produced by adopting a waste iron runner material. The storage iron runner castable comprises the following components in parts by mass: 15-20 parts of waste iron runner material, 20-30 parts of brown fused alumina particles, 3-5 parts of brown fused alumina fine powder, 5-10 parts of electric smelting compact corundum particles, 2-5 parts of electric smelting compact corundum fine powder, 3-5 parts of magnesia-alumina spinel, 10-20 parts of silicon carbide, 2-5 parts of silicon powder, 1-2 parts of activated aluminum oxide micro powder, 4-6 parts of crystalline flake graphite, 0.5-1 part of a silane coupling agent, 3-8 parts of aluminate cement, 1-4 parts of a compound water reducer, 1-2 parts of a compound antidetonant, and 1-2 parts of an antioxidant. The storage iron runner castable makes full use of the waste material, thus greatly lowering comprehensive cost; due to the materials of the different particle sizes, the construction efficiency is improved; for the addition of the crystalline flake graphite and magnesia-alumina spinel powder, the molding density of the castable is improved, the castable is promoted in sintering, and the density, strength, volume stability and residue resistance of the castable are improved.

Owner:长兴煤山新型炉料有限公司

Industrial solid waste autoclaved aerated concrete block and preparation method thereof

The invention discloses an industrial solid waste autoclaved aerated concrete block and a preparation method thereof. The concrete block uses fly ash, carbide slag, red mud, lime, desulfurized gypsumand cement as main raw materials and aluminum powder, sodium hydroxide, water glass and the dispersing agent silica fume as additives; the coal ash reacts with components in the carbide slag to generate ettringite, so the strength of the concrete block can be enhanced; a large amount of aluminum oxide contained in the red mud can a replace part of lime and undergo a hydration reaction with the cement, and the aluminum oxide in the red mud can react with calcium hydroxide in the carbide slag, so the strength of the block is enhanced; the coal ash, the carbide slag and the red mud react with oneanother to generate hydrated calcium silicate and hydrated calcium aluminate, so the structural compactness of the block can be improved; and the additives can enhance the foaming stability of the aluminum powder and improve the early strength of the block under an alkaline condition. The method is green and environment-friendly, and the waste of non-renewable resources is effectively reduced.

Owner:张延年

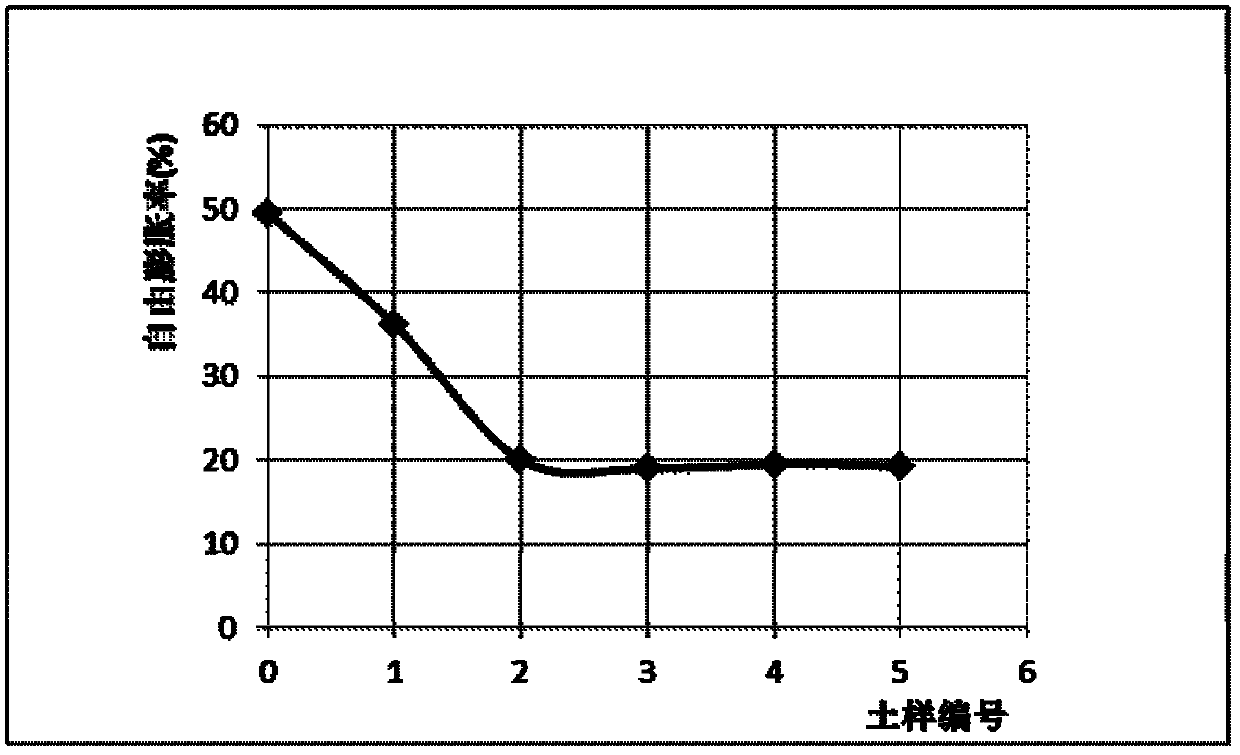

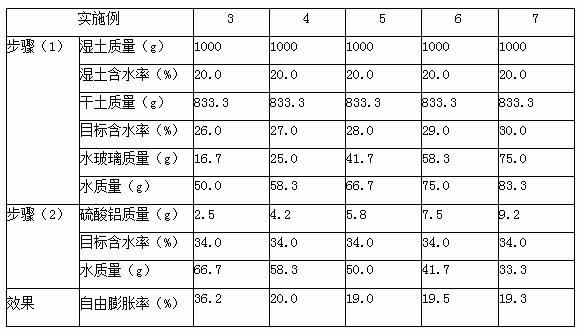

Spraying method of secondary solution for improving expansive soil

InactiveCN102515187AImprove early strengthHigh bonding strengthSilicon compoundsSoil scienceAluminum sulphate

The invention relates to a spraying method of a secondary solution for improving expansive soil. The spraying method is characterized by comprising the following steps of: (1) dissolving water glass with the mass m1 into water with the mass mw1 to prepare water glass solution, uniformly spraying the water glass solution into dry expansive soil with mass ms, mixing uniformly, standing for 2-12h for later use; and (2) dissolving aluminum sulfate powder with mass m2 into water with mass mw2 to prepare an aluminum sulfate solution, uniformly spraying the aluminum sulfate solution in a standby soil sample obtained in the step (1), mixing uniformly, standing for over 2h, and carrying out compaction treatment when the moisture content is reduced to the optimal moisture content. Compared with the traditional method for improving lime or cement and the like, the spraying method is simple in process and remarkable in effect and meets the requirement for environment friendliness.

