Patents

Literature

55results about How to "High recycling cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

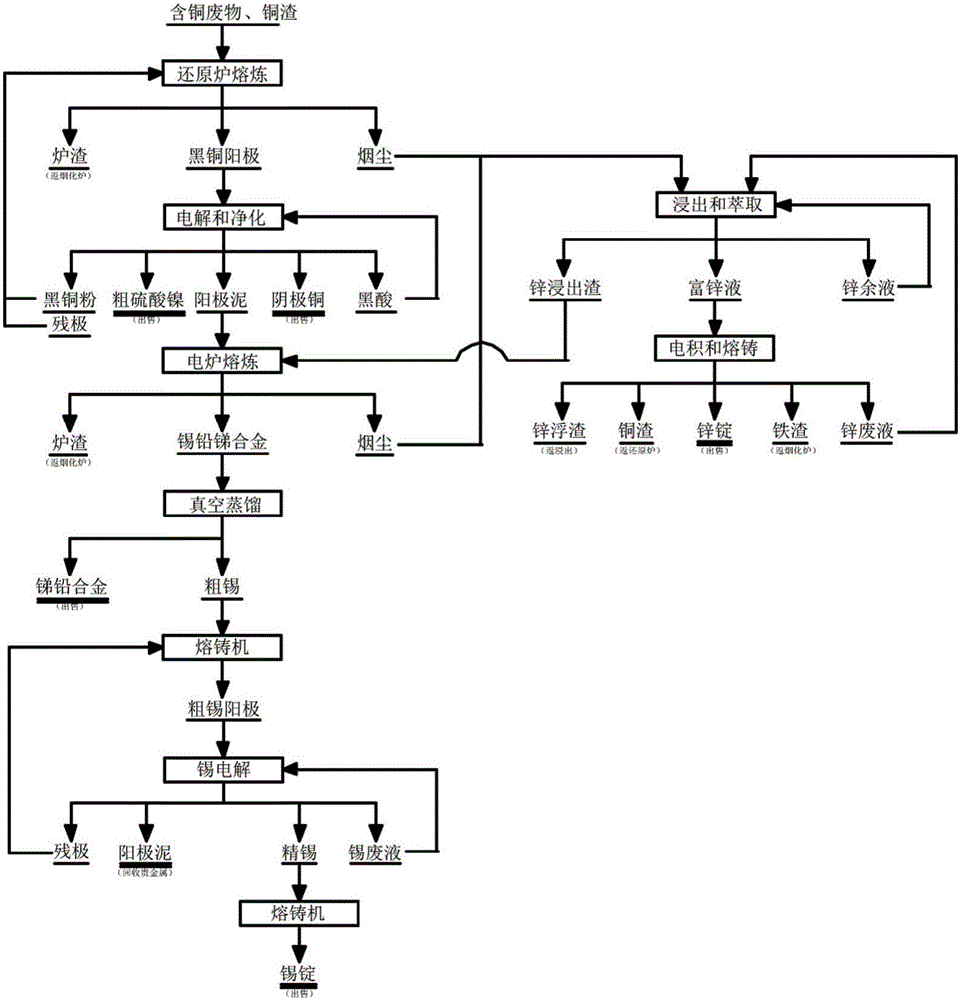

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

Process for producing polyarylene sulfide

There is disclosed a process for producing a polyarylene sulfide (PAS) which comprises reacting a sulfur source with a dihalogenated aromatic compound in the presence of an aprotic organic solvent, characterized in that the process comprises at least one polymerization reaction step wherein a polymer phase as a dispersed phase is in the form of spherical droplets. It is made possible by the continuous polymerization process to discharge the polymer phase and solvent phase from a polymerization vessel at a constant ratio and as a result, to maintain PAS composition (concentration) at a constant level at all times, and thus to provide a continuous PAS production process which is effective for enhancing its molecular weight and stabilizing the same.

Owner:IDEMITSU KOSAN CO LTD +1

Method for preparing silk protein composite cellulose fibers

ActiveCN102505170AHigh recycling valueLow viscosityArtificial filaments from viscoseProtein solutionSulfonate

The invention discloses a method for preparing silk protein composite cellulose fibers, which includes steps: firstly, adding degummed waste silk into LiBr solution, dissolving the waste silk to prepare silk protein solution in which silk protein accounts for 3-15%, by weight; secondly, adding the silk protein solution into sodium hydroxide solution with cellulose sulfonate to obtain blended solution of silk protein and cellulose, wherein blended silk protein solution accounts for 5-50% of that of the sodium hydroxide with cellulose sulfonate by weight; and thirdly, spinning the blended solution by coagulating bath and obtaining the silk protein composite cellulose fibers by post-processing. By the method, recovery value of the waste silk is improved greatly, special effects of whitening and skin caring of the silk protein composite cellulose fibers can be realized, and the fibers are smooth and soft to touch as silk, and have the skin caring and whitening effects that the effects of protein powder fibers or blended fibers of protein powder and cellulose solution cannot match.

Owner:赛得利(盐城)纤维有限公司

Method for recovering germanium from germanium-containing smoke dust

ActiveCN102181653ALow recovery rateHigh recycling costProcess efficiency improvementResource utilizationDistillation

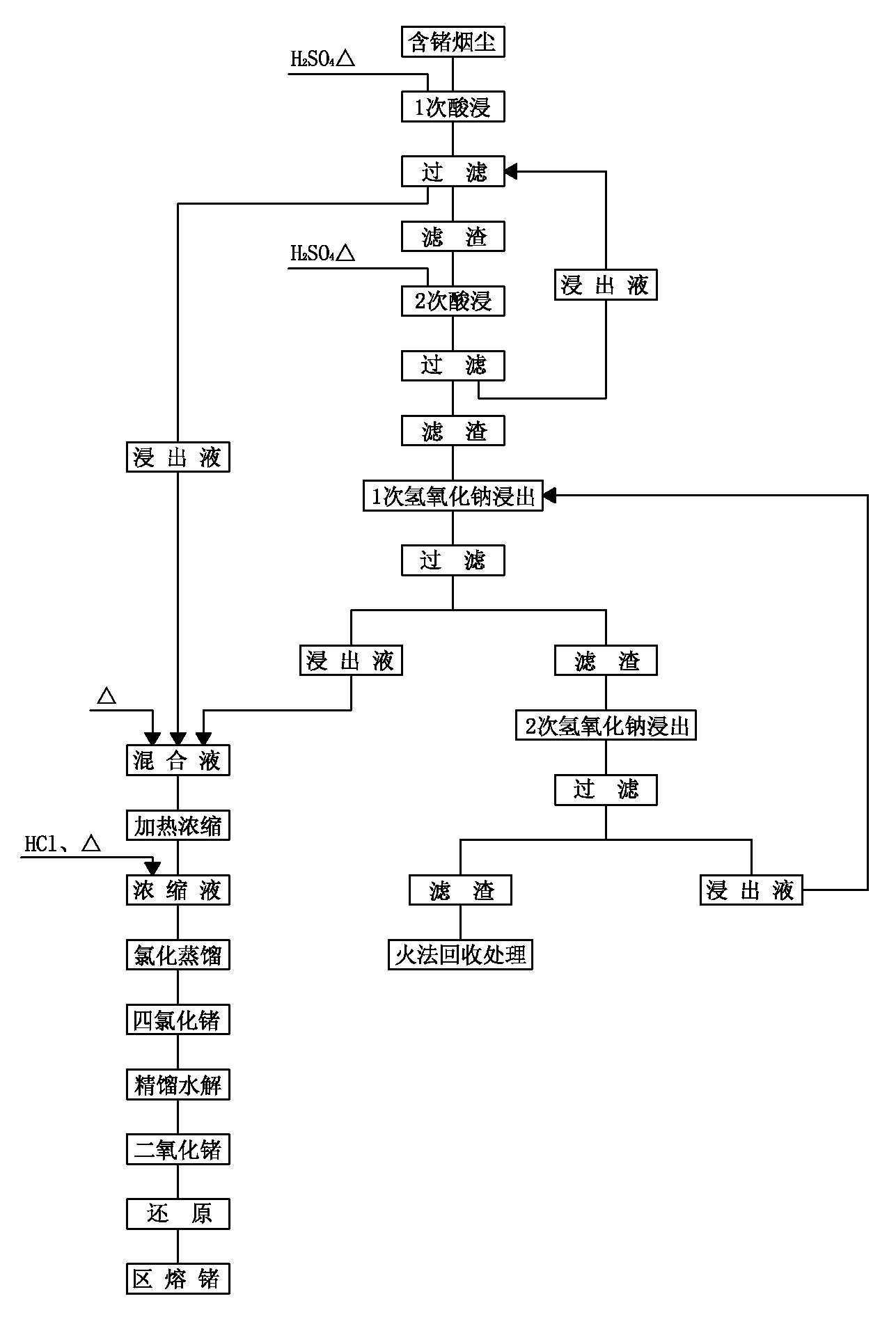

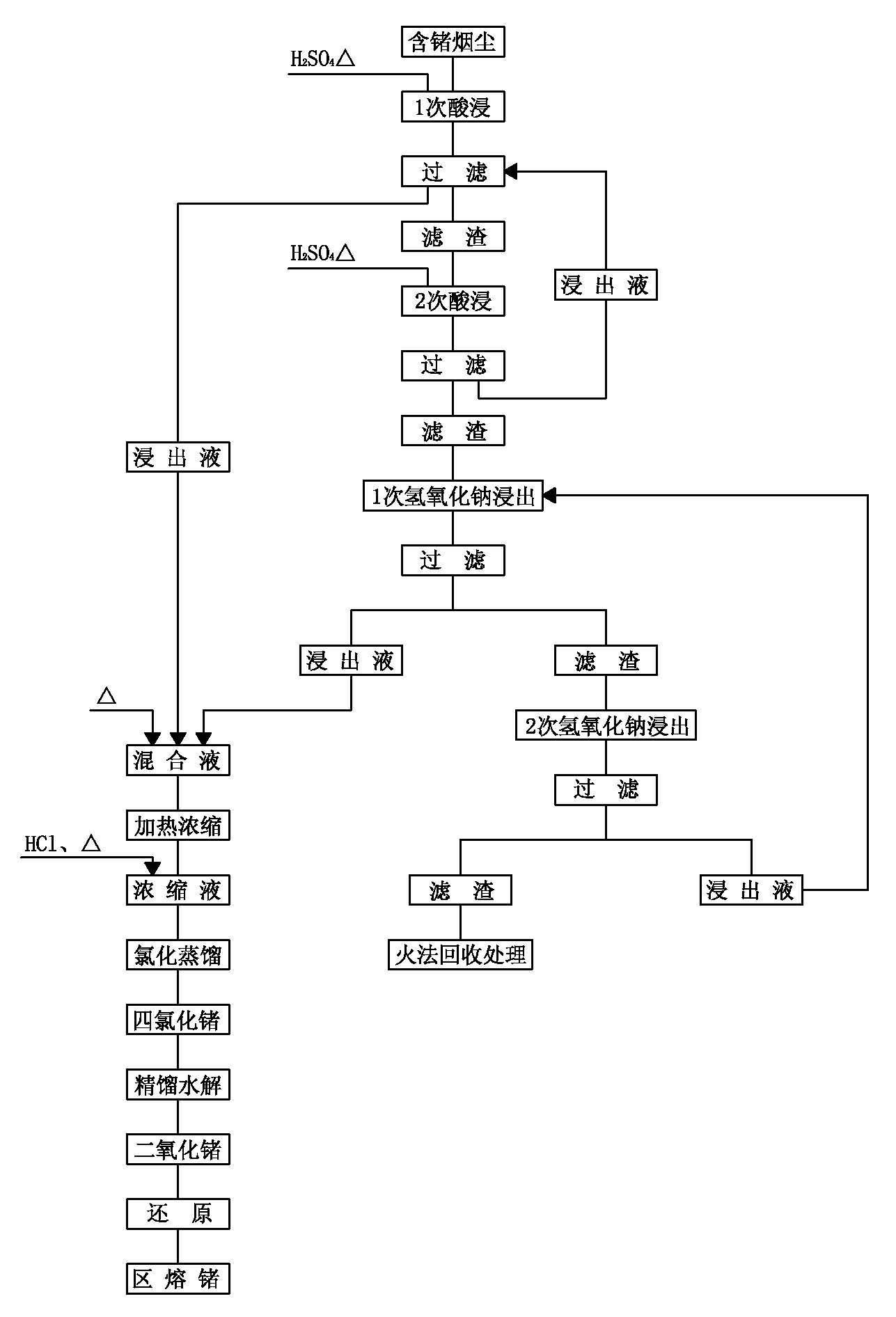

The invention relates to a method for recovering germanium from germanium-containing smoke dust, in particular to a method for leaching the germanium-containing smoke dust by using sulfuric acid and sodium hydroxide sequentially and recovering the germanium from the germanium-containing smoke dust by hydrochloric acid distillation, and relates to the technical field of wet-process metallurgy. The method is realized by processes of leaching by the sulfuric acid twice, leaching by the sodium hydroxide twice, neutralizing leachate, performing evaporating and concentrating, chloridizing and distilling, preparing germanium dioxide and the like. In the method for recovering the germanium, the recovery rate of the germanium is more than 93 percent, so the successful study of the method has a great positive significance for the solving of problems of low recovery rate, high recovery cost and low resource utilization rate of the germanium in the germanium-containing smoke dust, a problem that distillation residues are needed to be processed repeatedly and a problem that environmental pollution is serious and the like.

