Sewage advanced treatment and recycling method capable of substantially raising economy

A technology for advanced treatment and sewage, which is applied in the direction of water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high treatment load, low removal rate of COD and suspended matter, and failure issues such as recycling standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

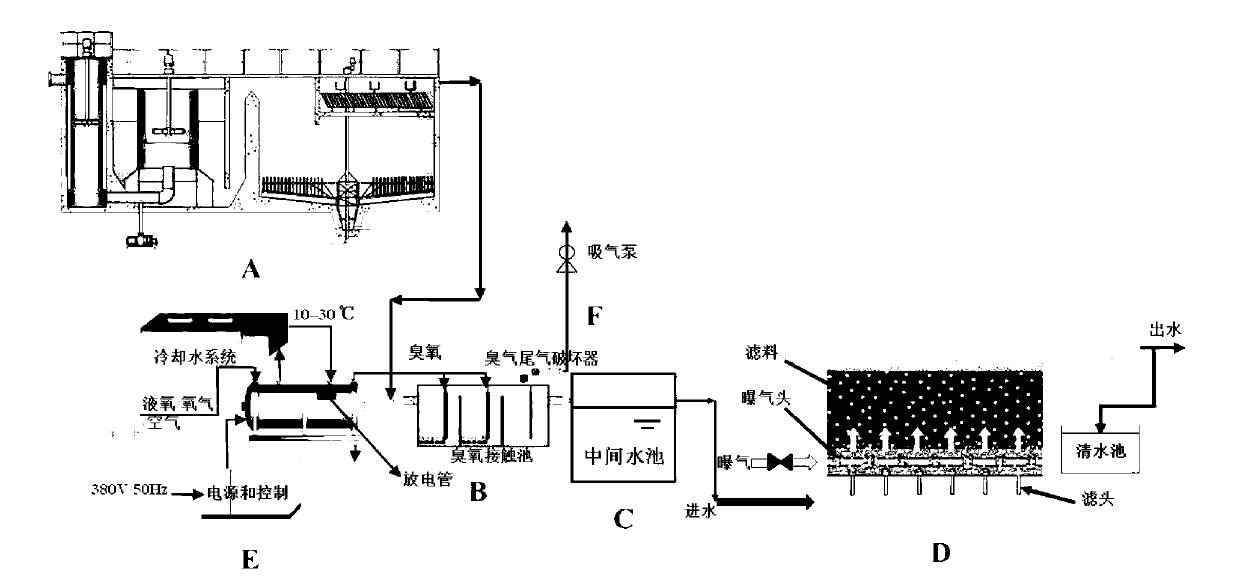

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

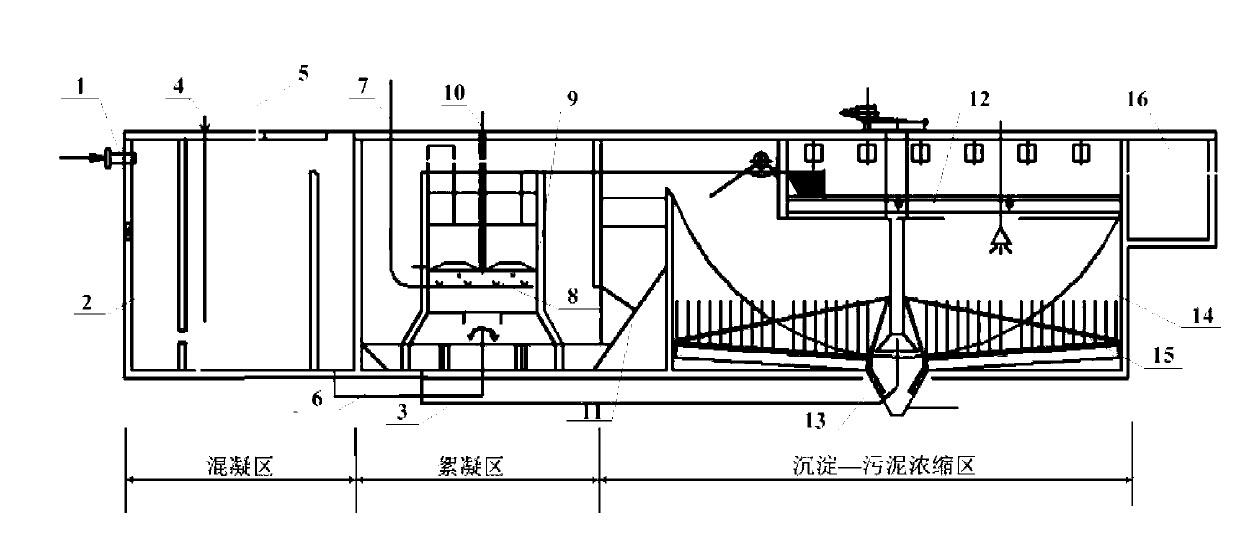

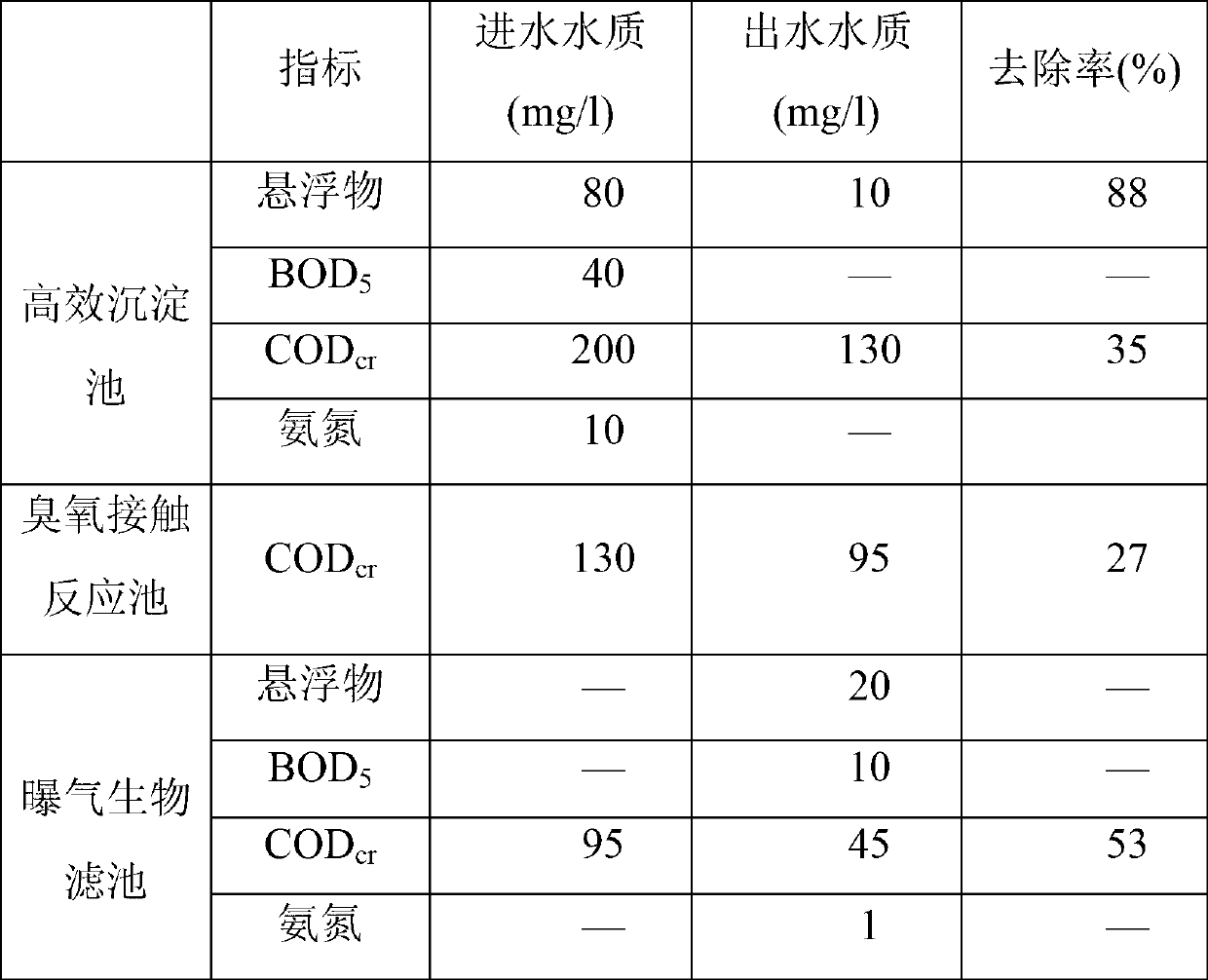

[0030] see figure 1 , The advanced treatment process of wastewater is a set of technological process including high-efficiency sedimentation tank A, ozone contact reaction tank B and biological aerated filter D as the main devices, supplemented by the use of ozone tail gas. see figure 2 , the sewage after the secondary treatment first enters the high-efficiency sedimentation tank and enters the micro-vortex hydraulic mixer 2 through the water inlet pipe 1. In this pool, an automatic dosing device 4 is used to add coagulant, such as polymerized FeCl with a content of 41%. 3 , lime, etc., the dosage is automatically adjusted according to the water inflow. A common dosing room is set up at the operation site to store medicines, and it is equipped with a liquid medicine dispensing system. The coagulant added is stirred with a coagulation agitator 5 to fully contact the poll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com