Owner:HOHAI UNIV

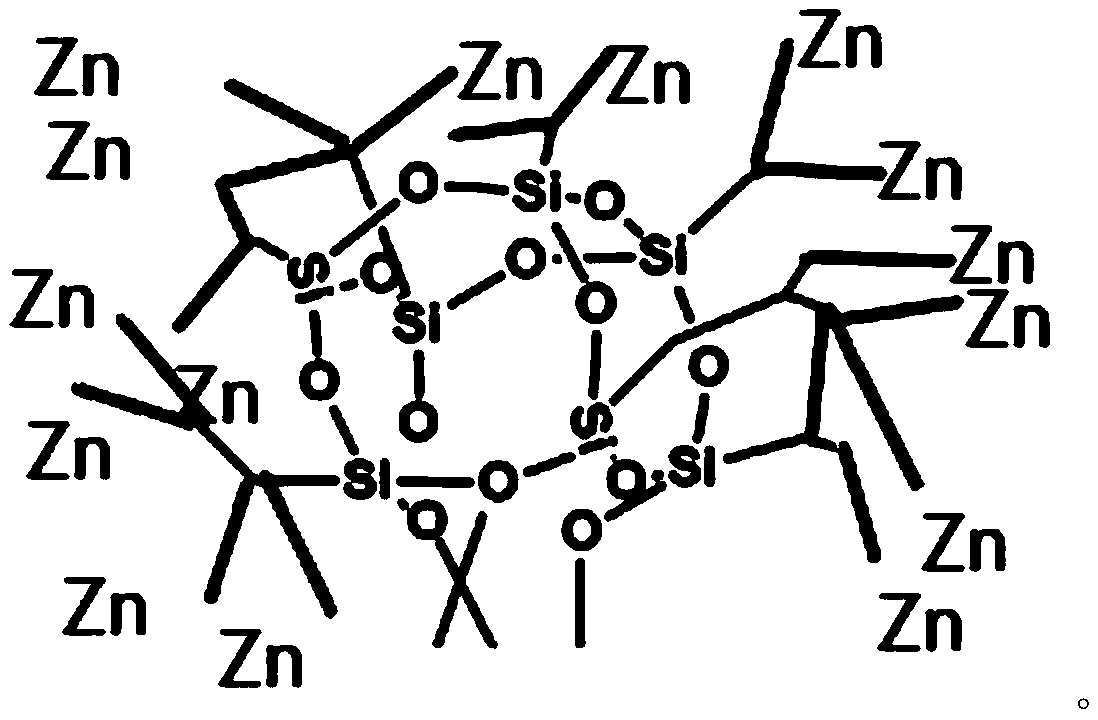

Preparation method of lead-zinc ore tailing sand filling body cementing material

The invention discloses a preparation method of a lead-zinc ore tailing sand filling body cementing material. The preparation method of the lead-zinc ore tailing sand filling body cementing material comprises the following steps: 1) spraying a polyhedral oligomeric silsesquioxane solution onto lead-zinc ore tailing sands with the particle size of below 100 [mu]m, and then precipitating to obtain modified tailing sands; and 2) mixing the modified tailing sands, cement, a polycarboxylate admixture and water to prepare the lead-zinc ore tailing sand filling body cementing material. The treatmentmethod ensures the good fluidity of the lead-zinc ore superfine tailing sand filling body cementing material, and effectively controls the setting time of a filling body, and the strength of the set filling body can also meet the filling requirement.

Owner:WUHAN UNIV OF TECH

Concrete retarder

The invention relates to a concrete retarder, which comprises the following components: 15-20 parts of sucrose, 10-25 parts of glucose, 9-16 parts of phosphoric acid, 5-14 parts of disodium phosphate, 3-7 parts of trisodium phosphate, 6-9 parts of disodium hydrogen phosphate, 8-20 parts of sodium pyrophosphate, 9-15 parts of alkyl phosphate, 3-7 parts of disodium ethylenediamine tetraacetate, 2-9 parts of humic acid, 5-11 parts of sodium fluosilicate, 8-13 parts of methylene phosphate derivatives, 5-12 parts of calcium sodium ethylenediamine tetramethylidene phosphate, 4-9 parts of dimethylamine, 8-17 parts of formaldehyde, 6-14 parts of phosphorous acid, and 4-12 parts of a mixture of boric acid, sodium bicarbonate and tartaric acid according to the ratio of 3 to 5 to 2.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Cast-in-situ wall material

InactiveCN105016689AControl clotting timeReduce water consumptionSolid waste managementUltra fineTime control

The invention relates to a cast-in-situ wall material. The cast-in-situ wall material is composed of a waterproof cushion material and an ardealite wall material. The waterproof cushion material comprises, by mass, 35%-45% of sulphoaluminate cement, 1%-3% of ultra-fine fly ash, 45%-55% of quartz sand, 3%-6% of expanding agent, 0.1%-1% of thickening time control agent and 0.5%-1% of water reducing agent. The ardealite wall material comprises, by mass, 78%-90% of ardealite powder, 8%-20% fly ash, 1%-3% of cement, 0.2%-0.5% of retarder, 0.1%-0.5% of water reducing agent and 0.05%-0.10% of air-entraining agent. The cast-in-situ wall material has the advantages that due to the fact that the cast-in-situ wall material is constructed in a layered pouring mode, labor force can be reduced, and construction efficiency is made higher.

Owner:WUHAN UNIV OF TECH

Special foam concrete for exterior wall external thermal insulation system engineering

InactiveCN108314378AImprove crack resistanceGood flexibilityCeramicwareThermal insulationSetting time

The invention provides a special foam concrete for exterior wall external thermal insulation system engineering. The special foam concrete comprises the following components in parts by weight: 100 parts of a cementing material, 0-50 parts of an admixture, 2-10 parts of a high polymer, 0.5-2 parts of fiber, 2-10 parts of a foaming agent and 2-15 parts of an additive. According to the special foamconcrete provided by the invention, other components are introduced into the common foam concrete, so that the special foam concrete has the characteristics of good fluidity, crack resistance, light weight, good affinity with a thermal insulation material, high bonding strength, adjustable setting time, function of repairing defects of a base wall, and the like, and the special foam concrete is filled between the insulation board and the base wall to play the role of bonding and repairing.

Owner:SHAANXI ACAD OF ARCHITECTONICS

Steady inflated steel tube concrete and construction method

InactiveCN1562860AControl clotting timeControl slump lossSolid waste managementSuperplasticizerBoric acid

The compound contains water, cement, sand material, flyash. The characteristic is that it also contains compound high-efficiency water-reducing mould-protecting agen, cement is aluminate sulfide cement 500-550, flyash 50-55, water 185-195, compound high-efficiency water-reducing mould-protecting agent 11-15, weight sand ratio of sand material is 38-42 percent. the compound high-efficiency water-reducing mould-protecting agent is composed by naphthalenes high-efficiency water-reducing agent, boric acid and xylon calcium sulphonic acid, weight percentage of each compound are azyl sulfonate high-efficiency water-reducing agent 32-38, nephthalenes high-efficiency water-reducing 37-43, boric acid 12-18, xylon calcium sylphonic acid 7-13.

