Silicon reclamation apparatus and method of reclaiming silicon

A recycling device and recycling method technology, applied in chemical instruments and methods, fine working devices, silicon, etc., can solve problems such as silicon shortage in solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

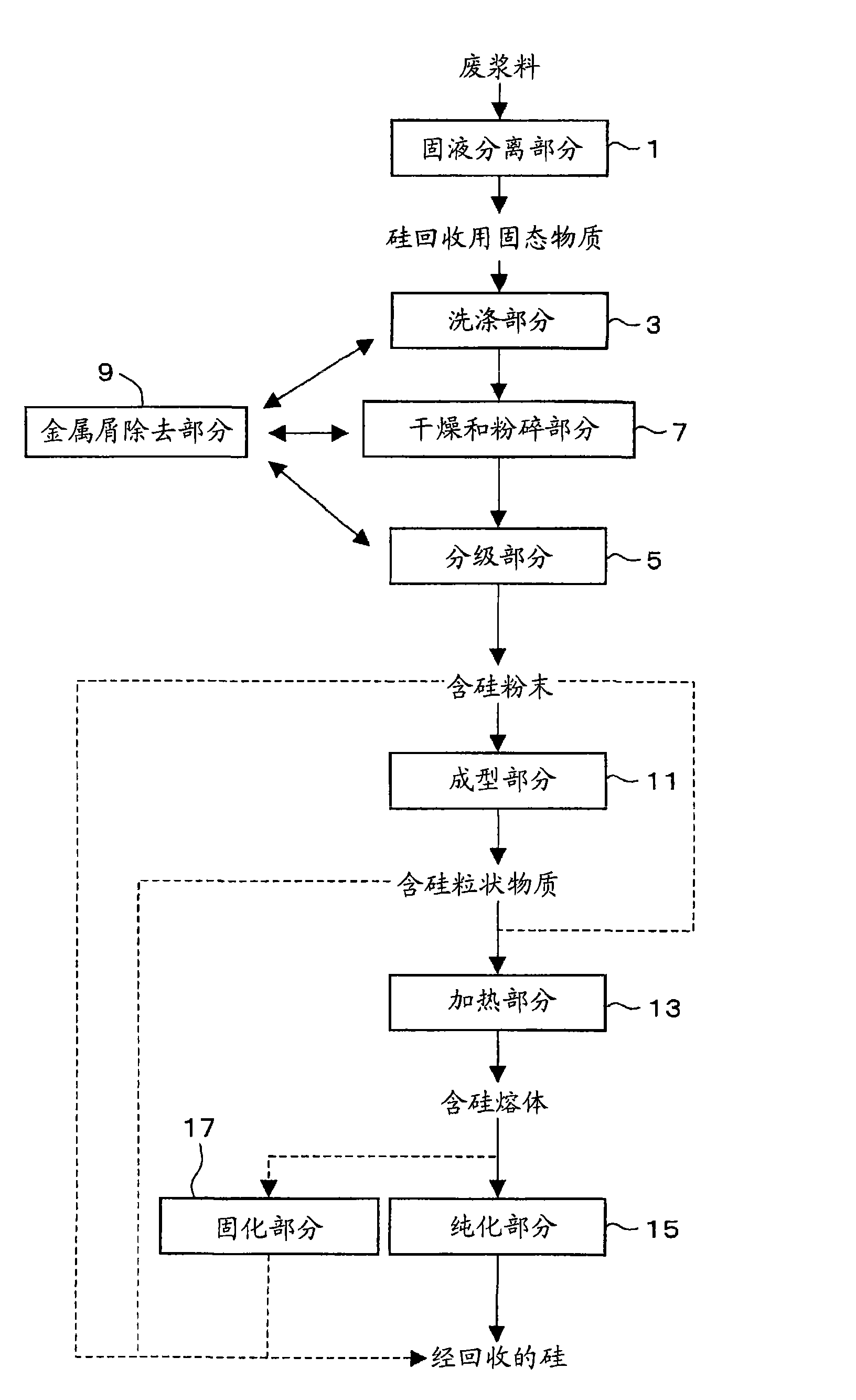

[0046] will use figure 1 The silicon recovery apparatus of the first embodiment of the present invention will be described. figure 1 It is a block diagram showing the structure of the silicon recovery apparatus of this embodiment.

