Patents

Literature

48results about How to "Low recycling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

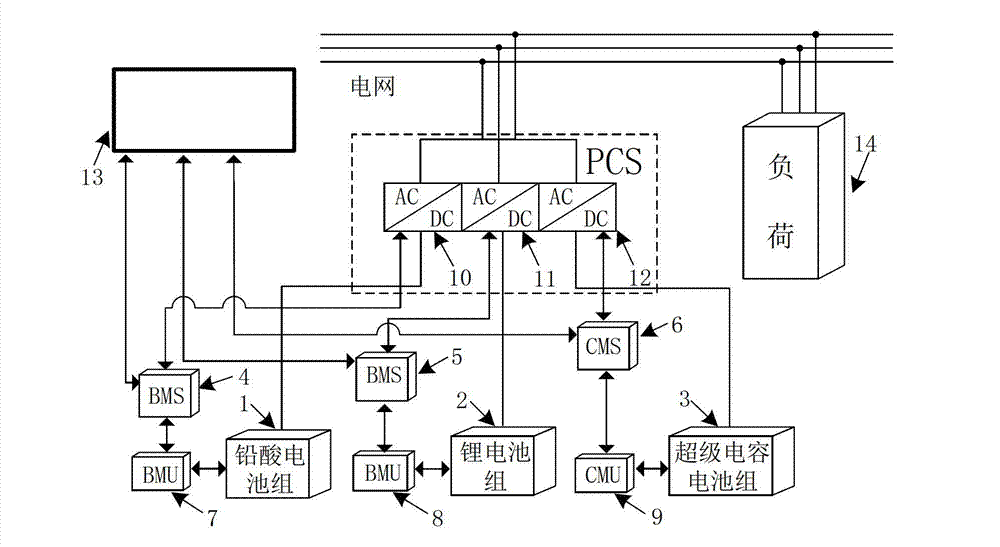

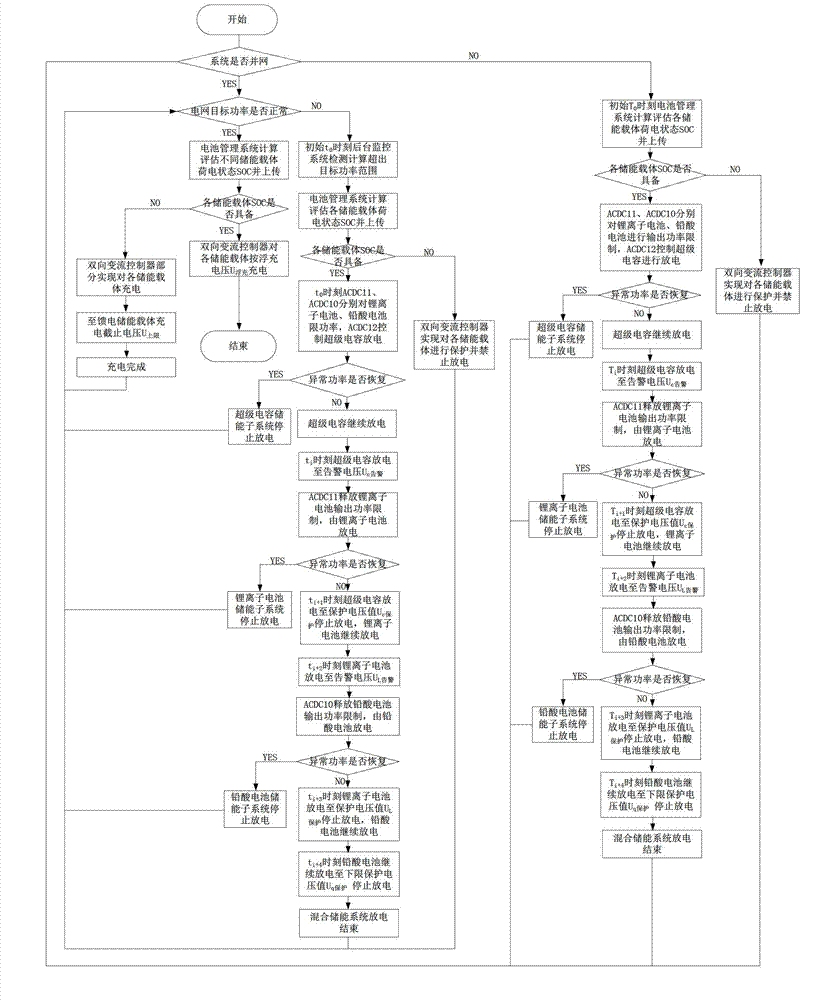

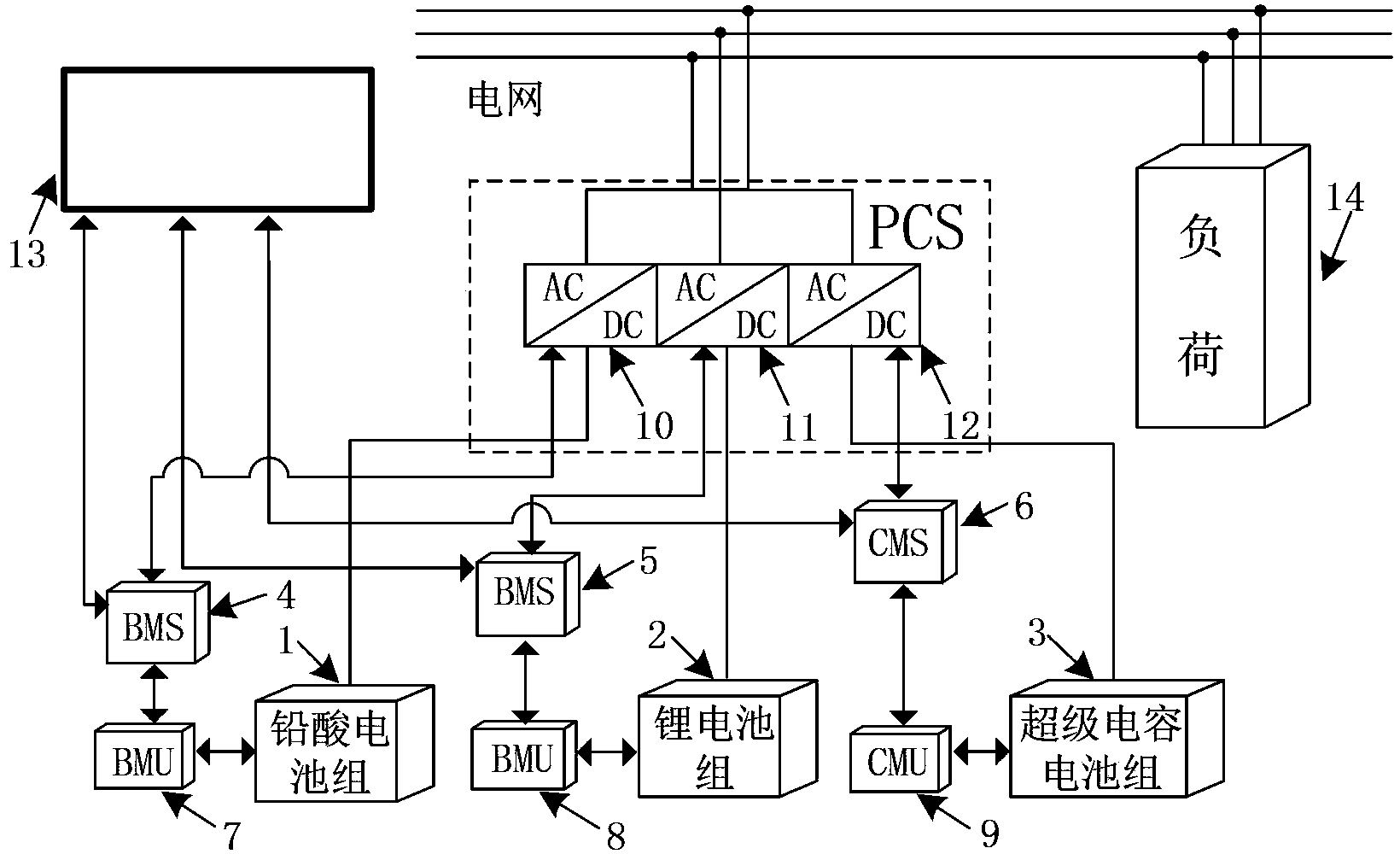

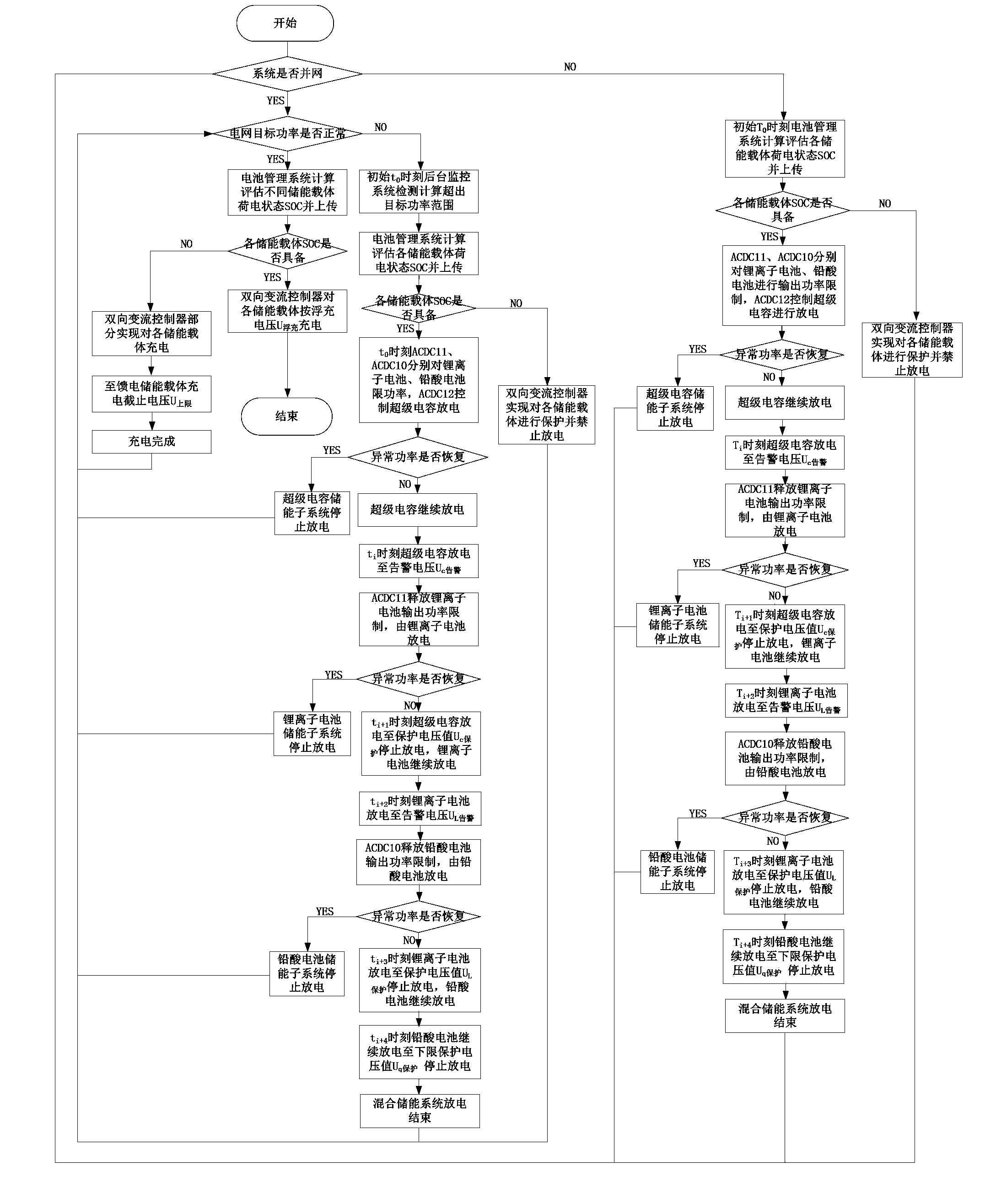

Hybrid energy storage system based on ordered energy control

The invention relates to a hybrid energy storage system comprising various energy storage carriers. The system is mainly based on an ordered energy control strategy, the energy storage carriers are selectively discharged in a current-limiting or power-limiting mode through a pulse width modulation (PWM) closed-loop control principle and a monitoring system selective control principle, the advantages of the energy storage carriers are combined and complemented, the disadvantages of the energy storage carriers are overcome, and the aim of ordered energy utilization of different energy storage carriers is fulfilled according to a discharge priority sequence, namely a third energy storage subsystem, a second energy storage subsystem and a first energy storage subsystem. By the hybrid energy storage system, the phenomenon that the power of a power grid fluctuates because a wind and light power generation system or a high-power load and the like are connected to the power grid is avoided, smoothing compensation is realized, the quality of electric energy is improved, and the stable operation of the power grid is ensured.

Owner:STATE GRID CORP OF CHINA +1

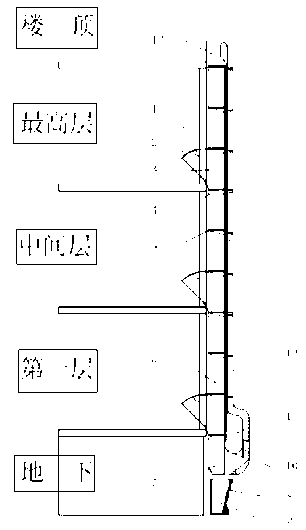

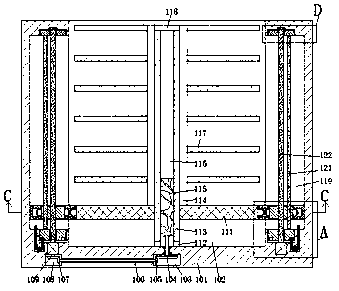

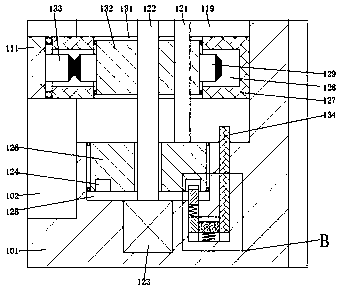

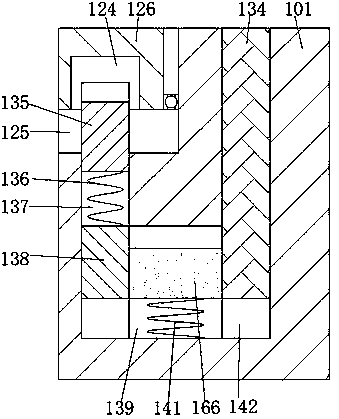

Automatic garbage sorting, putting and collecting system for building

InactiveCN102704658ARealization of classified deliveryIncrease motivationVertical ductsWaste managementWaste sorting

The invention relates to an automatic garbage sorting, putting and collecting system for a building. The automatic garbage sorting, putting and collecting system for the building at least comprises a building garbage channel, wherein a garbage sorting and collecting unit is arranged on the bottom of the building garbage channel; delivery mechanisms are arranged on the top and the bottom of the building garbage channel; the delivery mechanisms are provided with corresponding delivery units which are spaced according to the floor space; each of the delivery units is provided with a garbage putting hole on each layer, so that the garbage can be put into a garbage platform of the delivery units; the transmission mechanisms operate, so that the garbage or garbage bags on the garbage platform can be delivered to the garbage sorting and collecting unit; the garbage sorting and collecting unit puts the garbage or the garbage bags to a corresponding garbage sorting barrel according to the garbage sorting information. According to the system, the sorting treatment is carried out on the garbage from the source, so that the recyclable garage can be reutilized to the greatest extent, thereby reducing the garage treatment difficulty.