Owner:LINCANG JIECAIBA COAL IND

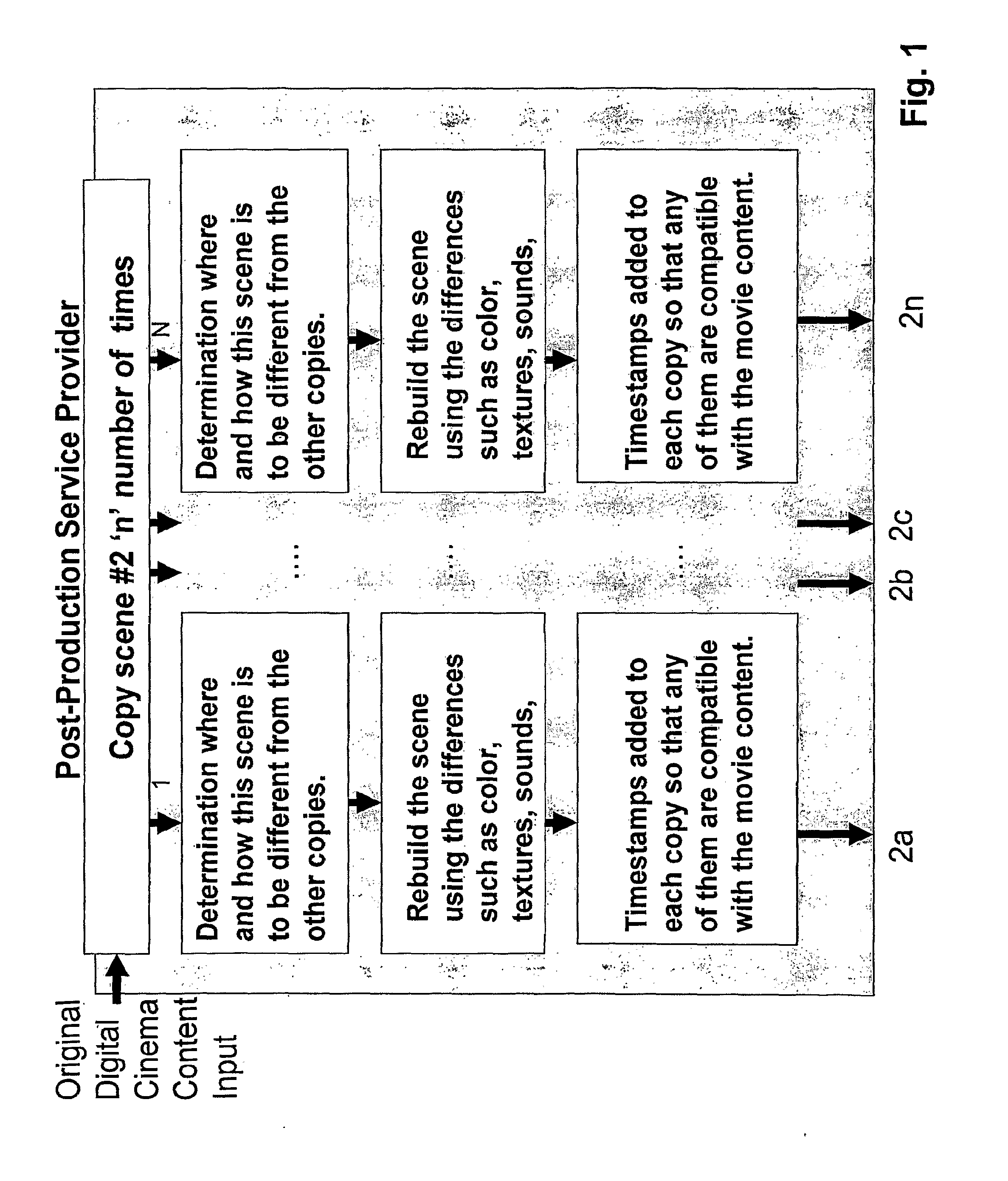

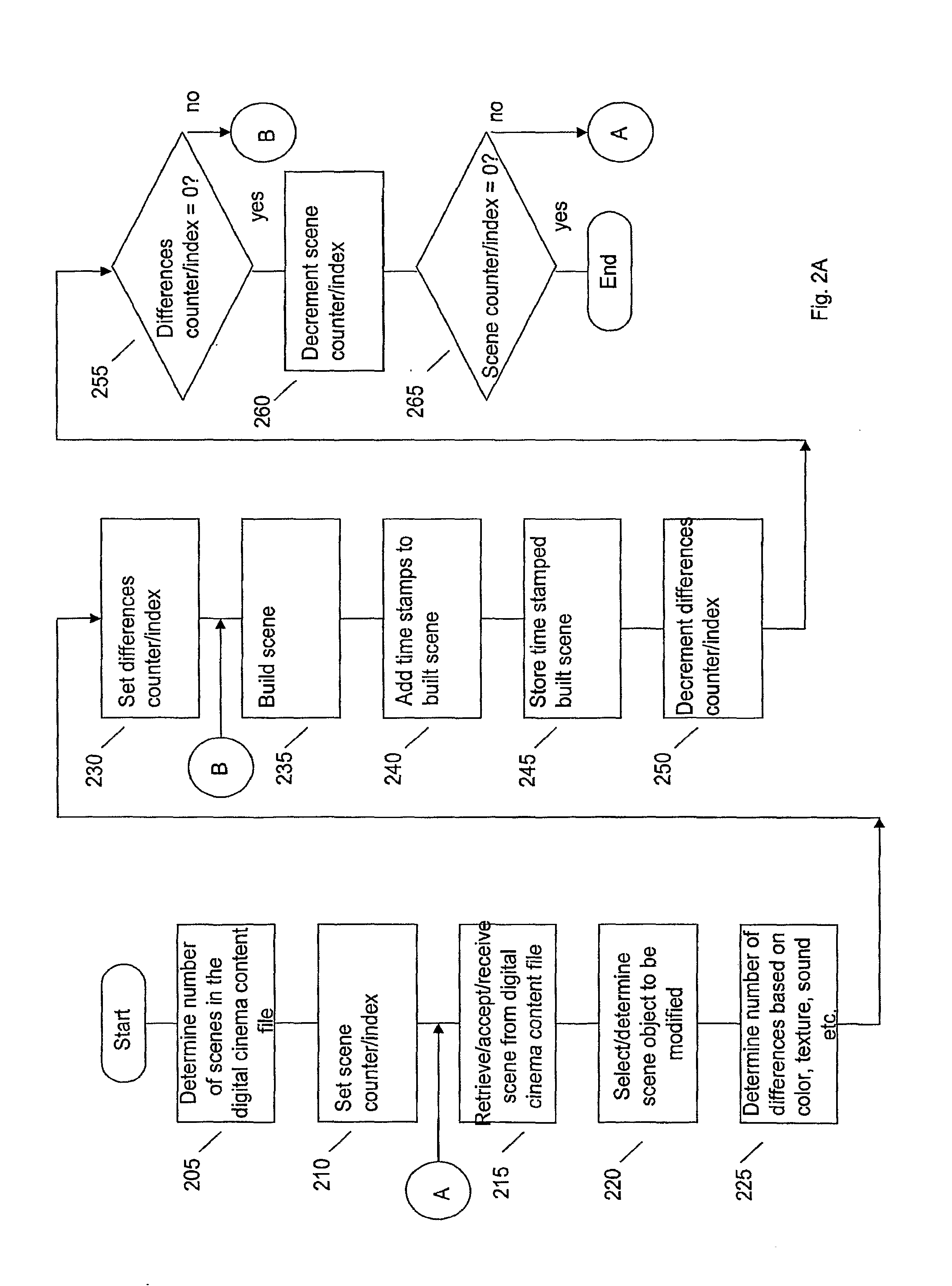

Movie based forensic data for digital cinema

InactiveUS20100098250A1Low costHigh recycling costTelevision system detailsImage data processing detailsComputer graphics (images)Feature based

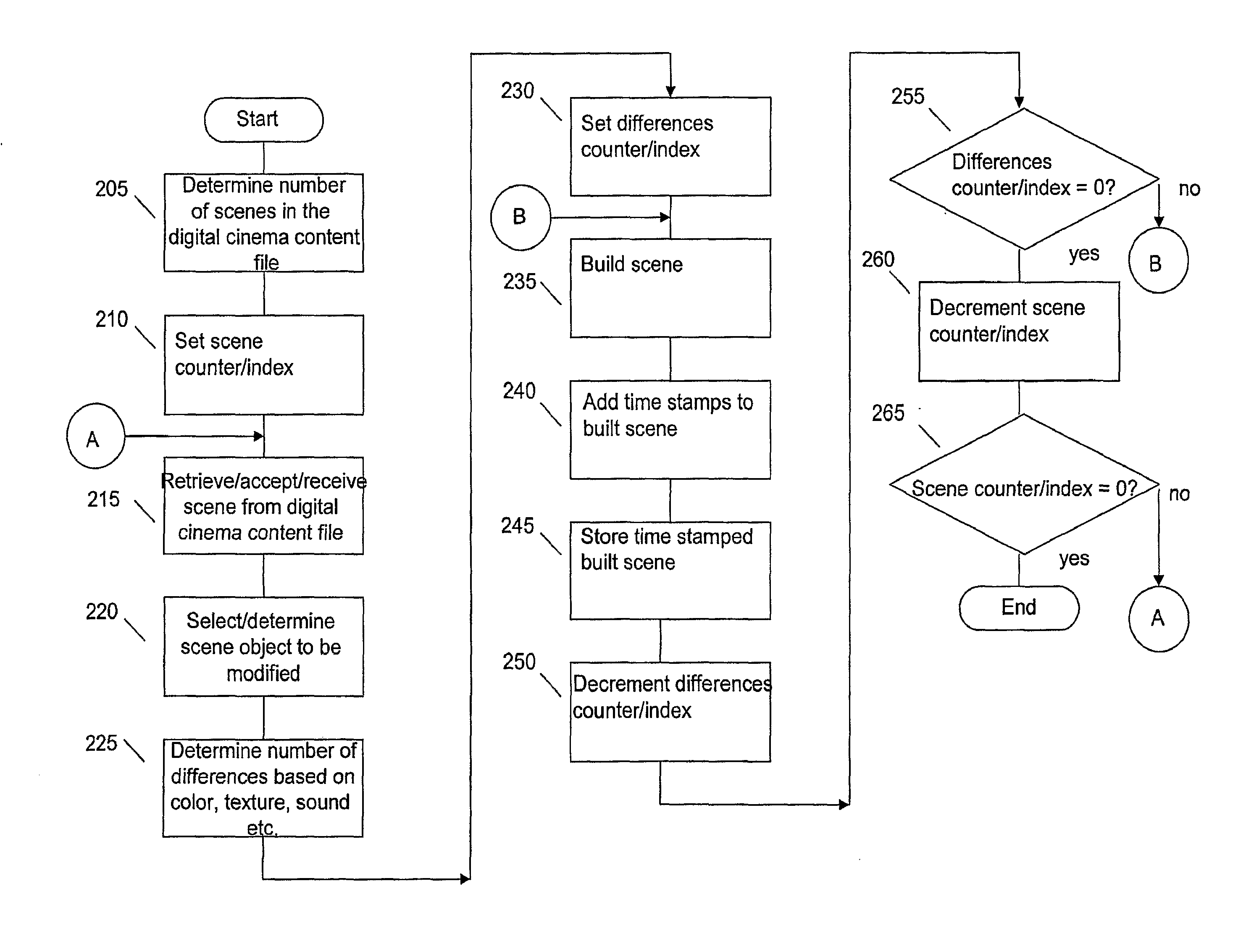

A method and apparatus are described for embedding information in digital cinema content, including accepting a scene from a digital cinema content file, selecting a scene object in the scene to be modified with the information, determining a characteristic for the selected scene object and generating a scene build based on the characteristic, wherein the characteristic is representative of the information. The method and apparatus further include time-stamping, compressing and storing the scene build. Further, a method and apparatus are described for embedding forensic information in digital cinema content, accepting a digital cinema content file having therein a plurality of scene builds, accepting a forensic code and selecting a scene build from the digital cinema content file based on the forensic code. The scene build, having forensic information, is thereafter displayed.

Owner:THOMSON LICENSING SA

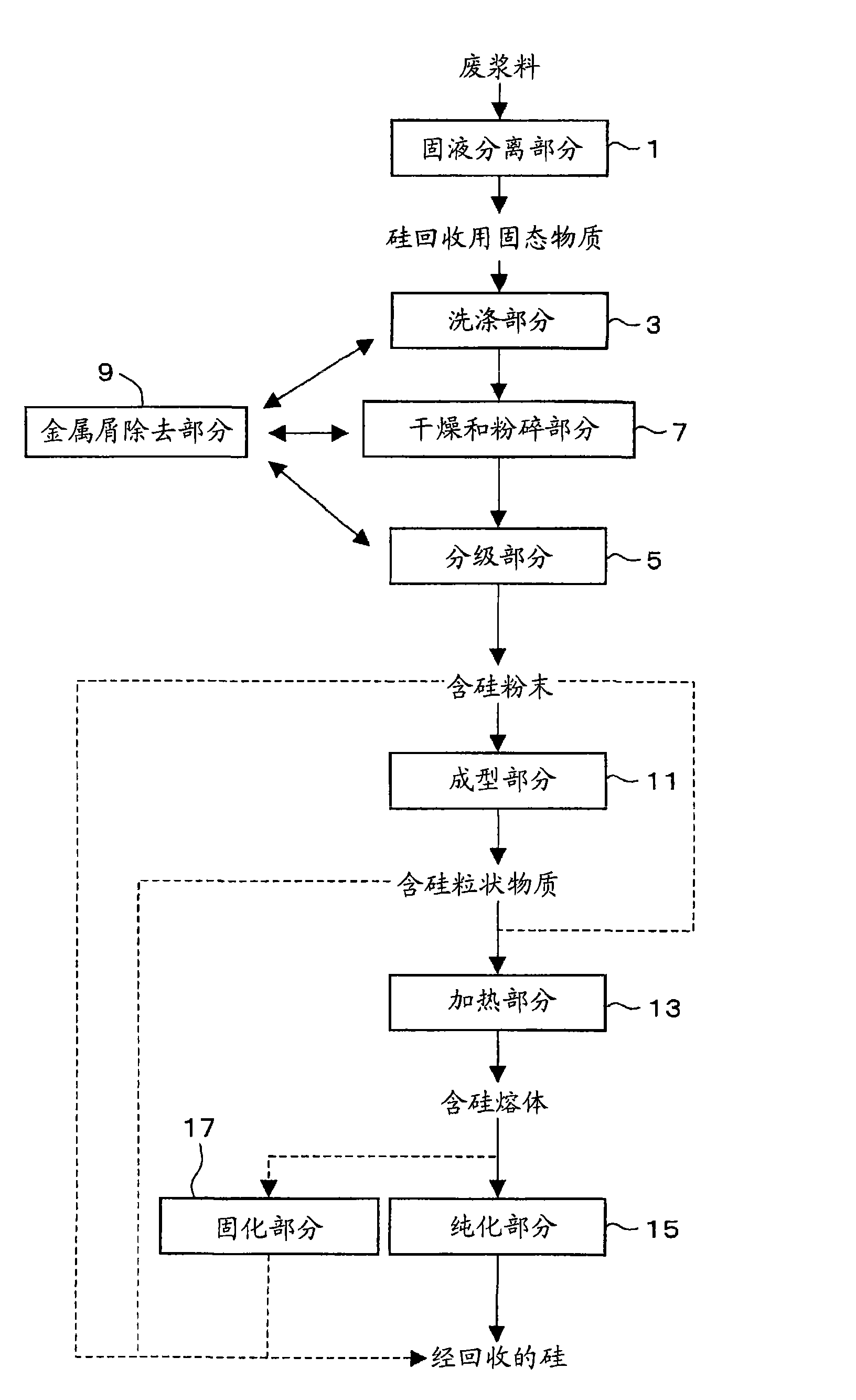

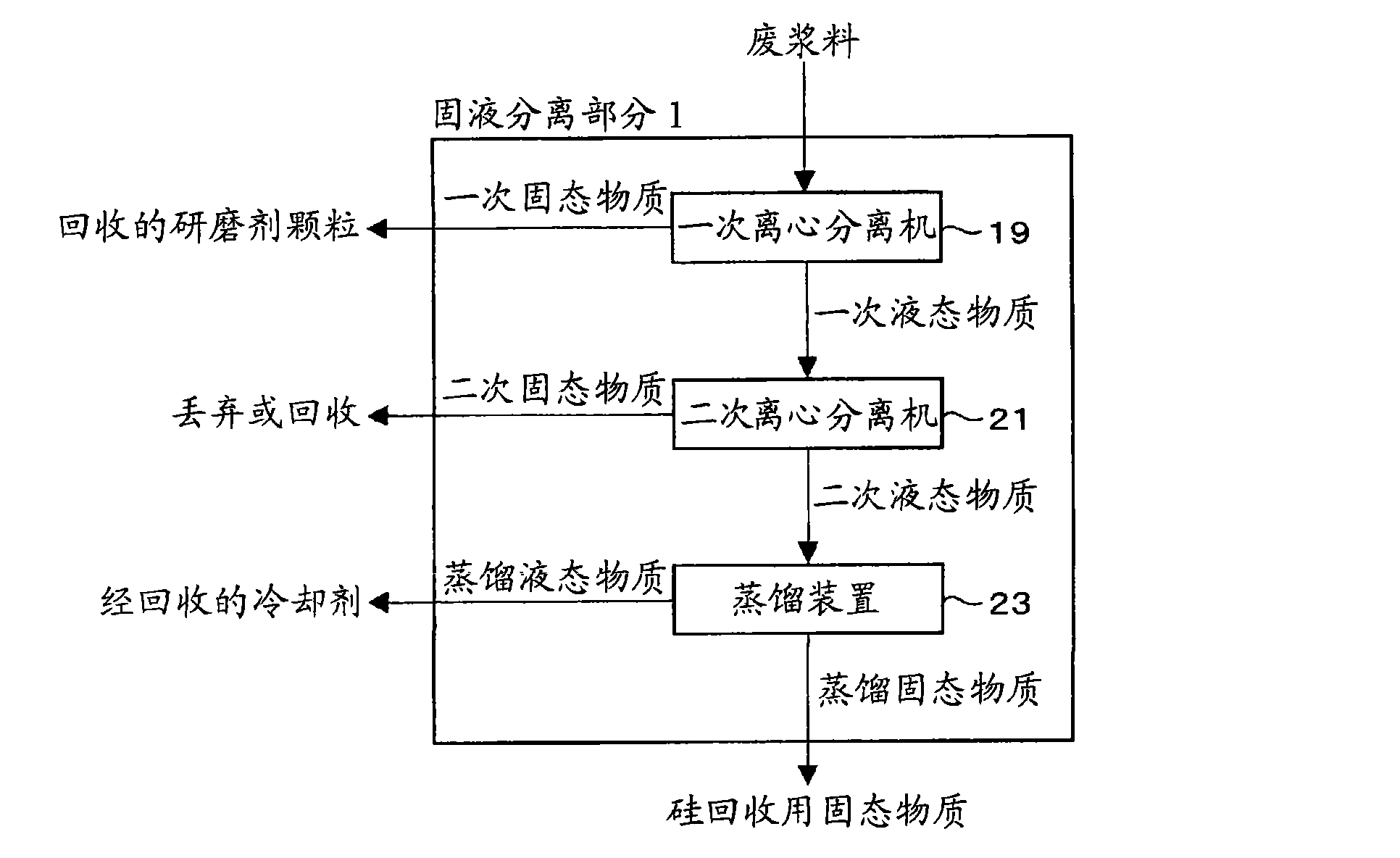

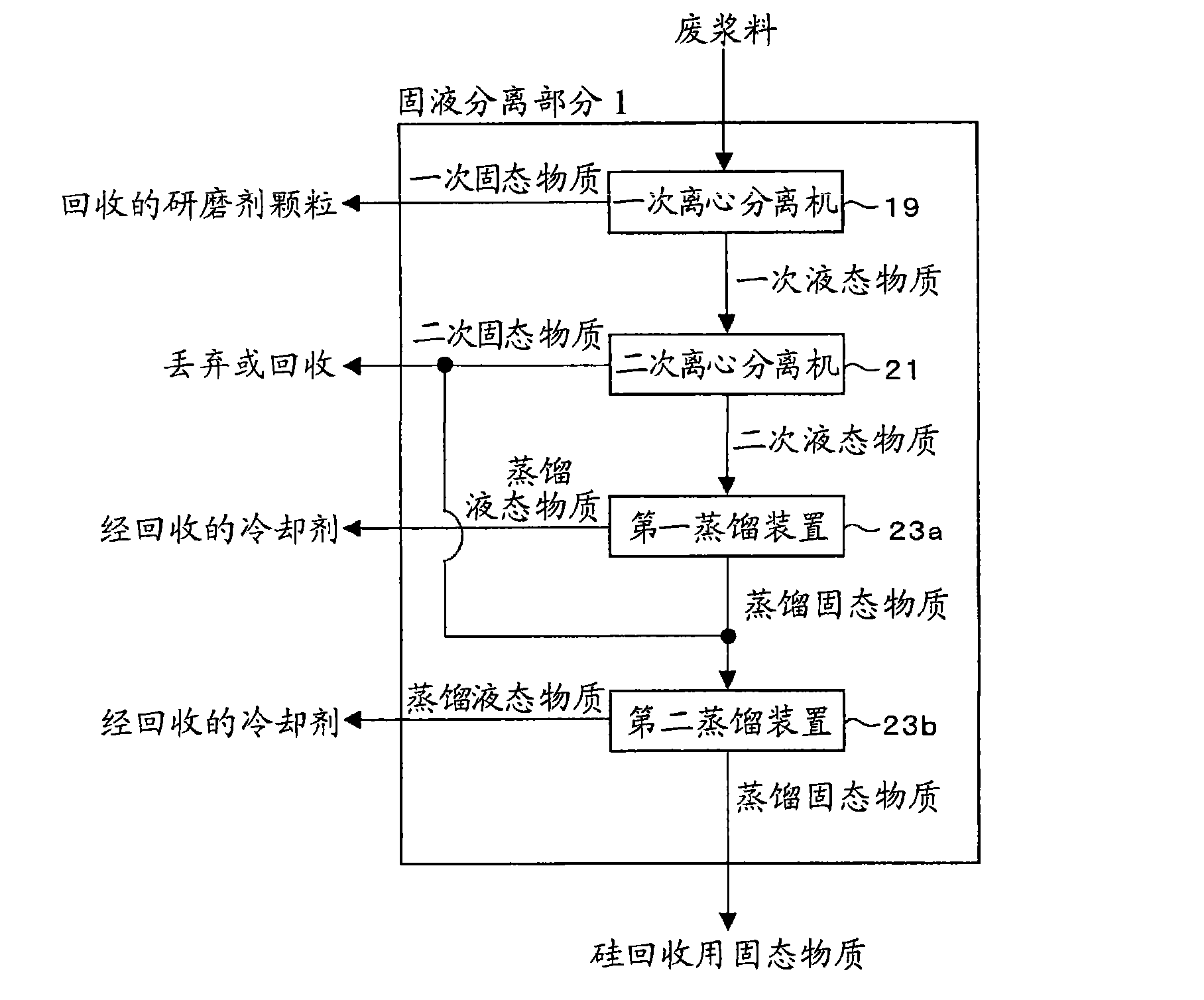

Silicon reclamation apparatus and method of reclaiming silicon

InactiveCN101528597ALow recovery rateHigh recycling costWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningOrganic solventSlurry

The present invention discloses a silicon reclamation apparatus with which a large amount of silicon can be easily reclaimed from a waste slurry. The silicon reclamation apparatus comprises: a solid-liquid separation part in which either a waste slurry discharged from a cutting device or polishing device in which a slurry comprising abrasive grains and a coolant is used for silicon cutting or polishing or a waste slurry concentrate obtained by concentrating the waste slurry is subjected to solid-liquid separation to obtain solid substances for silicon recovery; a washing part in which the solid substances for silicon recovery are washed with an organic solvent; and a classification part in which the solid substances for silicon recovery after the washing are classified to obtain a silicon-containing powder having a higher silicon content than before the classification.