Owner:WUHAN UNIV OF TECH

Super-early-strength type ultra-high performance concrete and preparation method thereof

PendingCN113480277AIncreased durabilityExtended working hoursArchitectural engineeringStructural engineering

The invention discloses super-early-strength type ultra-high performance concrete and a preparation method thereof, and belongs to the technical field of building materials. The super-early-strength type ultra-high performance concrete is prepared from the following components in parts by weight: 50 to 100 parts of cement, 10 to 30 parts of silica fume, 5 to 20 parts of fly ash, 80 to 150 parts of aggregate, 0.1 to 2 parts of slaked lime, 5 to 25 parts of steel fiber, 1 to 5 parts of a water reducing agent, 0.05 to 0.5 part of a retarder, 0.01 to 0.2 part of a coagulant and 10 to 30 parts of water. The super-early-strength type ultra-high performance concrete has the characteristics of super early strength, ultrahigh later strength, ultrahigh durability, controllable setting time, excellent working performance and the like, and has important practical value in various emergency repair projects and winter construction projects. The invention further discloses a preparation method of the super-early-strength type ultra-high performance concrete, wherein the preparation method is simple, easy to operate, easy to control preparation conditions and low in requirement for production equipment, and is easy to achieve industrial production .

Owner:华新超可隆新型建材科技(黄石)有限公司 +1

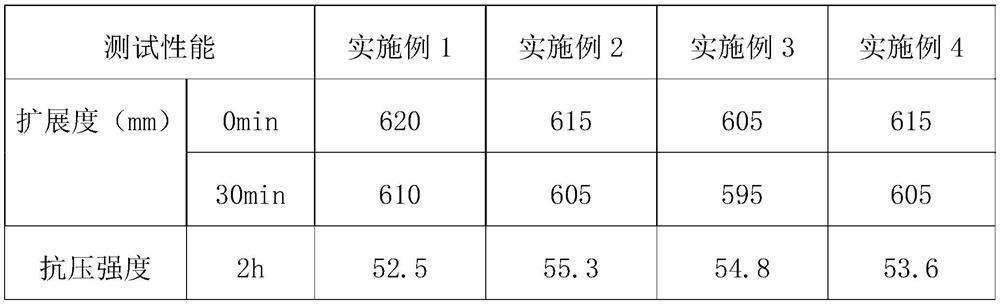

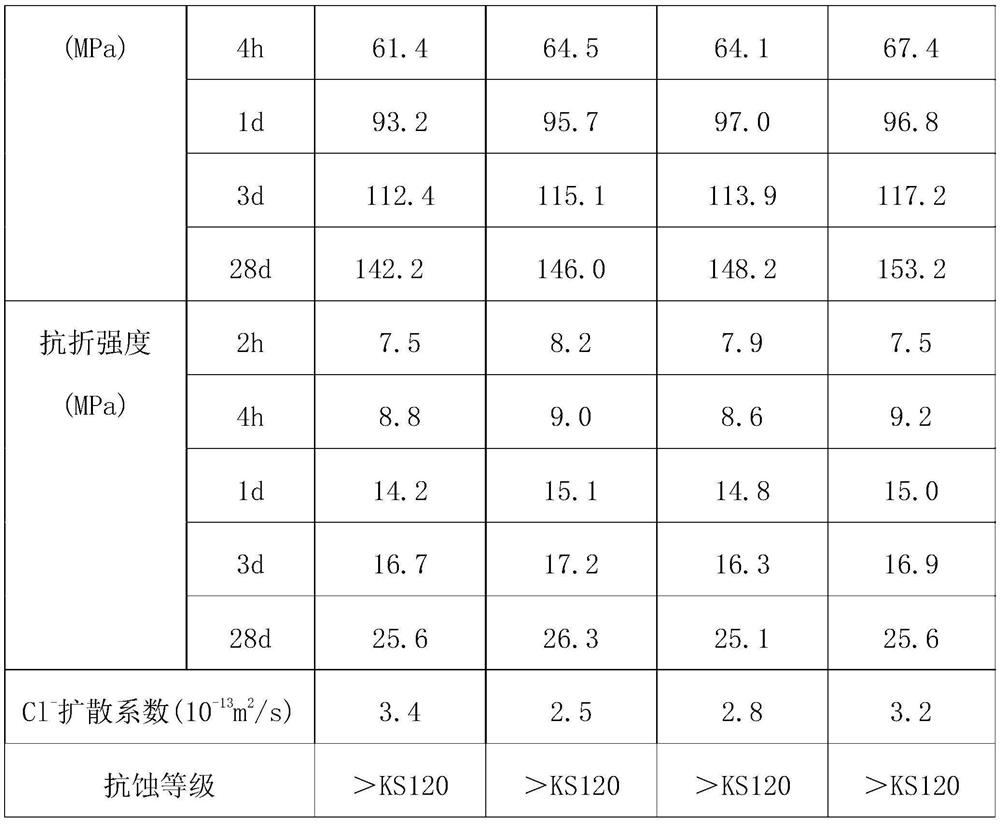

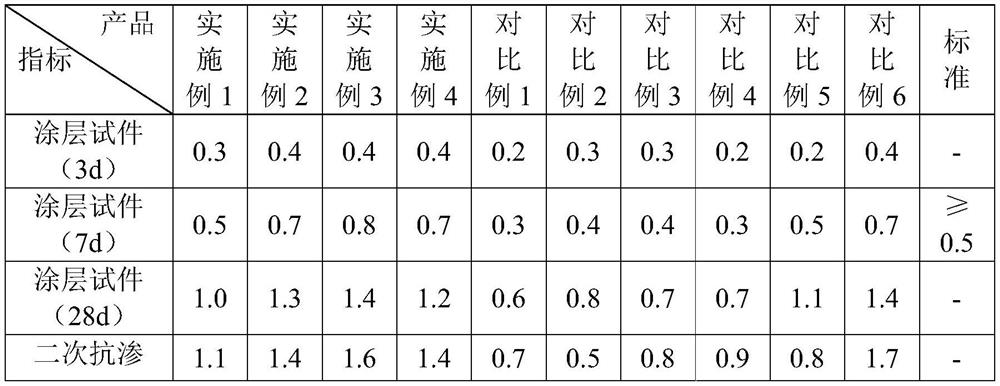

Self-healing backwater surface waterproof material capable of stopping open water, preparation method and application thereof

ActiveCN111825411AAchieve the effect of self-healing and self-repairingImprove self-waterproof performanceSolid waste managementProtective foundationAluminateAntiseptic Agent

