Environment-friendly method and environment-friendly device for mercury-antimony separation for mercury-antimony composite ore

A separation method and technology of a separation device, applied in the field of mineral processing, can solve the problems of high mutual content of products, high recovery cost, new pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

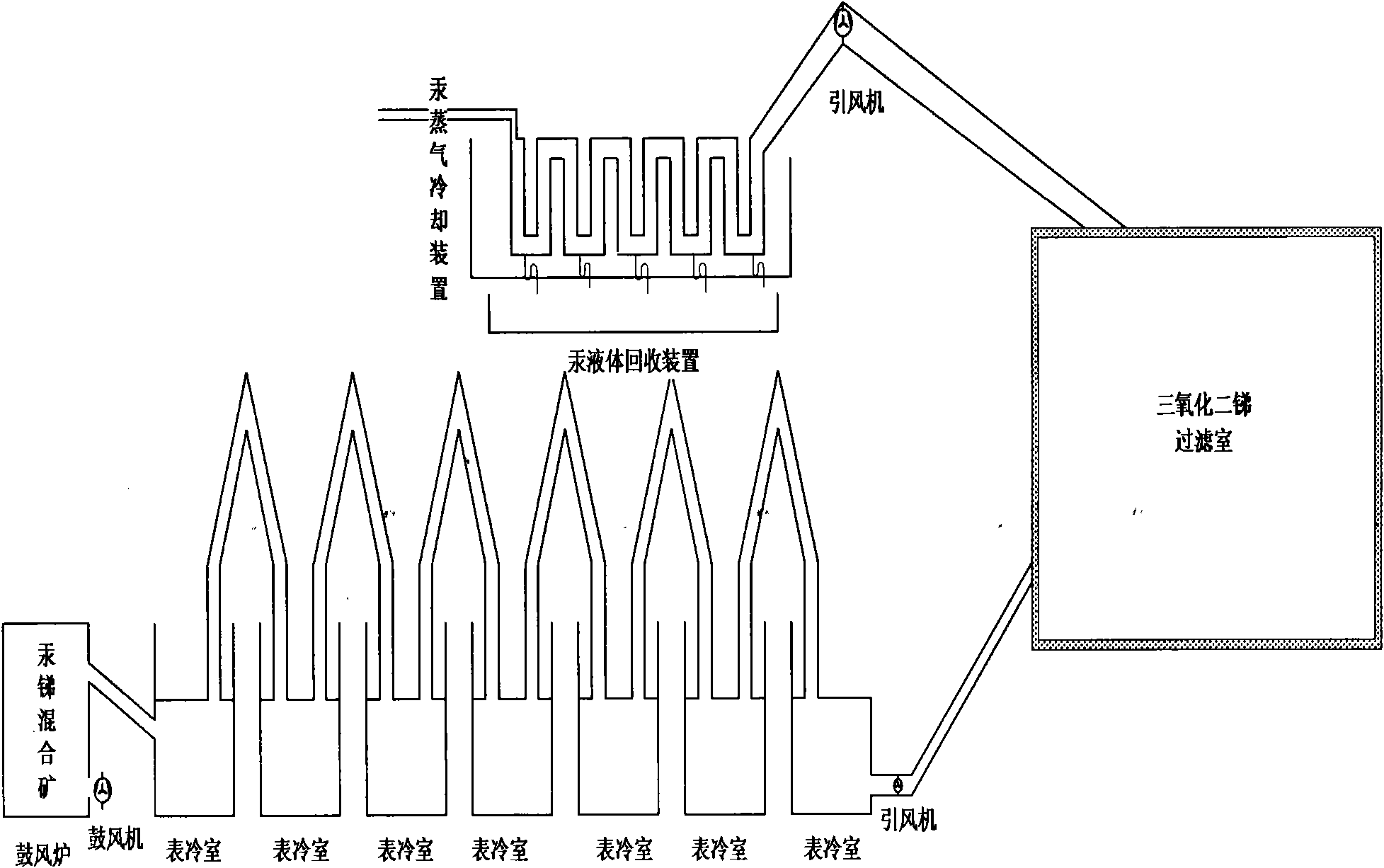

[0010] The present invention can add a mercury circulation cooling device and a recovery device on the basis of ore antimony processing equipment, add a cooling device composed of multiple rows of twisted steel pipes on the original antimony processing sewage pipe and put it into a cooling device filled with water. In the tank, after the mercury cools down, it flows into the recovery container of the mercury liquid through the liquid discharge pipe, which can realize the efficient separation of mercury and antimony.

[0011] With reference to the accompanying drawings, the specific implementation steps are as follows:

[0012] 1. Put the mercury-antimony composite ore in the blast furnace. This composite ore can be the mercury-antimony composite ore powder after pulverization, or the mercury-containing antimony concentrate or the antimony-containing mercury concentrate after washing.

[0013] 2. Use coal as raw material to heat the blast furnace to 1000~1200 degrees Celsius to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com