Owner:SHARP KK

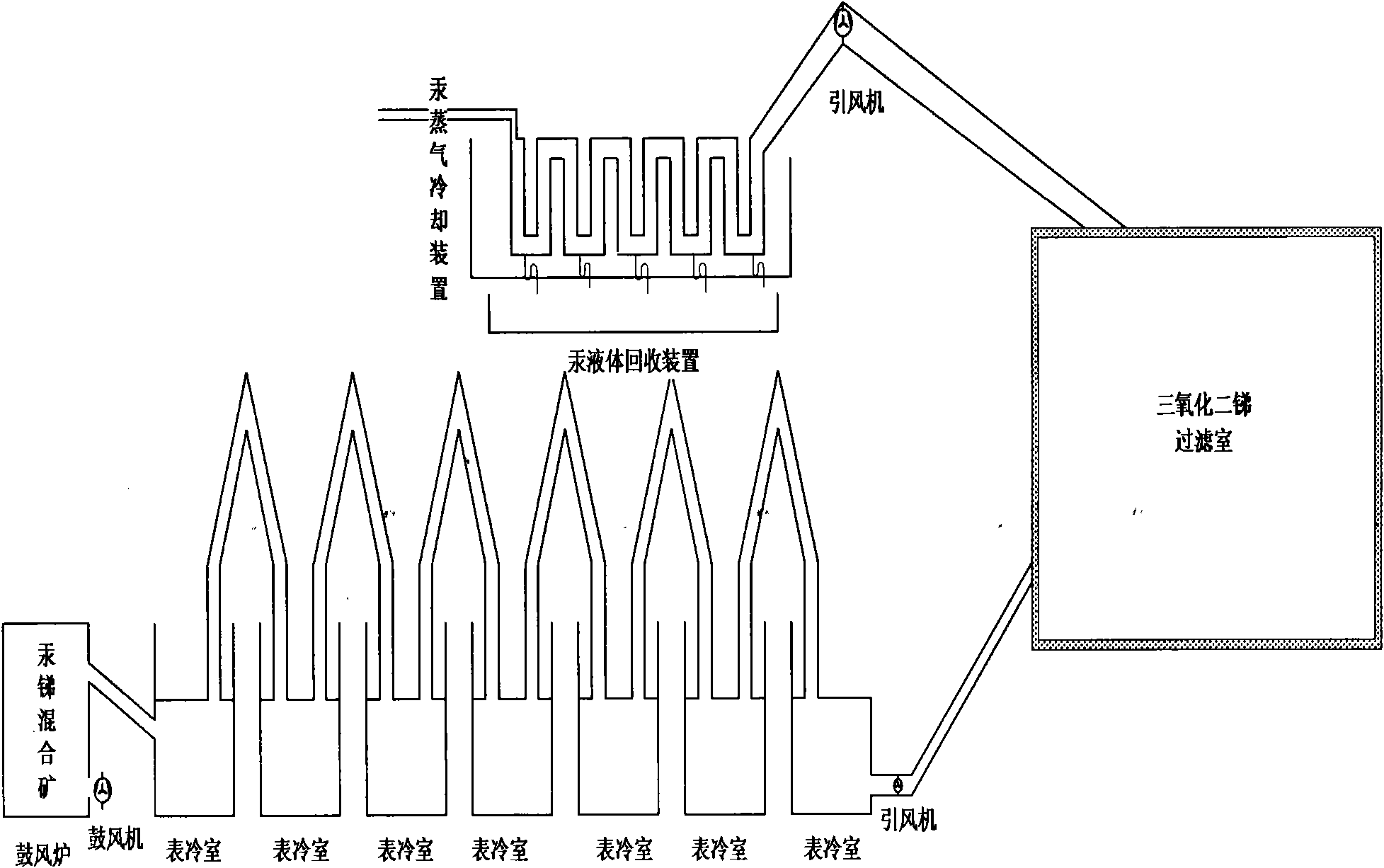

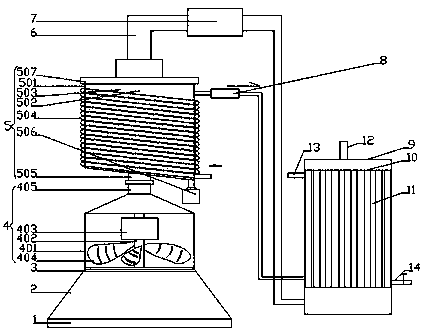

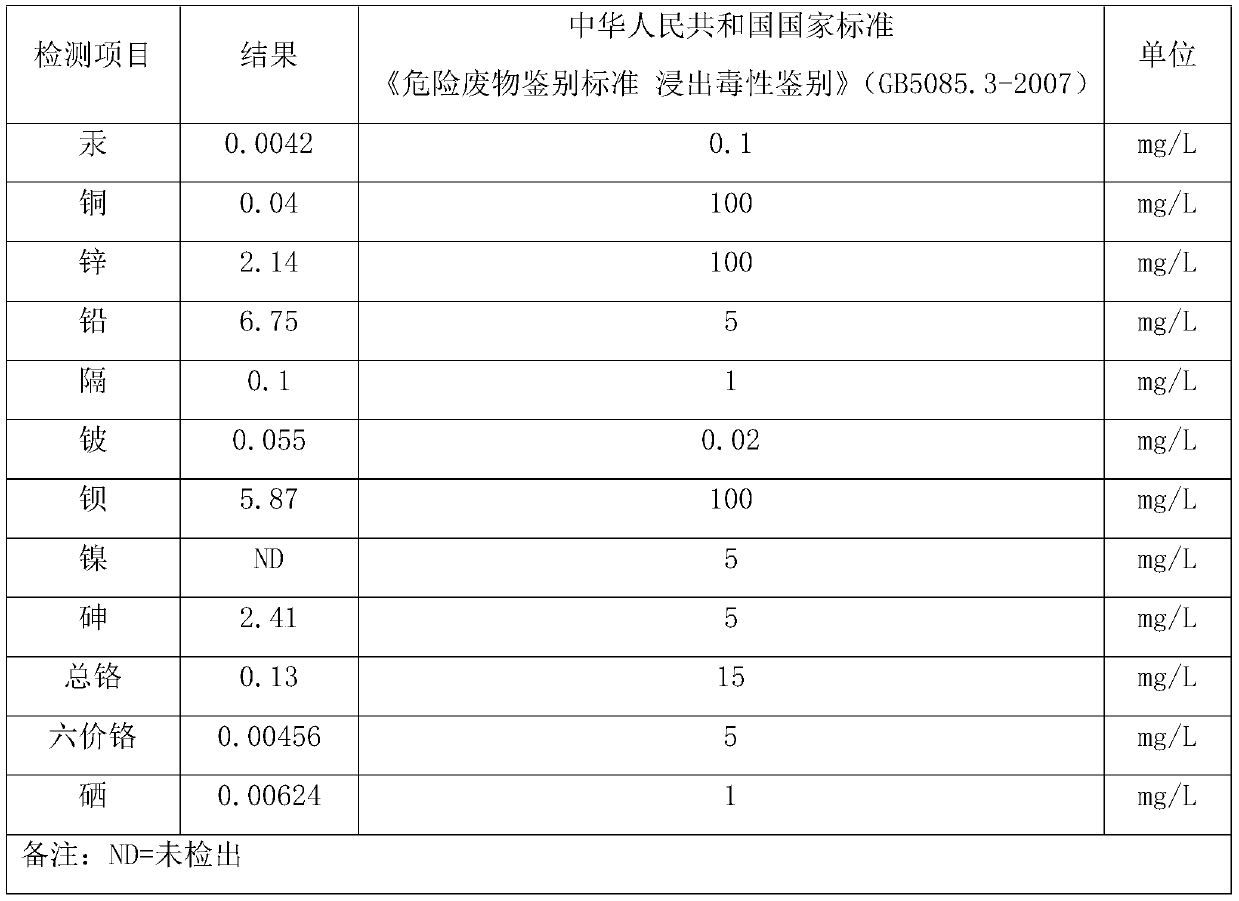

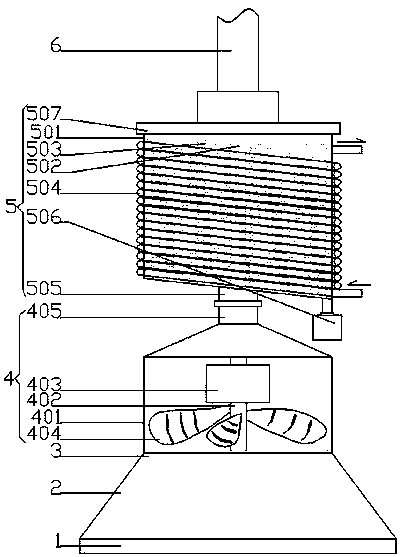

Environment-friendly method and environment-friendly device for mercury-antimony separation for mercury-antimony composite ore

The invention relates to the technical field of ore dressing, in particular to a mercury-antimony smelting separation process. In order to overcome the defects that the mercury-antimony flotation separation process has complex separation process, new pollution production, high reclamation cost, high inter-containing content of separated products, low reclaiming rate and the like in the prior art,the invention adopts a smelting separation method to design a mercury-antimony composite ore smelting device. The invention adopts the technical scheme that the method comprises the following steps: firstly, heating mercury-antimony composite ore powder to 1,000 to 1,200 DEG C at high temperature by a blast furnace to obtain antimony trioxide and mercury vapor, reacting the antimony trioxide and coal by adopting a reflecting furnace, and reclaiming the antimony; and then, cooling the mercury to 30 to 50 DEG C by adopting a circular cooling device, and reclaiming the mercury; therefore, the reclaiming rate of the mercury is as high as 98 percent, the reclaiming rate of the antimony is as high as 96 percent, a plurality of devices in the prior mercury-antimony separation process are simplified to one device, and the mercury is reclaimed with zero cost and inter-containing substances are not produced during smelting the antimony.