The invention discloses a self-healing backwater surface waterproof material capable of stopping open water, a preparation method and application thereof. The material comprises the following powder materials by weight: 16-22 parts of sulphoaluminate cement, 8-12 parts of mineral powder, 6-10 parts of fly ash, 40-48 parts of quartz sand, 4-6 parts of sodium silicate, 0.5-1 part of a waterproof agent, 4-8 parts of silica fume, 4-6 parts of rubber powder, 0.25-0.4 part of an early strength agent and 0.3-0.8 part of magnesium fluosilicate; and the liquid materials: 20-26 parts of a polymer emulsion, 0.1-0.2 part of an antifoaming agent, 0.05-0.15 part of a dispersant, 0.05-0.1 part of a multifunctional auxiliary agent, 0.06-0.12 part of an antiseptic, 0.08-0.14 part of an anti-freezing agentand 20-26 parts of water. The material disclosed by the invention is good in durability, impermeable, anti-cracking and anti-freezing; and the waterproof material is simple and convenient to manufacture and convenient to construct, has self-repairing and self-healing effects when leakage occurs again, and achieves an efficient and long-lasting waterproof effect.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

High-performance superfine-cement-based grouting material

The invention relates to a high-performance superfine-cement-based grouting material. The high-performance superfine-cement-based grouting material is prepared by, by weight, 2640-2760 parts of superfine cement, 60-110 parts of modified nanoscale calcium powder, 19-25 parts of polycarboxylate superplasticizer, 65-105 parts of superfine expanding agent, 70-120 parts of superfine low-calcium fly ash, 10-28 parts of superfine desulfurization gypsum and 0.5-1.3 parts of sodium aliphatic alcohol sulfate. The high-performance superfine-cement-based grouting material is reasonable in formula, low in production cost, good in working performance, easy to process, environmentally friendly, energy-saving, free of pollution and wide in application range.

Owner:GANSU ZHITONG TECH ENG DETECTION CONSULTING CO LTD

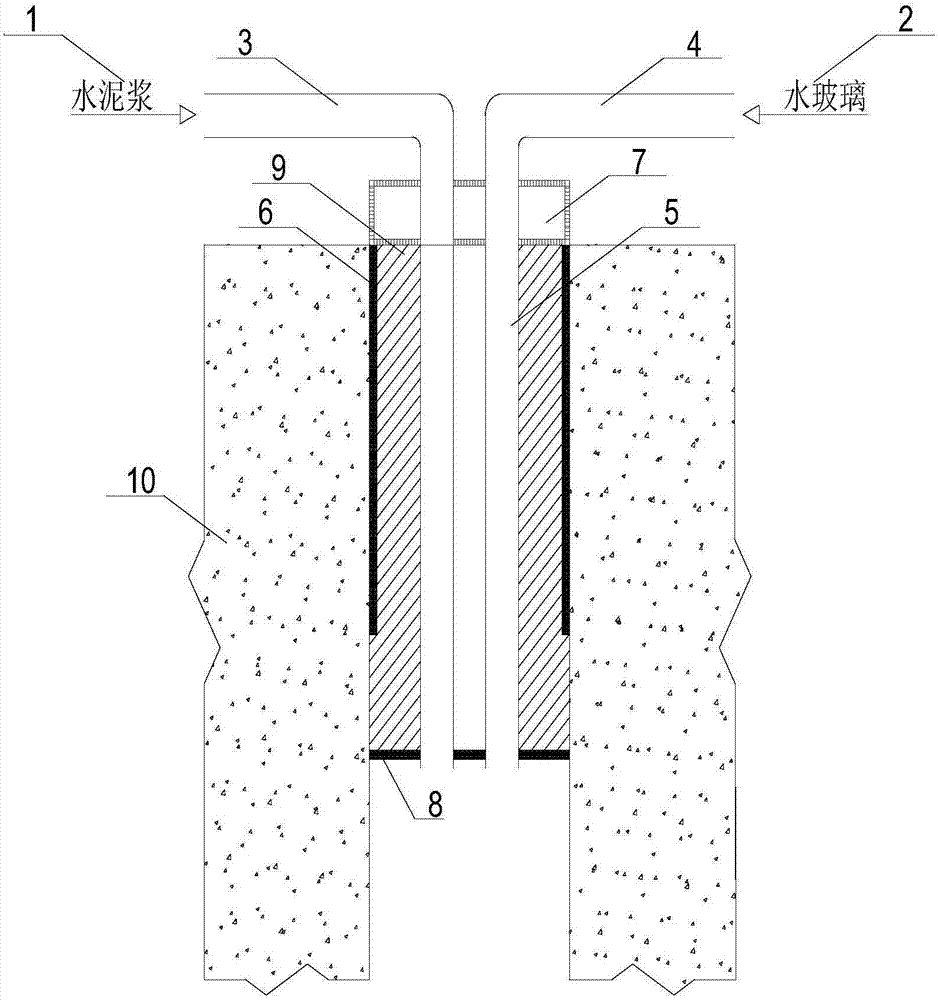

Double-fluid deep-hole bottom fixed-point accurate mixed construction process and grouting structure

PendingCN106894414AShorten the mixing distanceShorten mixing timeBulkheads/pilesSoil preservationClassical mechanicsPolyvinyl chloride

The invention discloses a double-fluid deep-hole bottom fixed-point accurate mixed construction process and a grouting structure. An accurate mixing problem of double-fluid grouting is solved, the matching ratio of the double-fluid can be quantitatively adjusted through a double-high-pressure PVC (Polyvinyl Chloride) grouting pipe, and the setting time is controlled; a double-fluid slurry is mixed at a hole bottom predetermined area, so that a double-fluid grouting range is artificially controlled; with fixed-point accurate double-fluid grouting, the mixing distance and the mixing time of the double-fluid in a drill hole can be reduced, and the dispersion range of the double-fluid slurry is expanded; and the operation can be carried out simply. The technical scheme is characterized in that the double-fluid deep-hole bottom fixed-point accurate mixed construction process comprises the following steps of drilling to the depth of an intact rock, and downwards placing a steel sleeve pipe in a drill hole to the intact rock part; adopting the double-fluid slurry for sealing an outer wall of the steel sleeve pipe and a drill hole wall; continuously drilling to the estimated grouting depth, and downwards placing two grouting pipes in the drill hole; and sealing the grouting pipes and the drill hole wall, and forming dense confining pressure sections outside the grouting pipes.

