Full-plant-fiber pulp-molded buckle

A technology of plant fiber and molded buckles, applied in the field of buckles, can solve problems such as environmental pollution, air pollution, and increased recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

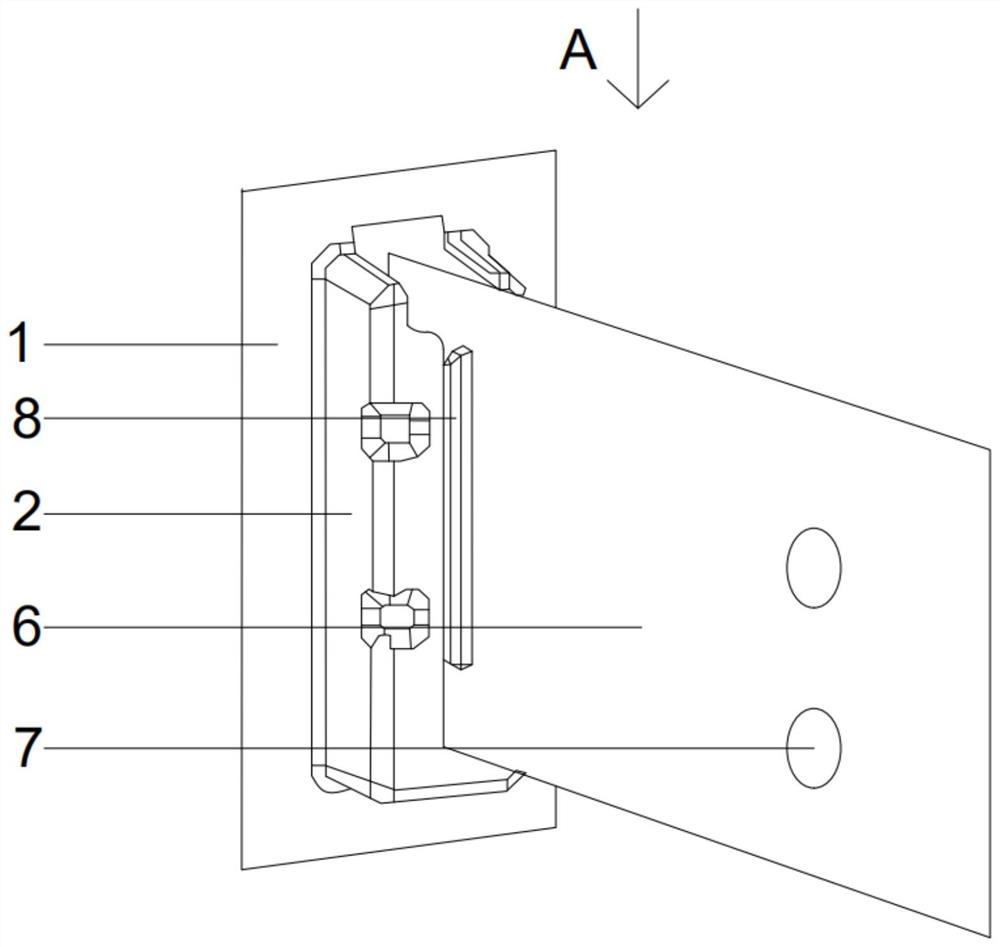

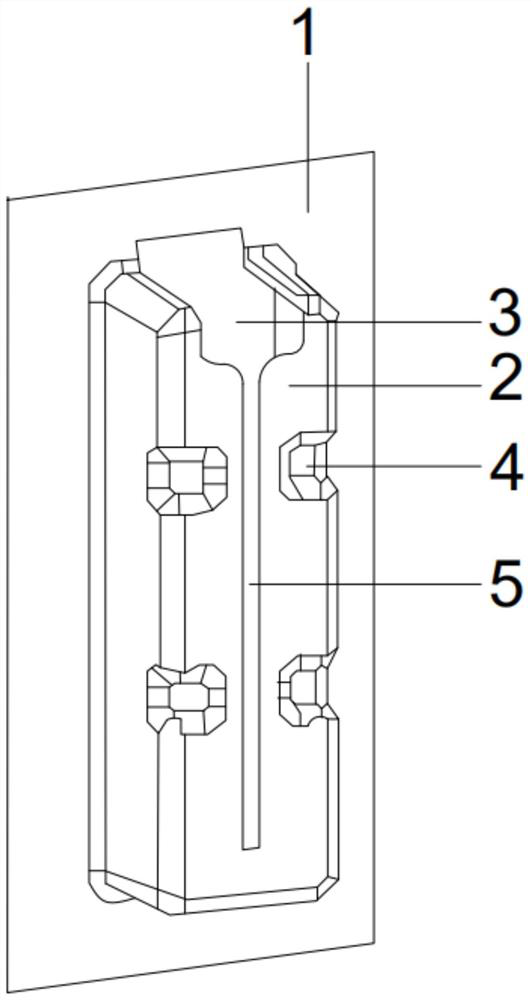

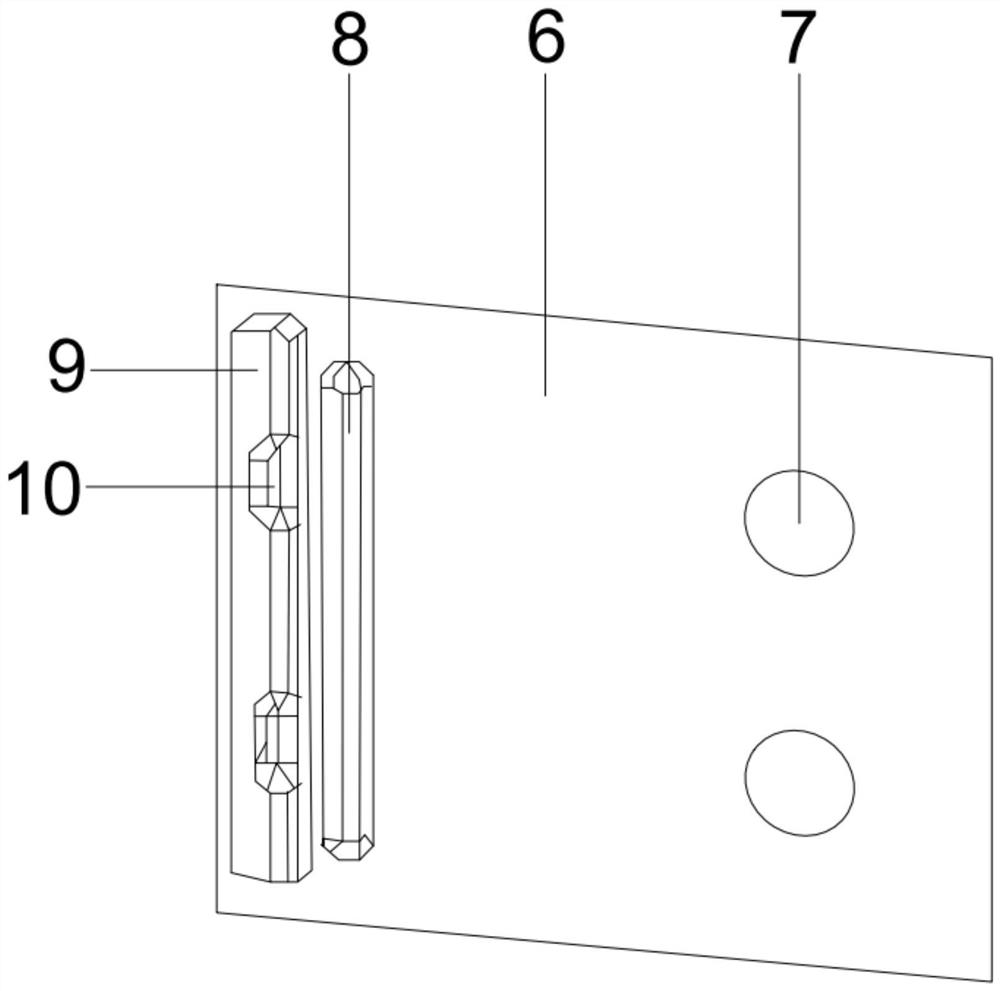

[0050] The embodiment of the present invention provides a whole plant fiber pulp molded buckle, such as Figure 1-Figure 3 As shown, it includes a female button 2 and a daughter card 6. The material of the female button 2 and the daughter card 6 is pulp made of all plant fiber pulp or recycled paper products. The rear end of the female button 2 is provided with a base 1. The inside of the female button 2 is provided with a mounting groove 3, the surface of the female button 2 is provided with a card slot 5, and the surface of the female button 2 is symmetrically provided with a number of positioning holes 4 on both sides of the length direction of the card slot 5, so that The side of the daughter card 6 close to the female buckle 2 is sequentially provided with a limit block one 8 and a limit block two 9 from the outside to the inside, the limit block two 9 is connected with the installation groove 3, and the limit block The block two 9 is provided with some positioning holes ...

Embodiment 2

[0060] On the basis of above-mentioned embodiment 1, as Figure 1-Figure 3 As shown, the number of the first positioning holes 4 is four, the number of the second positioning holes 10 is four, and the four first positioning holes 4 and the four second positioning holes 10 are evenly distributed.

