Method for recycling tantalum from tantalum-containing alloy waste

A technology of tantalum alloy and scrap, which is applied in the field of hydrometallurgy, can solve the problems of high-efficiency recovery that have not been found yet, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

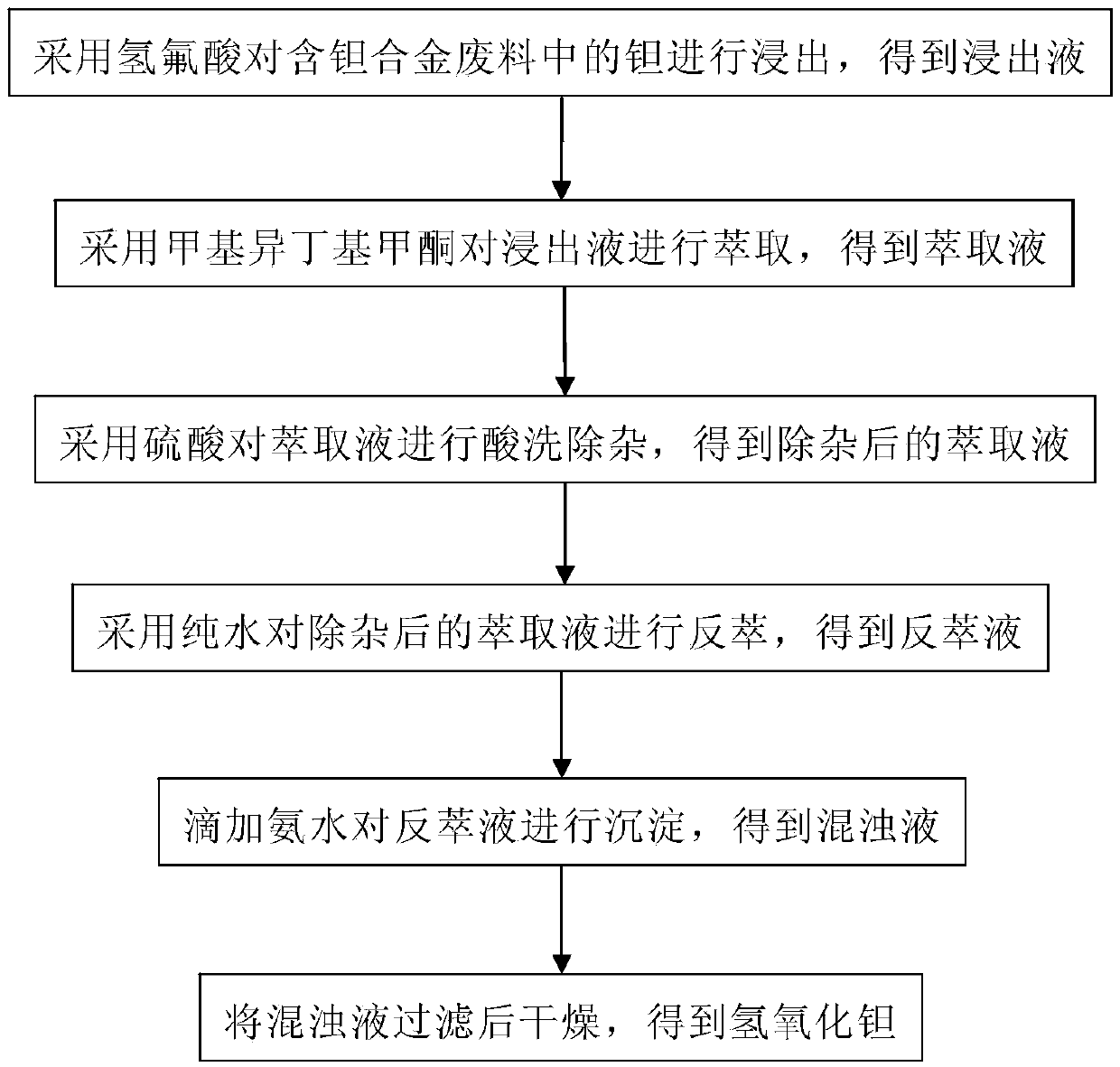

[0032] The main metal components of the tantalum-containing alloy scrap to be treated in this embodiment are calculated by weight percentage: Ta34.98%, Ti17.27%, Hf16.93%, W1.74%, Fe0.96%, Ni0.75%, Cr0.36%. combine figure 1 The method for recovering tantalum from tantalum-containing alloy waste in this embodiment comprises the following steps:

[0033] Step 1. Weigh 15g of tantalum-containing alloy waste, then measure 90mL of hydrofluoric acid with a concentration of 12mol / L according to the solid-to-liquid ratio of 1:6, and then use hydrofluoric acid as the leaching agent to leach tantalum in the tantalum-containing alloy waste treatment, the temperature of the leaching treatment is 90°C, and the time of the leaching treatment is 1.5h to obtain a tantalum-containing leach solution; in the specific implementation process, hydrofluoric acid and tantalum-containing alloy waste can be placed together in a 500mL polytetrafluoroethylene beaker , and then seal the mouth of the bea...

Embodiment 2

[0041] The main metal components of the tantalum-containing alloy scrap to be treated in this embodiment are calculated by weight percentage: Ta31.75%, Nb15.26%, Ti13.58%, Hf11.36%, W1.17%, Zr1.03%, Fe0.78%, Ni0.66%, Cr0.55%. combine figure 1 The method for recovering tantalum from tantalum-containing alloy waste in this embodiment comprises the following steps:

[0042] Step 1. Weigh 15g of tantalum-containing alloy waste, then measure 135mL of hydrofluoric acid with a concentration of 11mol / L according to the solid-to-liquid ratio of 1:9, and then use hydrofluoric acid as the leaching agent to leach the tantalum in the tantalum-containing alloy waste treatment, the temperature of the leaching treatment is 85°C, and the time of the leaching treatment is 2.5h to obtain a tantalum-containing leach solution; in the specific implementation process, hydrofluoric acid and tantalum-containing alloy waste can be placed together in a 500mL polytetrafluoroethylene beaker , and then sea...

Embodiment 3

[0050] The main metal components of the tantalum-containing alloy waste to be treated in this embodiment are calculated by weight percentage: Ta20.12%, Nb17.58%, Ti13.11%, Hf13.06%, Zr4.15%, Fe0.62%, Ni0.49%, Cr0.47%, Co0.11%. combine figure 1 The method for recovering tantalum from tantalum-containing alloy waste in this embodiment comprises the following steps:

[0051] Step 1. Weigh 15g of tantalum-containing alloy waste, and then measure 120mL of hydrofluoric acid with a concentration of 8mol / L according to the solid-to-liquid ratio of 1:8, and then use hydrofluoric acid as the leaching agent to leach tantalum in the tantalum-containing alloy waste treatment, the temperature of the leaching treatment is 70°C, and the time of the leaching treatment is 2 hours to obtain a tantalum-containing leach solution; in the specific implementation process, hydrofluoric acid and tantalum-containing alloy waste can be placed together in a 500mL polytetrafluoroethylene beaker, Then sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com