Owner:刘善安 +2

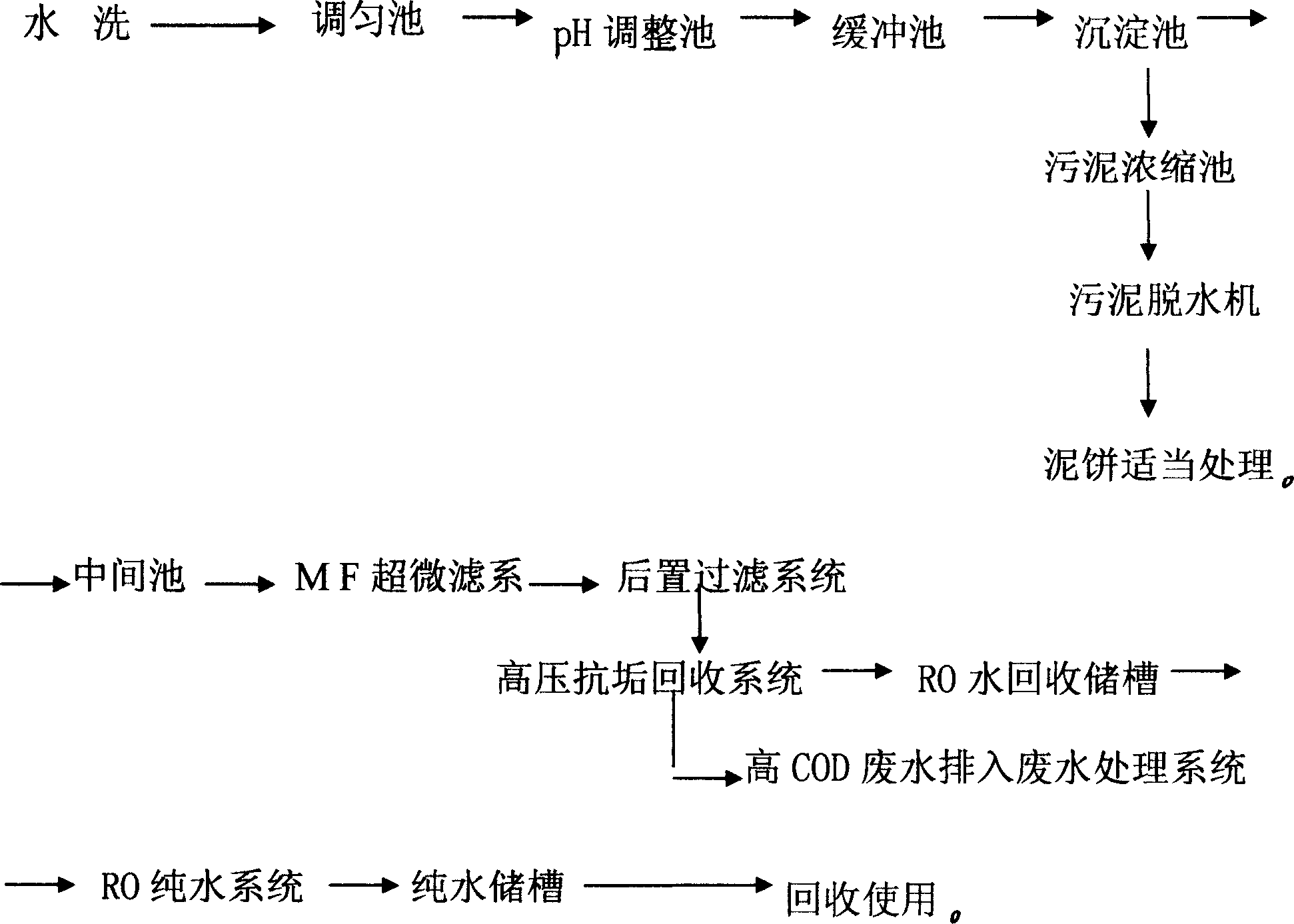

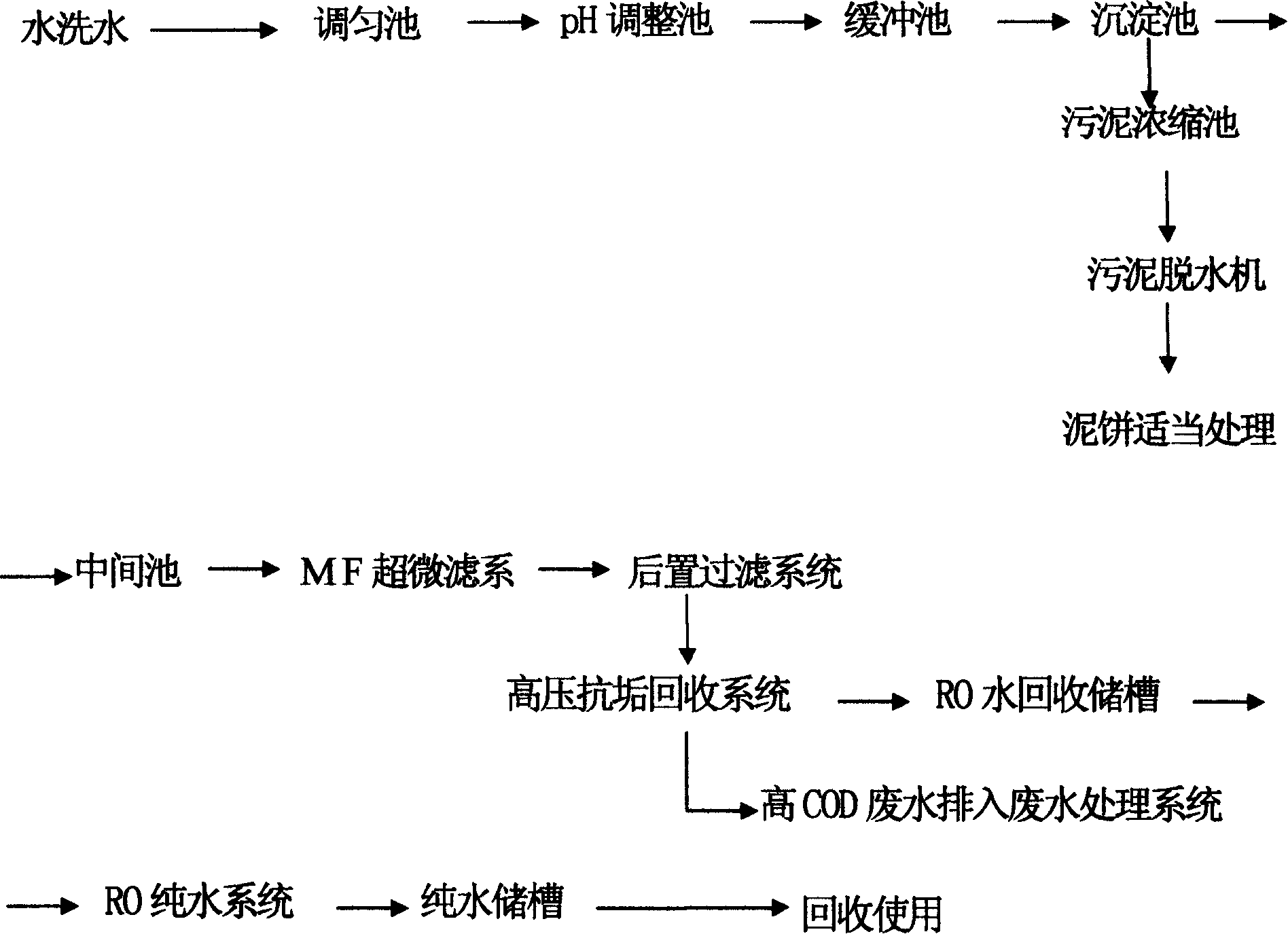

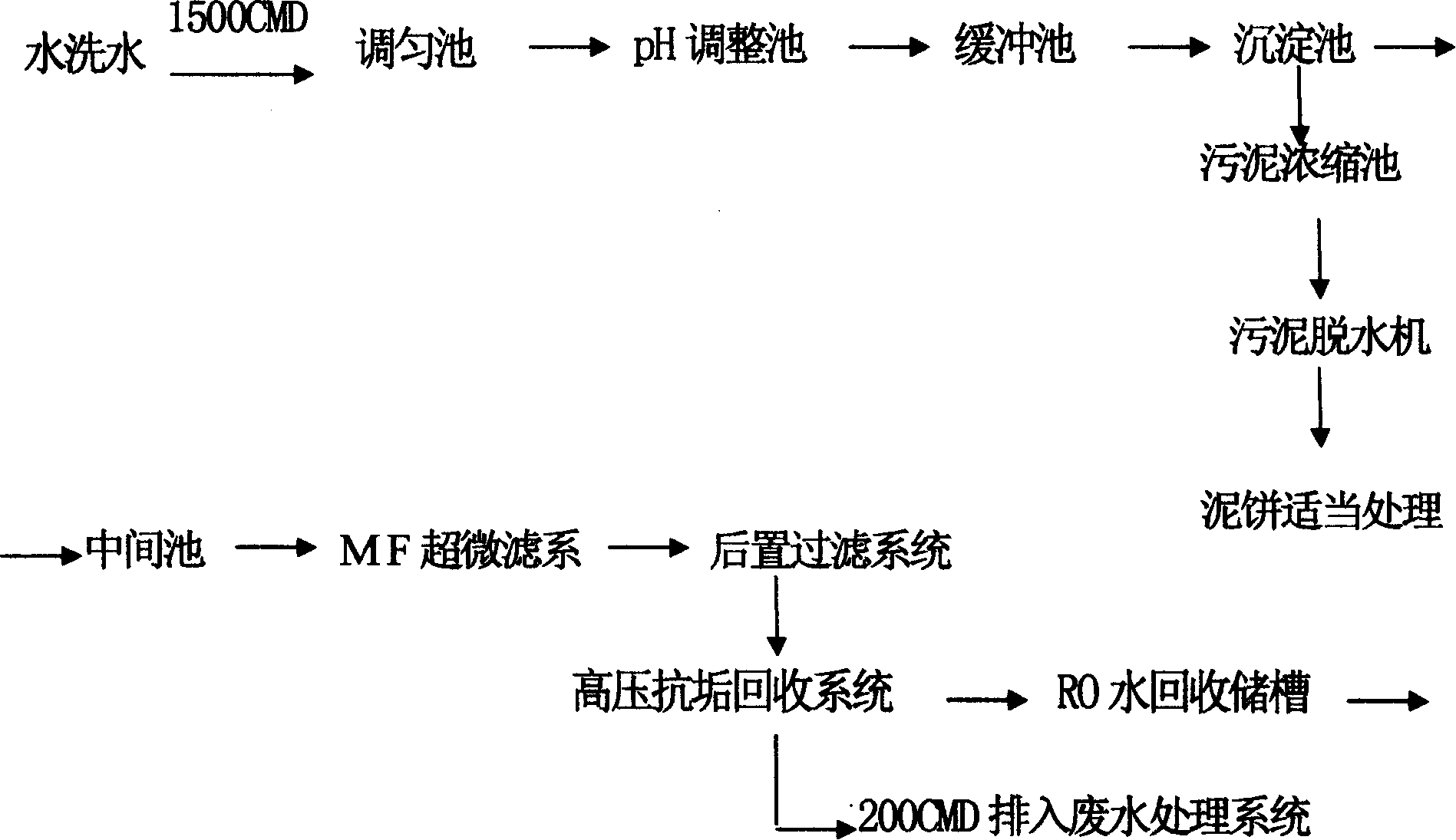

Circuit-board waste-water reutilizing process of reducing waste

ActiveCN101070211AHigh recovery rateWater recyclingWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentBreadboardPre treatment

The aim of this invention is to fill up above described blank and supplies a breadboard wastewater reclaiming craft. The aim is accomplished by follows technical proposal: partly introduce each wastewater department of breadboard workshop to mixing pool, through precipitation, then takes pretreatment filtration by microfilter and ultrafilter, then pass recovery system, the water quality can reach standard that conductivity less than 20us / sq cm, and has no particle that greater than 10 micrometer, PH is neutrality, can reclaim to workshop for water of productive using; flow tank sludge after dewatering is disposed by other departments.; high COD wastewater through this system can reach discharging standard; acid and alkali department, water washing, and complexation wastewater after precipitation is introduced to mixing pool, sludge after dewatering is disposed by other departments.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

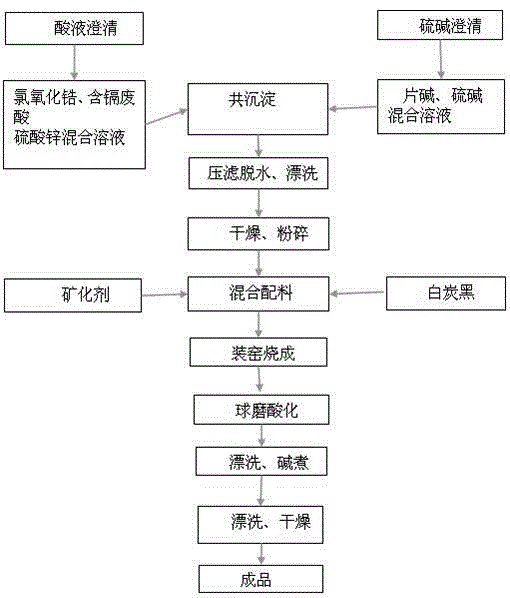

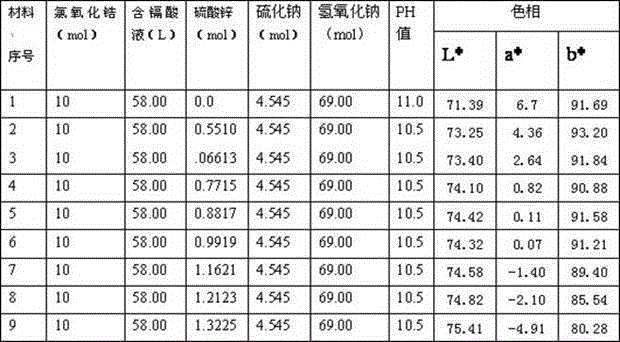

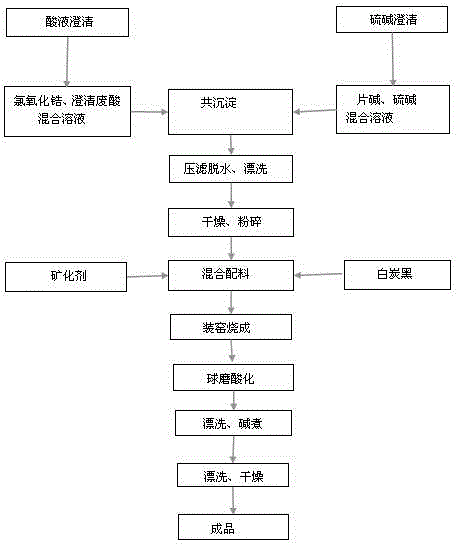

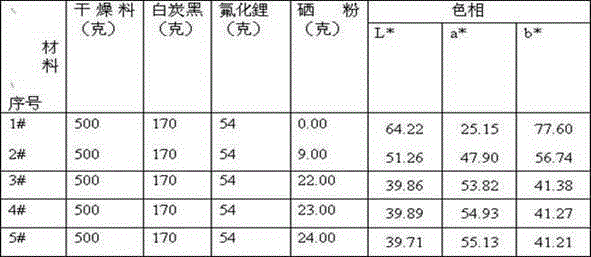

Method for preparing gilvous occlusion pigment from cadmium-containing waste acid solution generated in acid pickling process

The invention discloses a method for preparing a gilvous occlusion pigment from cadmium-containing waste acid solution generated in an acid pickling process. Cadmium-containing wastewater generated in the acid pickling process is directly utilized to produce a zirconium silicate microcrystal occluded cadmium sulfide pigment, and zinc ions are doped by virtue of introduction of zinc sulfate to form a cadmium sulfide and zinc sulfide solid solution color former which is used for producing the zirconium silicate microcrystal occluded zinc cadmium sulfide pigment. According to the invention, zirconium oxychloride, zinc sulfate and waste acid solution containing cadmium and selenium generated in the acid pickling process as well as sodium hydroxide and sodium sulphide are subjected to chemical coprecipitation reaction in a reaction kettle, filter-pressed and washed, and dried; and then the above reaction product is evenly mixed with a mineralizer and white carbon black according to a certain ratio and calcined at a high temperature, and the calcined product is acidized, ball-milled, filter-pressed, washed and dried to obtain the zirconium silicate occluded cadmium sulfide yellow pigment or zirconium silicate occluded zinc cadmium sulfide gilvous occlusion pigment product. The gilvous occlusion pigment can replace praseodymium yellow pigment for use.

Owner:LILING KEXING IND CO LTD

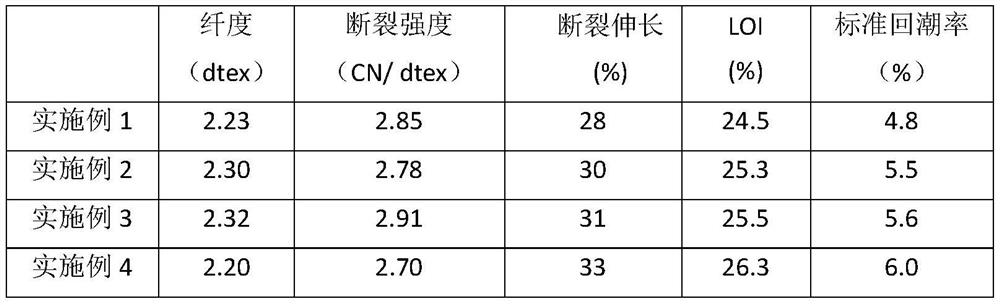

Preparation method of halogen-free flame-retardant polyacrylonitrile fiber

PendingCN112746347AAvoid churnHigh recycling costFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention provides a preparation method of a halogen-free flame-retardant polyacrylonitrile fiber. The method mainly comprises the following steps: heating and melting a halogen-free flame retardant containing phosphorus and nitrogen, then stirring and blending with a polyacrylonitrile spinning solution, carrying out wet spinning, and then carrying out cross-linking hydrolysis to obtain the flame-retardant polyacrylonitrile fiber. According to the preparation method disclosed by the invention, the halogen-free organic phosphorus-nitrogen flame retardant can be uniformly and stably dispersed in the spinning solution, so that a hole blocking phenomenon is effectively avoided during spinning, and the period of replacing a nozzle during spinning is greatly prolonged. Meanwhile, chemical modification of crosslinking and alkaline hydrolysis is further carried out on the surface of the fiber after a hot drafting procedure in a spinning process of the flame-retardant acrylic fiber, the flame retardance LOI of the prepared acrylic fiber is larger than or equal to 26%, and the hygroscopicity of the acrylic fiber is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

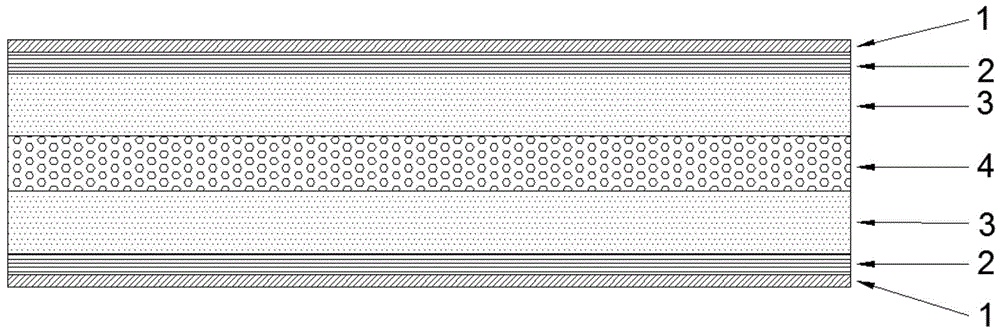

Hot water device for heating through cooking oil fume

InactiveCN108317870AUnique and novel cost recoveryReduce pollutionDomestic stoves or rangesRecuperative heat exchangersAir filterAir pollution

The invention discloses a hot water device for heating through cooking oil fume. The device comprises a fan housing, wherein the big end of the fan housing is clamped into an oil storing groove, and the upper small end is connected to a fan barrel body; a filtering net is arranged between the lower end of the fan barrel body and the small end of the fan housing; an air outlet of a fan is movably connected to an inlet pipe of an air filter; an outlet pipe of the air filter is connected to the sidewall of the bottom part of a water storing tank through a pipeline in a penetrating manner; one endof a spiral pipe of the air filter is in penetrating connection with the middle part of the water storing tank; the inner upper part and the inner lower part of the water storing tank are connected to separating plates; a plurality of air tubes are connected between the separating plates in a penetrating manner. The device is compact in structure, reasonable in design, and unique and novel in idea; the oil fume and the heat are pumped as blades rotate; the oil is removed by secondary filtering; the hot air is transferred to heat the spiral pipe, and the hot water in the spiral pipe is subjected to heat preserving and then is fed into the water storing tank. Therefore, the energy is saved; and moreover, the filtered oil can be recovered, so that the waste recovery cost is increased; the recovered hot air is used as the energy for heating water in the water storing tank, thus the energy utilization is realized; and meanwhile, the air pollution caused by the oil fume can be reduced; thedevice is obvious in effect, has a good application prospect and is worthy of popularization.

Owner:HEFEI XINKAICHUANG STAINLESS STEEL EQUIP

Food box device capable of preserving heat through excess heat of cooking oil fume

InactiveCN108317560ACompact structureReasonable designDomestic stoves or rangesLighting and heating apparatusExcess heatEngineering

The invention discloses a food box device capable of preserving heat through excess heat of cooking oil fume. The device comprises a fan housing, wherein the big end of the air housing is clamped intoan oil storing groove, and the upper small end is connected to a fan barrel body; a filtering net is arranged between the lower end of the fan barrel body and the small end of the fan housing; an airoutlet of a fan is movably connected to an inlet of an air filter; an outlet of the air filter is connected to one end of a heating pipe of a food box through a pipeline; two ends of a spiral pipe are correspondingly connected to two ends of a heat preserving pipe; the heating pipe and the heat preserving pipe are arranged in an interlayer of a groove body which is fixedly connected to the upperpart of a frame, and a storing rack is arranged at the lower part of the frame. The food box device is compact in structure, reasonable in design, and unique and novel in idea; the oil fume and the heat are pumped as blades rotate; oil is removed by secondary filtering; hot air is transferred to heat the spiral pipe, and hot water in the spiral pipe is capable of preserving the heat of foods in aheat preserving groove. Therefore, the energy is saved; in addition, the filtered oil can be recovered, thus the waste recovery cost is increased; the hot air is recovered through the excess heat andis used as energy for heating the food groove; the running cost of a catering enterprise is decreased, and meanwhile, the air pollution is reduced; the effect is obvious; the food box device has a good application prospect and is worthy of popularization.

Owner:HEFEI XINKAICHUANG STAINLESS STEEL EQUIP

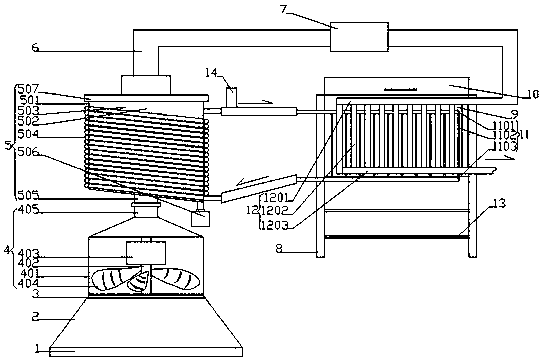

Efficient production and manufacturing method and equipment for lyocell fibers

PendingCN112779612AReduce quality fluctuationsAvoid smallArtificial thread manufacturing machinesMonocomponent cellulose artificial filamentCellulosePolymer science

The invention belongs to the technical field of fiber production and manufacturing, and relates to an efficient production and manufacturing method and equipment for lyocell fibers. A spinning stock solution prepared by dissolving is added into a screw extruder, is sheared and dissolved at a certain temperature and then is sprayed out after passing through a filter, a static mixer, a metering pump and a spinning assembly; sprayed tows are oriented and stretched in air and then enter a coagulating bath; due to solvent diffusion, the solvent concentration is reduced, cellulose is separated out, and the tows are coagulated and formed; then water washing, oiling and drying post-treatment procedures are carried out; and next, inspecting and packaging are performed to obtain short fibers.