Owner:SHANDONG UNIV +1

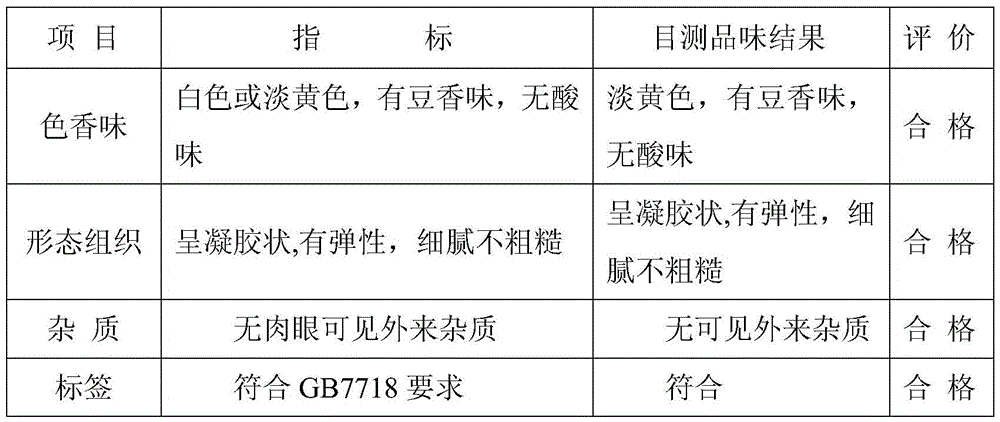

Box-packed bean curd and processing technology thereof

InactiveCN105638922AControl clotting timeImprove qualityCheese manufacturePackagingGluconolactoneAqueous solution

The invention discloses a box-packed bean curd. The box-packed bean curd is made from 11-14 baume degrees of soybean milk and 3-5% by soybean milk mass of a composite coagulator water solution, wherein the composite coagulator water solution is prepared by mixing a composite coagulator and water according to the mass ratio of 1:2-4, the composite coagulator is prepared from, by mass, calcium sulfate 65-75%, glucolactone 20-30%, magnesium chloride 2-5%, and the sum of the components is 100%. The box-packed bean curd is hygienic and safe, good in toughness, stable in quality and convenient to store and transport, has a fine and smooth taste, is not tender after long-time boiling and is suitable for long-distance sales. The invention further provides a processing technology of the box-packed bean curd. The processing technology comprises the steps of material selection, soaking, cleaning, pulping, pulp screening, pulp flushing and the like, is simple in process step, good in operability and low in production cost and is suitable for industrialized large-scale production.

Owner:安吉祖名豆制食品有限公司

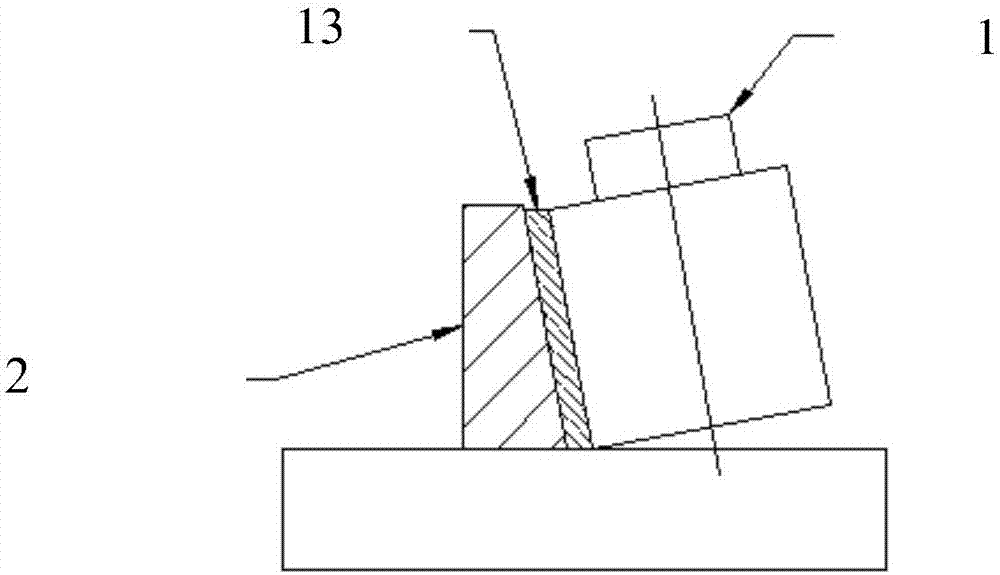

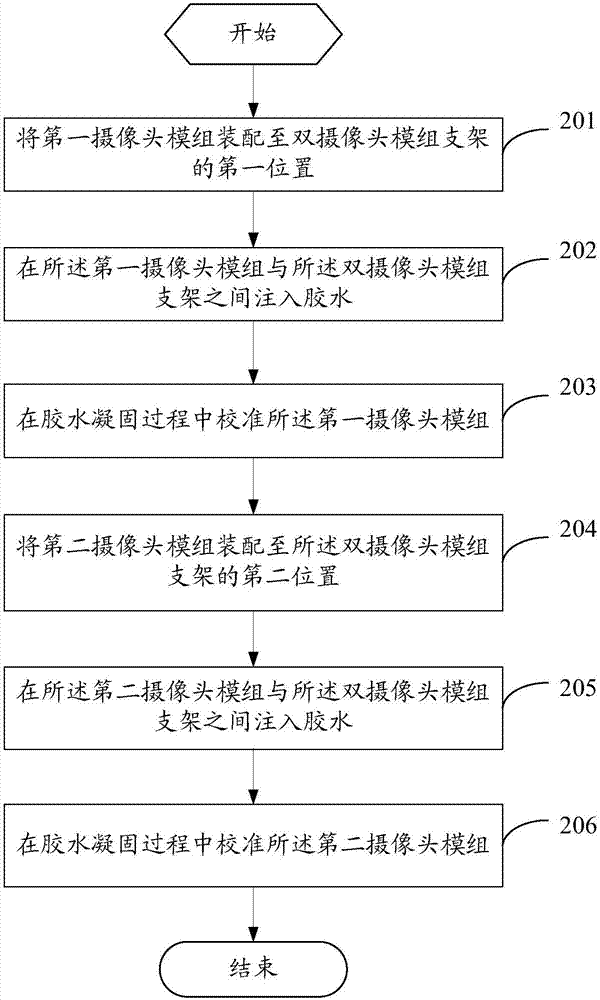

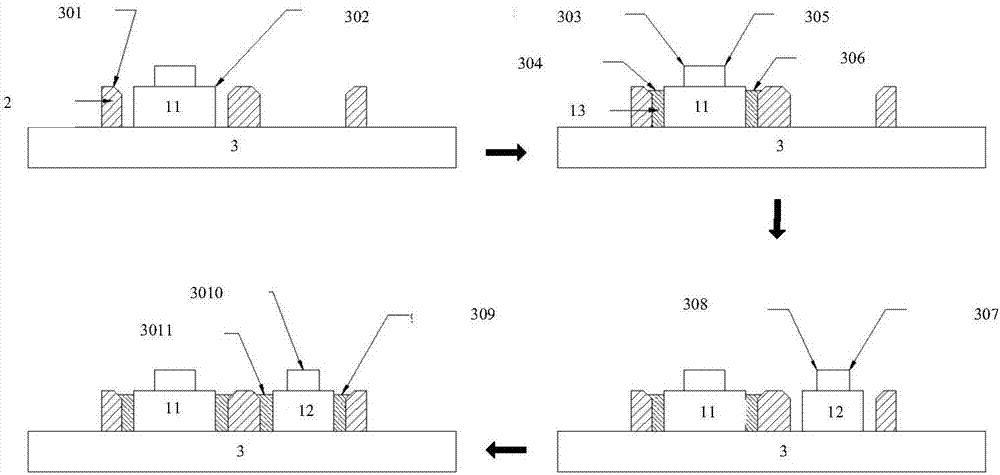

Dual-camera module assembling method, double camera modules and mobile terminal

ActiveCN106990499AIncrease calibration spaceEliminate the effects of manufacturing tolerancesTelevision system detailsColor television detailsCamera module

