Acid-soaked cadmium-selenium contained acid pickle direct recycling method

A waste acid liquid and acid immersion technology, which is applied in the field of ceramic pigment production, to achieve the effects of easy recycling, reducing environmental pollution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

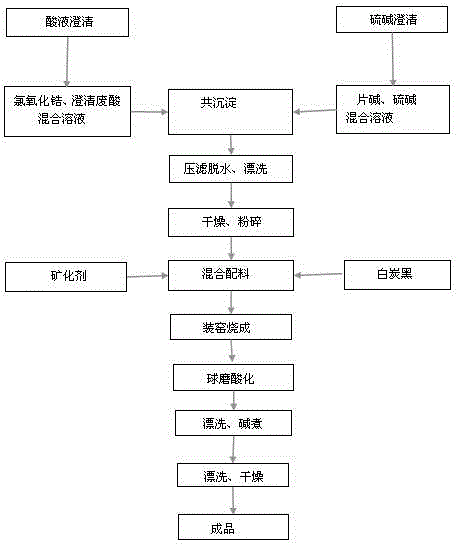

Method used

Image

Examples

Embodiment

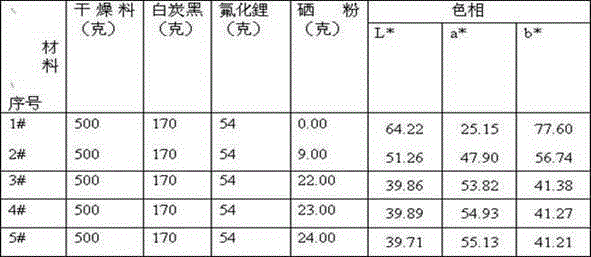

[0039] A method for direct recycling of waste acid liquid containing cadmium and selenium after acid soaking, using zirconium oxychloride, sodium hydroxide and sodium sulfide to process the waste acid liquid containing cadmium and selenium after acid soaking in the production of wrapped color materials; zirconium oxychloride and Acid soaking waste acid solution containing cadmium and selenium to prepare an acidic mixed solution, adding sodium hydroxide and sodium sulfide to prepare an alkaline mixed solution according to the required amount of water, then adding the acidic mixed solution to the alkaline mixed solution, and stirring After reacting with chemical reaction, press filter washing, dry, mix with mineralizer, white carbon black, selenium powder evenly, then calcined at high temperature, and the calcined product is acidified, ball milled, press filtered, washed with water, alkali boiled, press filtered 1. The process of washing with water, and drying to obtain a zirconi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com