Owner:山东鸿泰鼎新材料科技有限公司

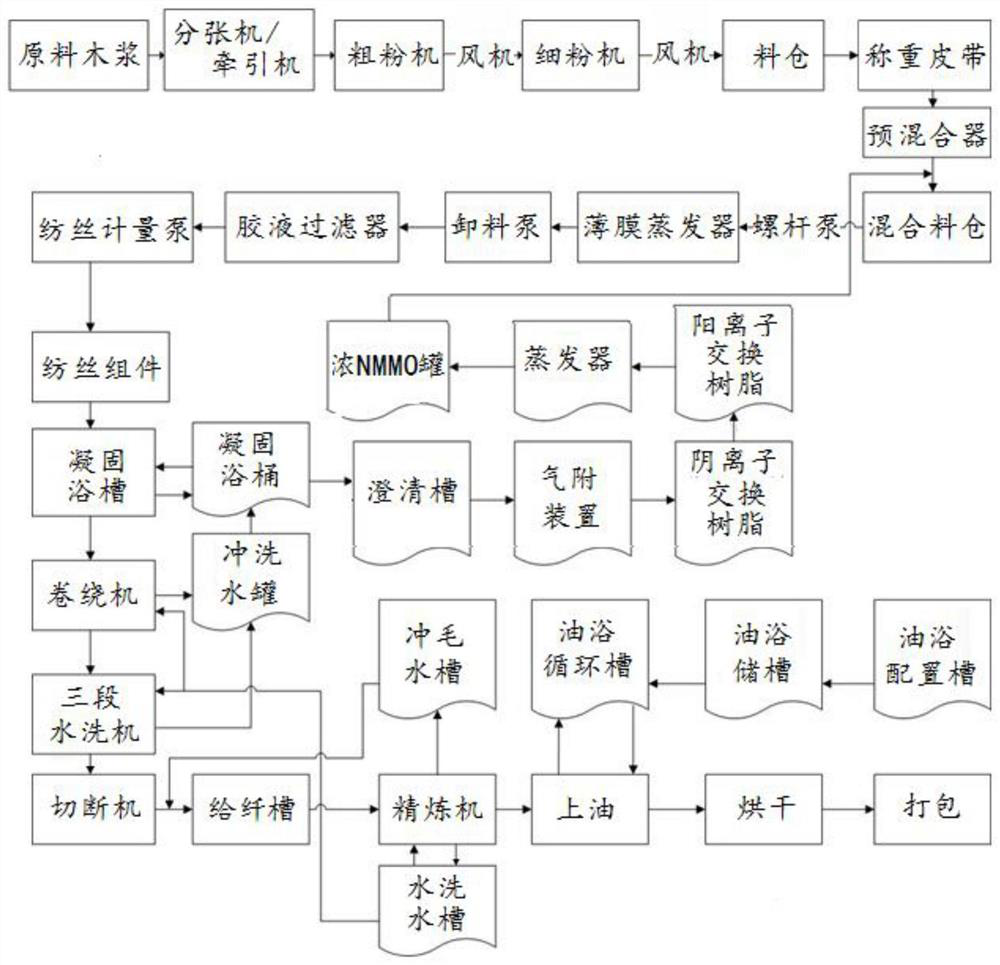

Light high-strength sandwich composite board and production method

ActiveCN104553169AIncrease profitHigh recycling costLamination ancillary operationsSynthetic resin layered productsScrapWoven fabric

The invention relates to a light high-strength sandwich composite board and a production method thereof. The sandwich composite board is formed by pressing and connecting a laminated non-woven fabric layer, a prepreg tape layer, a light felt layer, a waste prepreg tape scrap layer, a light felt layer, a prepreg tape layer and a laminated non-woven fabric layer which are sequentially arranged from top to bottom. According to the light high-strength sandwich composite board, the high strength of prepreg tapes, the lightness of felt and filling of waste prepreg tapes are used, the waste prepreg tapes are changed into wealth, the utilization rate of the prepreg tapes is increased, resources are saved, and the cost is reduced. The density of the produced board is in a range of 1-1.2 g / cm<3>, the bending strength is higher than 70 MPa, the bending modulus is higher than 6 GPa, and the board can be applied to fields of building, transportation and the like and has the broad market prospect.

Owner:上海昶勤实业有限公司

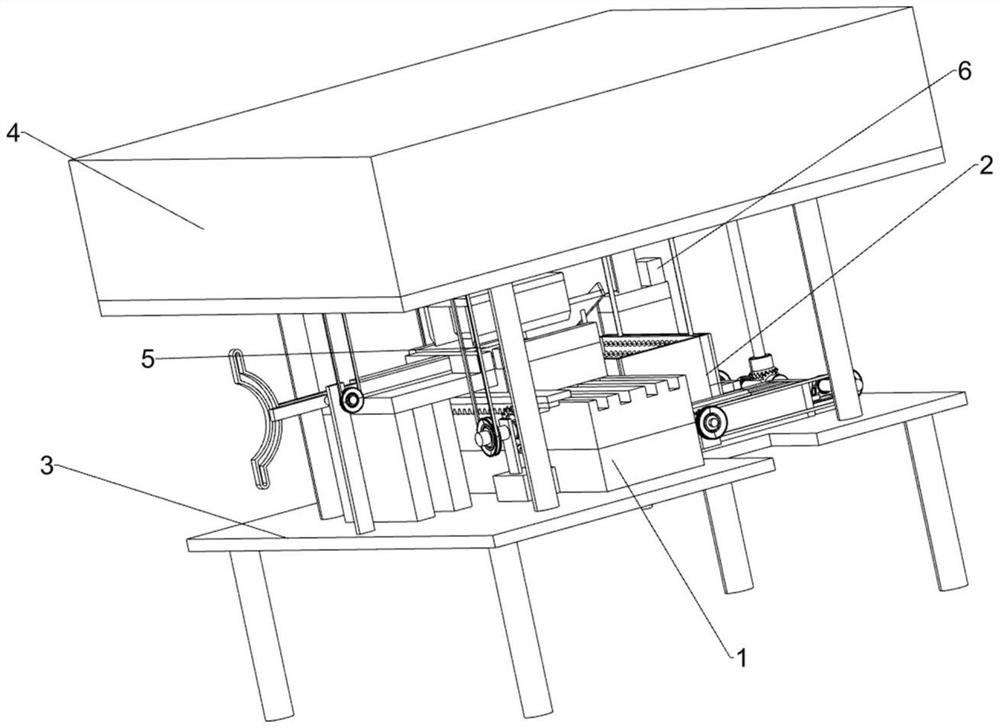

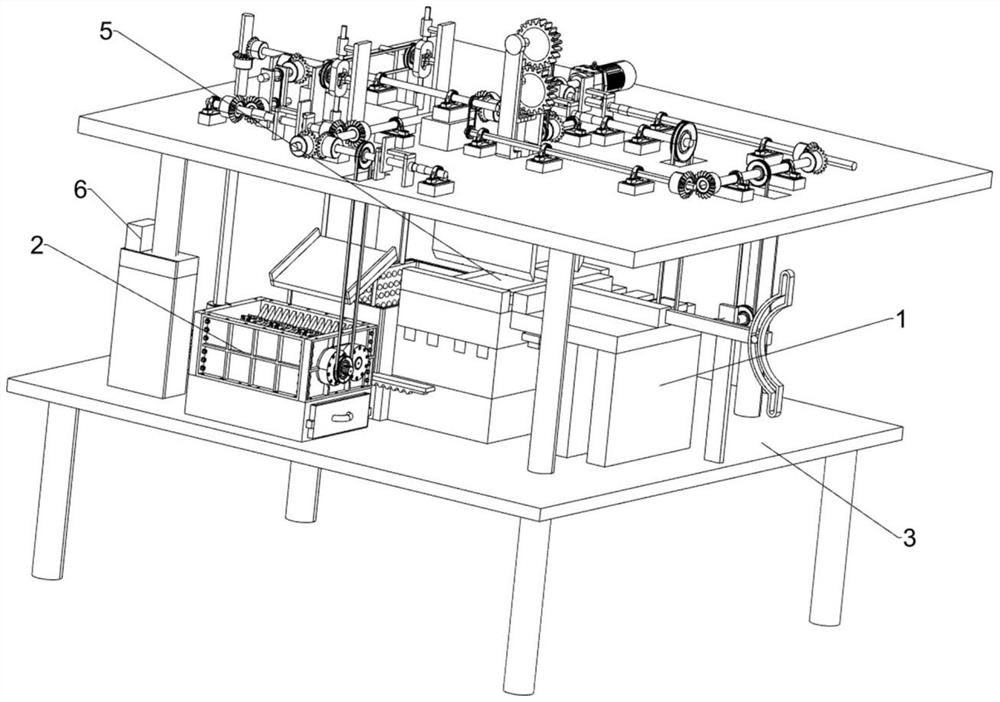

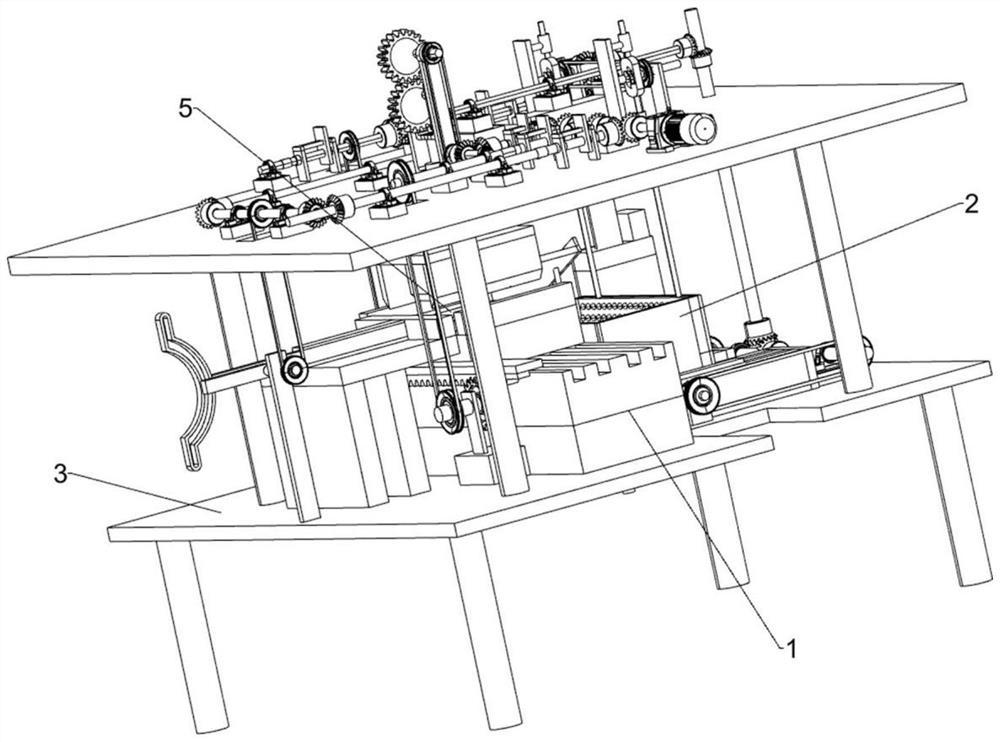

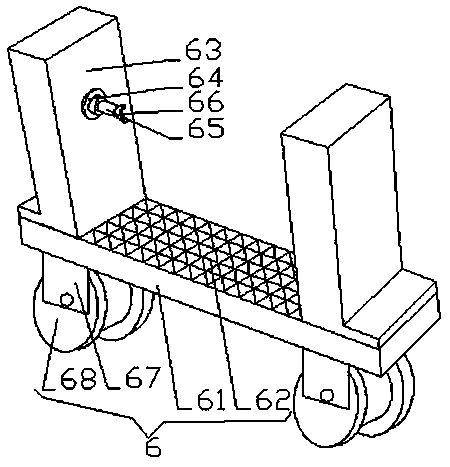

Recycling device of oiliness plastic bag

InactiveCN111844533AAchieve reuseTo achieve the effect of repeated usePlastic recyclingMechanical material recoveryOil separationProcess engineering

The invention relates to the field of environment-friendly recycling, in particular to a recycling device of an oiliness plastic bag. The technical problem to be solved is to provide a recycling device of an oiliness plastic bag. The recycling device of the oiliness plastic bag includes a transporting cutting mechanism, a deoiling separation breaking mechanism, a working table, a device protectiveshell, a plastic bag, and a control display screen. The transporting cutting mechanism and the deoiling separation breaking mechanism are arranged in the working table, the upper part of the workingtable is connected with the device protective shell, the transporting cutting mechanism is connected with the plastic bag, and the working table is connected with the control display screen. Accordingto the device, the problem that the oiliness plastic bag can not separate inner oiliness liquid so that the oiliness plastic bag can not be recycled is solved, and the purpose of protecting an environment can be achieved.

Owner:郭芸

Method for preparing silk protein composite cellulose fibers

ActiveCN102505170BHigh recycling valueLow viscosityArtificial filaments from viscoseProtein solutionSulfonate

Owner:赛得利(盐城)纤维有限公司

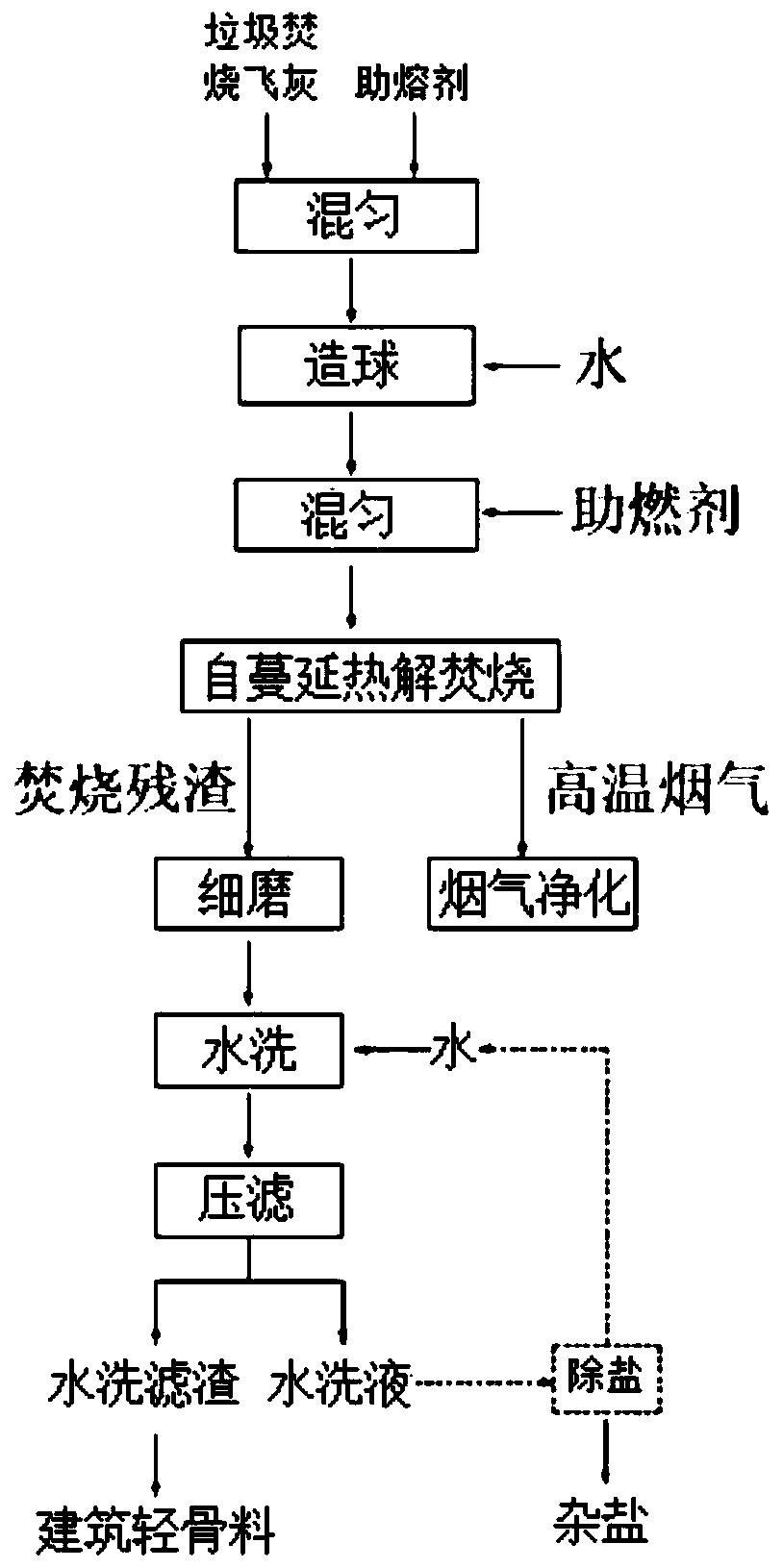

Innocent treatment method of waste incineration flying ash

PendingCN111594847AIncrease heat transfer areaIncrease the air permeability of the material layerIncinerator apparatusPre treatmentEnvironmental chemistry

The invention discloses an innocent treatment method of waste incineration flying ash, comprising the following steps: S1, pretreatment, evenly mixing waste incineration flying ash with fluxing agent,performing pelletizing treatment to obtain flying ash pellets, and further mixing the flying ash pellets with combustion improver to obtain mixture evenly; S2, self-propagating pyrolytic incineration, placing the mixture in a self-propagating pyrolytic incineration device to execute self-propagating pyrolysis treatment, wherein the self-propagating pyrolysis refers to that heat propagates by itself through materials to execute pyrolysis under the premise that the materials are not turned over; S3, washing, grinding incineration residues into residue powder in grain size of not more than 20 meshes, mixing the residue powder with water according to solid-liquid mass ratio of 1:4-8, stirring and pulpifying, standing and precipitating, separating and filtering to obtain washing liquid and washing filter residue. The method provided by the invention completely decompose Dioxin and heavy metal ions in the waste incineration flying ash, can realize innocent treatment of the waste incineration flying ash, simultaneously can remove most soluble salt, chlorine, and so on, in the residues, and can realize comprehensive utilization of the residues.

Owner:CHONGQING ANGRUIYUE SCI & TECH +1

Method for preparing ultralow-mercury catalyst by recycling waste batteries

ActiveCN113131031AHigh catalytic efficiencyEfficient recyclingWaste accumulators reclaimingBattery recyclingActivated carbonPtru catalyst

The invention discloses a method for preparing an ultralow-mercury catalyst by recycling waste batteries. The method comprises the following steps of: by taking battery powder obtained by disassembling waste batteries as a raw material, performing extraction with diluted hydrochloric acid under an oxidation condition to obtain extract liquor; and adding a regulator according to the weight ratio, adjusting the ratio of main elements including mercury, zinc, manganese, copper, cadmium, nickel and cobalt in the extract liquor to be (3-5): (2-6): (2-6): (1-5): (1-5): (0.1-2): (0.1-2) to obtain an adjusted solution, adding activated carbon, soaking the activated carbon, and drying a product to obtain the ultralow-mercury catalyst for vinyl chloride synthesis catalysis. Valuable metal elements in the waste batteries are separated, the vinyl chloride synthesis catalyst is prepared, and recycling of the waste batteries is achieved.