Owner:贾超

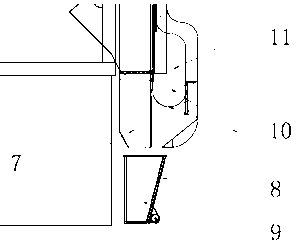

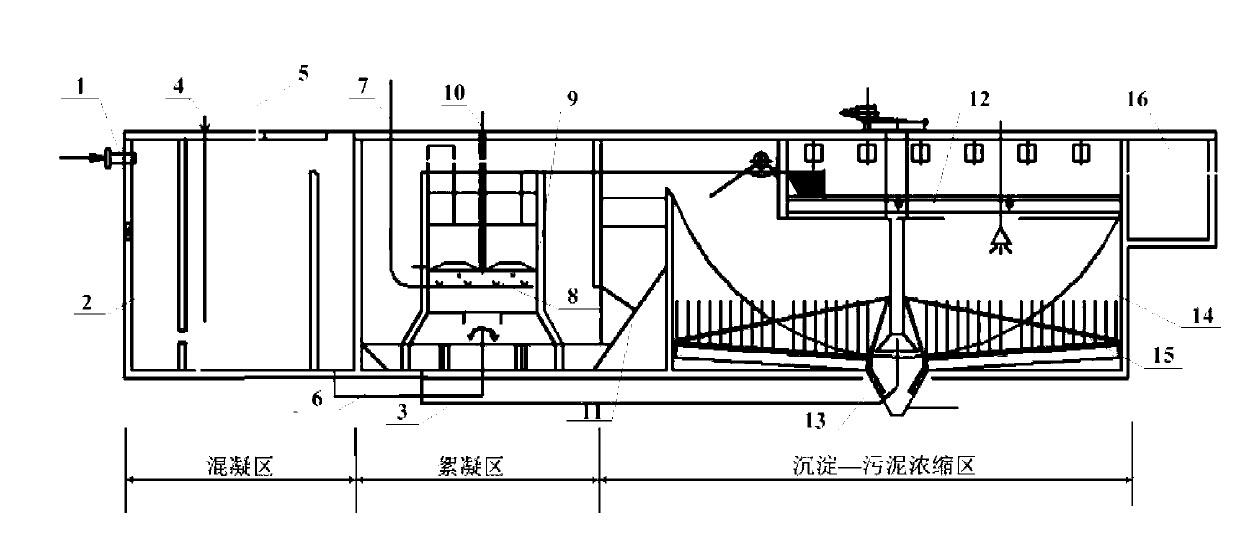

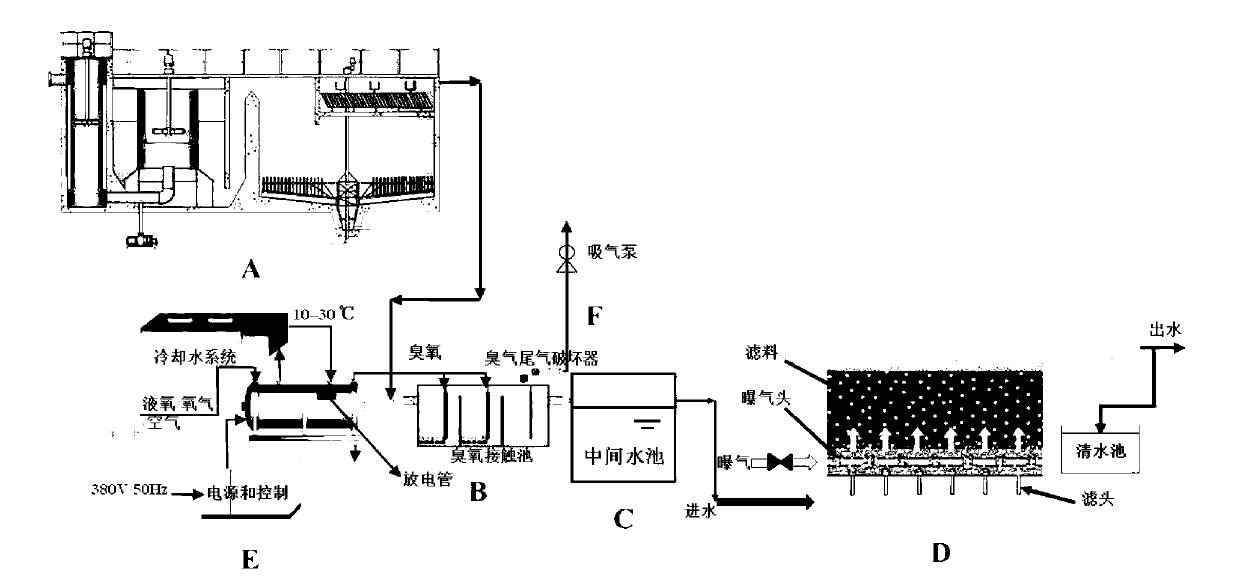

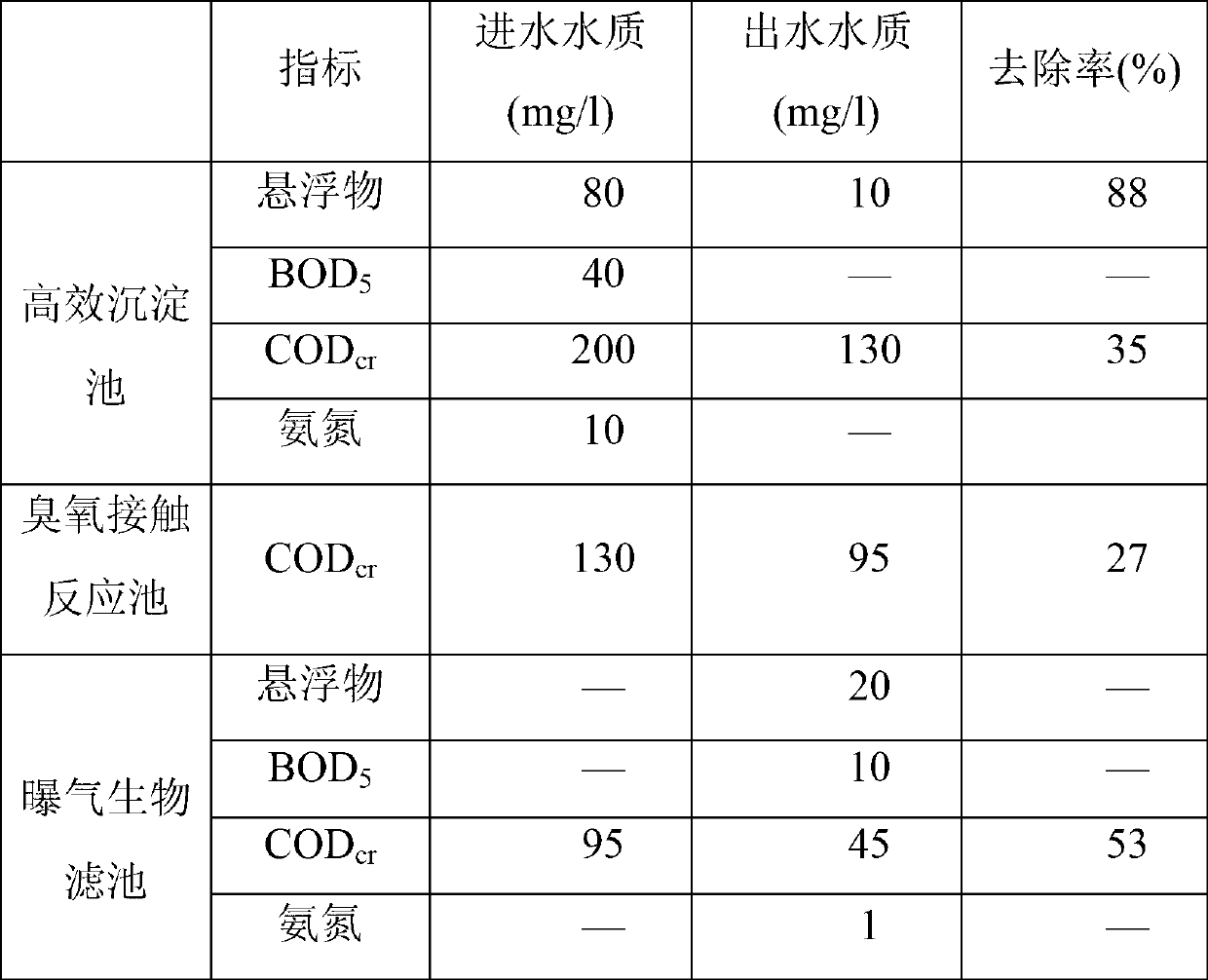

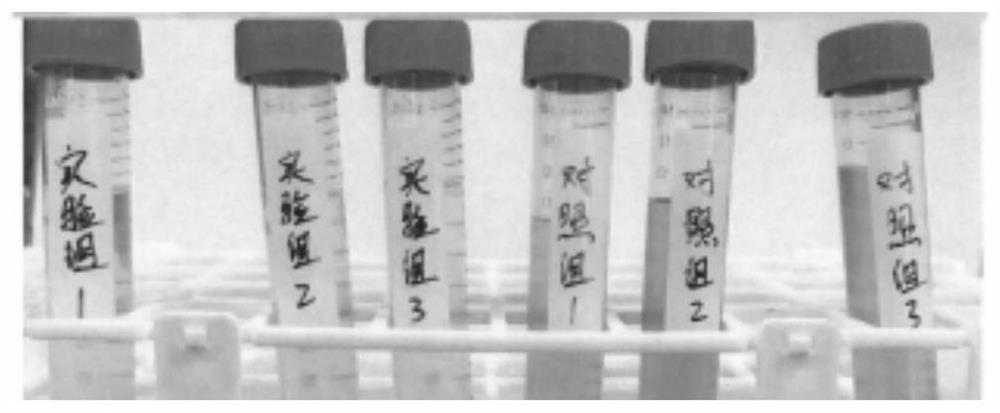

Sewage advanced treatment and recycling method capable of substantially raising economy

InactiveCN103214141AReduce removal rateLow recycling rateMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationFiltration

The invention provides a sewage advanced treatment and recycling method capable of substantially raising economy, comprising processes of high efficiency coagulation deposition, ozone oxidation and biochemical treatment, wherein the method is characterized in that a coagulation deposition stage integrates coagulation, flocculation, deposition and sludge backflow, a forced sludge outer circulation backflow mode is utilized, sludge concentration in a flocculation reaction is increased, contact flocculation and deposition net capturing effects of backflow sludge is fully utilized, and a removal rate of COD suspensions is raised, thereby substantially reducing a subsequent additive amount of ozone. In an ozone oxidation stage, COD in sewage id further removed by adding ozone, and biodegradability of sewage is raised. Ozone tail gas generated in the stage is converted into pure oxygen, which is collected and conveyed to a front biochemical stage for providing oxygen required for aeration, thereby reducing operation cost. Biochemical degraded COD generated in the ozone oxidation stage is removed by an aeration biological filtration pool in the biochemical treatment process.

Owner:北京翰祺环境技术有限公司

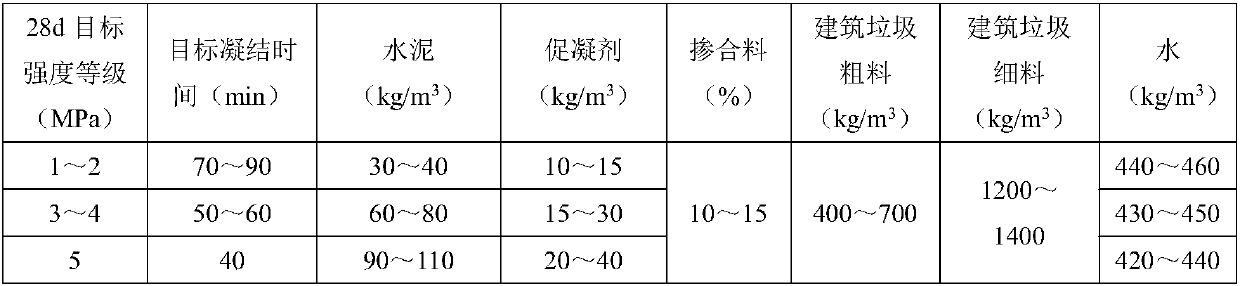

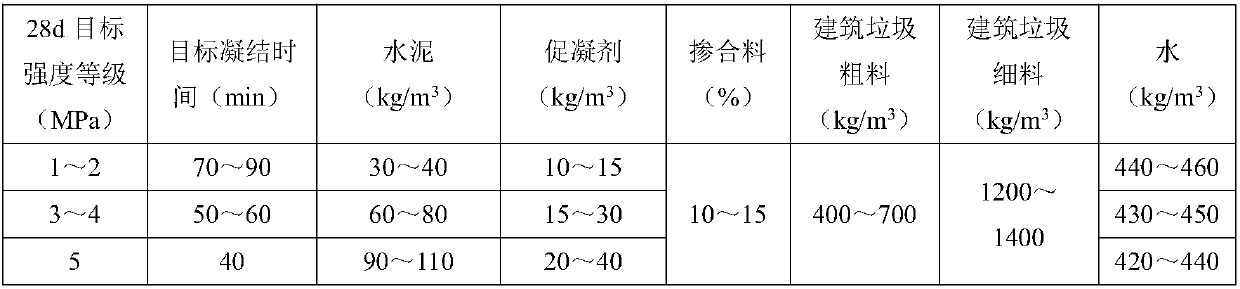

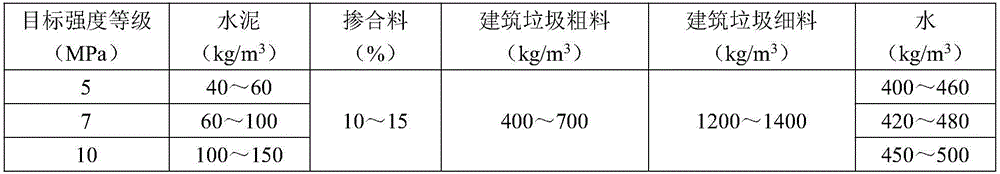

Road pipe trench quick backfill material produced with building wastes and construction technology thereof

The invention discloses a road pipe trench quick backfill material produced with building wastes and a construction technology thereof. The backfill material is prepared by mixing a building waste renewable coarse material, a building waste renewable fine material, cement, sprayed concrete coagulator shrinkage reducing agent, admixture and water. Building waste renewable products are classified and managed strictly in specification and quality, and are treated with other engineering technologies, so that the material fully utilizes building waste renewable aggregates of various specifications,and meets the technological requirements of pipe trench backfill and requirement of quick setting and hardening at the same time; the hardened material is adjusted in mechanical strength according toengineering need, 2h strength adjustment range is 0.2-1.0MPa, and 28d strength adjustment range is 1.0MPa-6.0MPa. The material utilizes building waste renewable materials generated in city construction to the maximum degree and is quick hardening, early strengthening low-strength concrete suitable for backfilling of city road pipe trenches and grooving.

Owner:BEIJING UNIV OF TECH

Low-intensity groove concrete produced by using red brick construction wastes and construction technology of low-intensity groove concrete

InactiveCN106699069AQuality improvementLow recycling rateRoadwaysSolid waste managementBrickArchitectural engineering

The invention discloses a low-intensity groove concrete produced by using red brick construction wastes and a construction technology of the low-intensity groove concrete. The construction wastes generated in the city construction process are utilized for recycling, and the low-intensity groove concrete is prepared by stirring a construction waste recycled coarse material, a construction waste recycled fine material, cement, an admixture and water. Through strict classification and management of the specifications and the quality of construction waste recycled products, various construction waste recycled aggregates with various specifications are fully utilized by the materials, meanwhile, the technical requirements of pipe canal backfilling are met, and the mechanical strength of the low-intensity concrete after being hardened is adjusted according to the engineering requirements. A new way for recycling the construction wastes is expanded, the backfilling construction problem that backfilling materials in backfilling construction of some parts cannot be easily compacted effectively is solved, more importantly, the problem that artificial excavation is not facilitated after pipe canal backfilling at present is solved, unnecessary waste resources in municipal engineering are reduced, and meanwhile, the construction wastes with various specifications are fully utilized.

Owner:BEIJING UNIV OF TECH

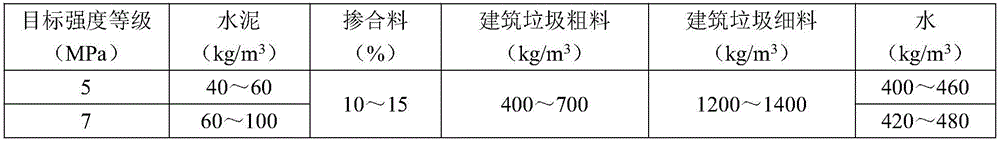

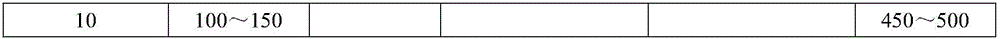

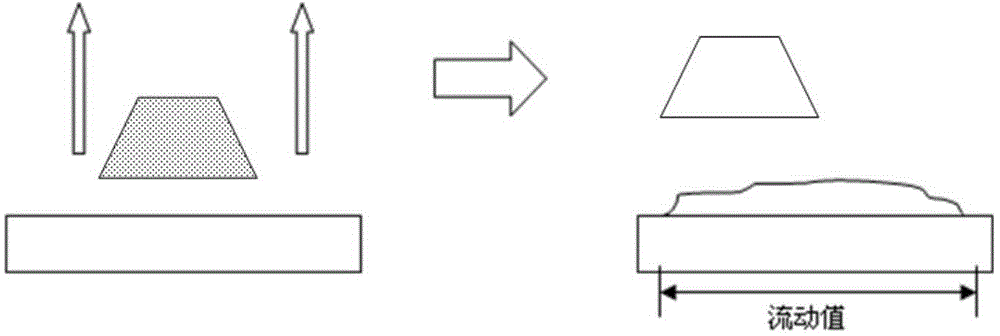

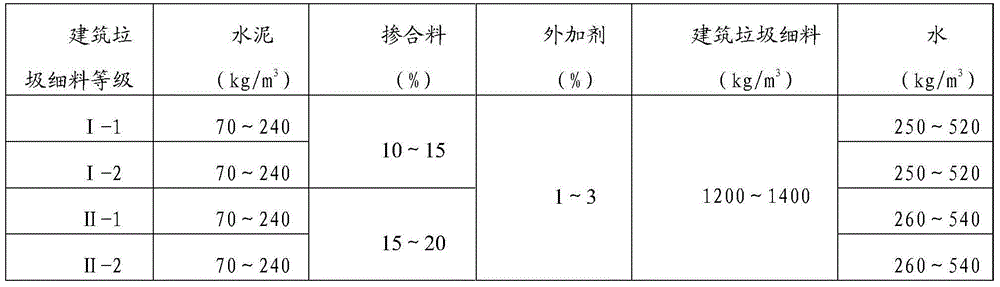

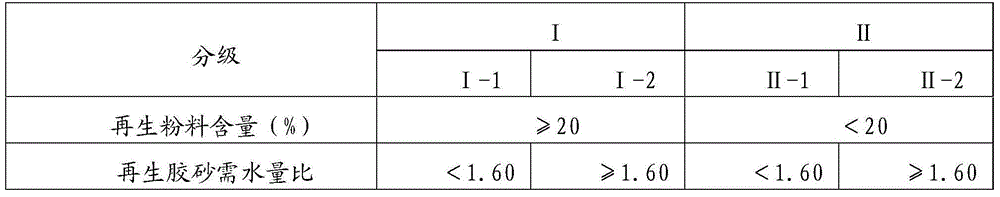

Sulfoaluminate-cement-based quick-setting quick-hardening flowable backfilling material prepared from construction waste

The invention relates to a civil engineering material, particularly a sulfoaluminate-cement-based quick-setting quick-hardening flowable backfilling material prepared from construction waste, which is suitable for emergency repair or quick backfilling of collapse and other dangerous situation on the road surface and also suitable for underground engineering, narrow construction pit backfilling and the like. The backfilling material is characterized by comprising 1200-1400 kg / m<3> of construction waste fine material, 70-240 kg / m<3> of cement, an additive which accounts for 1-3 wt% of the cement, an admixture which accounts for 10-20 wt% of the construction waste fine material, and the balance of water. The cement is quick-hardening sulfoaluminate cement, and the strength level is 42.5; and the admixture is one or any mixture of slag powder, fly ash, phosphorus slag powder, silica fume and clay soil. The material has the advantages of self-compaction filling and favorable flowability, and can satisfy the requirements of quick setting and hardening; and the mechanical strength is adjustable after the material is hardened.

