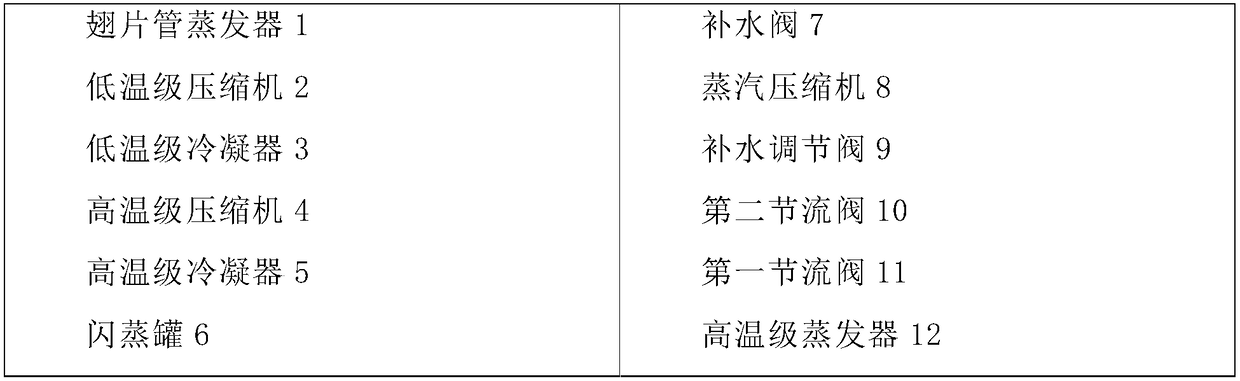

Patents

Literature

47results about How to "Water recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