[0047] Silicon recycling device of the present invention comprises following parts:

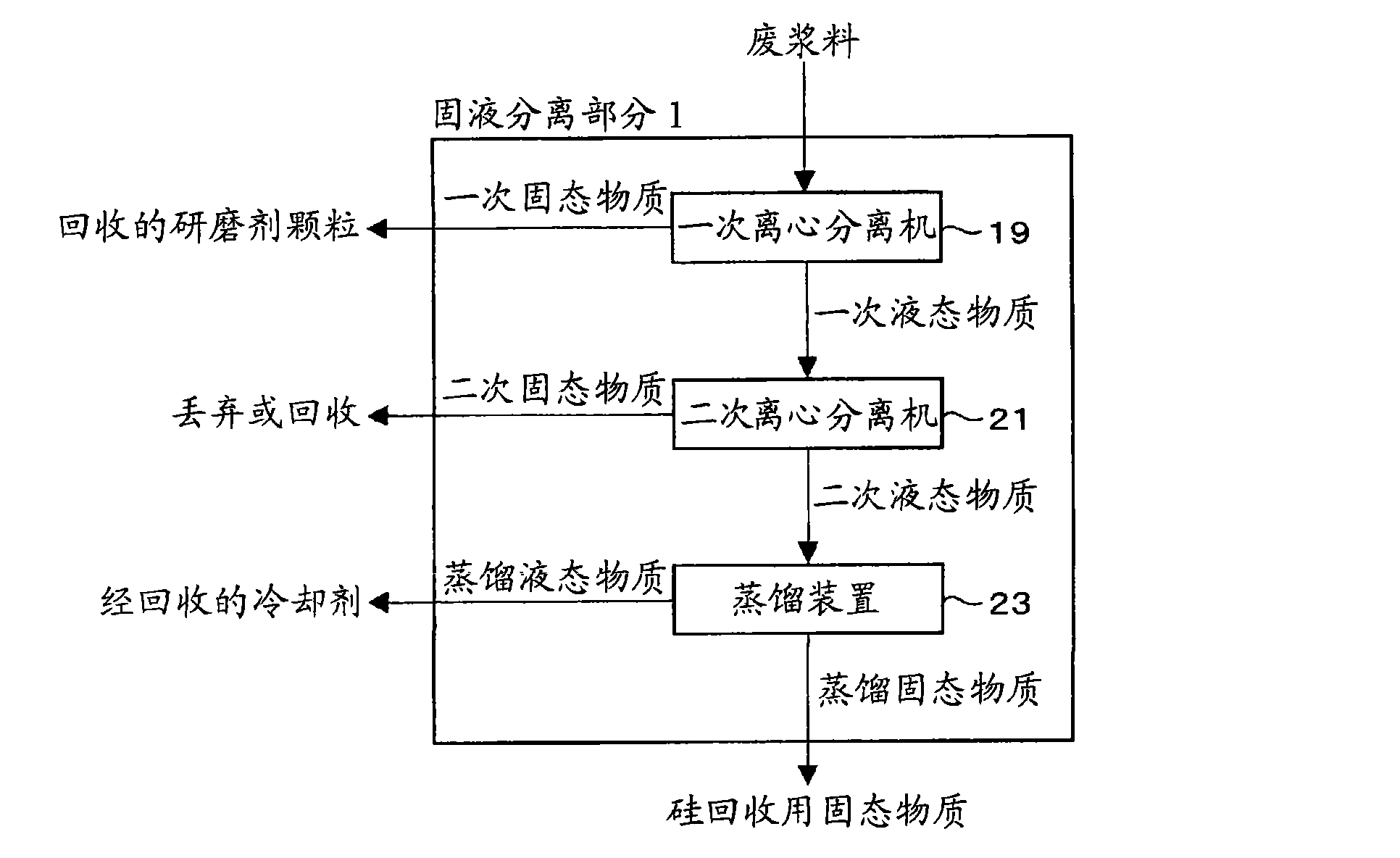

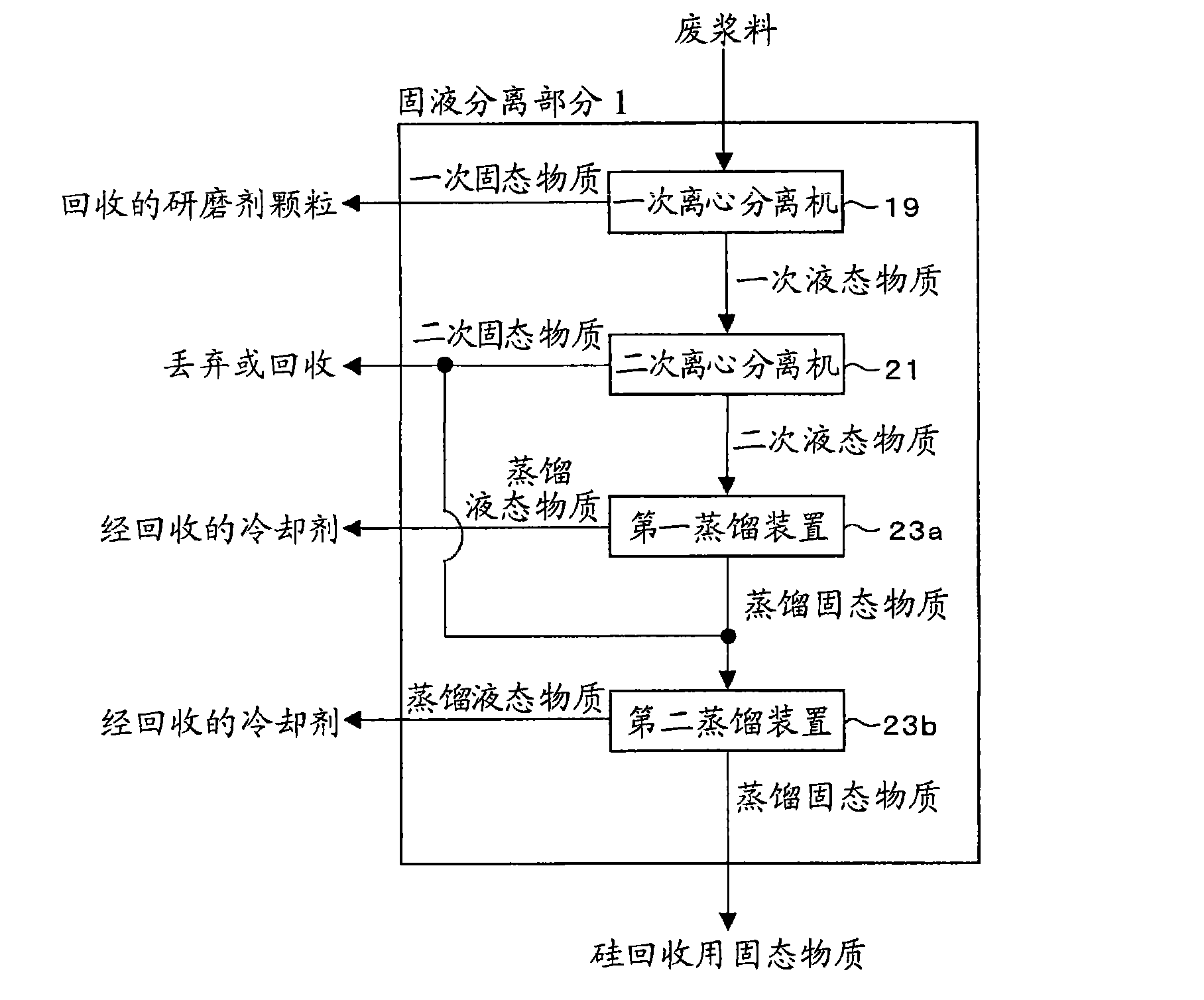

[0048] Solid-liquid separation part 1, which is used to obtain solid matter for silicon recovery containing silicon chips by solid-liquid separation of waste slurry or the concentrate of the waste slurry, wherein the waste slurry is a mixture of slurry and silicon a mixture of shavings obtained by cutting or polishing silicon blocks or silicon wafers using said slurry containing abrasive particles and coolant;

[0049] washing part 3, wherein the solid matter for silicon recovery is washed with an organic solvent; and

[0050]A classification section 5, wherein the solid matter for silicon recovery from the washing section is classified to obtain a silicon-cont...

no. 2 approach

[0117] Next, a silicon recovery device of a second embodiment of the present invention will be described. The structure of the silicon recovery device of this embodiment is similar to that of the first embodiment, but the difference lies in the objects to be processed. In the first embodiment the spent slurry itself undergoes treatment, but in the second embodiment the concentrate of the spent slurry undergoes treatment. The structure of the device of this embodiment is basically the same as that of the first embodiment, and the contents described in the first embodiment are basically applicable to this embodiment.

[0118] The "concentrate of waste slurry" refers to a substance obtained by concentrating the waste slurry before feeding the waste slurry to the silicon recovery apparatus of the present embodiment. The concentrate of spent slurry is usually in the form of a slurry or clay, but it can also be in other forms than these.

[0119]"Concentration of spent slurry" ref...

Embodiment

[0126] An example of a silicon recovery device and an example of a method of recovering silicon of the present invention will be described using specific numerical values. This example is where the use figure 1 and 2 An example of the recovery of silicon by the silicon recovery unit shown in , and will refer to figure 1 and 2 The invention is described.

[0127] In this example, waste slurry discharged from MWS was used in which slurry was formed by mixing abrasive particles in a coolant in a 1:1 weight ratio by adding propylene glycol to It is prepared by adding about 15% by weight of water (a dispersant to promote the dispersion of abrasive particles) and about 1% by weight of an organic acid as a pH regulator.

[0128] The waste slurry contains about 10 to 12% by weight of cutting chips made of silicon.

[0129] 1. Methods of recovering silicon

[0130] First, a method of recovering silicon will be described.

[0131] 1-1. Solid-liquid separation step

[0132] First...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com