Anticrack anticorrosion mass concrete and preparation method thereof

A mass concrete and concrete technology, applied in the field of building materials, can solve problems such as complex preparation process, and achieve the effects of simple formula, good workability, and easy control of construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

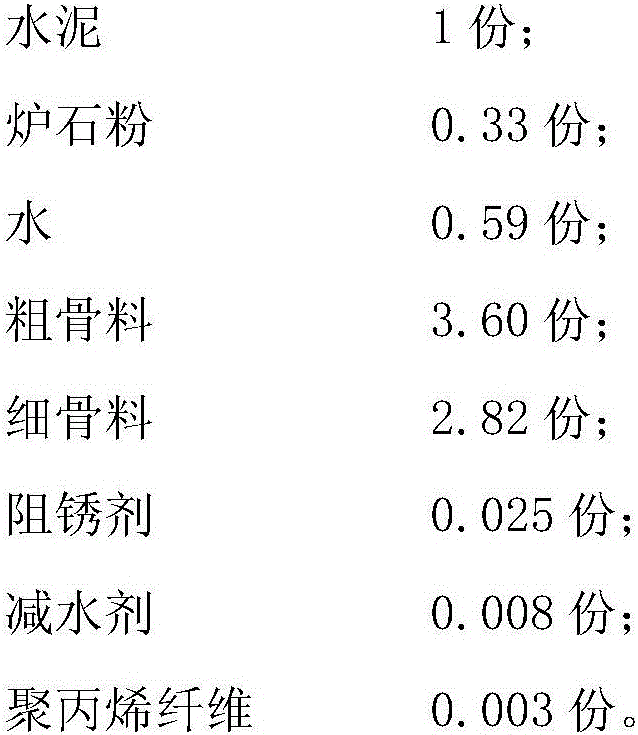

Embodiment 1

[0035] Relying on the general contracting project of the No. 1 and No. 2 blast furnace projects of Vietnam Formosa Plastics Ha Tinh Iron and Steel Industrial Co., Ltd., the foundation of the Vietnam Formosa Plastics blast furnace was prepared. The foundation platform of the Formosa Plastics blast furnace was designed to be 43.8 meters long and 30.8 meters wide. The elevation is FL-4.100m, the design label of the concrete platform is C40, and the theoretical total is 5396m 3 , the amount of concrete poured at one time is 5300m 3 , the design strength level requirement is C40.

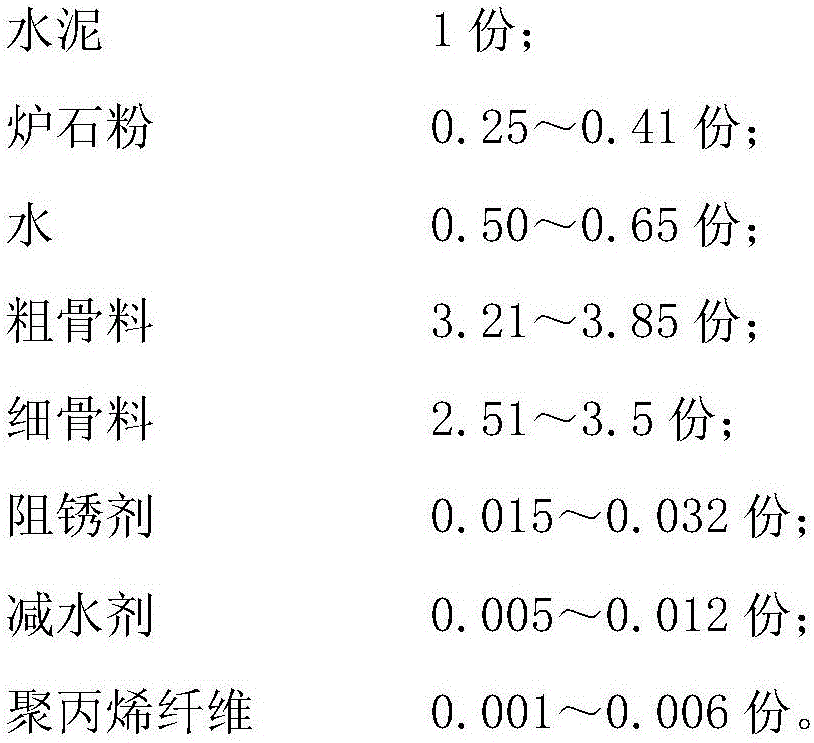

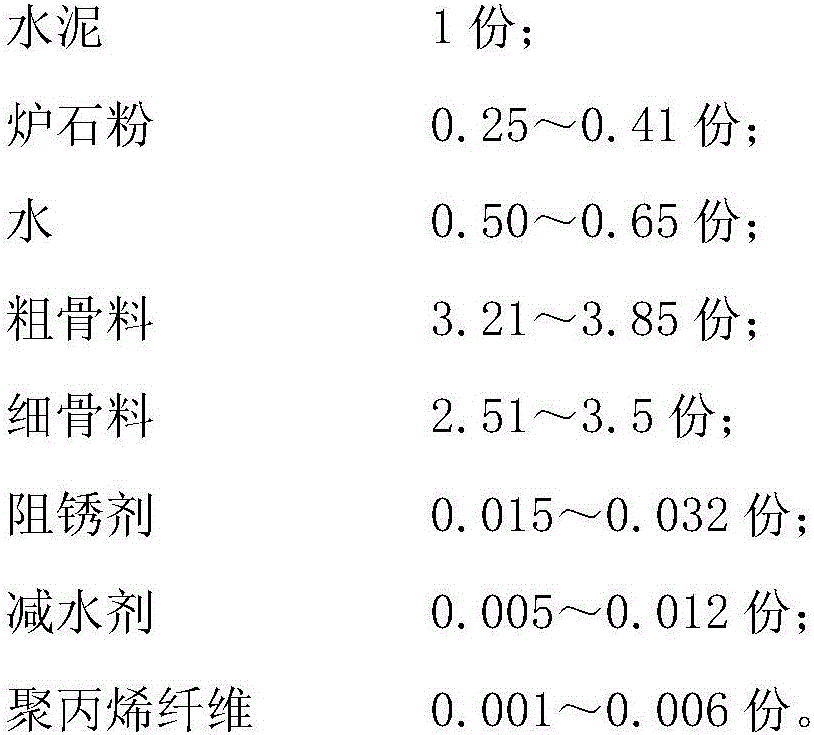

[0036] By selecting raw materials such as concrete cement, sand, stone, and admixtures in Vietnam, the concrete mix ratio design is carried out, mainly by adding a certain amount of rust inhibitor and furnace stone powder to the concrete mix ratio, because there are no mineral admixtures in Vietnam, the main The anti-crack performance of concrete is considered from the two aspects of reducing the heat o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com