Owner:BEIJING UNIV OF TECH

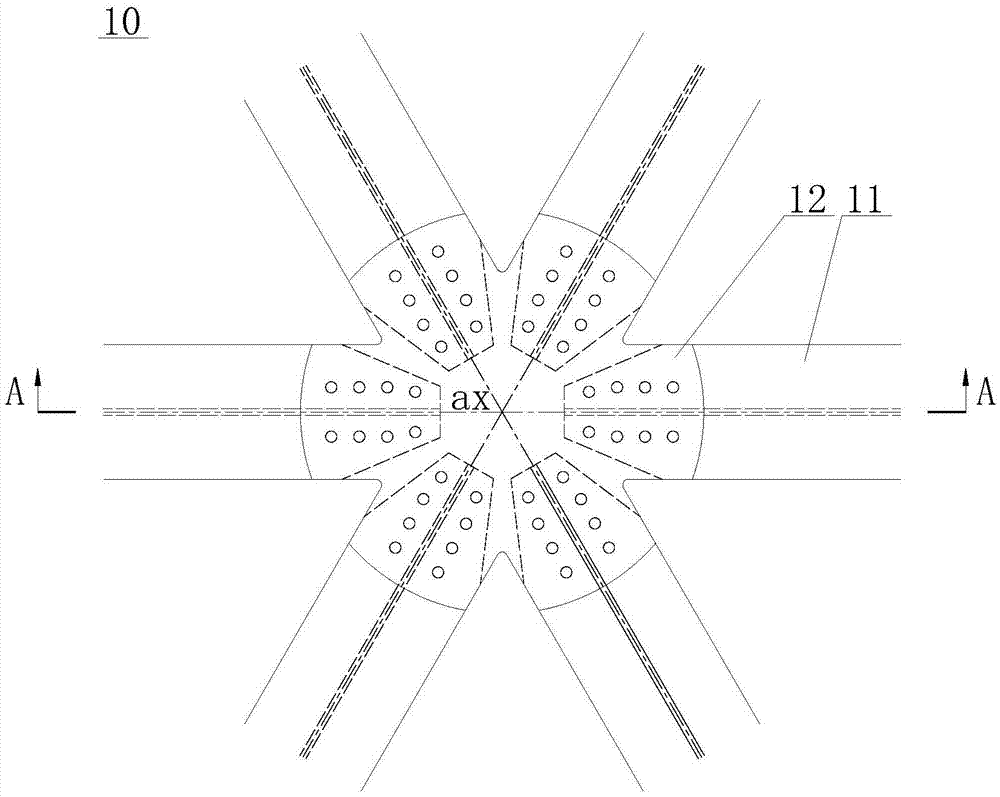

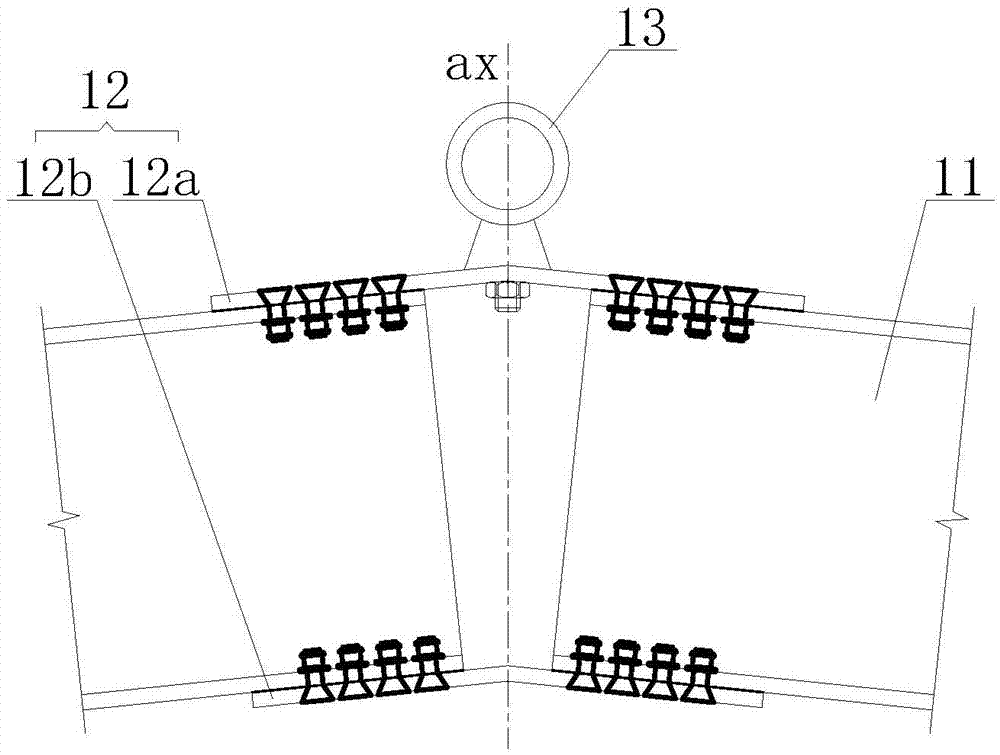

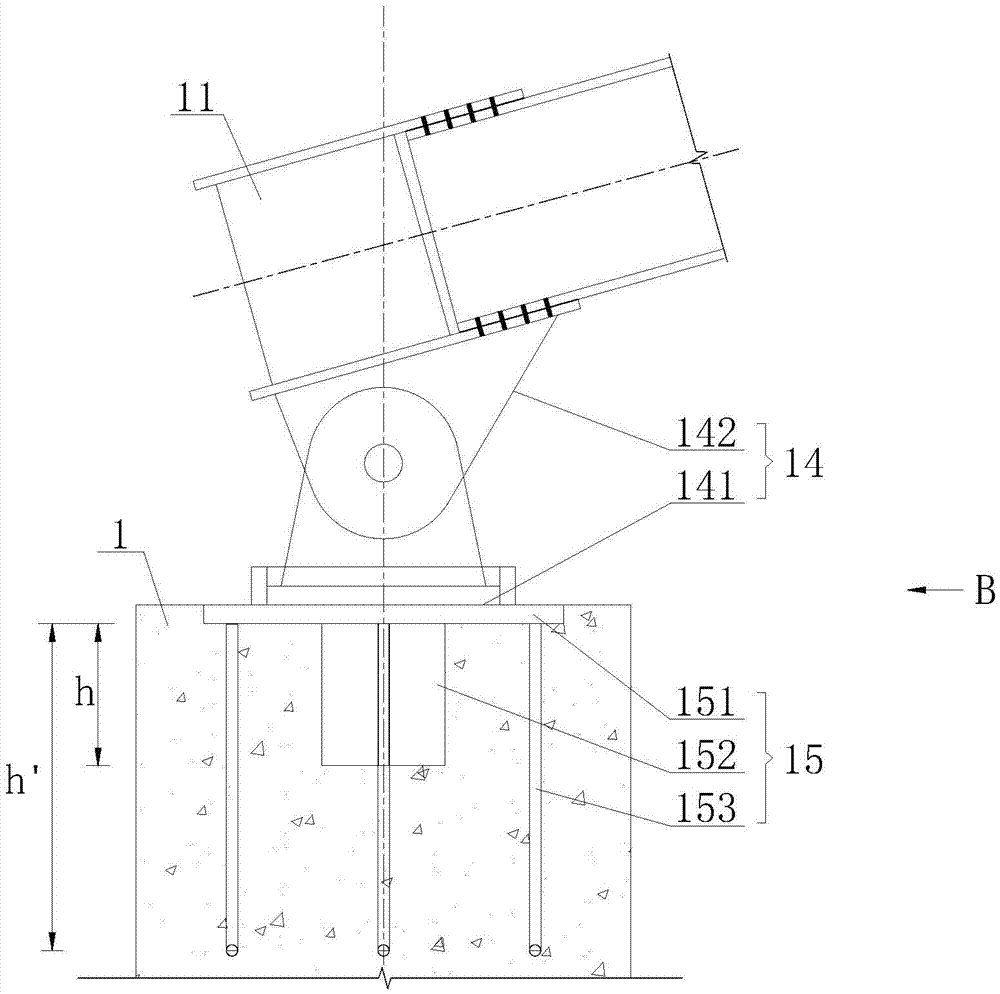

Space truss structure and construction method thereof

The invention discloses a space truss structure and a construction method thereof, and relates to the technical field of constructional engineering. The problems that an existing steel-structure truss is large in steel consumption, weak in overall rigidity, large in installation and construction difficulty and low in work efficiency are solved. The space truss structure is a space mesh structure formed by continuously splicing a plurality of truss units. Each truss unit comprises a plurality of rod pieces distributed in the axis of the truss unit in the radial direction, wherein the crossed ends of the rod pieces are fixedly connected together through a connecting plate, and each rod piece is made of aluminum alloy. The construction method includes the steps of prefabricating the rod pieces and the connecting plates in a factory, numbering all the components during site installation and construction, making the components correspond to the design drawings one to one, classifying the components, connecting all the rod pieces in the truss units with the connecting plates through bolts, supporting the rod pieces by a concrete structure or a steel column of a building through supports, and then completing splicing and fixing of the space truss structure step by step.

Owner:SHANGHAI MECHANIZED CONSTR GRP

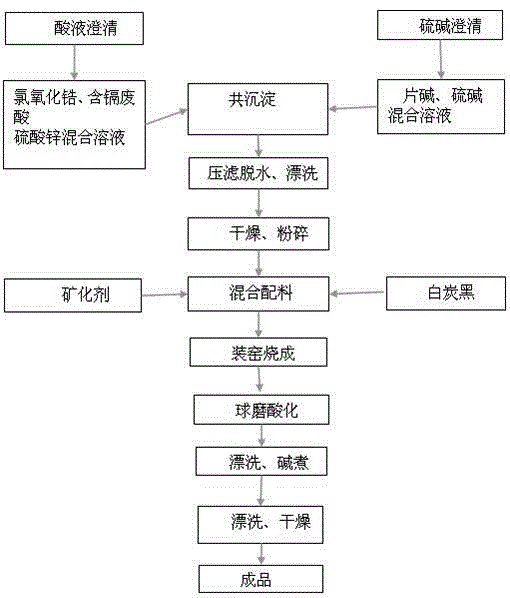

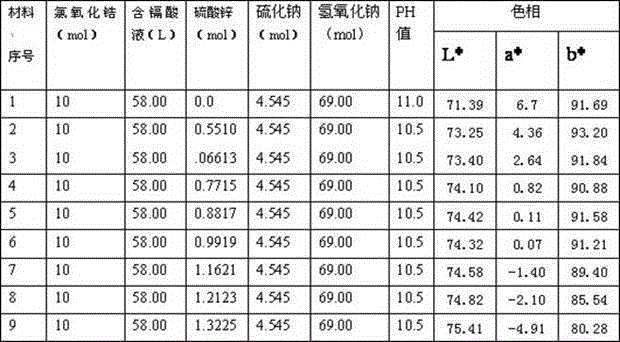

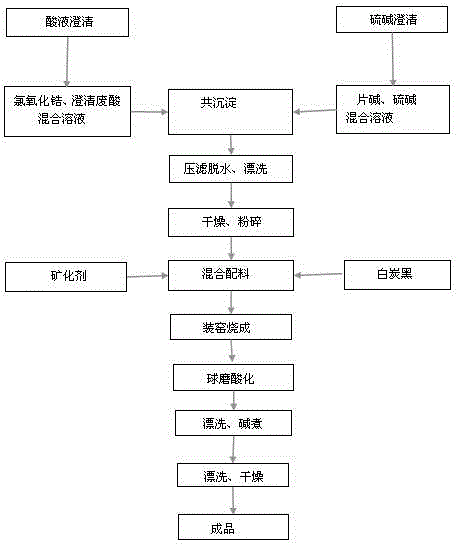

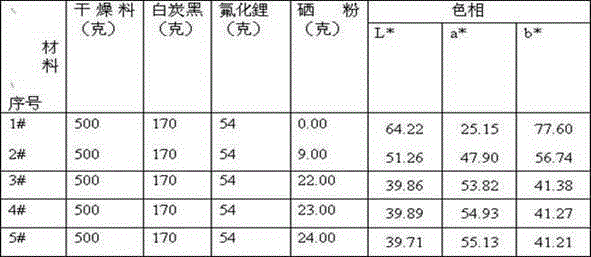

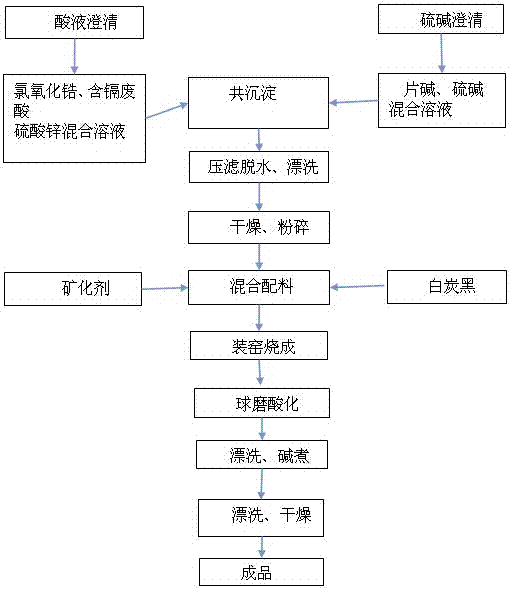

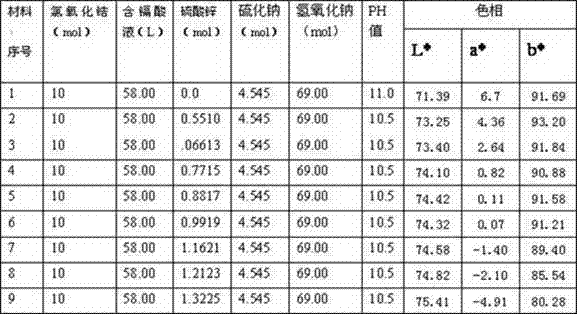

Method for preparing gilvous occlusion pigment from cadmium-containing waste acid solution generated in acid pickling process

The invention discloses a method for preparing a gilvous occlusion pigment from cadmium-containing waste acid solution generated in an acid pickling process. Cadmium-containing wastewater generated in the acid pickling process is directly utilized to produce a zirconium silicate microcrystal occluded cadmium sulfide pigment, and zinc ions are doped by virtue of introduction of zinc sulfate to form a cadmium sulfide and zinc sulfide solid solution color former which is used for producing the zirconium silicate microcrystal occluded zinc cadmium sulfide pigment. According to the invention, zirconium oxychloride, zinc sulfate and waste acid solution containing cadmium and selenium generated in the acid pickling process as well as sodium hydroxide and sodium sulphide are subjected to chemical coprecipitation reaction in a reaction kettle, filter-pressed and washed, and dried; and then the above reaction product is evenly mixed with a mineralizer and white carbon black according to a certain ratio and calcined at a high temperature, and the calcined product is acidized, ball-milled, filter-pressed, washed and dried to obtain the zirconium silicate occluded cadmium sulfide yellow pigment or zirconium silicate occluded zinc cadmium sulfide gilvous occlusion pigment product. The gilvous occlusion pigment can replace praseodymium yellow pigment for use.

