Cement grouting material

A technology for cement grouting and grouting material, applied in the field of cement grouting material, can solve the problems of low strength, difficult construction and poor performance, and achieve the effects of high fluidity, simple construction and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

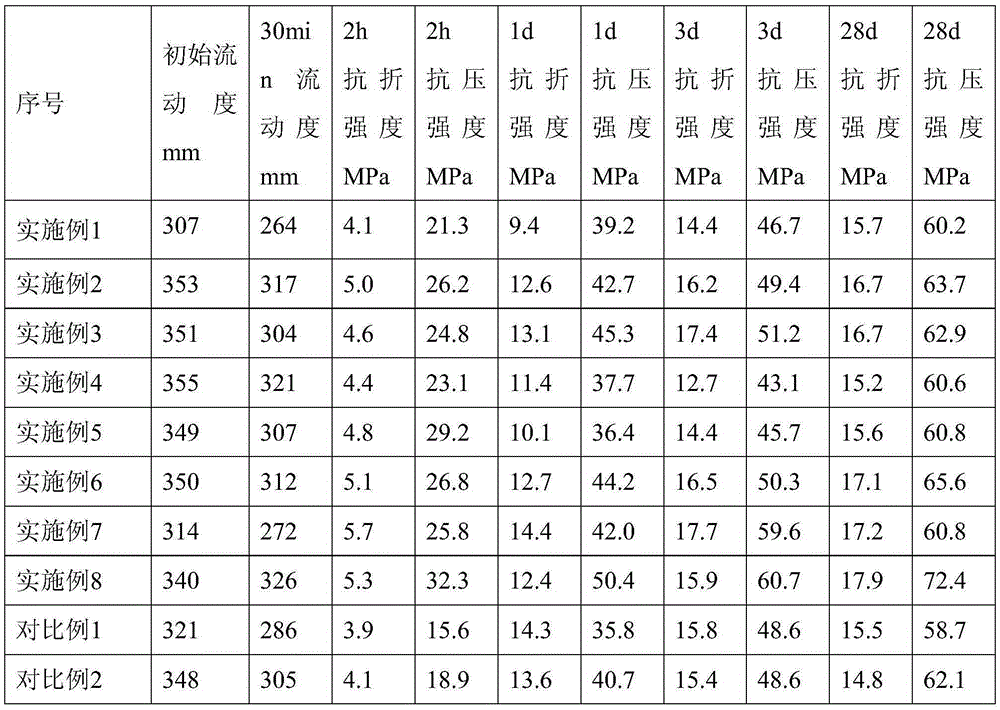

[0023] This embodiment provides a self-compacting high-fluidity grouting material, which includes the following components: 45 parts by weight of the cement component, specifically including 5 parts by weight of ordinary Portland cement and 40 parts by weight of sulphoaluminate cement ; The flow-promoting component is 0.16 parts by weight, specifically including 0.08 parts by weight of polycarboxylate high-performance water reducer and 0.08 parts by weight of defoamer; 5 parts by weight of the anti-cracking component, specifically including 4.8 parts by weight of UEA expansion agent part and 0.2 part by weight of pp fiber; otherwise plasticizer cellulose ether 0.2 part by weight; retarding component tartaric acid 0.2 part by weight; accelerating component comprises calcium hydroxide and lithium carbonate total 0.15 part by weight, wherein calcium hydroxide is 0.1 parts by weight; 50 parts by weight of 20-40 mesh quartz sand. See Table 1 for the standard curing performance data...

Embodiment 2

[0025] Same as Example 1, except that the cement component is 50 parts by weight, specifically including 5 parts by weight of ordinary Portland cement, 45 parts by weight of sulphoaluminate cement, and 45 parts by weight of quartz sand. And the flow-promoting component is 0.2 parts by weight in total, specifically including 0.12 parts by weight of polycarboxylate high-performance water reducer and 0.08 parts by weight of defoamer. See Table 1 for the standard curing performance data of the grout after adding 14% water.

Embodiment 3

[0027] This embodiment provides a self-compacting high-fluidity grouting material, which includes the following components: 47 parts by weight of the cement component, specifically including 7 parts by weight of ordinary Portland cement and 40 parts by weight of sulphoaluminate cement , quartz sand is 48 parts by weight. A total of 0.02 parts by weight of the flow-promoting components, specifically including 0.12 parts by weight of polycarboxylate high-performance water reducer and 0.08 parts by weight of defoamer; 0.015 parts by weight of plasticizer cellulose ether; coagulation-promoting components calcium hydroxide and A total of 0.2 parts by weight of lithium carbonate, wherein 0.15 parts by weight of calcium hydroxide; other conditions are the same as in Example 1. See Table 1 for the standard curing performance data of the grout after adding 14% water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com