[0061] The beneficial effect of above-mentioned technical scheme is:

[0062] By evenly distributing the first positioning holes 4 and the second positioning holes 10, the connection between the female buckle 2 and the daughter card 6 is more stable, preventing the positioning holes 4 and the second positioning holes 10 from being too concentrated or having a small number, resulting in insufficient retaining force and causing the female buckle 2 Buckle 2 and daughter card 6 have insufficient support.

Embodiment 3

[0064] On the basis of Example 1, such as Figure 4-Figure 5 As shown, the two sides in the length direction of the card slot 5 are the left and right sides of the card slot 5, the first stopper 8 and the second stopper 9 are on the surface of the female buckle 2 at the sides of the card slot 5 The left and right sides are attached, and the left and right sides of the limiting block 9 are symmetrically connected with a fixed block 16, and the fixed block 16 is connected with a block 14, and the block 14 includes two vertical plates 11, two bent Plate one 12, two inclined plates 13 and bent plate two 15, the left and right sides of said bent plate two 15 are symmetrically connected with one end of said two inclined plates 13, said inclined plate 13 is far away from one end of bent plate two 15 One end of the bent plate one 12 is fixedly connected, the other end of the bent plate one 12 is fixedly connected with the vertical plate 11, and the side of the vertical plate 11 close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com