Owner:LILING KEXING IND CO LTD

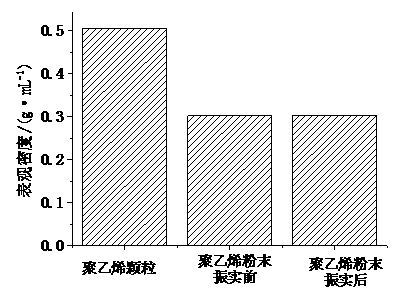

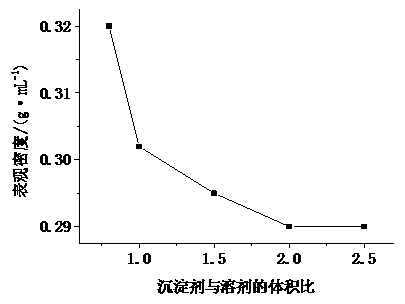

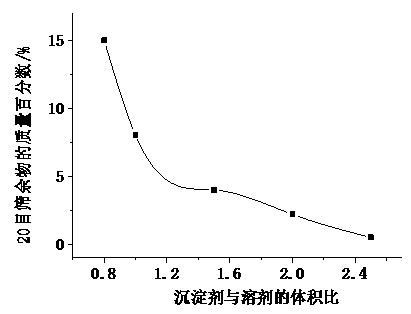

Polyolefin powder capable of uniform mixing with plant small piece and preparation method thereof

InactiveCN103214722AReduce weightWell mixedPowdery paintsHydrocarbon polymer adhesivesPolyolefinPlant roots

The invention relates to a polyolefin powder capable of uniform mixing with plant small pieces and a preparation method of the polyolefin powder. The powder comprises the ingredients of polyethylene, polypropylene, polystyrene or the mixture of the three, the particle size of the powder is 100nm-1mm, apparent density is 0.18g / mL-0.40g / mL, and the uniform mixing of the powder with the small pieces of plant root, stem, trunk, leaf, and seed case can be achieved through a mixing medium. The preparation process of the powder comprises the following steps of: mixing solid materials in various forms with a special solvent, heating the mixture for dissolution, carrying out thermo-precipitation using a special precipitant, carrying out separation, rolling homogenization and dispersion, separating the solvent and the precipitant for recycling, drying the resulting product, and grinding the dried product. The whole preparation process has the characteristics of material recycling, less volatile matter, strong environment protection and the like; the prepared powder can be applied to preparing an environment-friendly composite material which is further applied to fabricating a container, furniture, a finishing material, a toy and the like; and the prepared powder can be used as raw material for powder coating and a hot melt adhesive material which is easy in uniform coating.

Owner:JIUJIANG UNIVERSITY

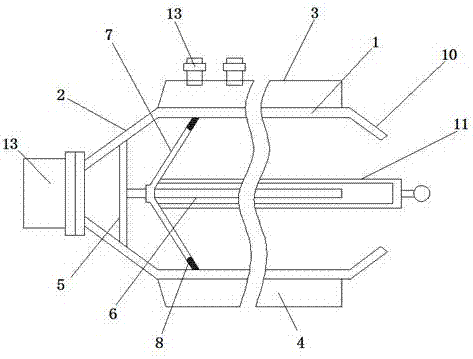

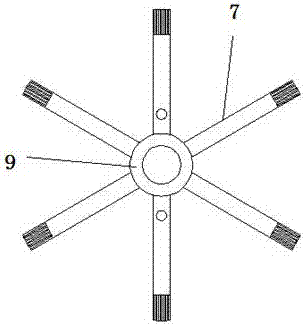

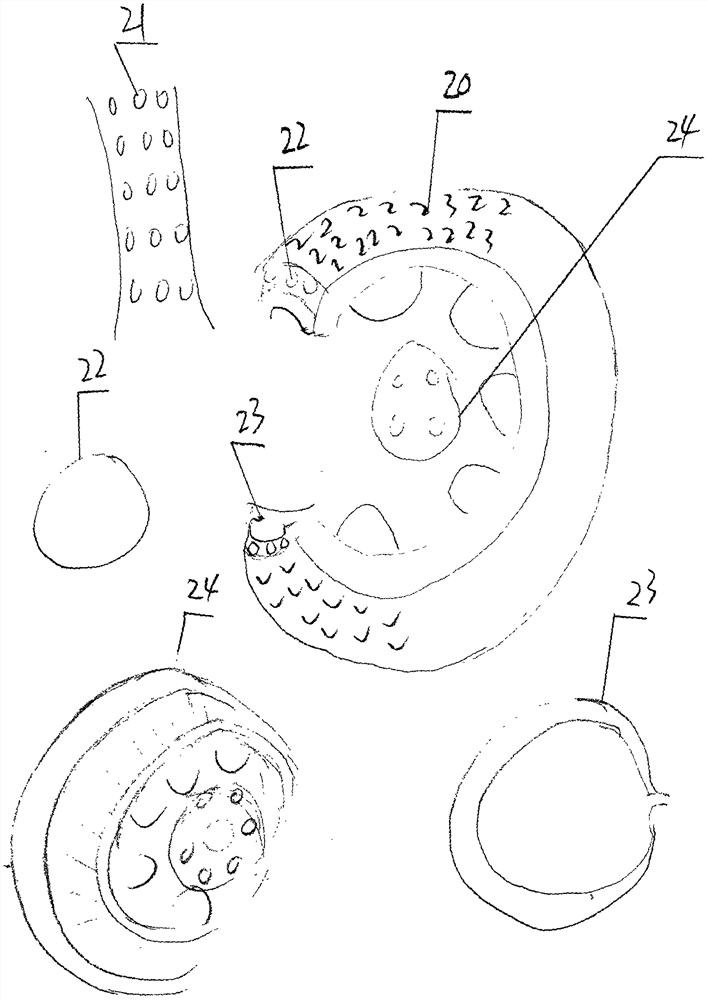

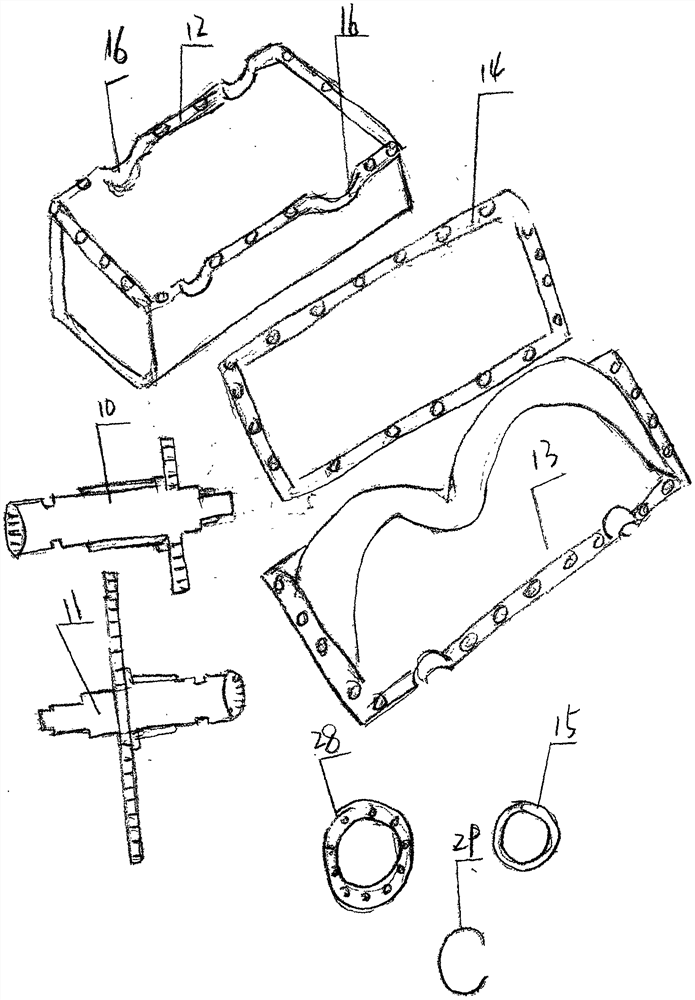

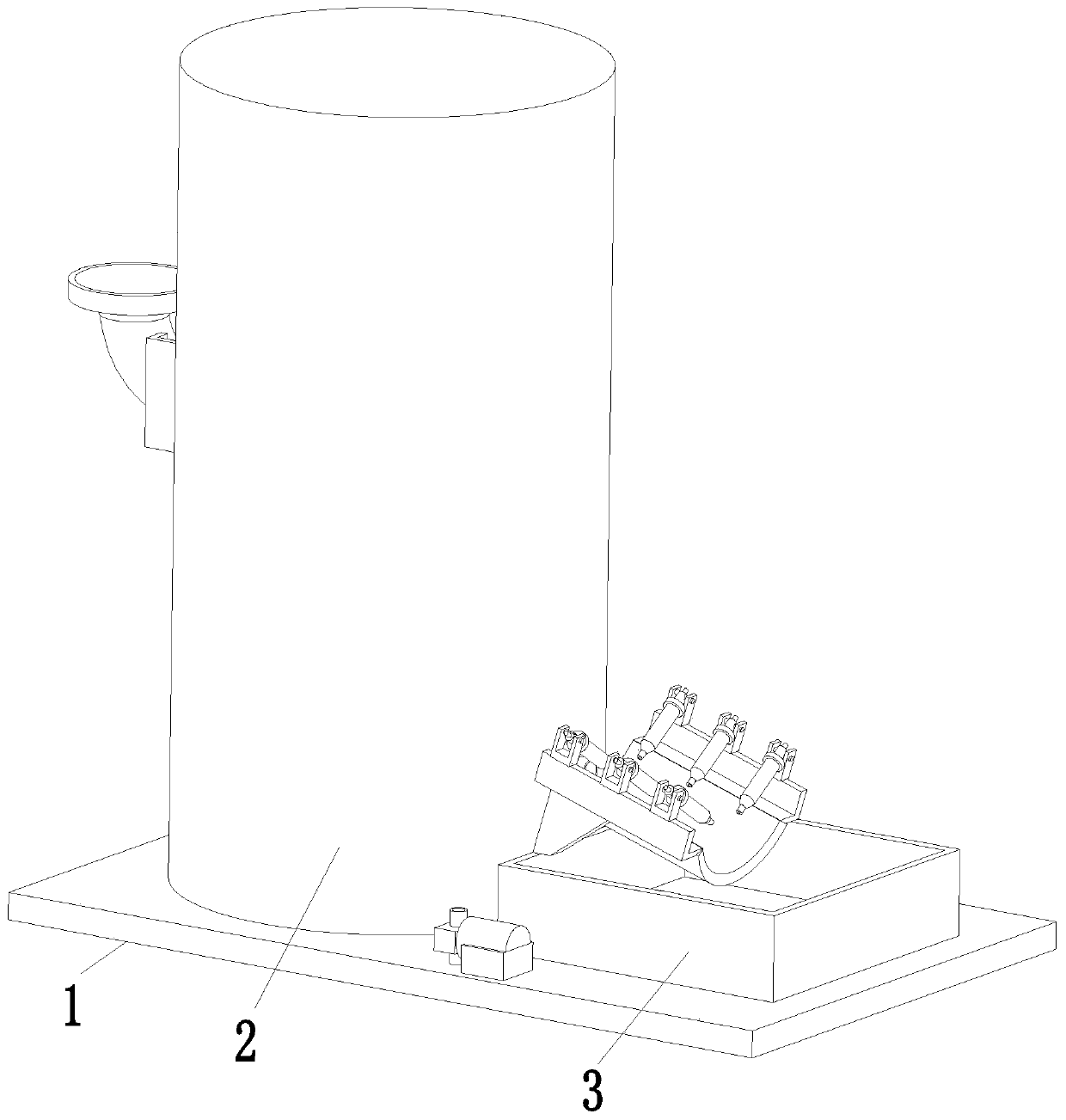

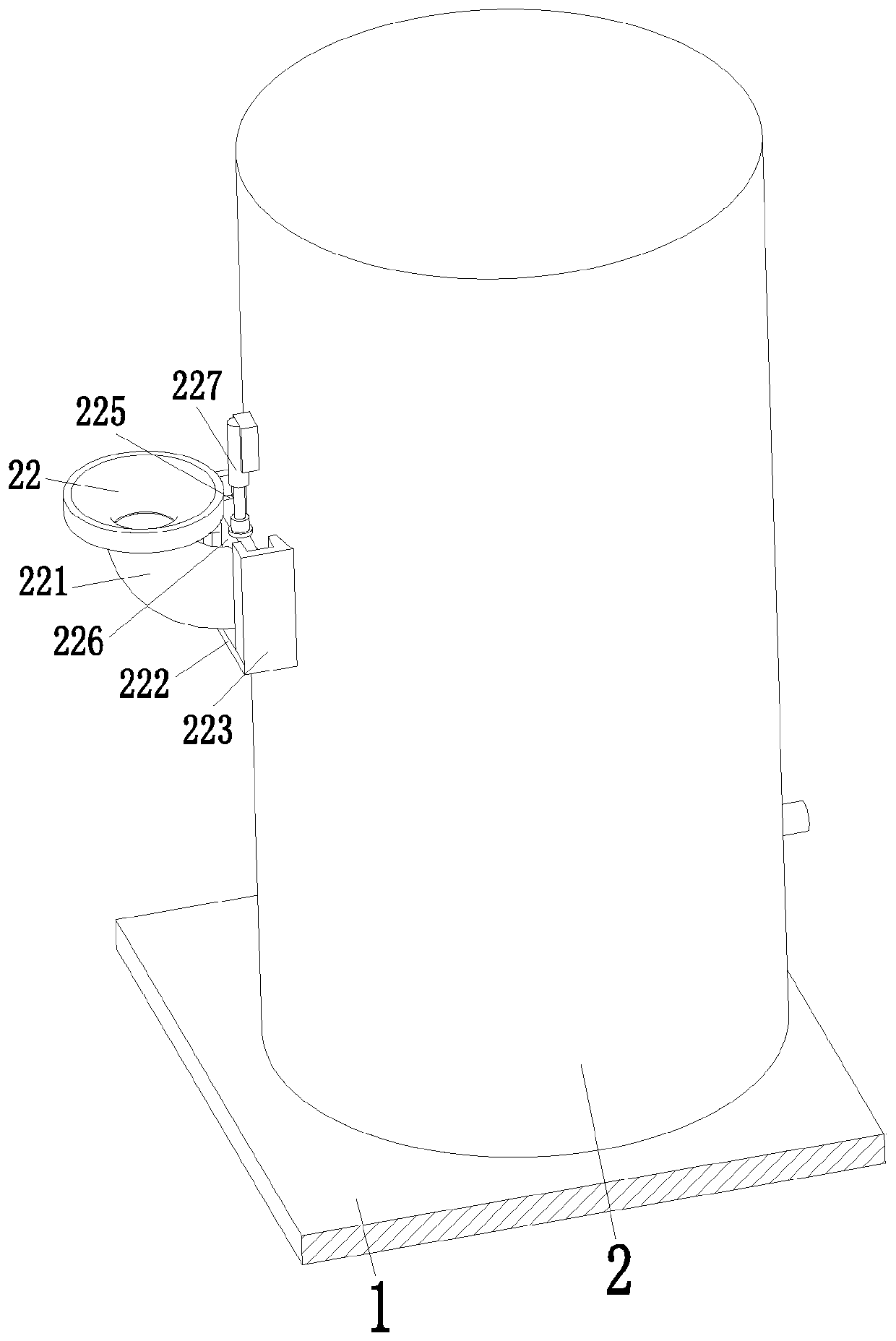

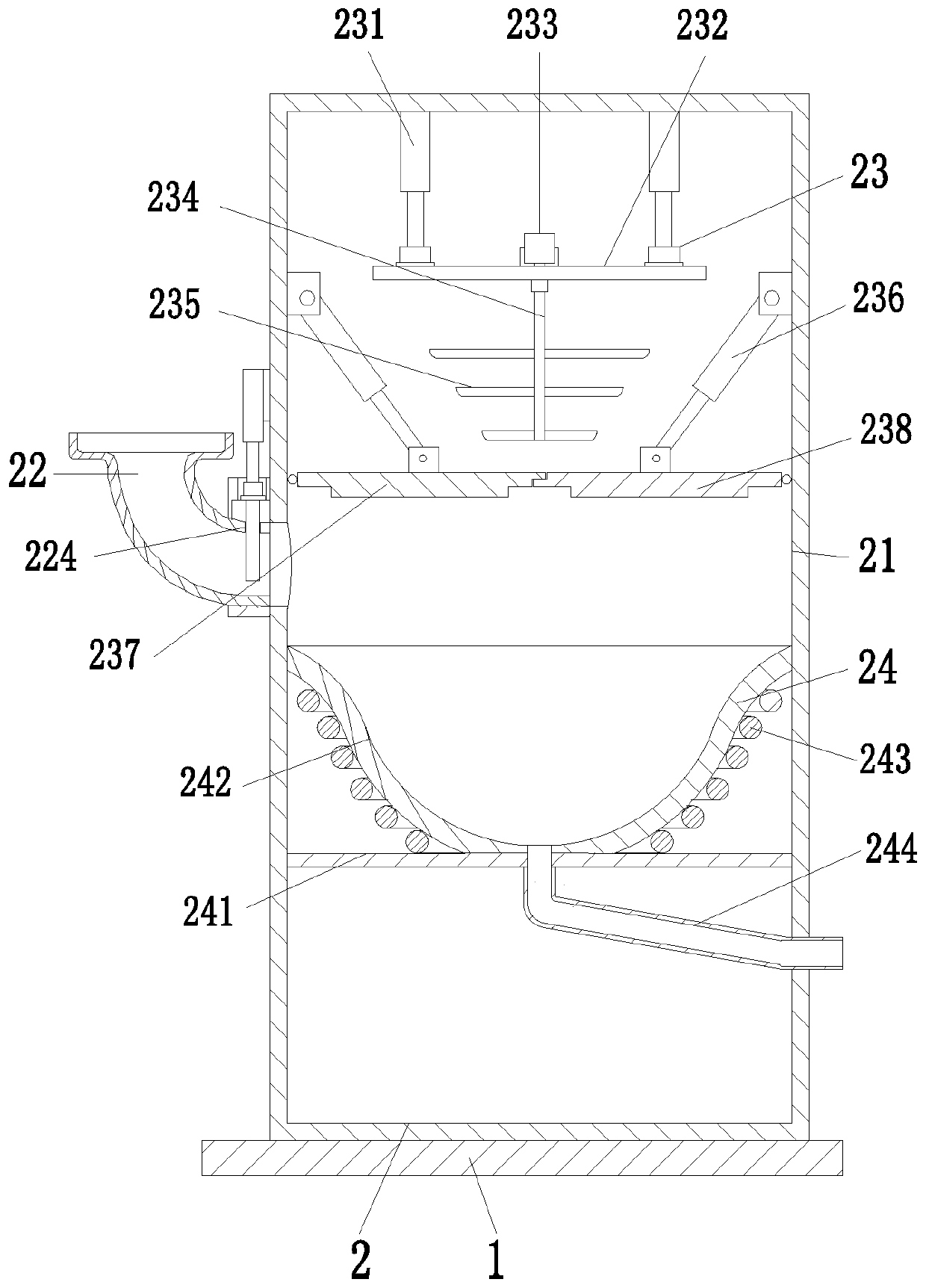

Mixing equipment for microcrystalline glass manufacturing, and microcrystalline glass mixing and manufacturing process