The present invention provides a dual-camera module assembling method, double camera modules and a mobile terminal. The method comprises the steps of assembling a first camera module at a first position of a dual-camera module support; injecting glue between the first camera module and the dual-camera module support; calibrating the first camera module during the glue solidification process; assembling a second camera module at a second position of the dual-camera module support; injecting the glue between the second camera module and the dual-camera module support; calibrating the second camera module during the glue solidification process, so that by increasing an assembly gap between the camera modules and the dual-camera module support, the calibration space of the camera modules is increased, the solidification time of the glue can be controlled, the influence of the manufacturing tolerance of the dual-camera module support is eliminated by utilizing the deformable characteristic of the glue, and the coaxiality of the double camera modules is guaranteed.

Owner:VIVO MOBILE COMM CO LTD

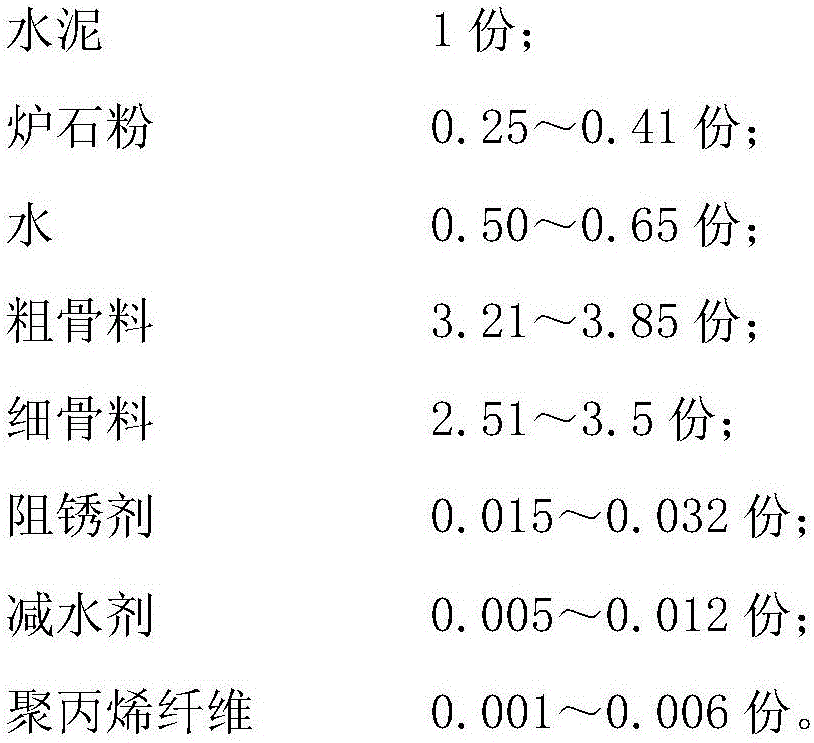

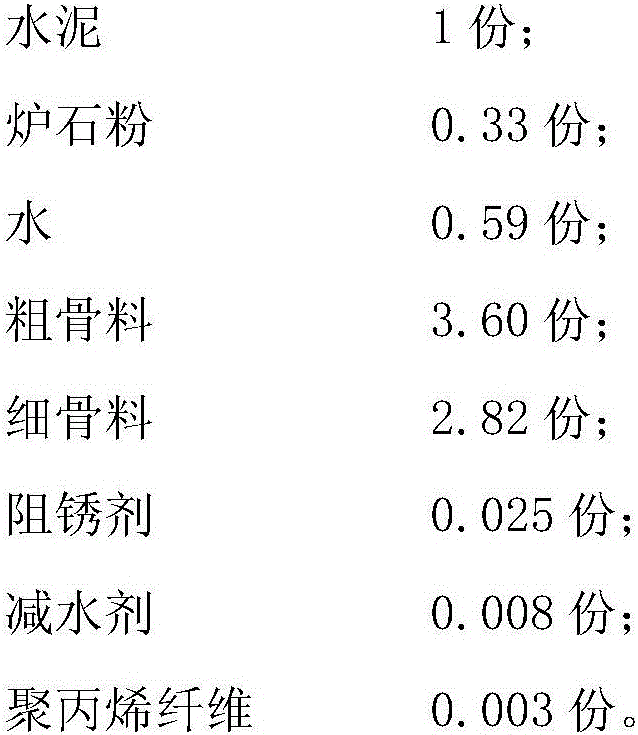

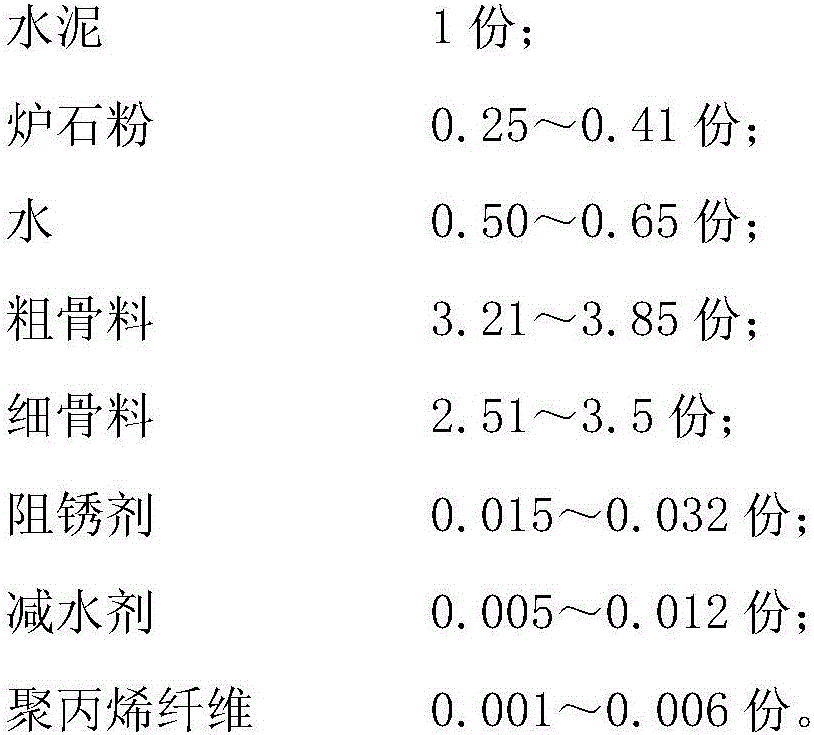

Anticrack anticorrosion mass concrete and preparation method thereof

The invention relates to anticrack anticorrosion mass concrete and a preparation method thereof and belongs to the technical field of building materials. The invention provides the anti-crack anticorrosion mass concrete. The anticrack anticorrosion mass concrete is prepared from 1 part by weight of cement, 0.25-0.41 parts by weight of hearthstone powder, 0.50-0.65 parts by weight of water, 3.21-3.85 parts by weight of coarse aggregate, 2.51-3.5 parts by weight of fine aggregate, 0.015-0.032 parts by weight of a corrosion inhibitor, 0.005-0.012 parts by