Magnesium oxychloride cement aggregate and preparation method thereof

A technology of magnesium oxychloride cement and aggregate, applied in the field of cement materials, can solve the problems such as poor water resistance, easy deformation of products, returning to halogen and frosting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

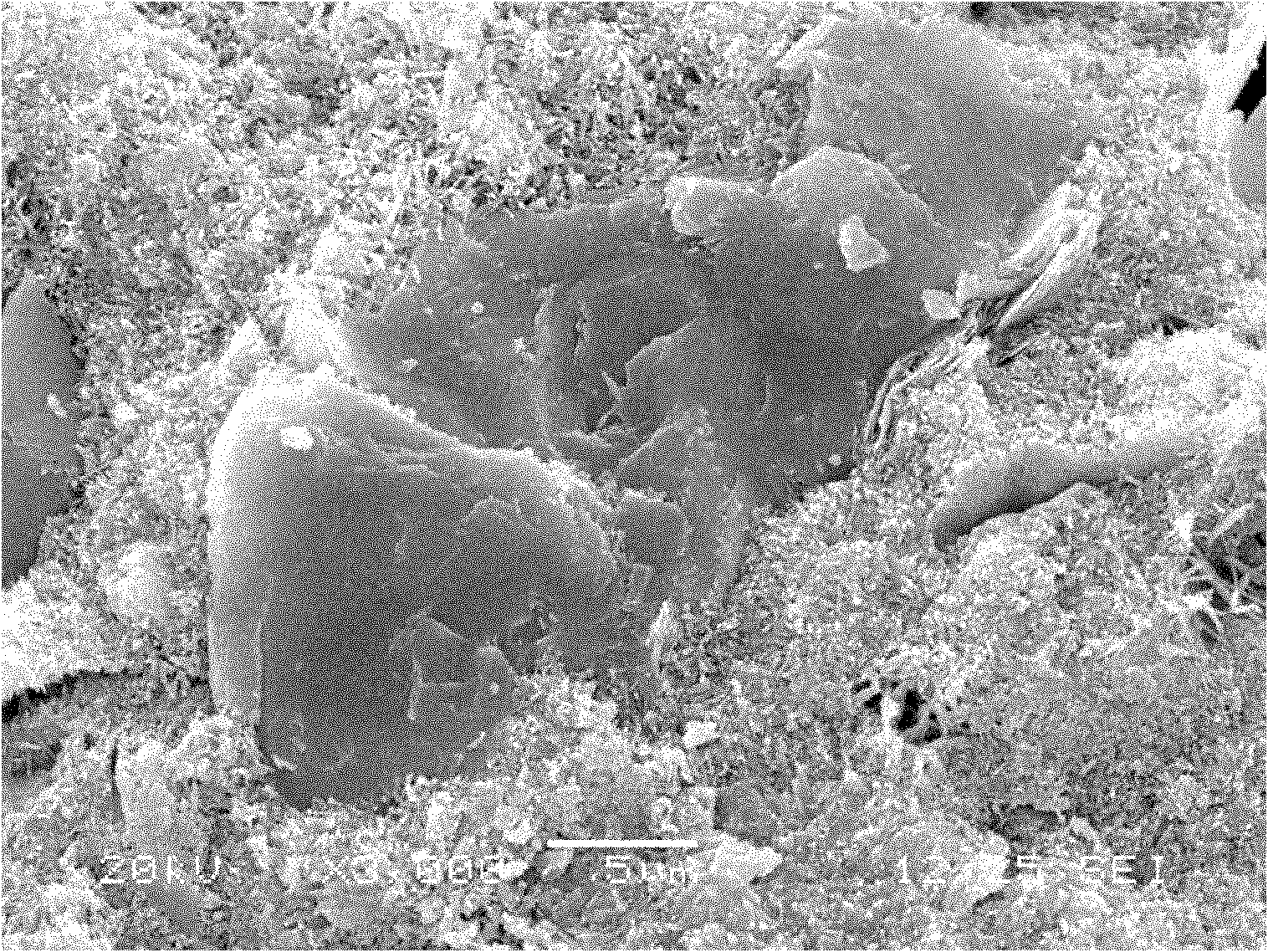

Image

Examples

Embodiment 1

[0016] The glass is crushed and sieved to obtain coarse glass with a mass percentage of 60% and a particle size greater than 40 mesh. Part of the coarse glass is crushed and sieved to obtain fine glass with a particle size of less than 160 meshes with a mass percentage of 50%. The above fine glass and coarse glass are mixed according to a mass ratio of 1:0.5 to obtain a glass mixture. Active magnesium oxide, magnesium chloride hexahydrate and glass mixture are mechanically stirred and mixed to obtain the magnesium oxychloride cement aggregate 1, wherein the mass ratio of magnesium oxide, magnesium chloride hexahydrate and glass mixture in the active magnesium oxide is 1:1 : 0.176.

[0017] The magnesium oxychloride cement aggregate 1 is cured by adding water at room temperature, its compressive strength is 56.3Mpa, and its mass loss in the abrasion resistance test is 1%. Under the same conditions, the blank magnesium oxychloride cement aggregate without adding glass was soli...

Embodiment 2

[0019] The glass is crushed and sieved to obtain coarse glass with a particle size greater than 40 mesh. Part of the coarse glass is crushed and sieved to obtain fine glass with a particle size of less than 160 mesh. The above fine glass and coarse glass are mixed according to a mass ratio of 1:0.1 to obtain a glass mixture. Active magnesium oxide, magnesium chloride hexahydrate and glass mixture are mechanically stirred and mixed to obtain the magnesium oxychloride cement aggregate 2, wherein the mass ratio of magnesium oxide, magnesium chloride hexahydrate and glass mixture in the active magnesium oxide is 1:0.9 : 0.5.

Embodiment 3

[0021] The glass is crushed and sieved to obtain coarse glass with a particle size greater than 40 mesh. Part of the coarse glass is crushed and sieved to obtain fine glass with a particle size of less than 160 mesh. The above fine glass and coarse glass are mixed according to a mass ratio of 1:0.01 to obtain a glass mixture. Active magnesium oxide, magnesium chloride hexahydrate and glass mixture are mechanically stirred and mixed to obtain the magnesium oxychloride cement aggregate 3, wherein the mass ratio of magnesium oxide, magnesium chloride hexahydrate and glass mixture in the active magnesium oxide is 1:1.1 : 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com