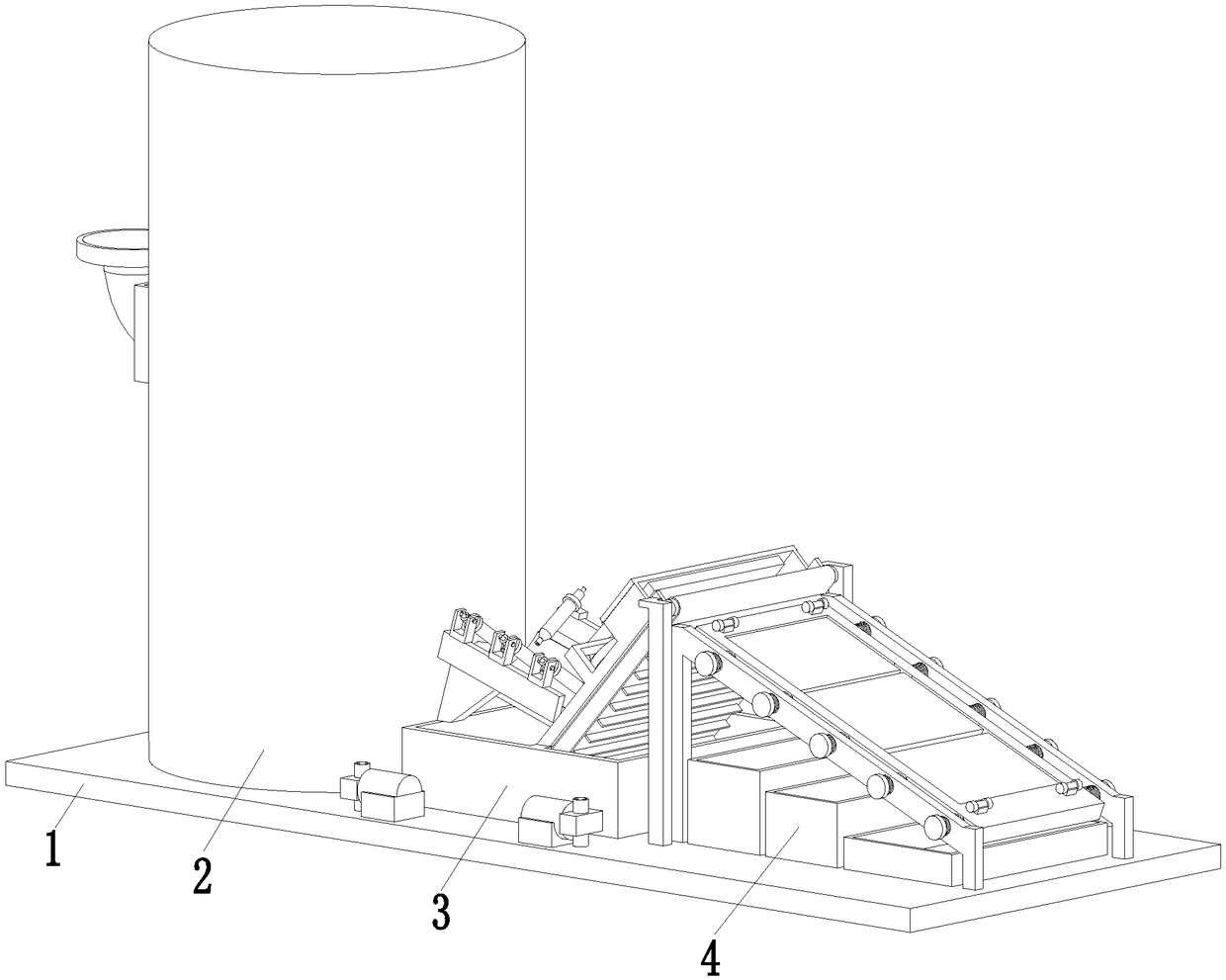

The invention relates to mixing equipment for microcrystalline glass manufacturing, and a microcrystalline glass mixing and manufacturing process. The mixing equipment comprises a base plate, a mixingdevice, a water quenching device and a grading device, wherein the left side of the upper end of the bottom plate is provided with the mixing device; the middle part of the upper end of the bottom plate is provided with the water quenching device, the right side of the upper end of the bottom plate is provided with the grading device, and the water quenching device is positioned between the mixing device and the grading device. The mixing equipment can be used to solve the following problems: existing red mud wastes are usually stored in a stacked mode, so that soil and water sources are polluted due to long-time stacking, and use is influenced; the recycling rate of the red mud wastes is low; when red mud is used for manufacturing microcrystalline glass, production efficiency is low andlabor intensity is high; the red mud cannot be uniformly mixed with added materials; and meanwhile, glass particles are often screened artificially after water quenching, so that working intensity isimproved, operation is complex, labor intensity is large, and working efficiency is low; and the like. Functions of automatic processing, forming and screening are achieved when the red mud is used tomanufacture the microcrystalline glass.

Owner:山东鑫诺新玻璃工程有限公司

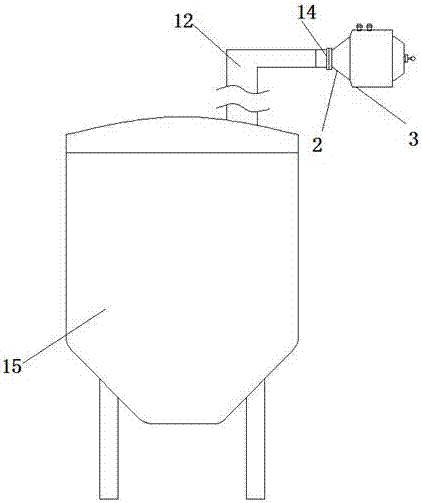

Heat recycle device of heat-conducting oil boiler

PendingCN107238205ALow recycling rateImprove recycling ratesFluid heatersCombustion technology mitigationHeat conductingEngineering

The invention relates to the technical field of boilers, in particular to a heat recycle device of a heat-conducting oil boiler. The heat recycle device comprises a recycle cylinder; the side wall of the recycle cylinder is fixedly connected with an inlet retraction cover; the side, far from the recycle cylinder, of the inlet retraction cover is fixedly connected with a flange; the inlet retraction cover is in seal connection with a smoke pipe by being connected with the flange; the end, far from the inlet retraction cover, of the smoke pipe is inserted into an inner cavity of the boiler; the inner wall of the inlet retraction cover is fixedly connected with a first fixed plate; a fixed rod is vertically mounted on the outer wall of the first fixed plate; the outer wall of the fixed rod is sleeved with a sleeve ring; the outer wall of the sleeve ring is fixedly connected with scrapers, and the scrapers make contact with the inner wall of the recycle cylinder; according to the heat recycle device of the heat-conducting oil boiler, waste heat in boiler smoke can be effectively absorbed and recycled, the situation that after the recycle device is used for a long time, the inner wall of the recycle cylinder adheres too much smoke duct, so that the recycle utilization rate of the recycle device is low can be prevented, and thus the heat recycle device has the high heat recycle utilization rate.

Owner:JIANGSU FENGXINYUAN IND CLOTH CO LTD

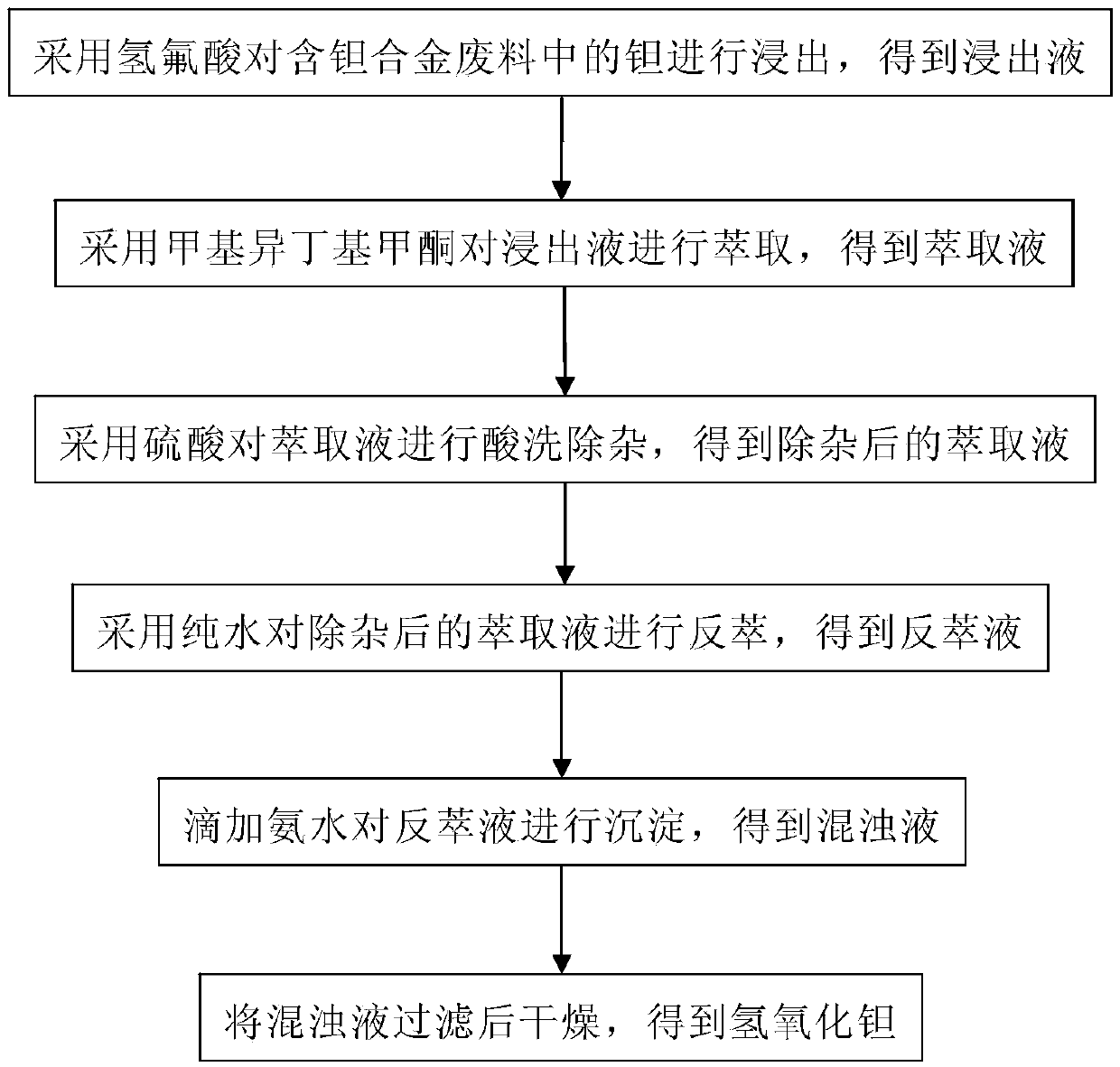

Method for recycling tantalum from tantalum-containing alloy waste

InactiveCN103773965AEasy to operateDifficult to separate and recycleProcess efficiency improvementScrapMethyl isobutyl ketone

The invention provides a method for recycling tantalum from tantalum-containing alloy waste, which comprises the following steps: (I) performing leaching treatment on tantalum in the tantalum-containing alloy waste by use of hydrofluoric acid; (II) performing extraction treatment on the leachate by use of methyl isobutyl ketone to obtain extraction liquid; (III) performing pickling and impurity removal on the extraction liquid by use of sulfuric acid; (IV) performing back extraction treatment on the extraction liquid after the impurity removal by use of pure water to obtain back extraction liquid; (V) dropwise adding ammonia water into the back extraction liquid to obtain turbid liquid; (VI) filtering the turbid liquid and drying to obtain tantalum hydroxide. In the invention, the research and development work is carried out according to the characteristics that the tantalum-containing alloy raw material contains multiple types of impurities and tantalum is difficult to separate, a new method for recycling tantalum from the tantalum-containing waste is proposed, the tantalum recycling rate is high, and the method has good industrial prospects.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

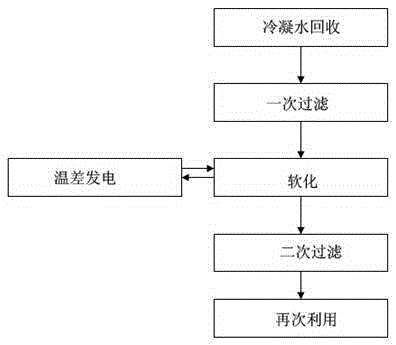

Process for comprehensively recovering heat energy and exchanging heat

ActiveCN105371268AImprove recycling ratesLow recycling rateHeat recovery systemsFeed water supplyWater qualityEngineering

The invention provides a process for comprehensively recovering heat energy and exchanging heat. The process comprises five steps, namely, the step of recovering condensed water, the step of filtering for the first time, the step of softening, the step of filtering for the second time, and the step of reusing. The process is simple in steps, and convenient to operate and control; the comprehensive recycling rate of condensed water and condensed water afterheat can be effectively improved, and moreover, the quality of the condensed water can be effectively improved, thus the recycling efficiency and safety of the condensed water can be improved, and as a result, the purposes of reducing the comprehensive utilization rate of the energy of a heating system and reducing the risk of failure of the heating system due to water scale and other reasons can be achieved.