Owner:GUIZHOU INST OF TECH +1

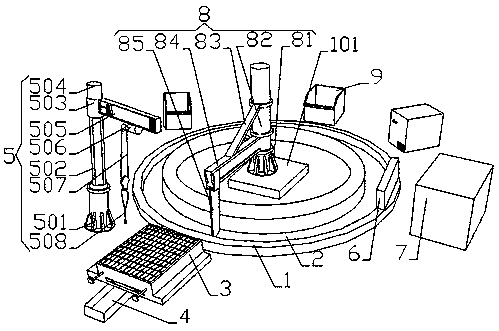

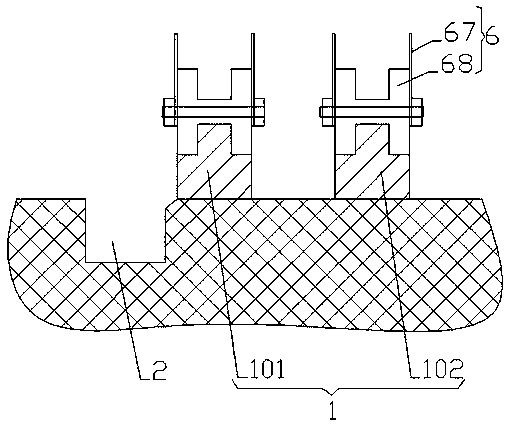

Scrapped automobile engine assembly dismantling and recycling non-polluting utilization device

The invention discloses a scrapped automobile engine assembly dismantling and recycling non-polluting utilization device. The device comprises a ring-shaped track, the ring-shaped track is fixedly installed on the ground, an open groove is arranged on the inner side ground of the inner rail of the ring-shaped track, a seat stand is arranged in the open groove and is provided with a cleaning mechanism, the outer side of the outer rail of the ring-shaped track is provided with a base, a blind groove is arranged under the base, one end of the blind groove is communicated with the open groove, oneside of the base is provided with a jack mechanism, the ring-shaped track is provided with a dismantling mechanism, and the periphery of the outer side of the ring-shaped track is provided with a plurality of dismantling stations. The device has a compact structure, a reasonable and novel design, a unique idea, strong practicability and high mechanization operation efficiency. An engine is hoisted and clamped in the dismantling mechanism, is subjected to disassembly in multiple processes and discharges oil. The waste oil is recovered through the dark groove. The disassembled parts are recovered so that a recovery cost is increased. The device has no secondary pollution on the environment, greatly reduces the labor intensity of the operator, improves the working efficiency by 8-10 times and realizes the fast dismantling of the scrapped automobile engine.

Owner:滁州市洪武报废汽车回收拆解利用有限公司

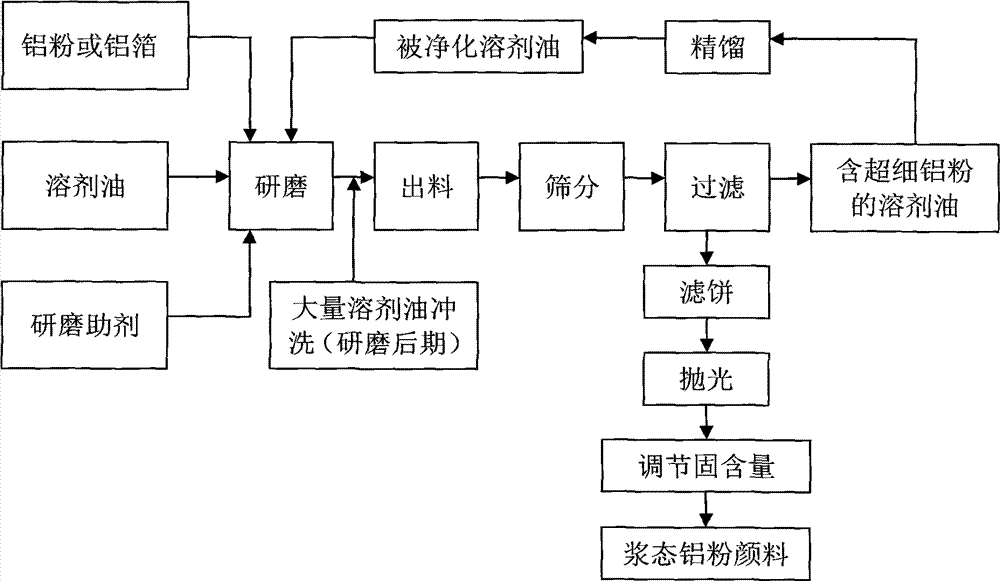

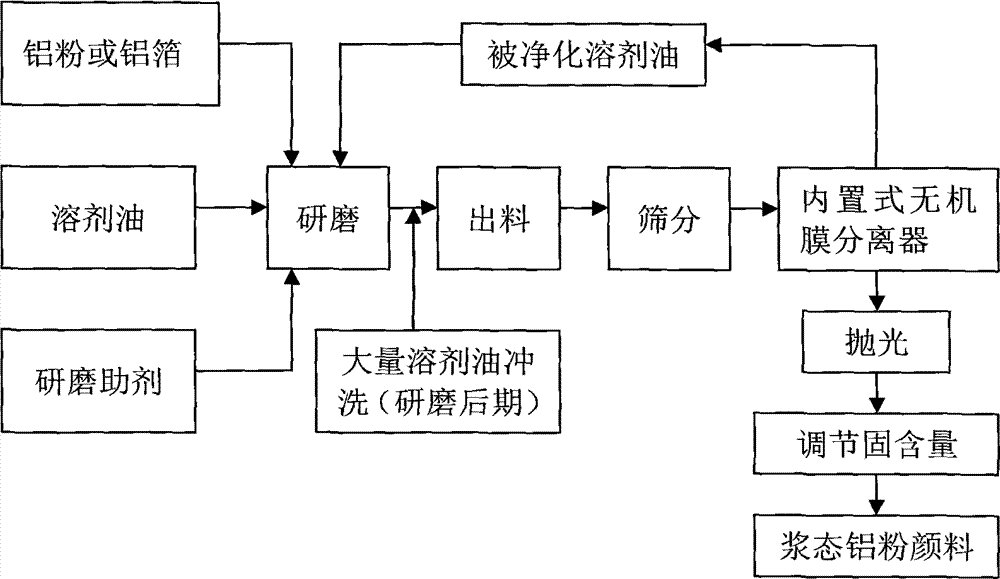

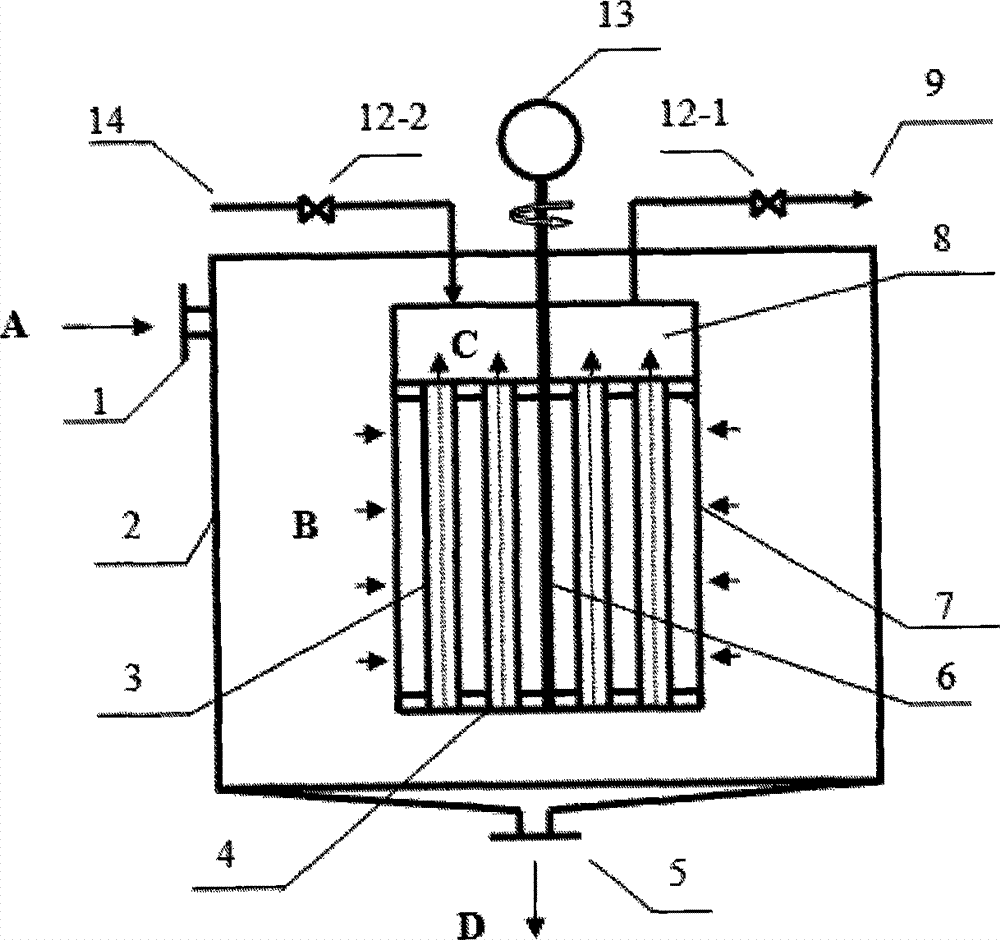

Method of producing oil-dosage-form aluminium powder pigment by utilization of inorganic membrane filtration and device for the method

InactiveCN104119706AReduce pollutionImprove throughputPigment physical treatmentPigment treatment with non-polymer organic compoundsFiltrationAluminium powder

The invention belongs to the technical field of pigment preparation, and particularly relates to a method of producing an oil-dosage-form aluminium powder pigment by utilization of inorganic membrane filtration and a device for the method. The production device comprises a grinding device, a sieving device and a separating device, wherein the sieving device and the separating device are connected after the grinding device in sequence. The separating device is a built-in type inorganic membrane separator. The inorganic membrane separator with a special structure is adopted to perform solid-liquid separation, thus achieving simultaneous performing of separation and purification of solvent oil, guaranteeing the product quality, simplifying processes at present, largely reducing the energy consumption in processes and saving the production cost.

Owner:HUNAN UNIV OF SCI & TECH

Method for separating semifiber and fiber frame plant stalks

The present invention relates to a method for separating hemi-fiber and fiber from plant stalk. Said method includes the following steps: soaking the fibrous material in dilute sulfuric acid, using drum to roll the fibrous material and remove the most of acid liquor, then heating the fibrous material and placing the fibrous material into a closed large container, heat-insulating, after a period of time, adding warm water and utilizing column extractor to make extraction so as to obtain the invented hemi-fibre and fiber.

Owner:ZHONGAOSHENGHUA SCI & TECH DEV TIANJIN

Alkaline silica sol composition and application thereof in preparation of cracking catalyst

ActiveCN101745415BSimple preparation processReduce consumptionCatalytic crackingMolecular sieve catalystsMolecular sieveAlkali metal oxide

Owner:CHINA PETROLEUM & CHEM CORP +1

Acid-soaked cadmium-selenium contained acid pickle direct recycling method

The invention discloses an acid-soaked cadmium-selenium contained acid pickle direct recycling method. Acid-soaked cadmium-selenium contained acid pickle is directly used for preparing and producing a zirconium silicate microcrystal wrapped cadmium selenide pigment after being subjected to comprehensive treatment by use of a chemical reaction method. Zirconium oxychloride, sodium hydroxide and sodium sulfide are used for performing treatment on the acid-soaked cadmium-selenium contained acid pickle; after the zirconium oxychloride is added into the acid-soaked cadmium-selenium contained acid pickle, and the sodium hydroxide and the sodium sulfide are prepared to be a mixed solution by the addition of water according to needs, after a stirring synthetic reaction, filter pressing and washing are performed, drying is performed, then the obtained mixture is mixed with a mineralizer, white carbon black and selenium powder to be uniform, then high-temperature calcination is performed, the calcined product is subjected to the working procedures including acidification, ball-milling, filer pressing, washing, soda boiling, filer pressing and washing, and the zirconium silicate microcrystal wrapped cadmium selenide pigment product is obtained after drying.

Owner:LILING KEXING IND CO LTD

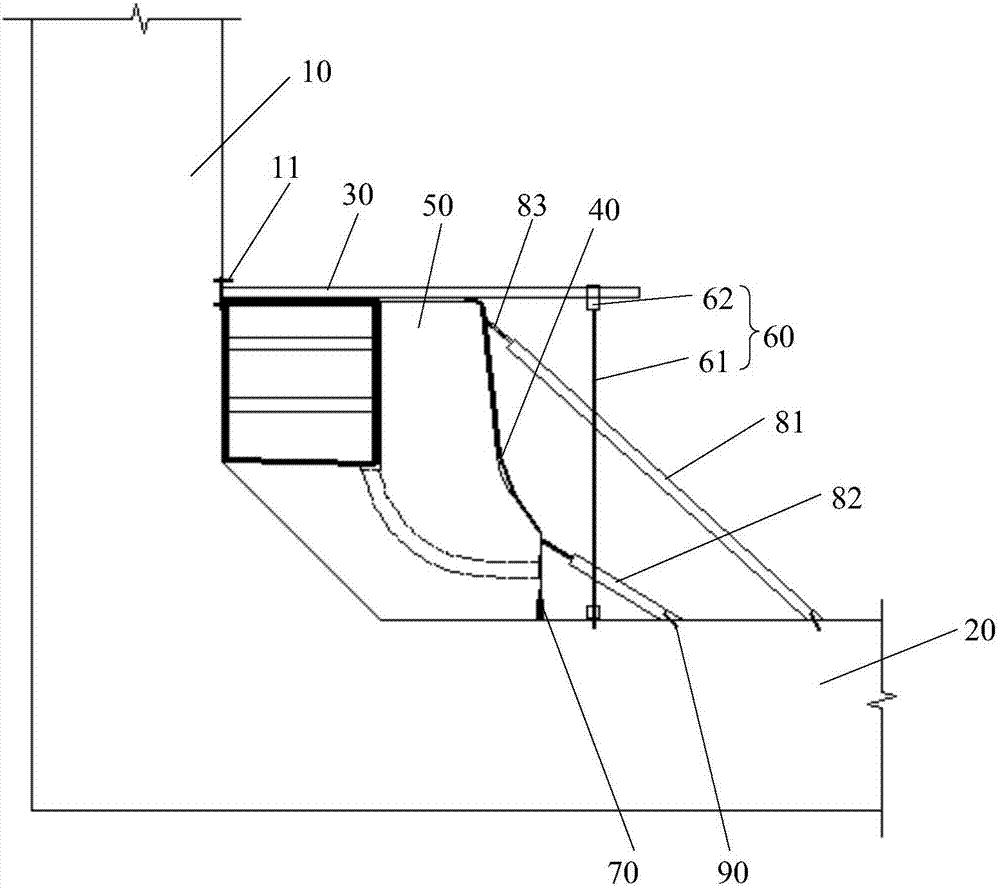

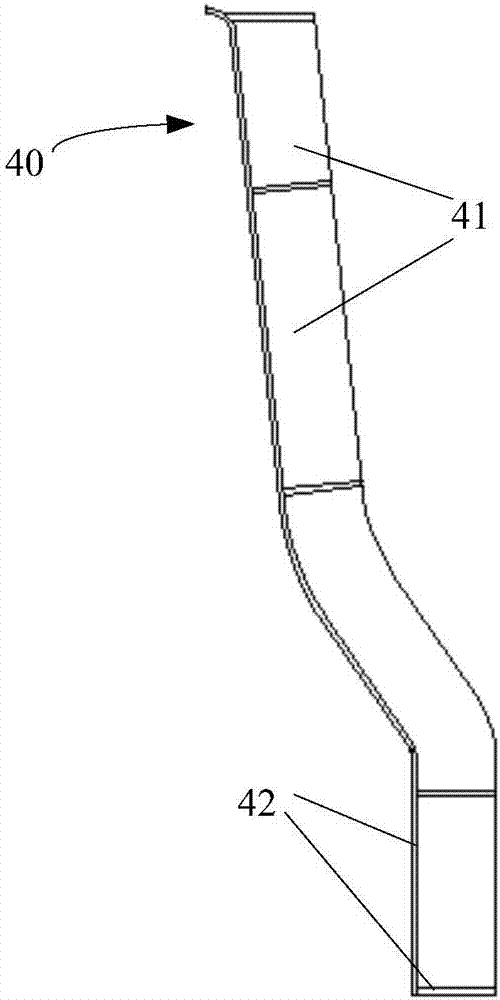

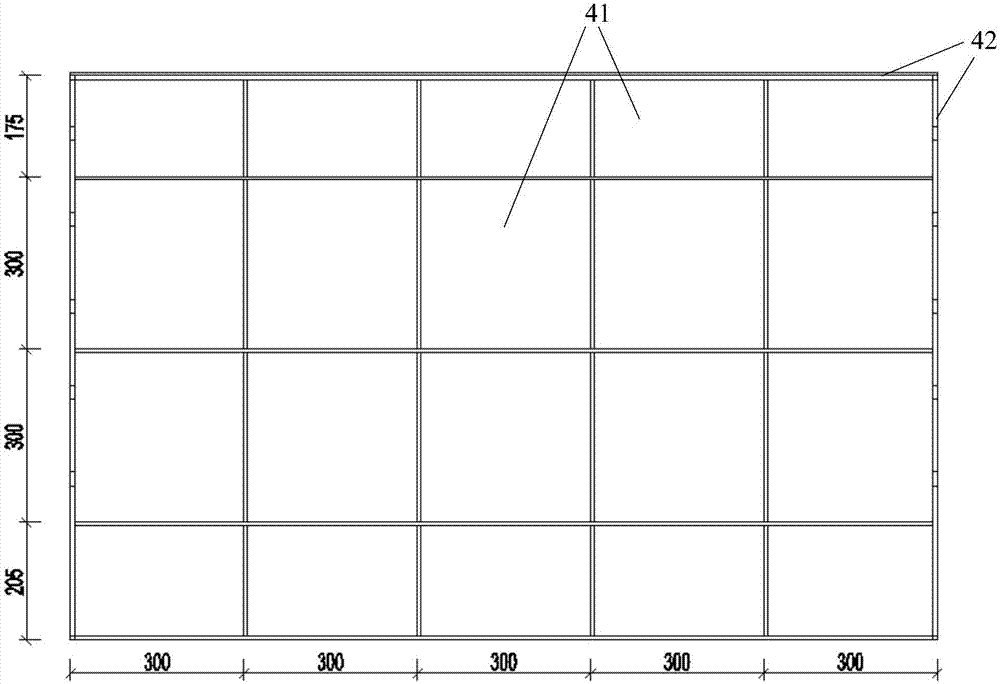

Tunnel anti-collision wall formwork strengthening system and construction method

PendingCN108004986AIncrease stiffnessAccurate dimensional accuracyUnderground chambersTunnel liningMaterial consumptionEngineering

