Scrapped automobile engine assembly dismantling and recycling non-polluting utilization device

A technology for engine assembly and motor vehicles, which is applied in the fields of waste treatment and resource recycling. It can solve the problems that parts cannot be reused, cannot be stored and recycled in a centralized manner, and there is no collection pool for oil, so as to achieve high mechanized operation efficiency and increase recycling. Cost, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

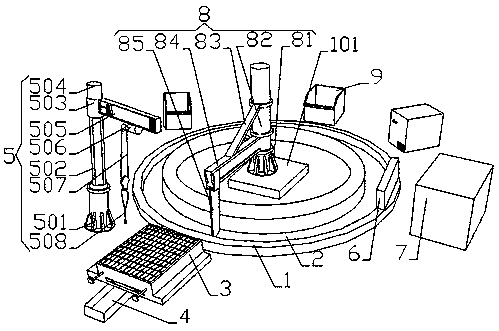

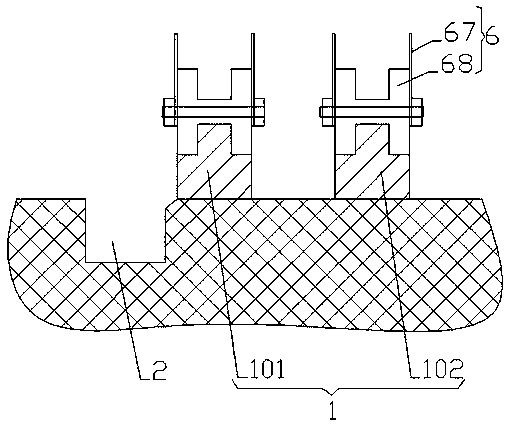

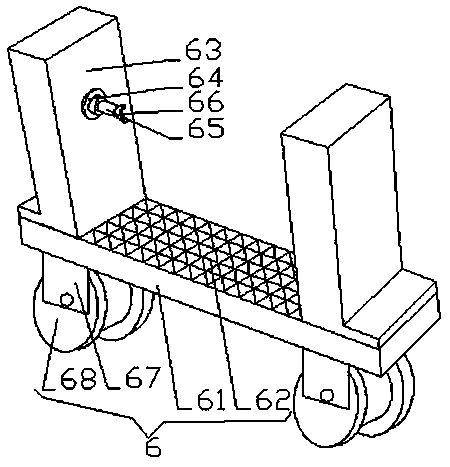

[0019] Such as Figure 1-3 As shown in , a waste motor vehicle engine assembly dismantling and recycling non-pollution utilization device includes a ring track 1, the ring track 1 is fixedly installed on the ground, and the inner side of the inner rail 201 of the ring track 1 is provided with an open ditch on the ground 2. A platform 103 is arranged in the middle, and a cleaning mechanism 8 is installed on the platform 103. An abutment 3 is provided on the outer side of the outer rail 102 of the annular track 1, and a dark ditch 4 is provided under the abutment 3, and one end thereof is connected to the open ditch 2 Connected, a lifting mechanism 5 is installed on one side of the base 3, a dismantling mechanism 6 is provided on the ring track 1, and a number of dismantling stations are also provided on the outer periphery of the ring track 1.

[0020] As a further imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com