Owner:GUANGHAN MAIDELE FOOD CO LTD

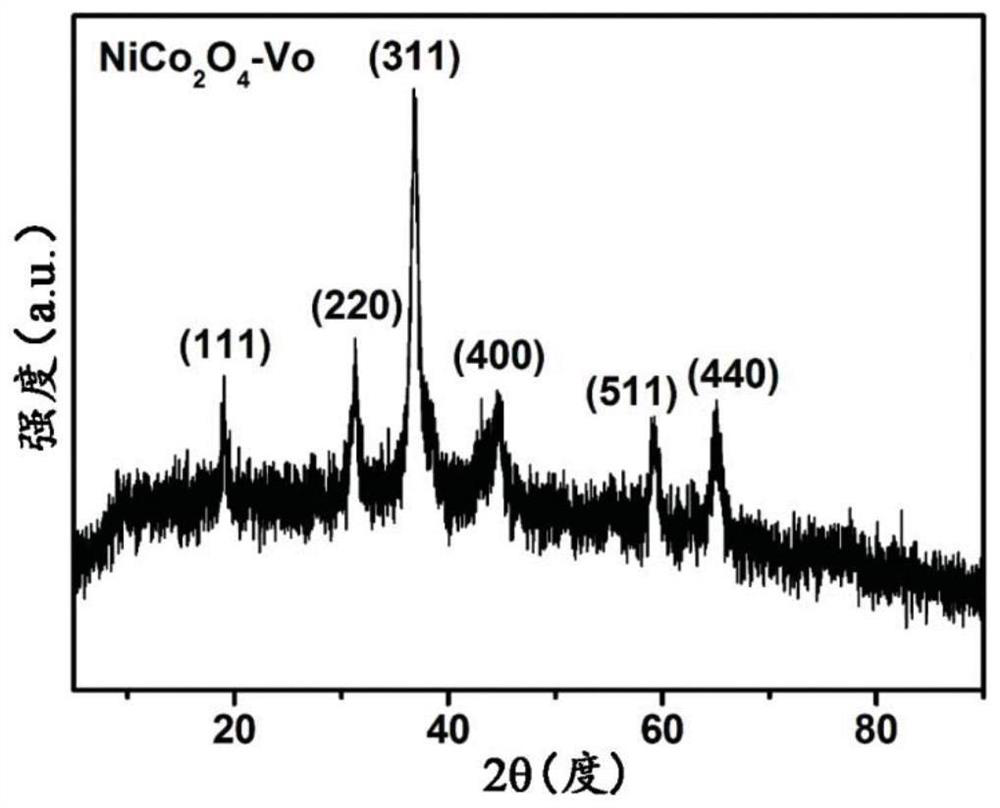

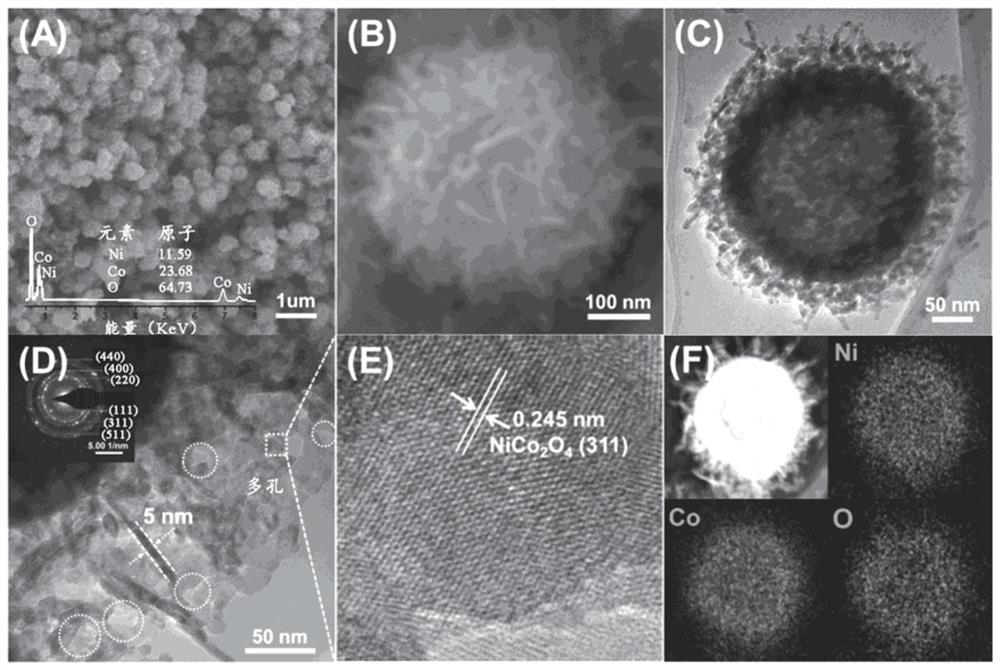

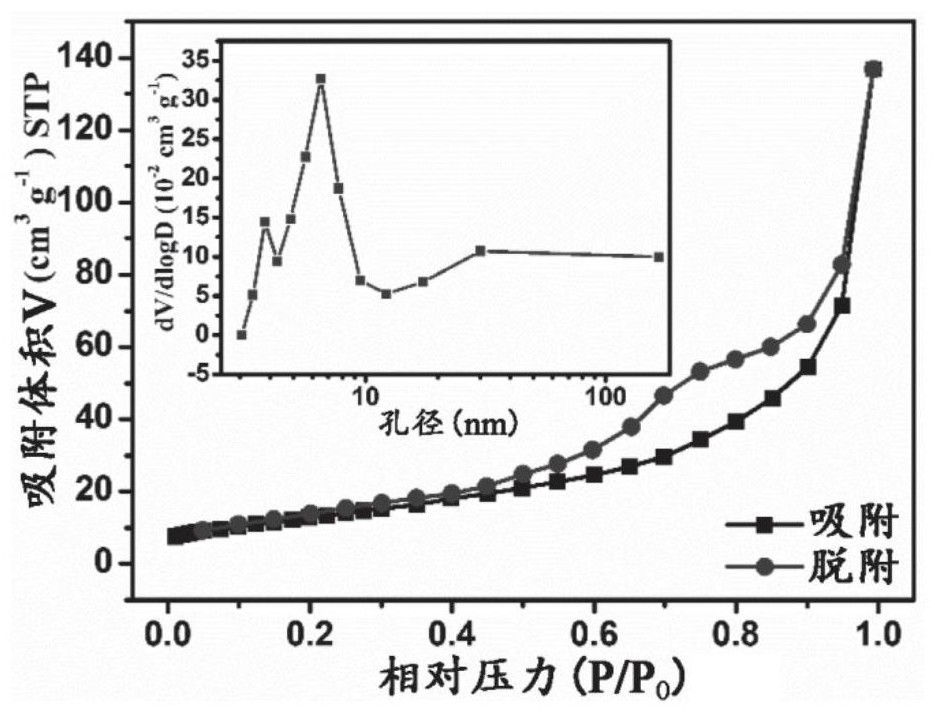

Nickel cobaltate nano material as well as preparation method and application thereof

ActiveCN112939097APoor circulationLow cost of preparationCell electrodesNanotechnologyNickelOxygen rich

The invention discloses a nickel cobaltate nano material as well as a preparation method and application thereof. The nano material is spherical, is in the diameter of 0.1-1 mu m, has a porous and hollow structure, has oxygen-rich vacancy defects and has the specific surface area of 20-70 m < 2 > / g. The nickel cobaltate nano material is high in activity and low in preparation cost, the preparation method is simple and easy to implement, large-scale batch preparation can be achieved, and the nickel cobaltate nano material has good industrial application prospects.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

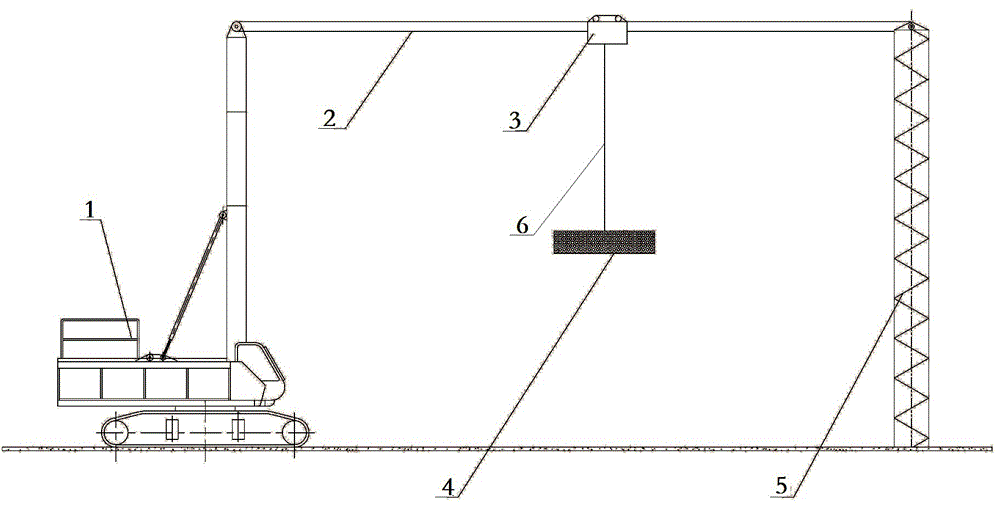

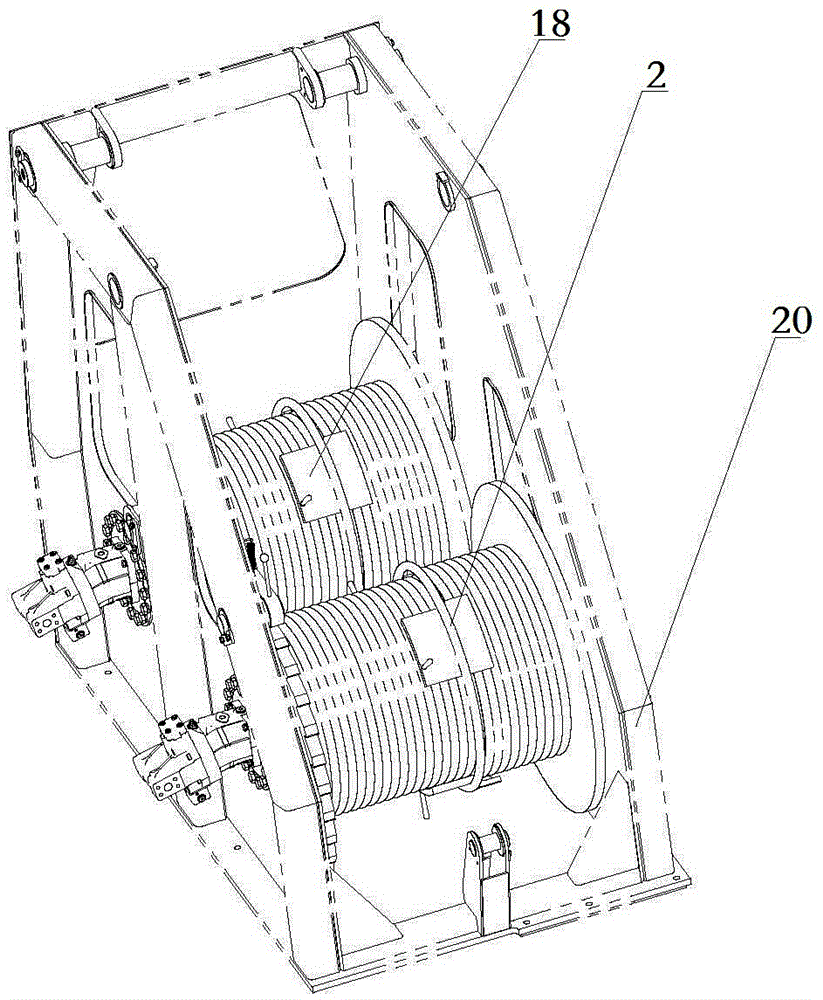

Movable freight cableway device

A movable freight cableway device comprises a tower and / or suspension-arm movable trolleys. A bearing cable, a pulling cable, a haul-back cable, a lifting cable and an assisting cable are connected and mounted between the suspension-arm movable trolley and the tower or between the two suspension-arm movable trolleys. The steel cables are connectively controlled by winches of the suspension-arm movable trolleys, a small moving trolley is mounted on the bearing cable, and the lifting cable is connected to the small moving trolley. The pulling cable and the haul-back cable are connected to the front end and the rear end of the small moving trolley respectively. The assisting cable is a pulling guide cable during erection of the bearing cable. Bearing platform assemblies, winch assemblies, tower arm assembles, power assembles, hydraulic oil tank assemblies, amplitude changing mechanisms, hydraulic system assemblies, lower trolley assemblies and electric systems are mounted on frames of the suspension-arm movable trolleys. The movable freight cableway device is flexible, convenient and rapid, manpower and material resources are saved, and the movable freight cableway device does not pollute the land and can be reused.

Owner:CHANGSHA ZHENGZHONG TECH DEV

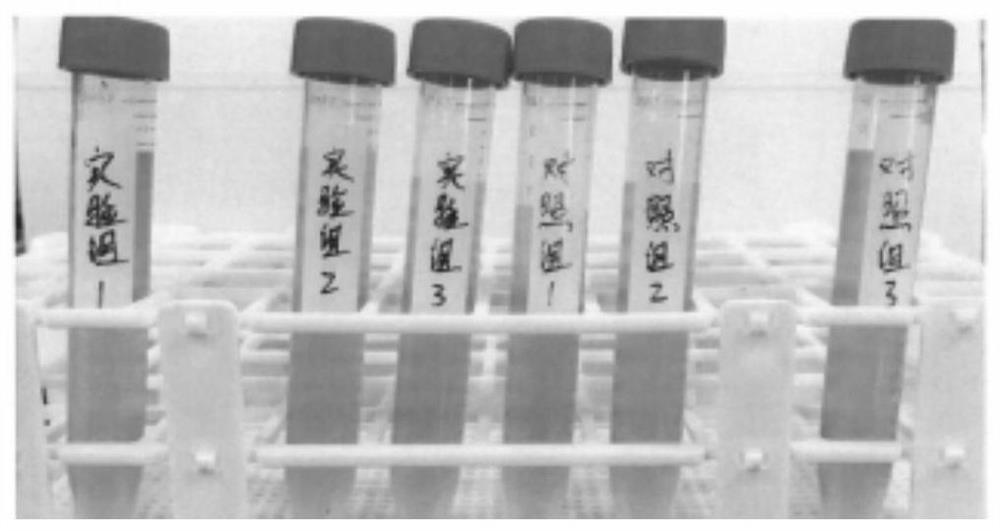

Sludge recycling method and biological water purification particles

InactiveCN114032191ALow recycling rateLow recycling valueBacteriaMicroorganism based processesIron saltsMagnesium salt

The invention relates to a sludge recycling method and biological water purification particles, and the sludge recycling method comprises the following steps: strain screening; strain separation; strain screening and fermentation; preparation of modified biochar: mixing sludge with magnesium salt and iron salt, conducting heating and stirring, then adding an alkaline reagent to adjust the pH value to 9-10, continuously conducting heating and carrying out a heat preservation reaction, drying the product, crushing the product, conducting sieving with a sieve, performing high-temperature calcination, and conducting cooling to obtain modified charcoal; and preparation of the biological water purification particles from a fermentation suspension and the modified biochar by an embedding method. The invention provides a new sludge recovery thought, specific strains capable of efficiently purifying water can be rapidly screened out by utilizing sludge and sewage, biomass loading is carried out by utilizing the modified charcoal, and the obtained biological water purification particles have an excellent water purification effect.

Owner:XIAMEN UNIV OF TECH

Power generation structure for electric automobile and kinetic energy circulation conversion control method

PendingCN113541393AIncrease potential energyReduce the risk of failureBatteries circuit arrangementsCharging stationsReduction driveIntelligent management

The invention discloses a power generation structure for an electric automobile and a kinetic energy circulation conversion control method. The power generation structure is characterized in that the power generation structure is composed of a steel ball wheel assembly, a hub, an axle sleeve, a transmission short shaft, a speed reducer and a power generator; the outer end of the transmission short shaft is connected with the steel ball wheel assembly and the hub; the inner end of the transmission short shaft penetrates into an inner hole of the axle sleeve to be connected with an input shaft of the speed reducer; the inner spline shaft sleeve of an output shaft of the speed reducer is connected with an outer spline shaft head of a generator rotor shaft; and the speed reducer is used for being matched with the rotating speed of the steel ball wheels of the electric automobile in running and the working rotating speed of the power generator and increasing output torque when the steel ball wheels rotate. An electric automobile energy efficiency intelligent management circuit integration is composed of a generator load control association inductor assembly, a power supply and control device assembly and an instrument display assembly, and is used for monitoring the kinetic energy dynamic state in the running process of the electric automobile in real time and controlling the on-off state of a generator circuit and the intensity of an output load in real time through a related control assembly.

Owner:杨晓东

Acid-soaked cadmium-selenium contained acid pickle direct recycling method

The invention discloses an acid-soaked cadmium-selenium contained acid pickle direct recycling method. Acid-soaked cadmium-selenium contained acid pickle is directly used for preparing and producing a zirconium silicate microcrystal wrapped cadmium selenide pigment after being subjected to comprehensive treatment by use of a chemical reaction method. Zirconium oxychloride, sodium hydroxide and sodium sulfide are used for performing treatment on the acid-soaked cadmium-selenium contained acid pickle; after the zirconium oxychloride is added into the acid-soaked cadmium-selenium contained acid pickle, and the sodium hydroxide and the sodium sulfide are prepared to be a mixed solution by the addition of water according to needs, after a stirring synthetic reaction, filter pressing and washing are performed, drying is performed, then the obtained mixture is mixed with a mineralizer, white carbon black and selenium powder to be uniform, then high-temperature calcination is performed, the calcined product is subjected to the working procedures including acidification, ball-milling, filer pressing, washing, soda boiling, filer pressing and washing, and the zirconium silicate microcrystal wrapped cadmium selenide pigment product is obtained after drying.

Owner:LILING KEXING IND CO LTD

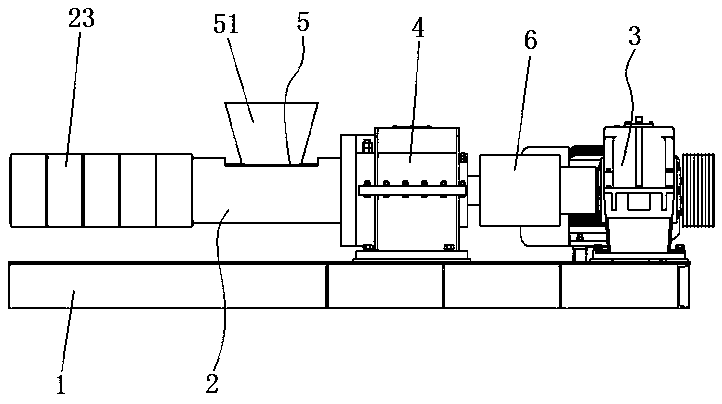

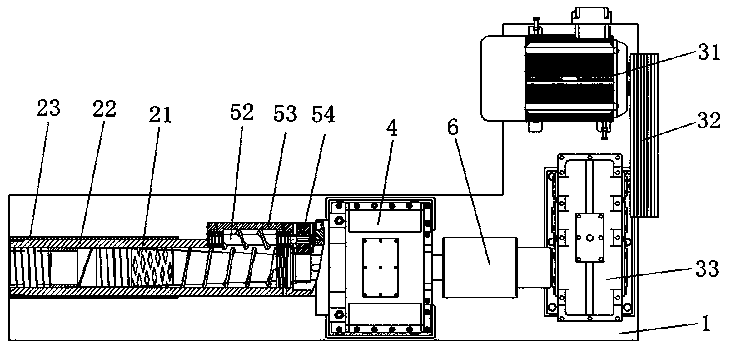

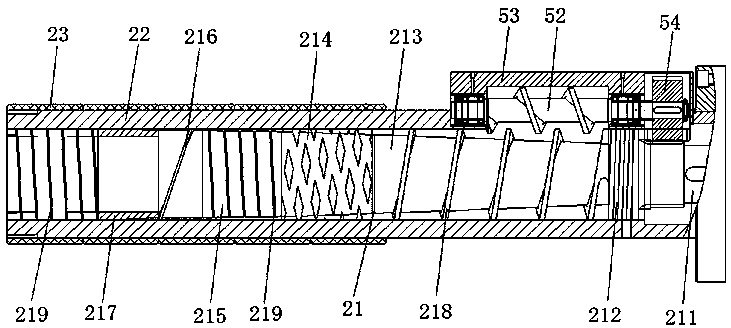

Foaming waste low-temperature cracking extruding machine and extruding method

The invention discloses a foaming waste low-temperature cracking extruding machine and an extrusion method, and belongs to the field of waste plasticizing extrusion. The foaming waste low-temperaturecracking extrusion method comprises the steps that a, a foaming waste cracking extrusion system is established, the foaming waste cracking extrusion system comprises a driving mechanism, an extrusionmechanism, and a feeding mechanism, and the feeding mechanism is connected with the extrusion mechanism; the extrusion mechanism comprises an extrusion screw and a screw barrel, the screw barrel is provided with a heating part, and the driving mechanism is connected with the extrusion screw in a transmission mode; and the extrusion screw comprises a connecting section, a feeding compression section, a crushing section, and a grinding section; b, the screw barrel is preheated by the heating part; c. the extrusion screw is driven through the driving mechanism to idle at a speed of no more than 40r / min; rotation speed of the extrusion screw is increased, preliminary feeding is conducted, and at the same time, the driving mechanism provides a low-temperature of 165 to 190 degrees; d, after discharging is normal, the extrusion screw rotates at a speed of 40 r / min to 50 r / min and keeps feeding; and e, discharged materials are collected. According to the foaming waste low-temperature crackingextruding machine and the extrusion method, low-temperature plasticizing extrusion is realized, waste recycling utilization rate is high, and effects of energy saving and environmental protection areachieved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