weight of a water reducer and 0.001-0.006 parts by weight of polypropylene fibers. The blast furnace base anticrack anticorrosion mass concrete, which is prepared from specific components and satisfies saline-alkali geological environment requirements, has good workability and high strength, is convenient for construction work control and concrete construction, has a simple formula, greatly saves a cost, is prepared through simple and easy processes, is free of mineral admixtures and can be promoted in saline-alkali geological environments in Vietnam and China.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR

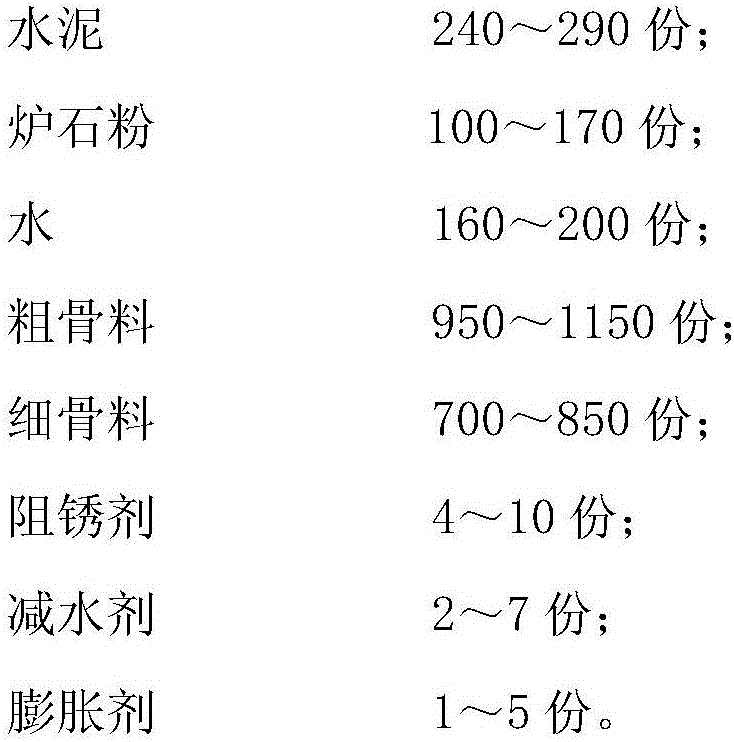

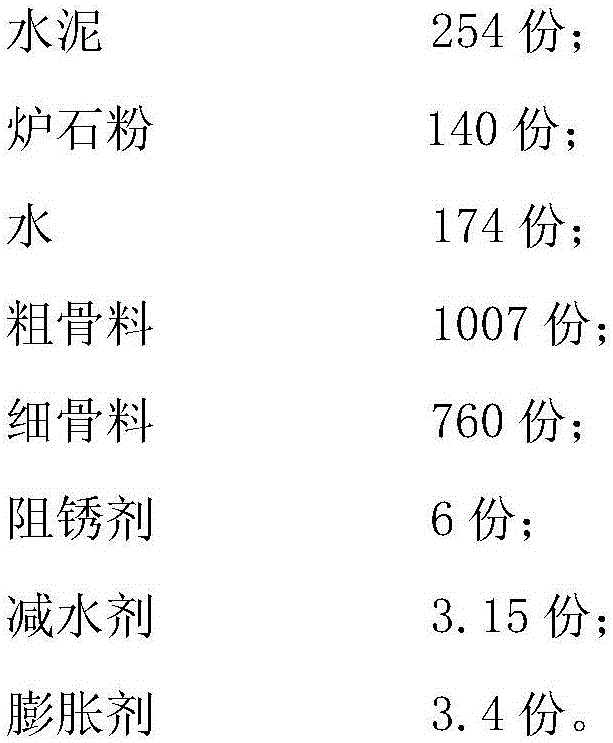

Rust-proof corrosion-resistant non-shrinkage concrete for blast furnace and preparation method thereof

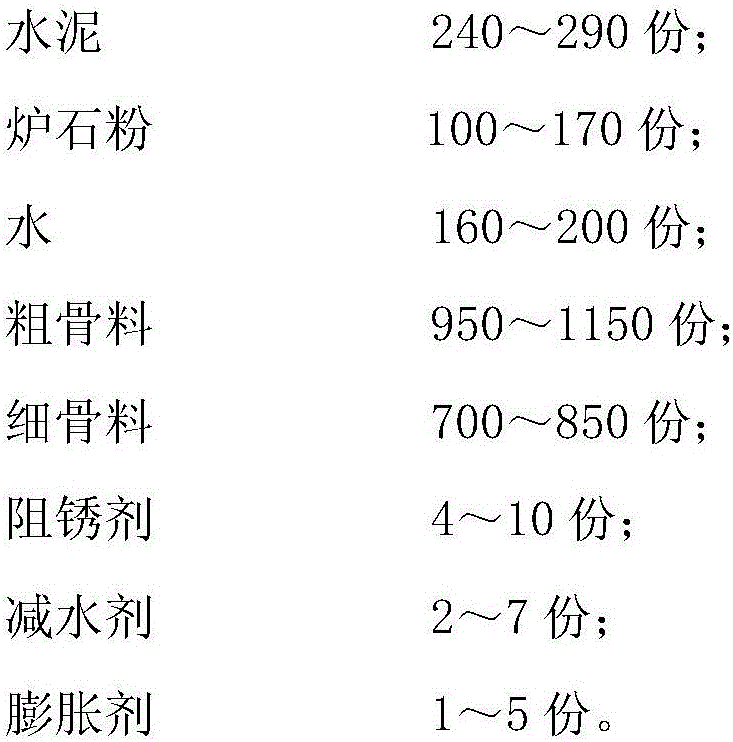

The invention relates to rust-proof corrosion-resistant non-shrinkage concrete for a blast furnace and a preparation method thereof and belongs to the technical field of building materials. The rust-proof corrosion-resistant non-shrinkage concrete comprises, by weight, 240-290 parts of cement, 100-170 parts of hearthstone powder, 160-200 parts of water, 950-1150 parts of crude aggregate, 700-850 parts of fine aggregate, 4-10 parts of a corrosion inhibitor, 2-7 parts of a water reducer and 1-5 parts of an expanding agent. The rust-proof corrosion-resistant non-shrinkage concrete suitable for saline-alkali soil is prepared from specific ingredients according to a ratio, has good workability and high strength, is convenient for construction time control and concrete construction, has a simple formula, saves a lot of cost, can be prepared through simple and easy processes, is free of a mineral admixture and can be promoted and used at home and abroad.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR

