Tunnel anti-collision wall formwork strengthening system and construction method

A formwork reinforcement and construction method technology, which is applied in the field of construction engineering, can solve the problems of poor concrete molding quality, substandard actual measurement, and irregular yin and yang angles, achieving high turnover utilization rate, improving actual measurement results, and turnover times. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in detail:

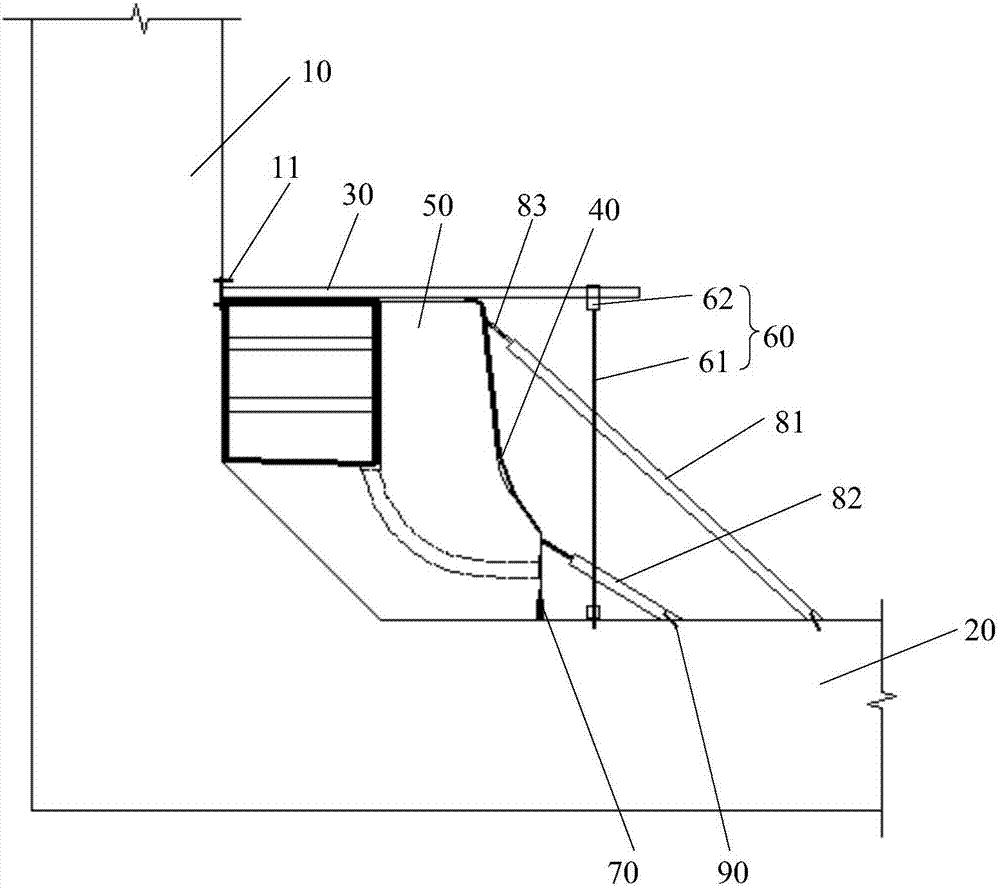

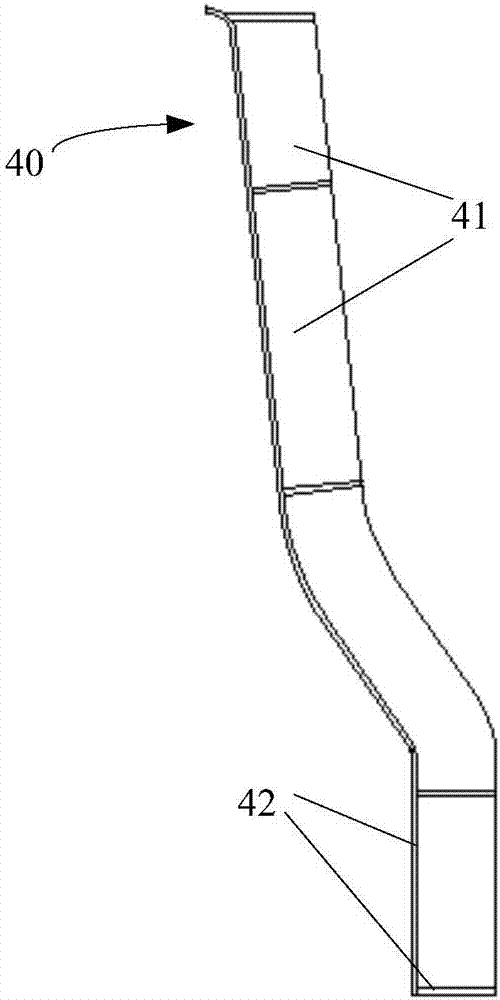

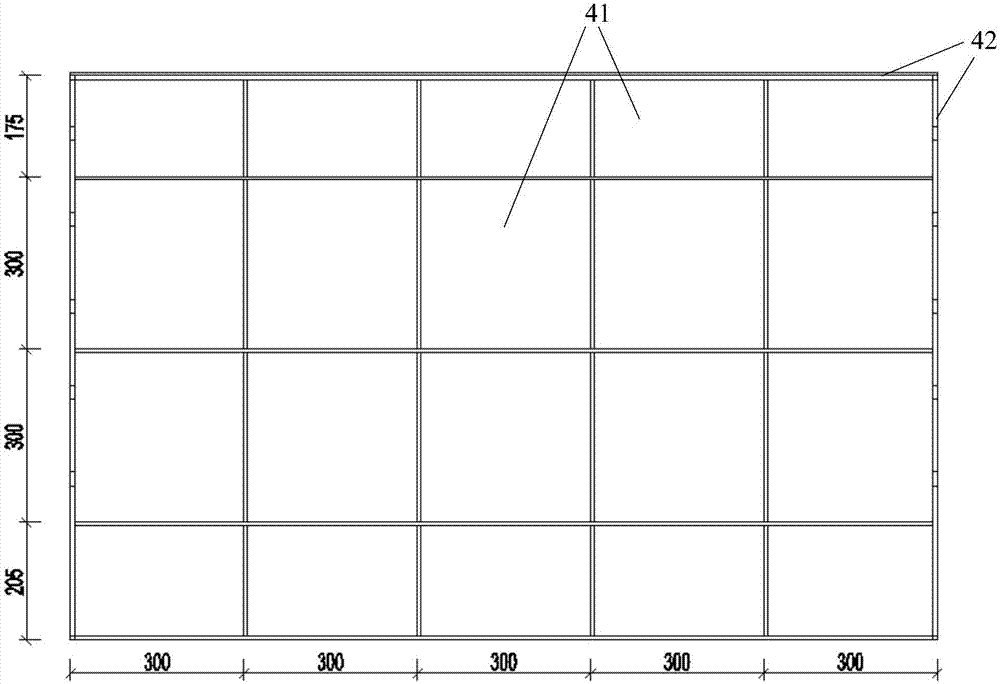

[0029] like figure 1 As shown, the present invention provides a tunnel anti-collision wall formwork reinforcement system, which is arranged between the side wall 10 and the structural bottom plate 20, and is used for formwork support and positioning before pouring the anti-collision side stone 50, including one end of which is fixed on the side Several horizontal square steel pipes 30 on the wall 10, the top ends are in contact with the lower bottom surface of the horizontal square steel pipes 30, and the bottom ends are fixed on several steel formwork 40 on the structural bottom plate 20, installed on the outer side of the steel formwork 40 and the structural bottom plate 20. A plurality of steel pipe diagonal braces therebetween and the upper and lower ends are respectively connected to the horizontal square steel pipe 30 and the flower basket structure 60 of the structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com