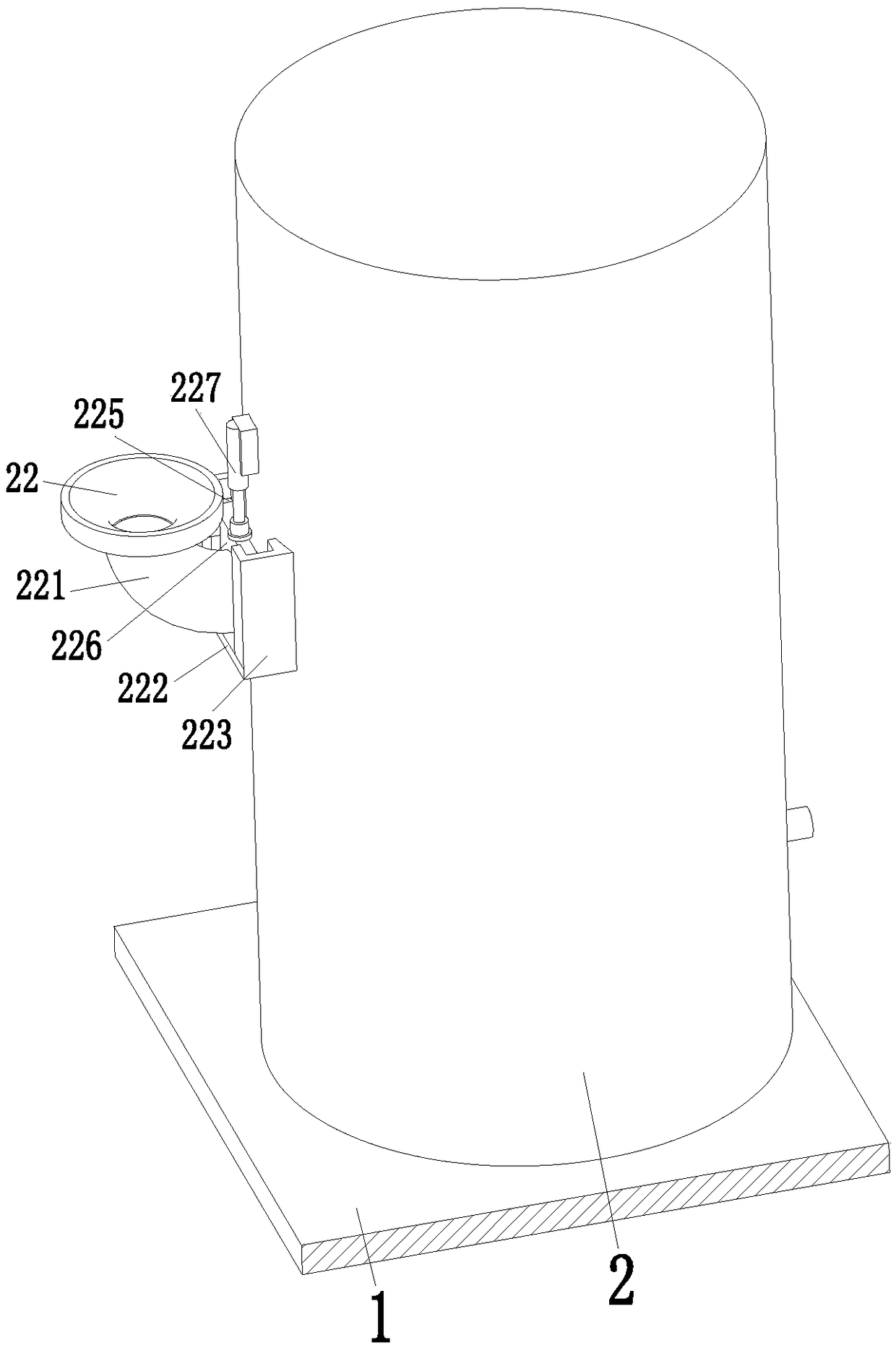

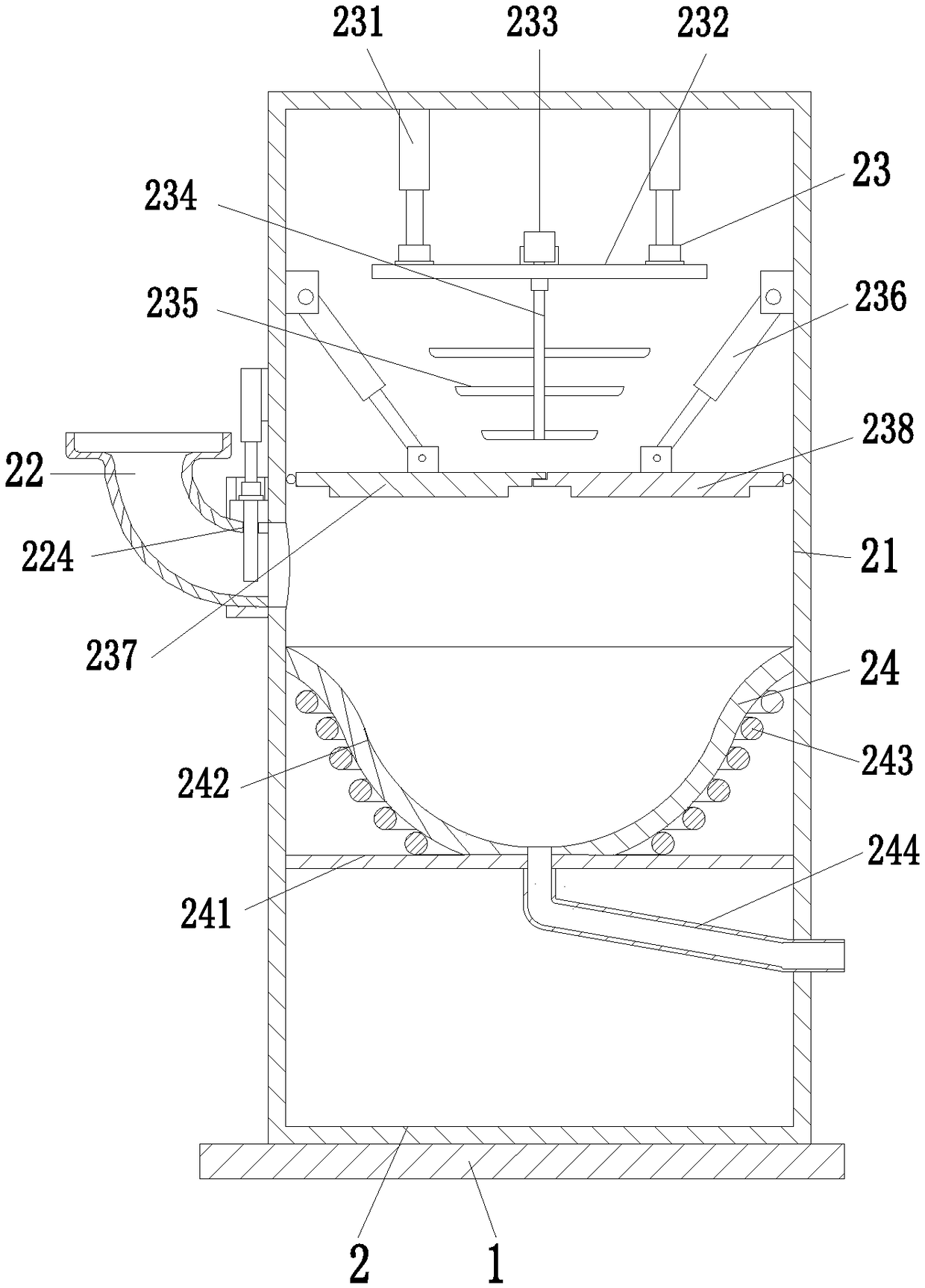

A kind of aluminum oxide refining industrial solid waste recycling processing equipment

The invention relates to recycling and processing equipment of industrial solid wastes in alumina refining. The recycling and processing equipment comprises a bottom plate, a mixing device and a waterquenching device, wherein the mixing device is arranged at an upper left end of the bottom plate, and the water quenching device is arranged at an upper right end of the bottom plate. The recycling and processing equipment has the advantages that the difficulties that the existing red-mud wastes are generally accumulated for storage, after long-time accumulation, the land and water sources are polluted, the use of the land and water sources is affected, the recycling rate of the red-mud wastes is low, when the red mud is used for manufacturing microcrystal glass, the production efficiency islow, the labor intensity is large, the red mud can not be uniformly mixed with added materials, the operation is complex, the labor intensity is large and the working efficiency is low and the like can be solved; the functions of automatic mixing, melting and water quenching for the red-mud wastes can be realized, the hazard of red-mud accumulation to the environment can be avoided, the recyclingrate of the red mud can be increased, the red mud can be uniformly mixed with the added materials, the manual operation can be avoided, the operation is simple, the labor intensity is low and the working efficiency is high and the like.

Owner:广西振钢再生资源有限公司

Environment-friendly indoor building material and preparation method thereof

The invention provides an environment-friendly indoor building material and a preparation method thereof, and relates to the field of building materials. The environment-friendly indoor building material includes the following raw materials in parts by weight: waste polyethylene foam, phosphate rock slag, foamed cement, nano rubber powder, glass micro Beads, hydroxypropyl methylcellulose, glass wool, quartz sand, gravel, activated carbon, air-entraining agent, water reducing agent, expansion agent, retarder, inorganic binder and water; the preparation method comprises the following steps: ( 1) Weighing raw materials, (2) crushing, (3) stirring, (4) molding into molds. The invention solves the problems of insufficient energy saving, environmental protection and flame retardancy of existing indoor building materials.

Owner:中科协创环境科技江苏有限公司

Magnesium oxychloride cement aggregate and preparation method thereof

InactiveCN101973720ATake advantage ofImprove wear resistanceMagnesium chloride hexahydrateUltimate tensile strength

The invention provides magnesium oxychloride cement aggregate which comprises active magnesium oxide, magnesium chloride hexahydrate and glass, wherein the weight rate of magnesium oxide in the active magnesium oxide to the magnesium chloride hexahydrate to the glass is 1:0.9 to 1.1:0.1 to 1, part of glass is distributed in magnesium oxychloride cement and can generate brittle fracture for enhancing the strength of the magnesium oxychloride cement; the other part of the glass is distributed on the surface of the magnesium oxychloride cement for reinforcing the wear resistance of the magnesium oxychloride cement; and because the glass is used as a filler of the magnesium oxychloride cement, not only waste glass resources are thoroughly utilized but also the wear resistance and the strength of the magnesium oxychloride cement are better improved.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Lithium-sulfur battery positive electrode material and preparation method thereof

InactiveCN109494366ASimple processEasy to operatePositive electrodesLi-accumulatorsCarbon compositesPorous carbon

The invention discloses a lithium-sulfur battery positive electrode material and a preparation method thereof. Specifically, the lithium-sulfur battery positive electrode material is a sulfur-carbon composite material containing porous-structured carbon with in-situ doped nitrogen and sulfur elements. The preparation method of the lithium-sulfur battery positive electrode material comprises (1) ina high-temperature inert gas atmosphere, carbonizing silkworm excrement to obtain a carbon material with in-situ doped nitrogen and sulfur elements; (2) activating the carbon material through potassium hydroxide to obtain porous carbon; (3) mixing the porous carbon with sulfur at high temperature to obtain the sulfur-carbon composite positive electrode material. According to the sulfur-carbon composite positive electrode material, the carbon and the active sulfur achieve relatively strong physical and chemical effects to effectively inhibit shuttle effects and meanwhile can improve the utilization rate and the structural stability of sulfur. The prepared lithium-sulfur battery positive electrode material is excellent in electrochemical performance and low in cost and has a broad application prospect.

Owner:NANCHANG UNIV

Hydroquinone preparation method

ActiveCN104628527ALow recycling rateIncrease production costOrganic chemistryOrganic compound preparationHydroquinone CompoundPotassium hydroxide

The present invention relates to a hydroquinone preparation method, especially to a method for preparing hydroquinone by adopting a supported solid alkali as a catalyst and carrying out an alkaline hydrolysis reaction on p-chlorophenol and a potassium hydroxide solution. According to the present invention, the supported solid alkali is adopted as the catalyst, the p-chlorophenol and the potassium hydroxide solution are subjected to an alkaline hydrolysis reaction at a certain temperature, the alkaline hydrolysis solution is filtered to recover the catalyst so as to be applied indiscriminately, the filtrate is acidified with hydrochloric acid to achieve the pH value of 2-3, the reaction product is extracted with methyl isobutyl ketone, and the raw material content and the product content in the raffinate are less than 0.05%.