Low solid-content accelerator and preparation method thereof

The invention relates to a low solid-content accelerator and a preparation method thereof, which relate to a concrete additive, and especially relates to the low solid-content accelerator. The invention also relates to the preparation method of the accelerator. The low solid-content accelerator takes active aluminium hydroxide, aluminum sulfate, sodium silicate, sodium carbonate, sodium hydroxide,deionized water, and triisopropanolamine as raw materials for a reaction, and the above raw materials are subjected to a reaction to prepare mother liquor of the low solid-content accelerator; thickening agents such as sodium polyacrylate and maltodextrin as well as a stabilizing agent cellulose ether MF4 are added as a reaction auxiliary agent during usage of the mother liquor, the solid contentof the accelerator through complex formulation is 35%, an application amount of the low solid-content accelerator is reduced during usage, production usage cost can be greatly reduced, and the earlystage intensity of the concrete and the usage intensity at a later stage cannot be influenced.

Owner:云南森博混凝土外加剂有限公司

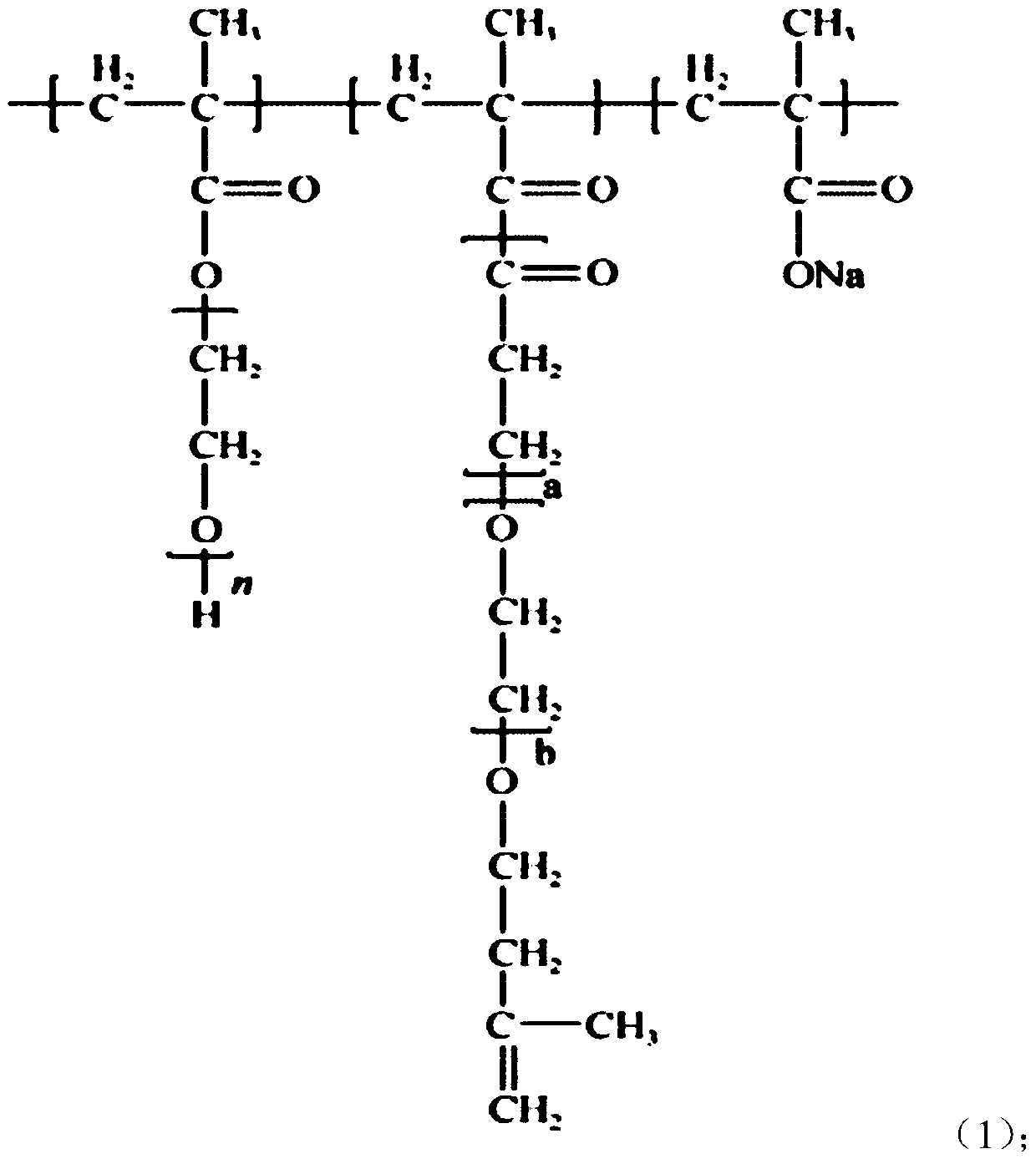

Preparation method of environmental protection type water reducer for improving cement concrete performance

The present invention relates to a preparation method of environment-protecting type water-reducing agent capable of improving cement concrete performance, belonging to the field of high-molecular polymer and cement concrete functional adjuvant preparation process technology. Said method is characterized by using polyethylene glycol (molecular weight 400-4000), acrylic acid or maleic acid and sodium methyl propyl sulfonate, etc. as main raw material, adopting continuous two-step synthesis method and utilizing the processes of polymerization and esterification reaction so as to obtain the invented polymer high-effective cement concrete water-reducing agent.

Owner:SHANGHAI UNIV +1

Synchronous shielding grouting material composite admixture

ActiveCN110498633AMeet water dispersion resistanceSatisfy dispersionWork performanceSuperplasticizer

The invention discloses a synchronous shielding grouting material composite admixture which comprises the following raw materials in percentage by mass: 10-20% of a coagulant, 10-20% of a retarder, 40-50% of an efficient water reducer, 10-20% of a tackifier, 1-5% of a defoaming agent and 1-5% of a plasticity expander. The admixture has the effects that in a high-pressure water-enriched stratum environment, on premise that equipment and pipelines are not changed, the curing time can be adjusted, the working performance loss is small within the curing time, and good water dispersibility resistance, efficient filling and rapid curing can be achieved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com