The invention discloses a tunnel anti-collision wall formwork strengthening system and a construction method. The tunnel anti-collision wall formwork strengthening system includes a plurality of horizontal square steel pipes of which one ends are fixed to a side wall, a plurality of steel templates of which the top ends abut against the lower bottom surfaces of the horizontal square steel pipes and the bottom ends are fixed to a structural base plate, a plurality of steel pipe inclined struts which are installed between the outer sides of the steel templates and the structural base plate and aflower basket structure of which the upper and the lower ends are separately connected with the horizontal square steel pipes and the structural base plate, and the steel templates are of a hook facestructure which is suitably matched with anti-collision side stones. The horizontal square steel pipes are fixed to the side wall to perform coping to the steel templates, the horizontal square steelpipes are high in rigidity and accurate in dimensional precision, are not prone to deforming, the contact area with the steel templates is large, and the entire stability of a strengthening system isimproved; the steel templates are machined and produced adopting uniform canalization, the specification is uniform, the installation and the disassembly are convenient, the construction efficiency is improved, and the material consumption is decreased; and the structure size and the appearance quality of the shaped anti-collision side stone are better, the performance of actual measurement is improved, and the subsequent decoration cost is reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

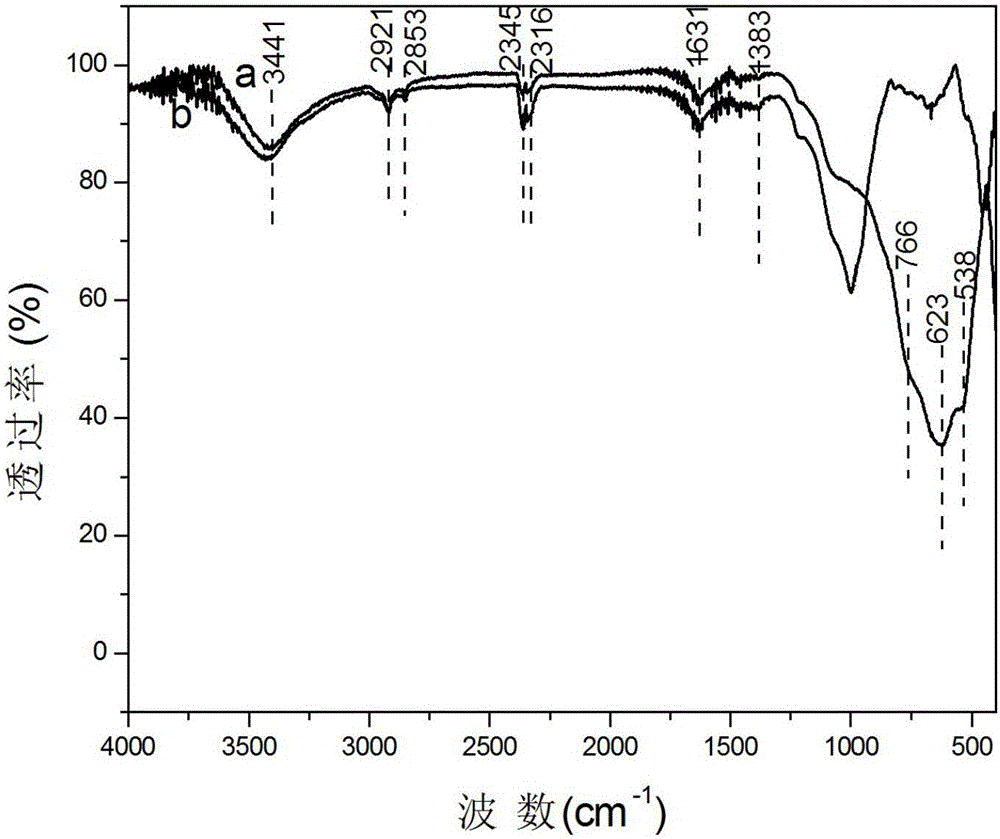

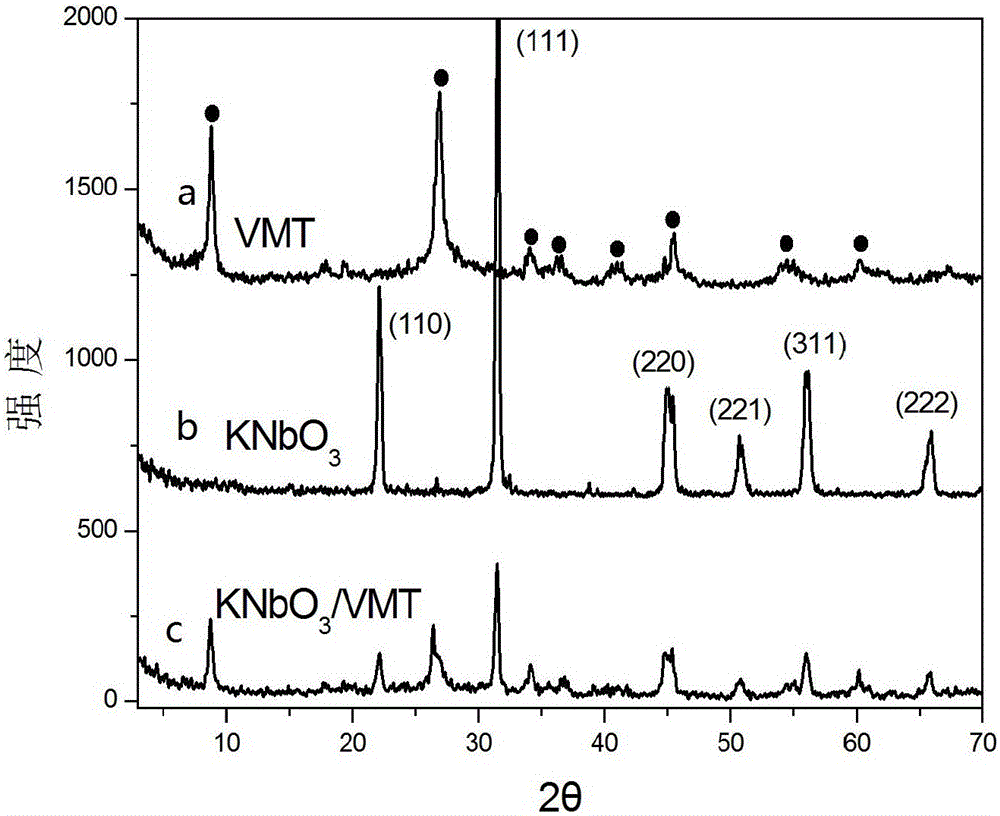

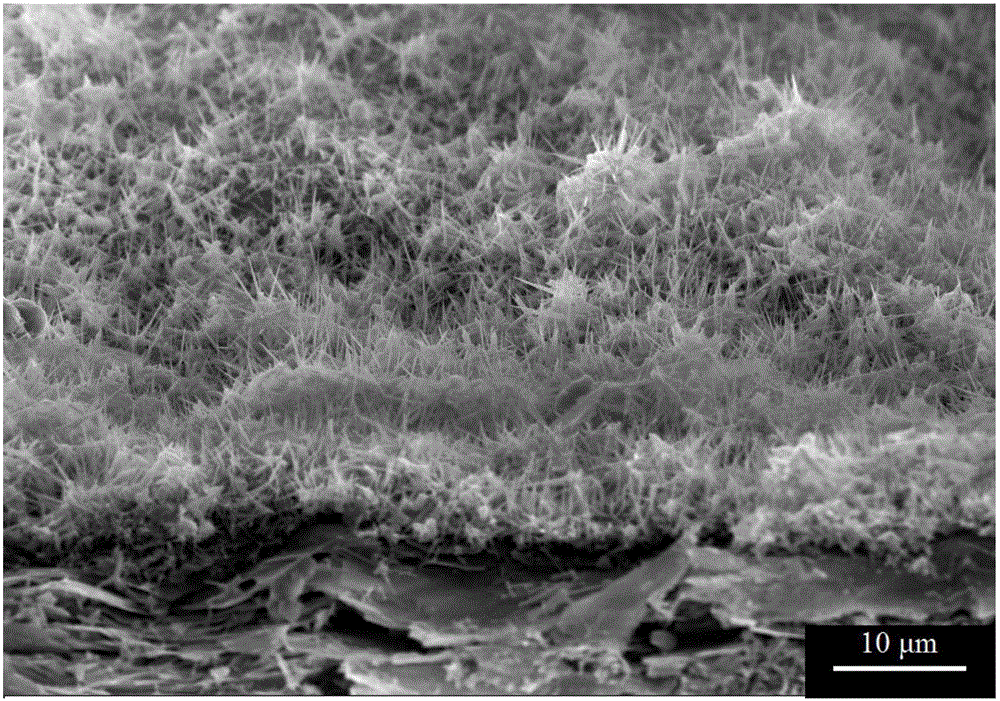

Vermiculite surface in-situ grown potassium niobate material and preparation method thereof

ActiveCN105664915ALow photodegradation efficiencyHigh recycling costWater/sewage treatment by irradiationWater treatment compoundsAdhesion forceNiobium

The invention relates to a vermiculite surface in-situ grown potassium niobate material and a preparation method thereof.The preparation method includes: adopting a one-step hydrothermal method; placing vermiculite in a solution containing potassium hydroxide and niobium pentachloride; controlling nucleation and growth of KNbO3 on vermiculite by controlling reaction temperature and time, wherein potassium niobate grows on the surfaces of inner and outer layers of two-dimensional layered vermiculite in-situ through a one-dimensional needle-like structure to form a KNbO3 / VMT material of a three-dimensional material, and KNbO3 and vermiculite interact through chemical bonds, so that adhesion force is large.The preparation method is simple and convenient in process.The material can be used as a photocatalytic material.The problem that reaction raw materials are prone to loss, difficult to store and separate and high in recovery cost due to the fact that only KNbO3 powder can be adopted as a catalyst in the past is solved.

Owner:BEIJING UNIV OF CHEM TECH

Thermal-insulated hybrid coating containing waste polystyrene foam plastic

InactiveCN107033758AGood gloss and color retentionImprove heat resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceDibenzoyl Peroxide

The invention discloses a thermal-insulated hybrid coating containing waste polystyrene foam plastic. The coating is prepared from raw materials as follows: perfluoroalkyl alcohol, methyl isobutyl ketone, HDI tripolymer, methyl methacrylate, styrene, hydroxyethyl methacrylate, tridecafluorooctyl methacrylate, benzoyl peroxide, methanol silica sol, propylene glycol methyl ether acetate, waste polystyrene, maleic anhydride, hexadecyl trimethyl ammonium chloride, an emulsifier OP-10, rosin, ferrite powder, a proper amount of 5% ammonia water, a proper amount of mercaptoalkylalkoxysilane, a proper amount of dimethyl silicone, a proper amount of 10% dibutyl tin dilaurate, a dispersant, a flatting agent, a defoaming agent, a proper amount of butyl acetate, a proper amount of 20% alkali liquor, ethyl acetate, a proper amount of dichloromethane, a proper amount of acetone and a proper amount of deionized water. The prepared coating has good hydrophobic and oleophobic effects, good thermal-insulated effects and high adhesion, is simple in preparation process and has better practical application prospects.

Owner:TIANCHANG YINHU PAINT

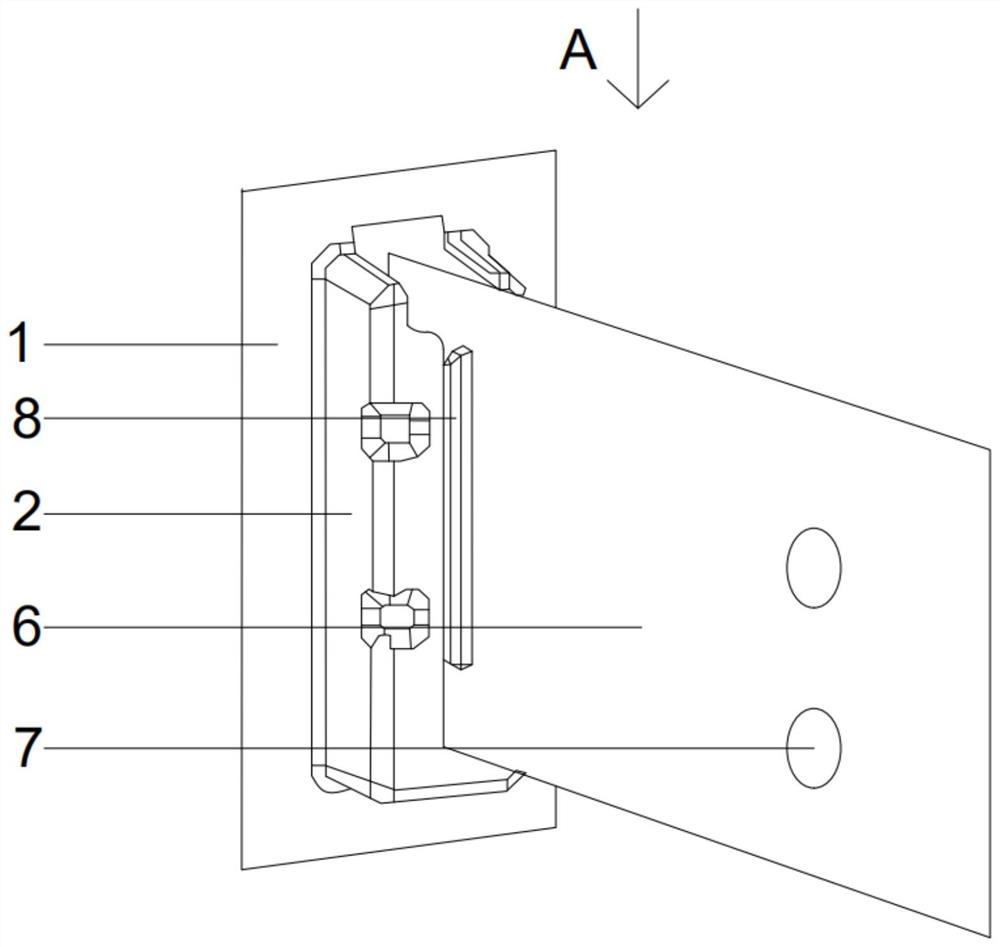

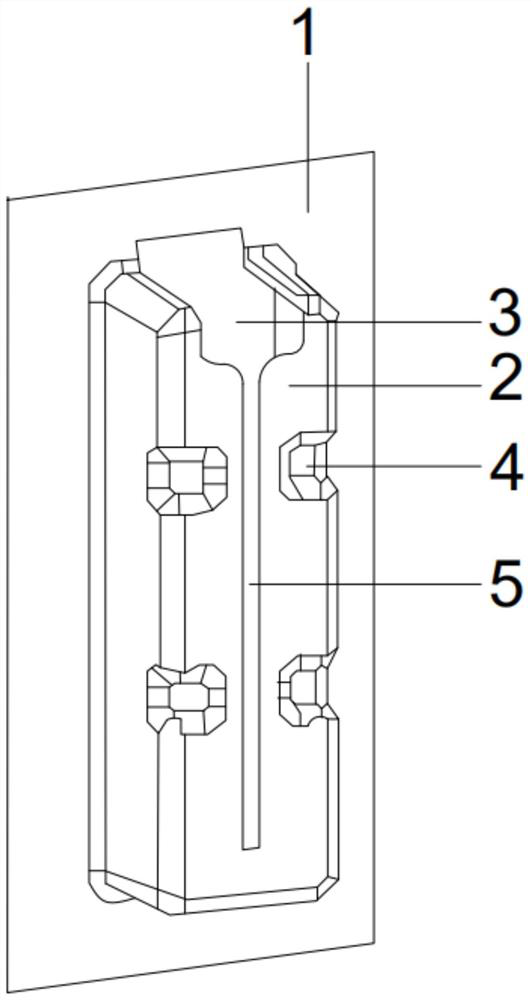

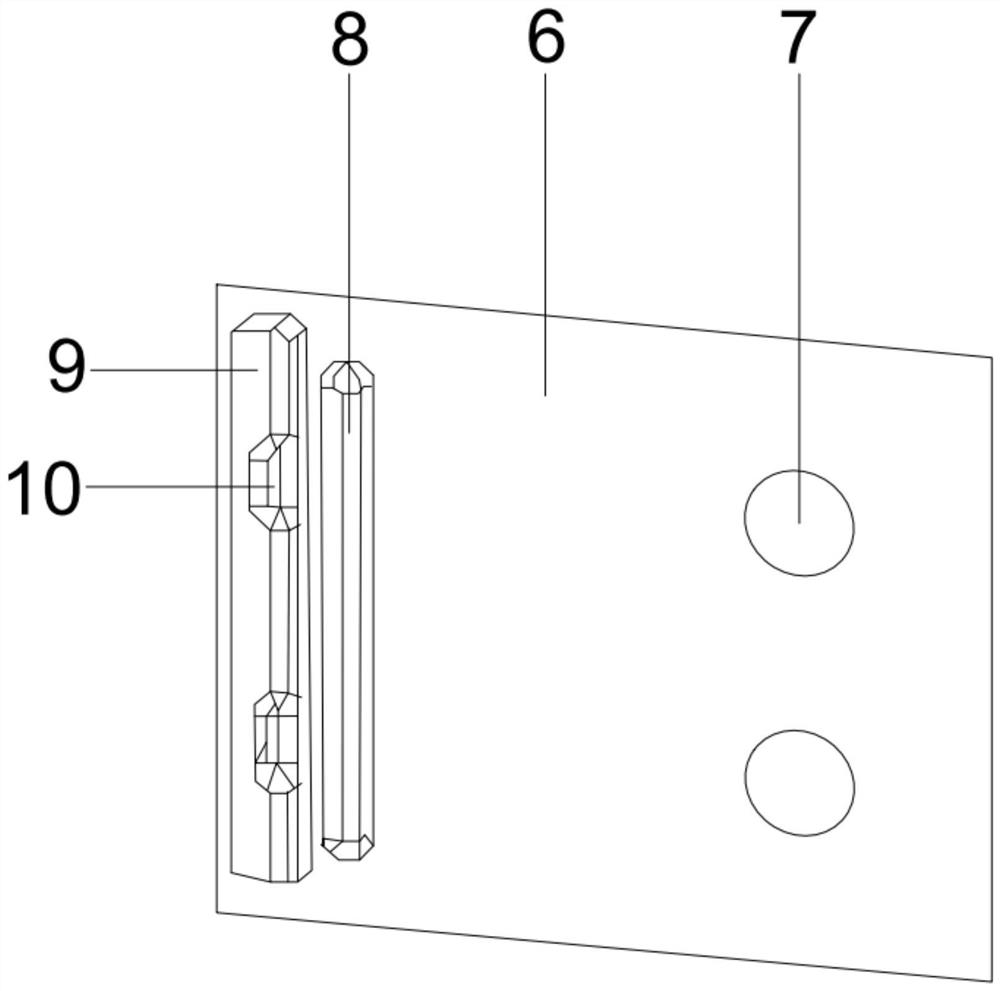

Full-plant-fiber pulp-molded buckle

ActiveCN112943756AMeet the load-bearing requirementsAchieve recyclingSecuring devicesApparatus for force/torque/work measurementPulp (paper)Sustainable economy

The invention provides a full-plant-fiber pulp-molded buckle. The full-plant-fiber pulp-molded buckle comprises a primary buckle body and a secondary buckle body, and the primary buckle body and the secondary buckle body are made of full-plant-fiber pulp or pulp made of recycled paper products. The full-plant-fiber pulp-molded buckle is designed and developed, is used for connecting and supporting a storage rack and can replace part of metal or plastic buckles, and the technical problems that metal or plastic buckles in the background art are troublesome to disassemble and need to be classified for the second time in the using process of part of storage racks, consequently, the recovery cost is increased, the cost is high in sustainable economic development, plastic buckles and part of storage racks are combined for supporting, bearing faces are formed for supporting placed objects, however, the storage racks and the plastic buckles are not made of the same material and cannot be naturally degraded, and consequently environmental pollution is serious are solved.