Owner:JIANGSU YANGNONG CHEM GROUP +2

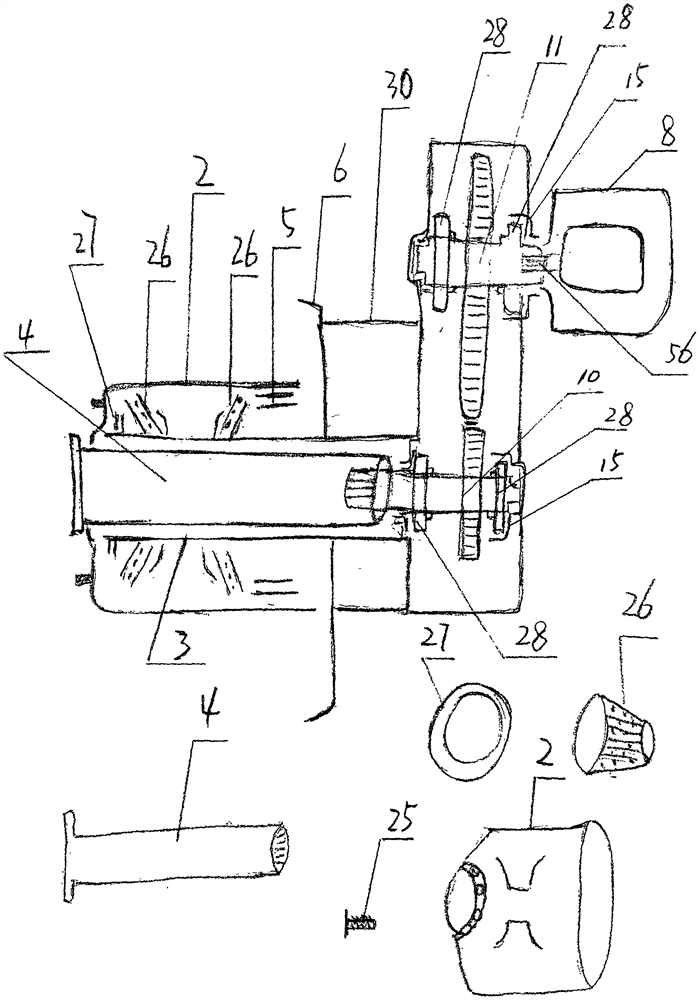

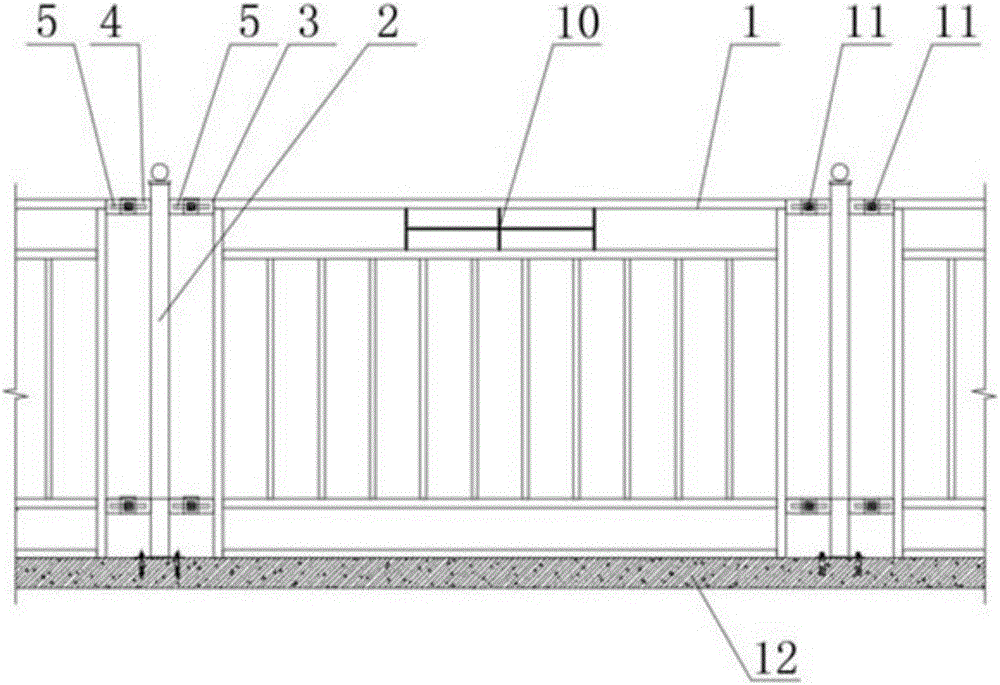

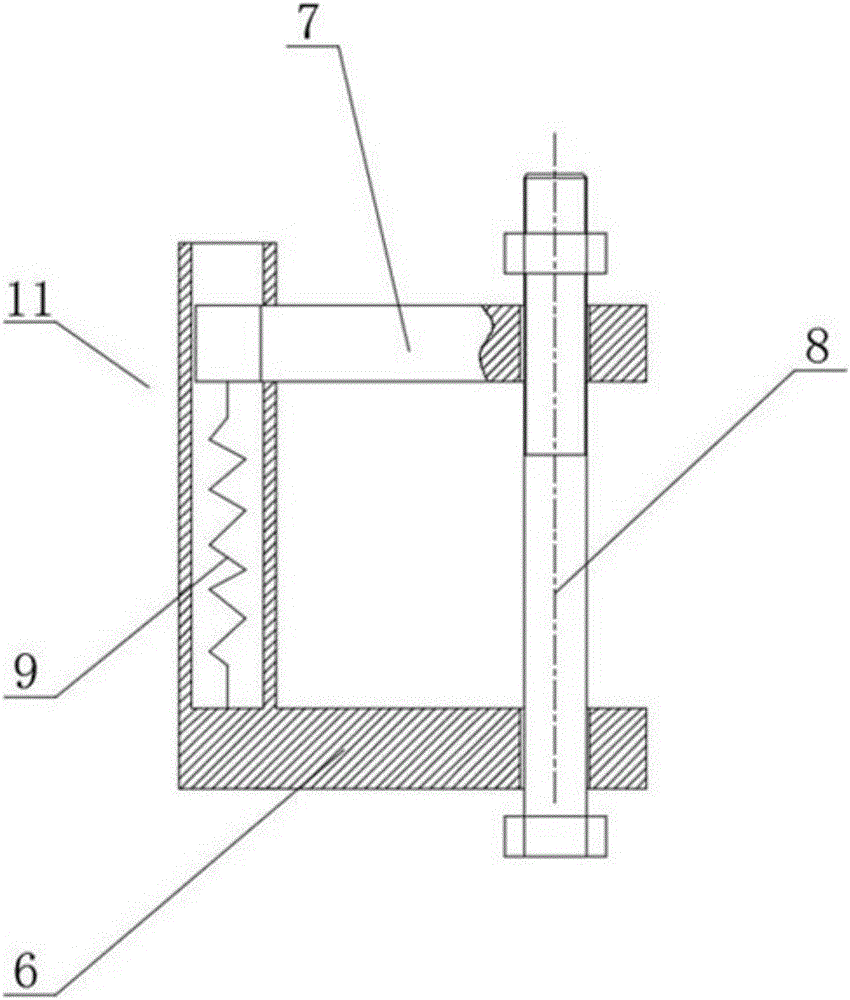

Building protection device

ActiveCN105756361ALow recycling rateImprove recycling ratesTraffic signalsBuilding material handlingEngineering

The invention discloses a building protection device which comprises a plurality of guardrail bodies (1), a plurality of fixed upright posts (2) and an F-shaped locking device (11), wherein the fixed upright posts (2) are arranged on the ground (12); the guardrail bodies (1) and the fixed upright posts (2) are alternately connected through the locking device (1) in sequence. The building protection device is simple in structure and convenient to use, rapid assembly and disassembly can be carried out in the using process; the assembly and disassembly time is greatly shortened; certain work efficiency is improved; meanwhile, the building protection device can be recycled for installation and use for a plurality of times; the recovery rate of the guardrails are improved; and the use cost is greatly reduced.

Owner:LINYI UNIVERSITY

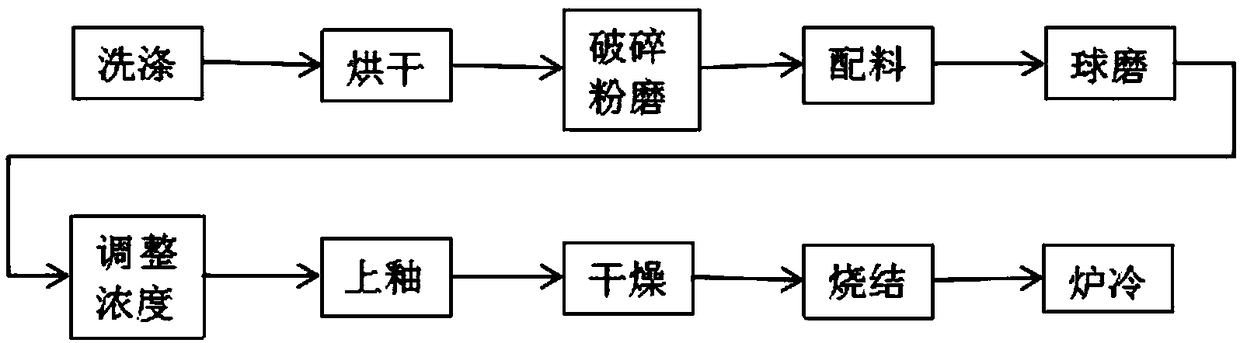

Waste beer bottle ceramic color glaze production and application method

The invention relates to a method for producing a ceramic color glaze by using waste beer bottle. The waste beer bottle is used as a main raw material to produce the ceramic color glaze, on one hand,the problem of difficult comprehensive treatment of the waste beer bottle is solved, on the other hand, the problem of high production cost of the current ceramic color glaze is solved, and the production cost of the ceramic product is reduced. The color glaze comprises the following raw materials: 30-100% of waste beer bottles, 0-5% of kaolin, 0-17% of quartz, 0-27% of albite, 0-3% of potash feldspar, 0-5% of limestone, 0-5% of dolomite, 0-8% of zinc oxide, and 0-3% of barium carbonate. The ceramic color glaze employs the waste beer bottle as the main raw material, processes of burdening, ball milling, and glazing and the like are carried out, and the ceramic color glaze can be obtained through high-temperature calcining. The ceramic color glaze has the advantages of high glaze quality, and controllable color and type. The raw material cost is low, the production technology is simple, and the ceramic color glaze production and application method has obvious economic benefit and socialbenefit.

Owner:FUJIAN UNIV OF TECH

Powder metallurgy titanium-based alloy waste precious metal recycling equipment

ActiveCN110373550AImprove reaction efficiencyLow recycling rateProcess efficiency improvementPowder metallurgyScrap

The invention provides powder metallurgy titanium-based alloy waste precious metal recycling equipment. The powder metallurgy titanium-based alloy waste precious metal recycling equipment comprises amain body, a reaction cavity is internally provided with a reaction cavity body with an opening being upward, the inner wall of the lower side of the reaction cavity body is fixedly provided with a supporting vertical column, the supporting vertical column and the inner wall of the lower side of the reaction cavity body are internally provided with extraction liquid circulation devices, the supporting vertical column is externally provided with supporting sleeve columns capable of sliding relative to the supporting vertical column in a sleeved manner, the arc-shaped end faces of the outer sides of the supporting sleeve columns are fixedly provided with a material placing rack device, the material placing rack device can be used for placing titanium alloy waste to be recycled, the inner walls of the left and right two sides of the reaction cavity body are internally provided with lifting cavities communicating with each other, and the lifting cavities are internally provided with liftable devices. The powder metallurgy titanium-based alloy waste precious metal recycling equipment aims to design a device capable of recycling precious metals in a titanium-based alloy through a soakingreaction method.

Owner:济南之舜再生资源利用有限公司

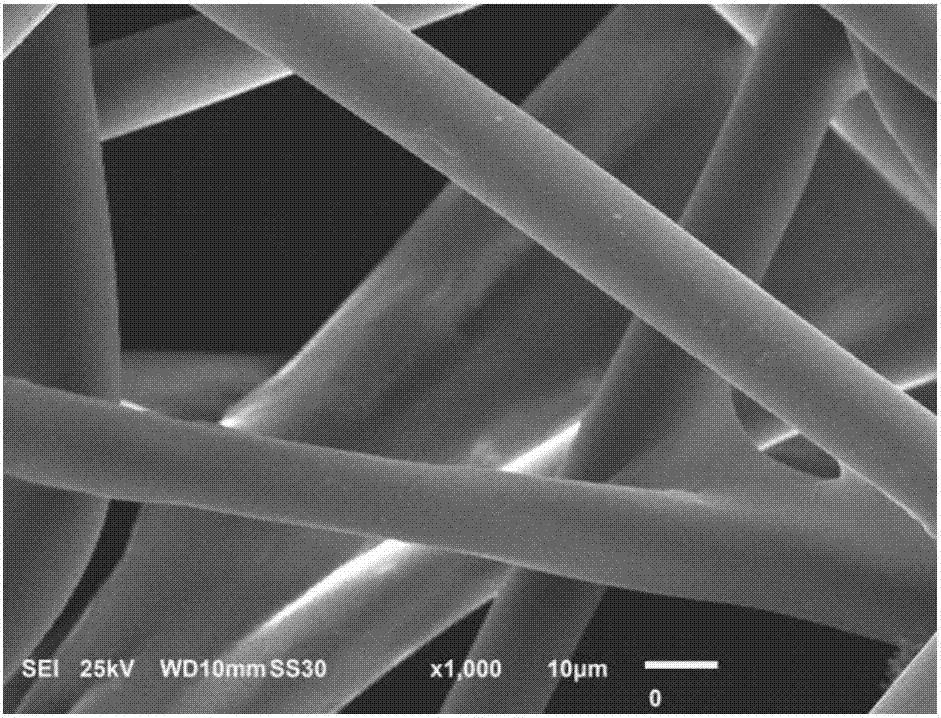

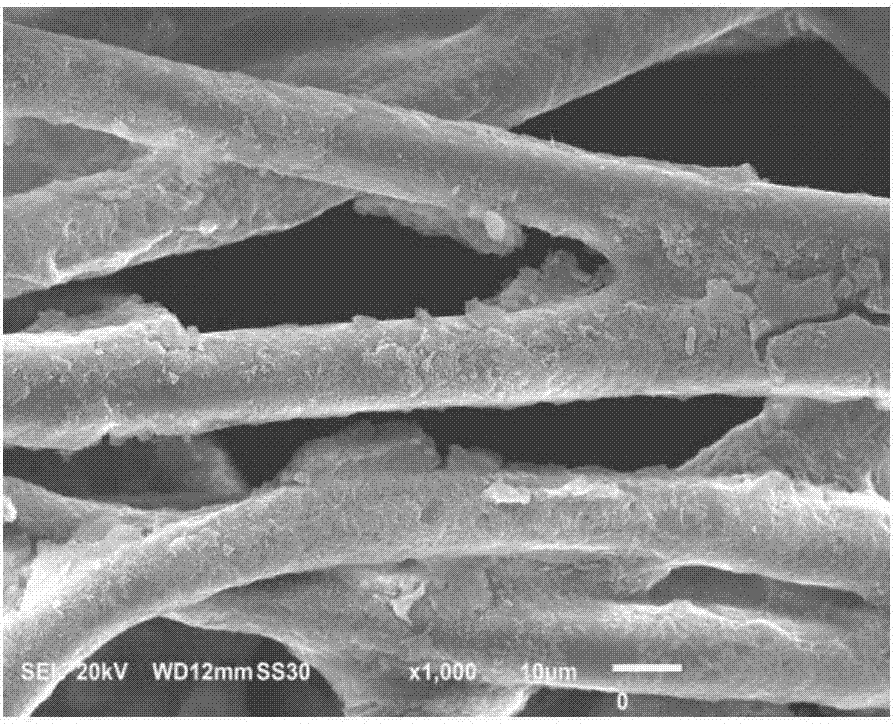

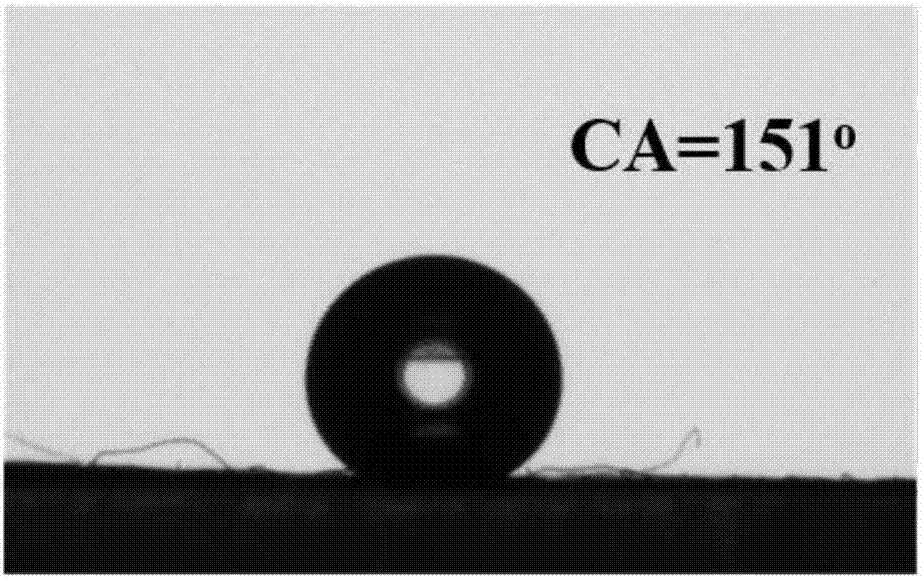

Preparation method and application of superhydrophobic non-woven material prepared from P(DVB (Divinyl Benzene)-VTES(Vinyl Triethoxysilane))

InactiveCN107151918ALow recycling rateReduce waste of resourcesFibre treatmentLiquid separationPolymer scienceTriethoxysilane

The invention provides a preparation method of a superhydrophobic non-woven fabric material prepared from P(DVB (Divinyl Benzene)-VTES(Vinyl Triethoxysilane)). The preparation method is characterized by comprising the following steps: step one, carrying out solvothermal reaction on a mixed solution which is impregnated with a non-woven fabric and contains DVB and VTES in the presence of a catalyst; step two, soaking a product obtained in the step one with an alkaline solution to obtain the superhydrophobic non-woven fabric material prepared from the P(DVB-VTES). According to the preparation method of the superhydrophobic non-woven material prepared from the P(DVB-VTES), provided by the invention, the non-woven fabric is used as a carrier; most non-woven fabrics are used as packaging materials and have extremely-low recycling rate; according to the preparation method provided by the invention, the waste of resources is greatly reduced.

Owner:JIANGSU UNIV

Hybrid energy storage system based on ordered energy control

ActiveCN103117552BIncrease capacityHigh specific energyAc network load balancingPower qualityEnergy control

The invention relates to a hybrid energy storage system comprising various energy storage carriers. The system is mainly based on an ordered energy control strategy, the energy storage carriers are selectively discharged in a current-limiting or power-limiting mode through a pulse width modulation (PWM) closed-loop control principle and a monitoring system selective control principle, the advantages of the energy storage carriers are combined and complemented, the disadvantages of the energy storage carriers are overcome, and the aim of ordered energy utilization of different energy storage carriers is fulfilled according to a discharge priority sequence, namely a third energy storage subsystem, a second energy storage subsystem and a first energy storage subsystem. By the hybrid energy storage system, the phenomenon that the power of a power grid fluctuates because a wind and light power generation system or a high-power load and the like are connected to the power grid is avoided, smoothing compensation is realized, the quality of electric energy is improved, and the stable operation of the power grid is ensured.

Owner:STATE GRID CORP OF CHINA +1

A method of soaking cadmium-containing waste acid solution in acid to prepare wrapped pure yellow pigment

A method of soaking cadmium-containing waste acid solution in acid to prepare coated yellow pigments. The cadmium-containing wastewater treated by acid soaking is directly used to produce zirconium silicate microcrystals to wrap cadmium sulfide pigments, and zinc ions are introduced into doped zinc ions through zinc sulfate to form cadmium sulfide. , Zinc sulfide solid solution chromogenic agent, producing pure yellow pigment coated with cadmium zinc sulfide crystallite zirconium silicate. The present invention utilizes zirconium oxychloride, zinc sulfate and acid to soak waste acid solution containing cadmium and selenium to carry out chemical co-precipitation reaction in the reactor with sodium hydroxide and sodium sulfide. After the reaction is completed, carry out pressure filtration washing and drying; The ratio is mixed with mineralizer and white carbon black evenly, after high-temperature calcination, the calcined product is subjected to acidification, ball milling, pressure filtration, water washing processes, and dried to obtain zirconium silicate-wrapped cadmium sulfide yellow pigment or wrapped zinc cadmium sulfide-wrapped pure yellow Pigment products. Encapsulated pure yellow pigment can be used instead of praseodymium yellow pigment.

Owner:LILING KEXING IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com