Preparation method of halogen-free flame-retardant polyacrylonitrile fiber

A technology of polyacrylonitrile fiber and flame-retardant polyacrylonitrile, which is applied in the manufacture of fire-resistant and flame-retardant filaments, fiber chemical characteristics, single-component synthetic polymer rayon, etc., and can solve the problems of high smoke generation of flame-retardant fibers , to achieve the effect of improving flame retardant effect, improving hygroscopicity, and improving flame retardant durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

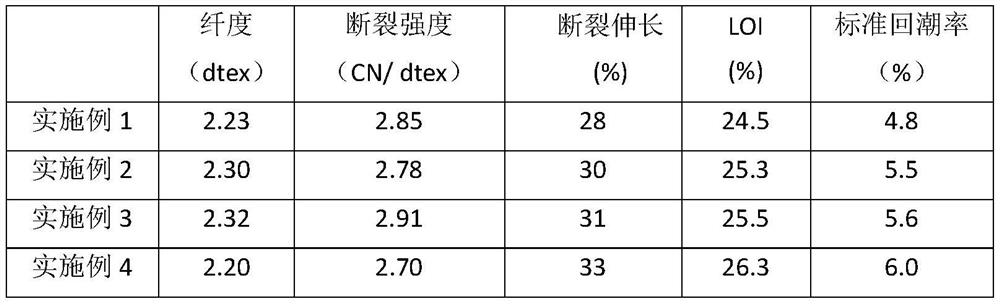

Examples

Embodiment 1

[0026] Step 1: Heat and melt the halogen-free phosphorus and nitrogen-containing flame retardant vinylphosphonic acid, raise the temperature to above 85°C, and stir continuously for more than 30 minutes until it completely melts to a transparent light yellow liquid.

[0027] Step 2: In the stirring state, mix the liquid halogen-free phosphorus and nitrogen-containing flame retardant vinylphosphonic acid obtained in step (1) and polyacrylonitrile spinning stock solution in a weight ratio of 30:70, and the stirring speed is 1000r / min , and the stirring time was 30 minutes to obtain a blended flame retardant spinning stock solution;

[0028] Among them, the polyacrylonitrile spinning stock solution is prepared in two steps:

[0029] The polyacrylonitrile slurry with a concentration of 34wt% from the storage tank at a temperature of 50°C and the NaSCN solvent with a concentration of 58wt% from a concentrated solvent storage tank at a temperature of 85°C enter high-shear dissolutio...

Embodiment 2

[0033] Step 1: Heat and melt the halogen-free phosphorus and nitrogen-containing flame retardant (methyl vinyl phosphonate and ethyl vinyl phosphonate mixed at a mass ratio of 1:2), raise the temperature to above 85°C, and stir continuously for more than 30 minutes. Until completely melted to a transparent light yellow liquid.

[0034] Step 2: Under agitation, the mixture of the liquid halogen-free phosphorus and nitrogen-containing flame retardant vinyl phosphonate and ethyl vinyl phosphonate prepared in step (1) is mixed with the polyacrylonitrile spinning stock solution by weight 35:65 mixed evenly, the stirring speed was 1200r / min, and the stirring time was 40 minutes to obtain the blended flame retardant spinning stock solution;

[0035] Among them, the polyacrylonitrile spinning stock solution is prepared in two steps:

[0036]The polyacrylonitrile slurry with a concentration of 34wt% from the storage tank at a temperature of 50°C and the NaSCN solvent with a concentrat...

Embodiment 3

[0040] Step 1: Heat and melt the halogen-free phosphorus and nitrogen-containing flame retardant allyl phosphate methyl ester, raise the temperature to 42°C, and stir continuously for more than 30 minutes until it completely melts to a transparent light yellow liquid.

[0041] Step 2: The liquid halogen-free phosphorus and nitrogen-containing flame retardant allyl phosphate methyl ester that step (1) makes is passed through the high-shear dissolving machine with the polyacrylonitrile spinning stock solution by weight ratio of 25: 75 for online blending, the feed ratio is automatically cascade controlled by DSC, and the cascade ratio is adjusted at 0.3-0.45:1 to obtain a blended flame retardant spinning stock solution;

[0042] Among them, the polyacrylonitrile spinning stock solution is prepared in two steps:

[0043] The polyacrylonitrile slurry with a concentration of 34wt% from the storage tank at a temperature of 50°C and the NaSCN solvent with a concentration of 58wt% fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com