Spraying method of secondary solution for improving expansive soil

A technology of expansive soil and spraying method, applied in the field of geotechnical engineering, to achieve the effect of improving compressive strength, meeting engineering requirements, and inhibiting adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

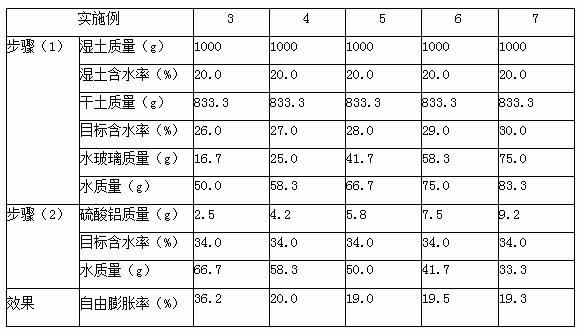

[0015] Taking expansive soil with wet soil mass m=1000g as an example, the initial moisture content of expansive soil is 20%, and the target moisture content is 26%, then the dry soil mass m s =1000÷(1+20%)=833.3g.

[0016] 1. According to m 1 :m s =3:100, weigh m 1 = 25.0g of industrial water glass (purchased from Nanjing Hengliang Fine Chemical Co., Ltd., with a Baume degree of 0.45 and a modulus of 2.7), the mass of water required m w1 =833.3×(26%-20%)=50.0g, dissolve the water glass in water, spray the prepared water glass solution evenly into the expansive soil, mix well, and let it stand for 2 hours for later use.

[0017] 2. According to m 2 :m s =5:1000, the mass of aluminum sulfate powder (purchased from Jiangsu Qiangsheng Chemical Co., Ltd., chemically pure white powder, particle size unlimited) m 2 =833.3×5÷1000=4.2g, the target water content of this step is 30%, then the mass m of water needed to dissolve aluminum sulfate w2 =833.3×(30%-26%)=33.3g, di...

Embodiment 2

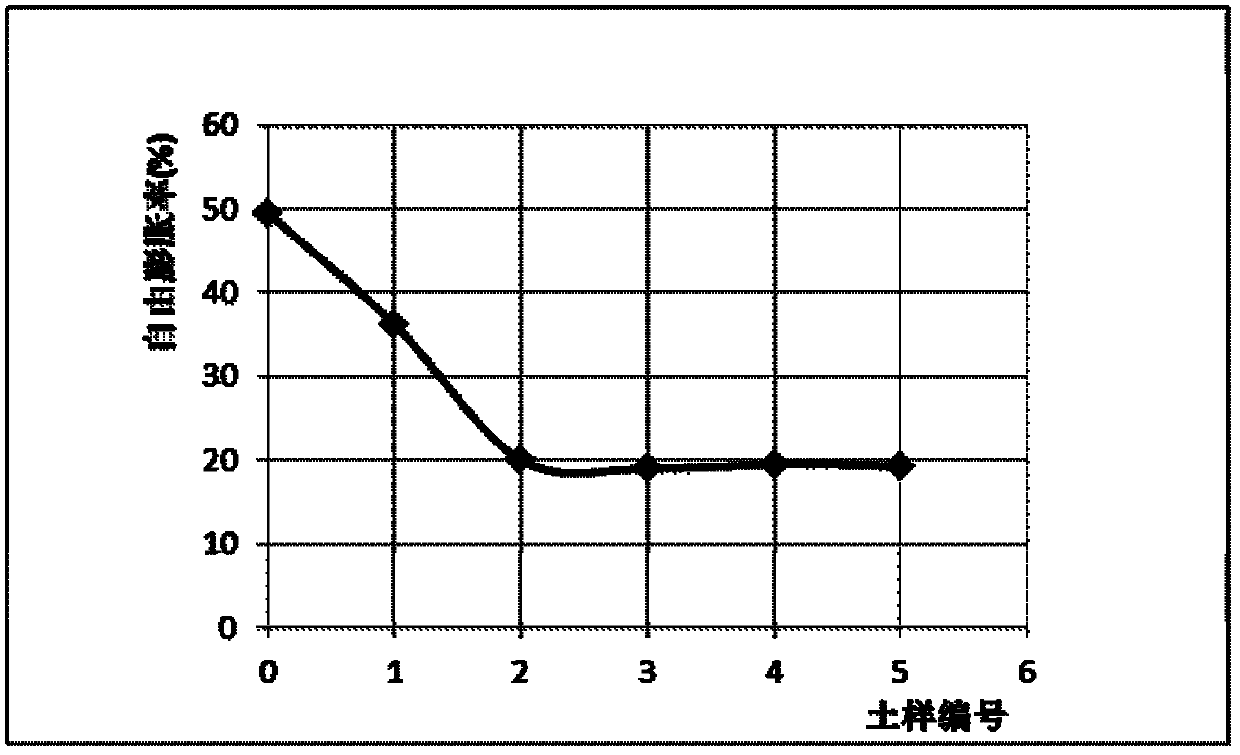

[0020] The improvement effect of the method described in Example 1 of the present invention to expansive soil is shown in Table 1, and the investigation method is to adopt the mode of comparing the free expansion rate of the improved soil with the free expansion rate of the plain soil.

[0021] Table 1 Investigates the improvement effect result table of the method of the present invention on expansive soil with the free expansion rate index

[0022]

[0023] It can be seen from Table 1 that the improvement effect of using water glass alone is not obvious, while the free expansion rate of the improved soil sprayed with the secondary solution is reduced by about 60%, and the expansion of the improved soil has been eliminated, which meets the requirements of engineering use.

[0024] The improved soil treated by spraying the solution twice in Example 1 was adjusted to the optimal water content of 19.8%, compacted according to the 95% compaction degree to make a ring knife sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com