Light high-strength sandwich composite board and production method

A sandwich composite board, high-strength technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of unresolved prepreg tape waste treatment, achieve high recycling costs, improve Effect of Utilization Rate and Broad Market Prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

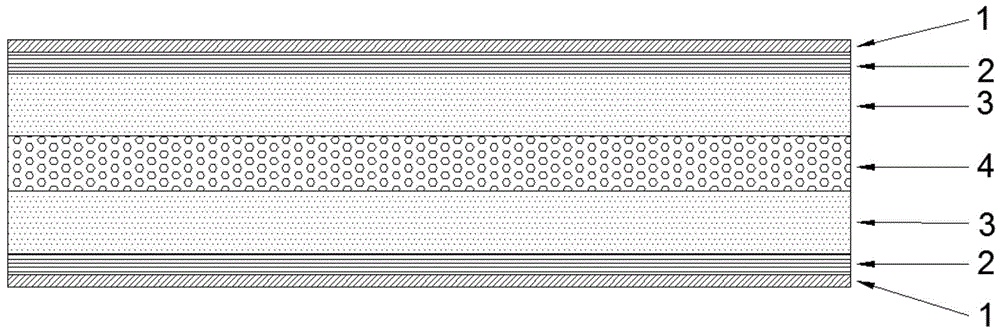

[0027] A lightweight high-strength sandwich composite panel, including a seven-layer structure, from top to bottom is polypropylene coated white dot polyester non-woven fabric, continuous glass fiber reinforced polypropylene prepreg tape, polypropylene fiber and glass fiber composite lightweight Quality mat, waste continuous glass fiber reinforced polypropylene prepreg tape scraps, polypropylene fiber and glass fiber composite lightweight mat, continuous glass fiber reinforced polypropylene prepreg tape, polypropylene coated white dot polyester non-woven fabric.

[0028] Polypropylene coated white dot polyester non-woven fabric with a unit weight of 140g / m 2 , the thickness is 0.2mm, and the unit weight of polypropylene is 70g / m 2 , The unit weight of the white dot polyester non-woven fabric used in the polypropylene coated non-woven fabric is 70g / m 2 The mass content of glass fiber in the continuous glass fiber reinforced polypropylene prepreg tape is 50%, and the thickness ...

Embodiment 2

[0036] A lightweight high-strength sandwich composite panel, including a seven-layer structure, from top to bottom is polypropylene coated white dot polyester non-woven fabric, continuous glass fiber reinforced polypropylene prepreg tape, polypropylene fiber and glass fiber composite lightweight Quality felt, waste continuous glass fiber reinforced polypropylene prepreg tape scraps, polypropylene fiber and glass fiber composite lightweight mat, continuous glass fiber reinforced polypropylene prepreg tape, polypropylene coated white dot polyester non-woven fabric.

[0037] Polypropylene coated white dot polyester non-woven fabric with a unit weight of 180g / m 2 , the thickness is 0.24mm, and the unit weight of polypropylene is 90g / m 2 , The unit weight of the white dot polyester non-woven fabric used in the polypropylene coated non-woven fabric is 90g / m 2 The mass content of glass fiber in the continuous glass fiber reinforced polypropylene prepreg tape is 60%, and the thicknes...

Embodiment 3

[0045] A lightweight high-strength sandwich composite panel, including a seven-layer structure, from top to bottom is polypropylene coated white dot polyester non-woven fabric, continuous glass fiber reinforced polypropylene prepreg tape, polypropylene fiber and glass fiber composite lightweight Quality mat, waste continuous glass fiber reinforced polypropylene prepreg tape scraps, polypropylene fiber and glass fiber composite lightweight mat, continuous glass fiber reinforced polypropylene prepreg tape, polypropylene coated white dot polyester non-woven fabric.

[0046] Polypropylene coated white dot polyester non-woven fabric with a unit weight of 160g / m 2 , the thickness is 0.22mm, and the unit weight of polypropylene is 80g / m 2 , The unit weight of the white dot polyester non-woven fabric used in the polypropylene coated non-woven fabric is 80g / m 2 ; The mass content of glass fiber in the continuous glass fiber reinforced polypropylene prepreg tape is 55%, and the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com