Preparation method of lead-zinc ore tailing sand filling body cementing material

A technology of tailings sand and lead-zinc ore, which is applied in the field of mine filling, can solve the problems of long coagulation time, short coagulation time and high strength, and achieve the effect of improving various performances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

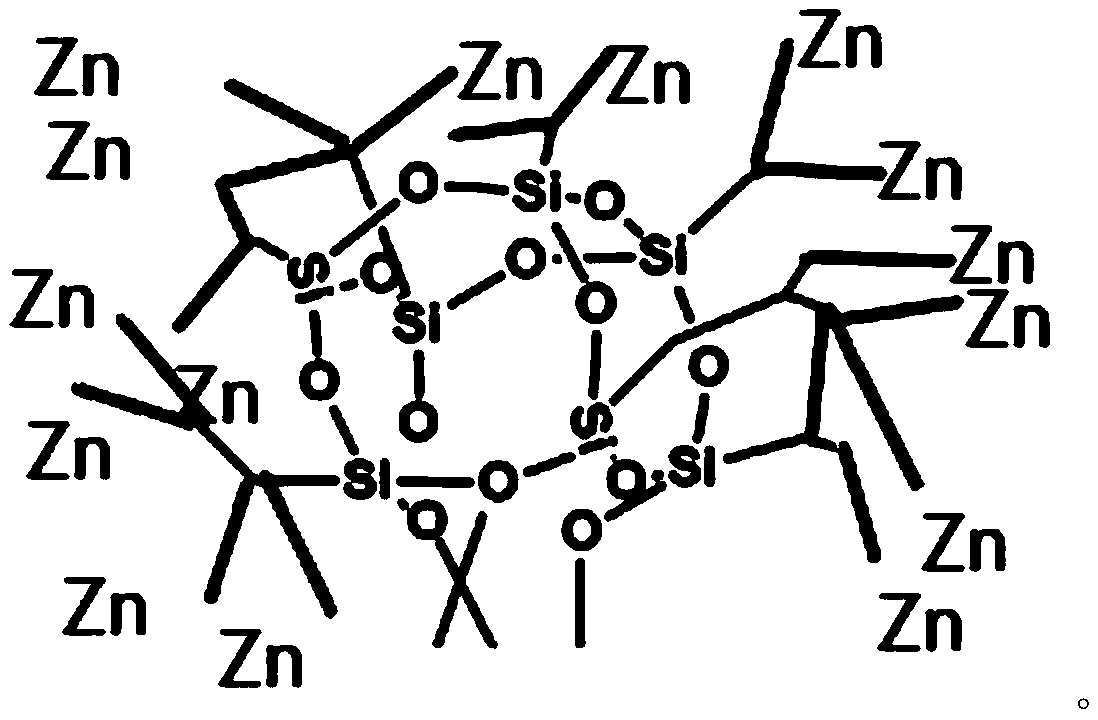

[0082] 1. POSS spray treatment

[0083] Use a cyclone classifier to divide the tailings produced by mineral processing into two types of tailings: one is tailings sand (CT: coarse tailings) with 50% of particles larger than 100 μm; the other is tailings powder with more than 50% of particles smaller than 100 μm (FT: finetailings). The tailings powder less than 100 μm obtained in the second part is used as ultrafine tailings sand.

[0084] After testing, the XRF analysis results of the main oxide components of the selected ultra-fine tailings sand are shown in Table 2.

[0085] Table 2 Composition of tailings sand

[0086] Oxide MgO Al 2 o 3

SiO 2

SO 3

CaO Fe 2 o 3

loss Content (wt%) 2.69 4.88 20.11 8.66 28.41 5.68 27.61

[0087] It can be seen from Table 2 that the oxide composition of tailings sand is also mainly Al 2 o 3 , SiO 2 , CaO, Fe 2 o 3 and SO 3 , higher loss on ignition. The phase analysis of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com