Owner:WING FAT (HENAN) MOLDED FIBER TECH DEV CO LTD

Kitchen fume sucking and recycling device

InactiveCN108087933AReduce pollutionHigh recycling costDomestic stoves or rangesCooking fumes removalEngineeringWaste recovery

The invention discloses a kitchen fume sucking and recycling device. The kitchen fume sucking and recycling device comprises a fan cover, wherein an oil storage tank is clamped on the big end of the fan cover, a fan cylinder is connected to the small end of the upper part of the fan cover, a filter screen is arranged between the lower end of the fan cylinder and the small end of the fan cover, anair outlet of a fan is movably connected with an inlet of an air filter, an inlet pipe is connected to the outer bottom of a housing of the air filter in a penetrating mode, an oil storage pipe is connected to the side of the housing of the air filter in the penetrating mode, a spiral pipe is arranged on the outer wall of the housing, and a connecting end cover is spirally sealed on an upper end opening of the housing. The kitchen fume sucking and recycling device has the advantages of compact structure, reasonable design and unique and novel concept; blades rotate to suck fume and heat, secondary filter is realized so as to remove oil, the spiral pipe is heated by hot air through a transfer layer, and hot water in the spiral pipe is used, so that energy is saved; in addition, filtered oilcan be recycled, so that the waste recovery cost is increased, and air pollution is reduced.

Owner:HEFEI XINKAICHUANG STAINLESS STEEL EQUIP

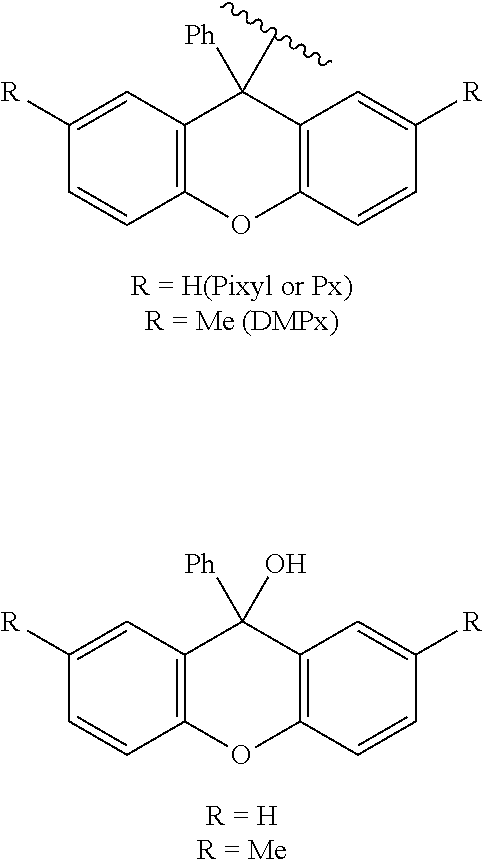

Method of solid-phase nucleic acid synthesis and solution composition for solid-phase nucleic acid synthesis

ActiveUS20210206797A1High recycling costIncrease aciditySugar derivativesPeptide preparation methodsCombinatorial chemistryToluene

This invention is intended to discover a novel solvent that can be used as an alternative to toluene in the step of deprotection in the method of solid-phase nucleic acid synthesis. With the use of such novel solvent, various problems caused by the use of toluene are dissolved.This invention is also intended to provide a method of solid-phase nucleic acid synthesis in which protected nucleoside phosphoramidites in which a protective group is bonded to a hydroxyl group at the 5′position or the 3′ position of a nucleoside are sequentially bound on a solid phase carrier, where a reaction of removing the protecting group from the protected nucleoside phosphoramidite is carried out in a solution comprising an acid with a pKa of 0.2 to 0.8 and acetonitrile.

Owner:NITTO DENKO CORP

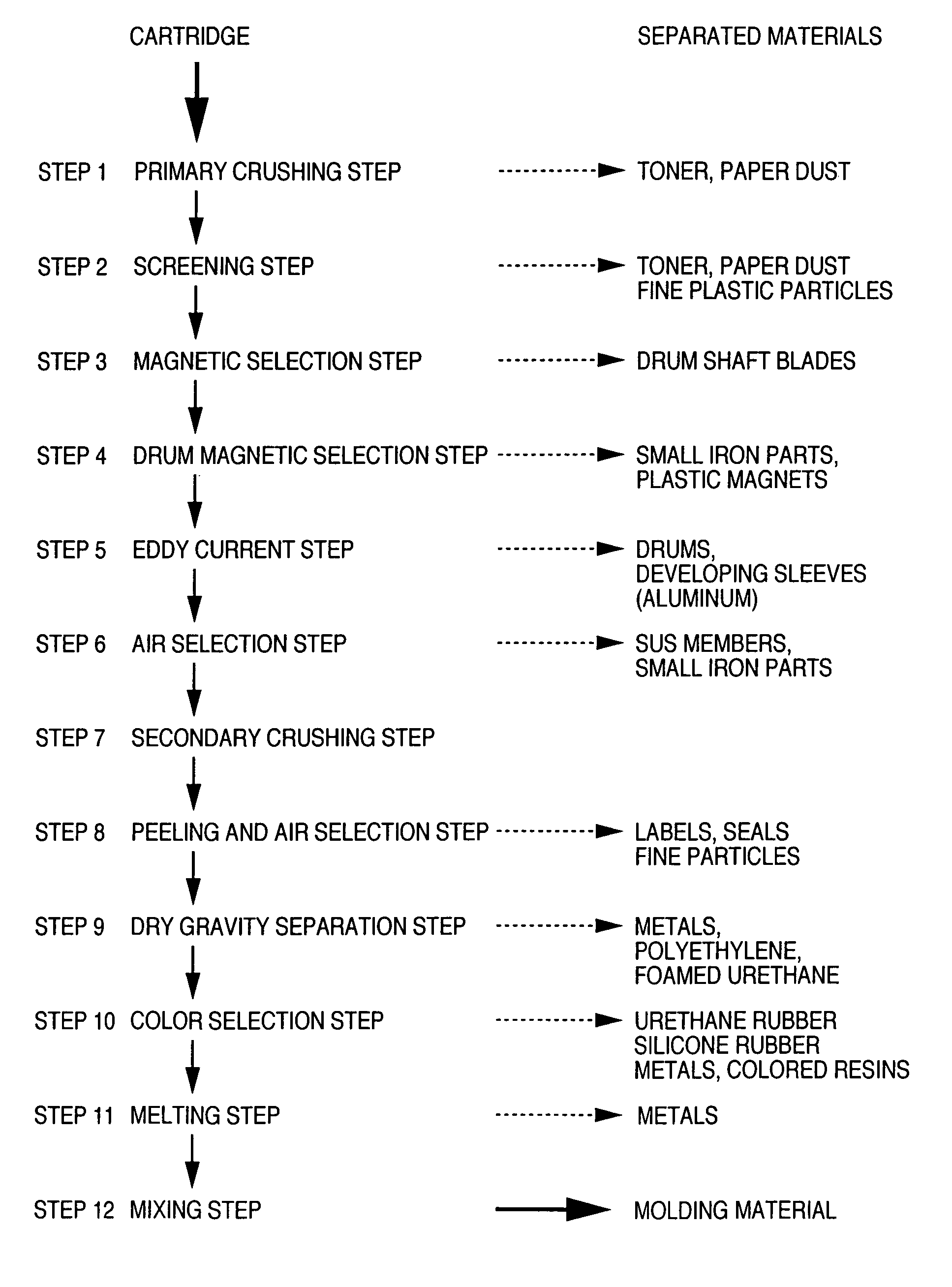

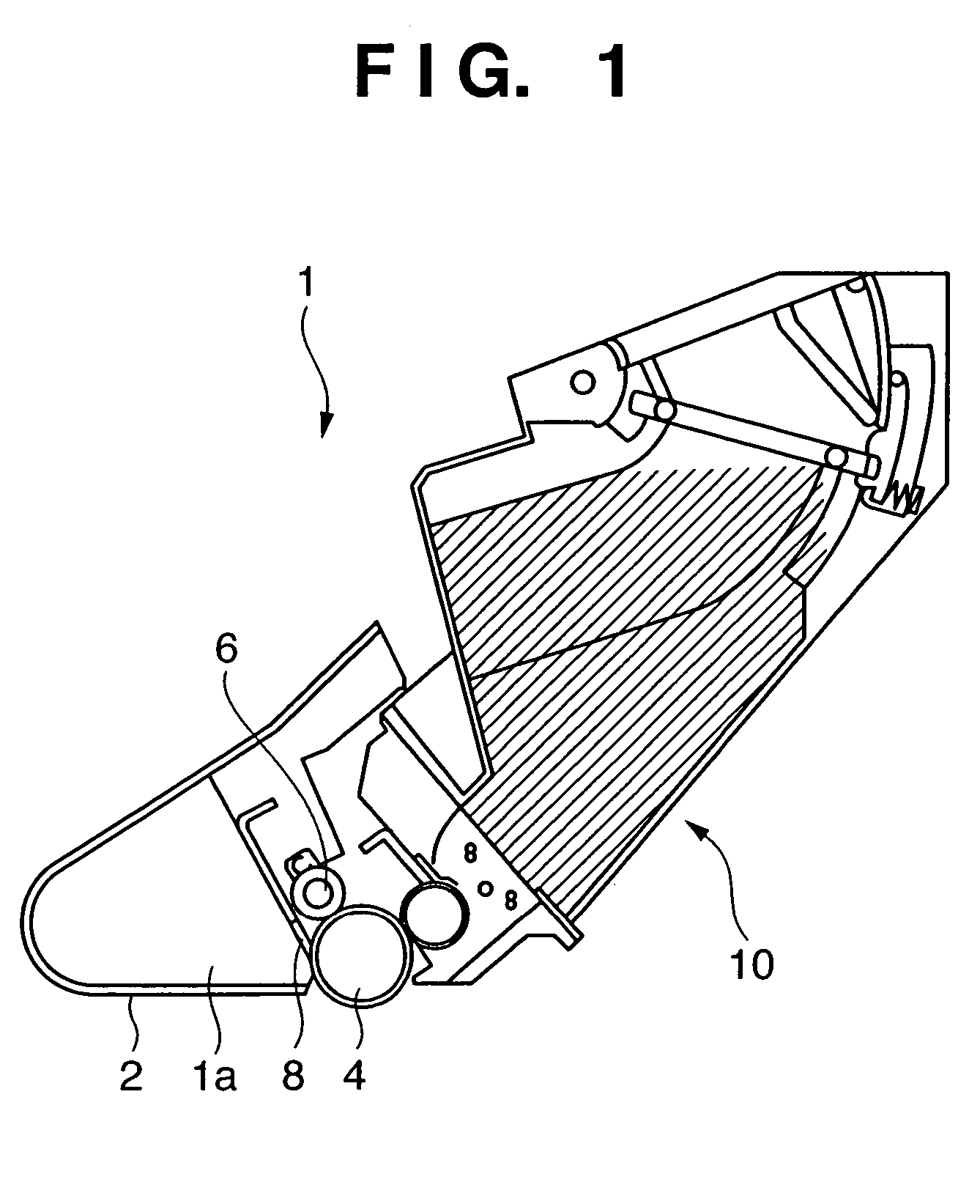

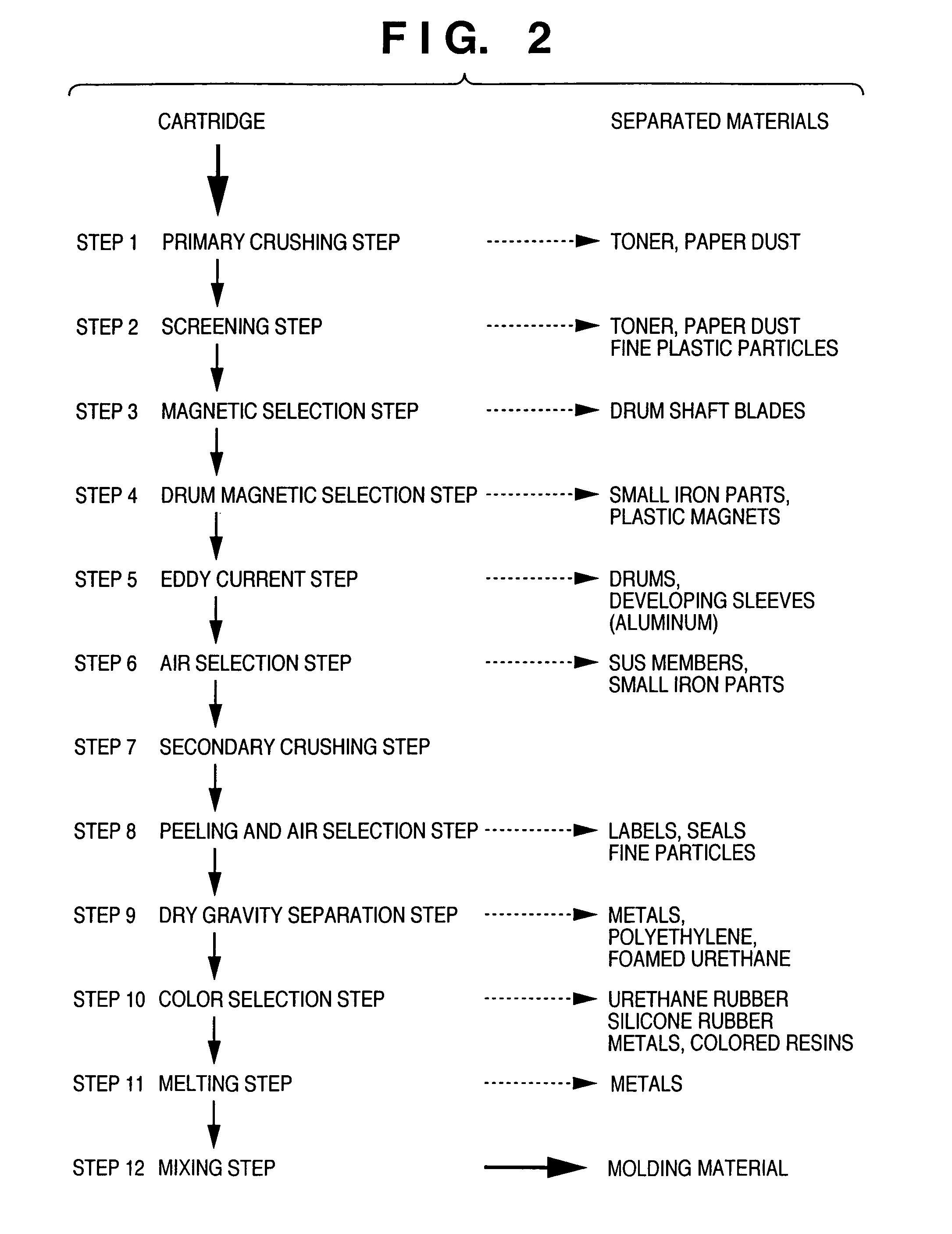

Method of recycling plastic material of process cartridge

InactiveUS7178748B2Reduced strengthHigh recycling costGrain huskingGrain polishingForeign matterMetallic materials

It is an object of this invention to efficiently recycle a plastic resin material used in a process cartridge. To achieve this object, in a method of recycling a plastic material of a process cartridge, the process cartridge is crushed in a crushing step while particles such as toner are collected by suction, particles including toner are further separated in a screening step, metal materials are separated in a magnetic selection step, a drum magnetic selection step, and an eddy current step, particles including toner and foreign matter are separated in an air selection step, a secondary crushing step, a peeling step, and a dry gravity separation step, and a plastic material having a specific density is separated in a color selection step.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com