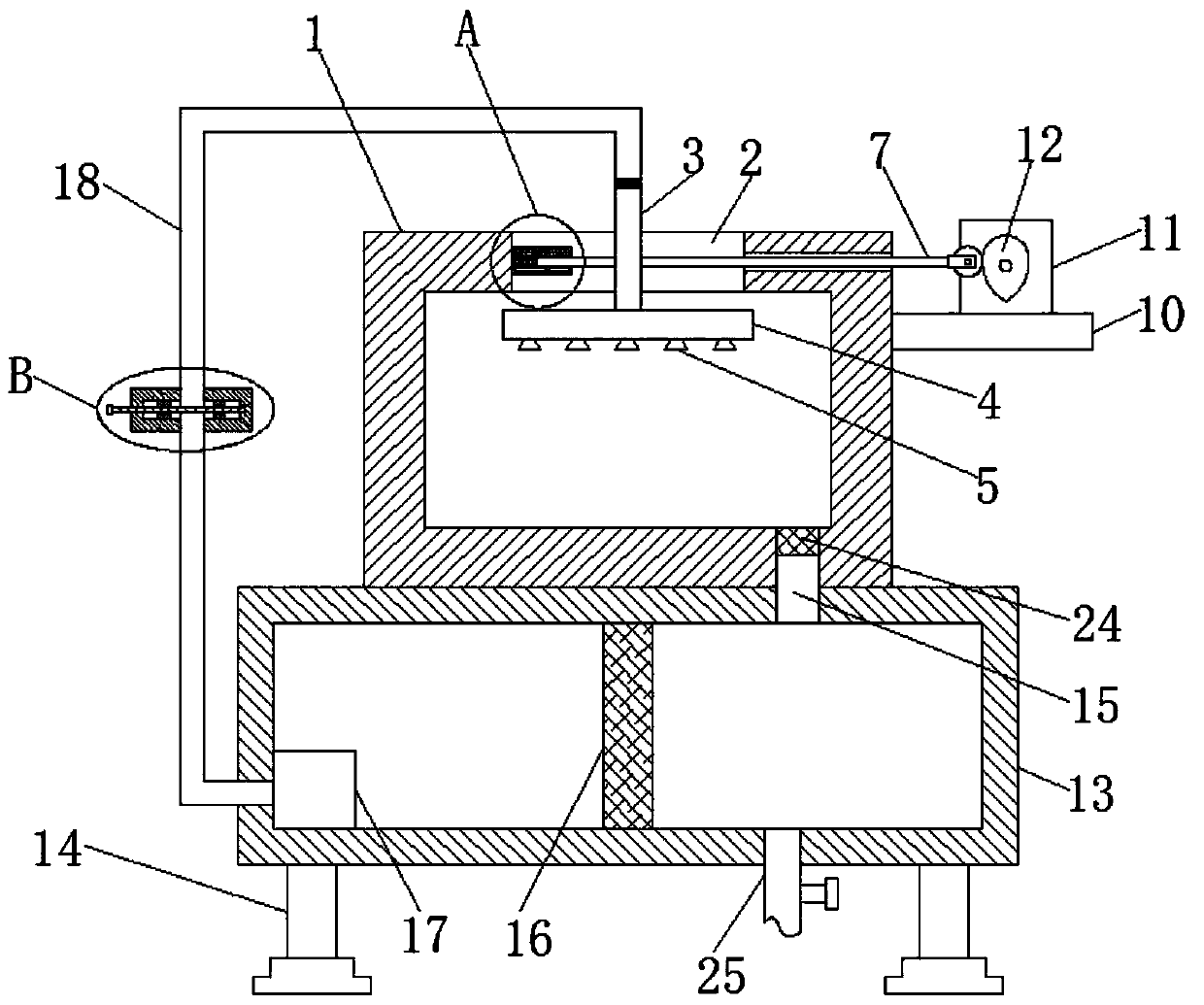

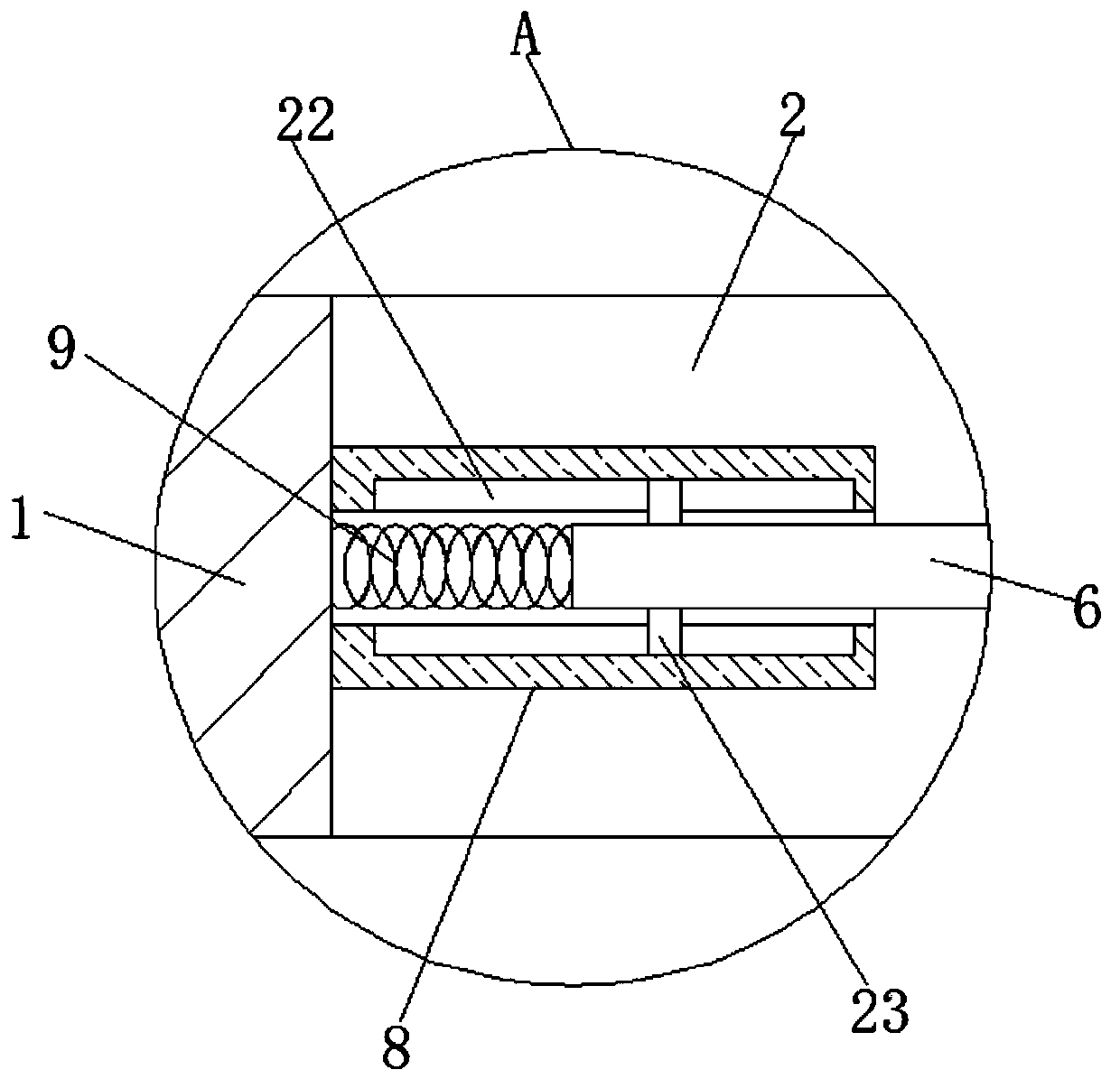

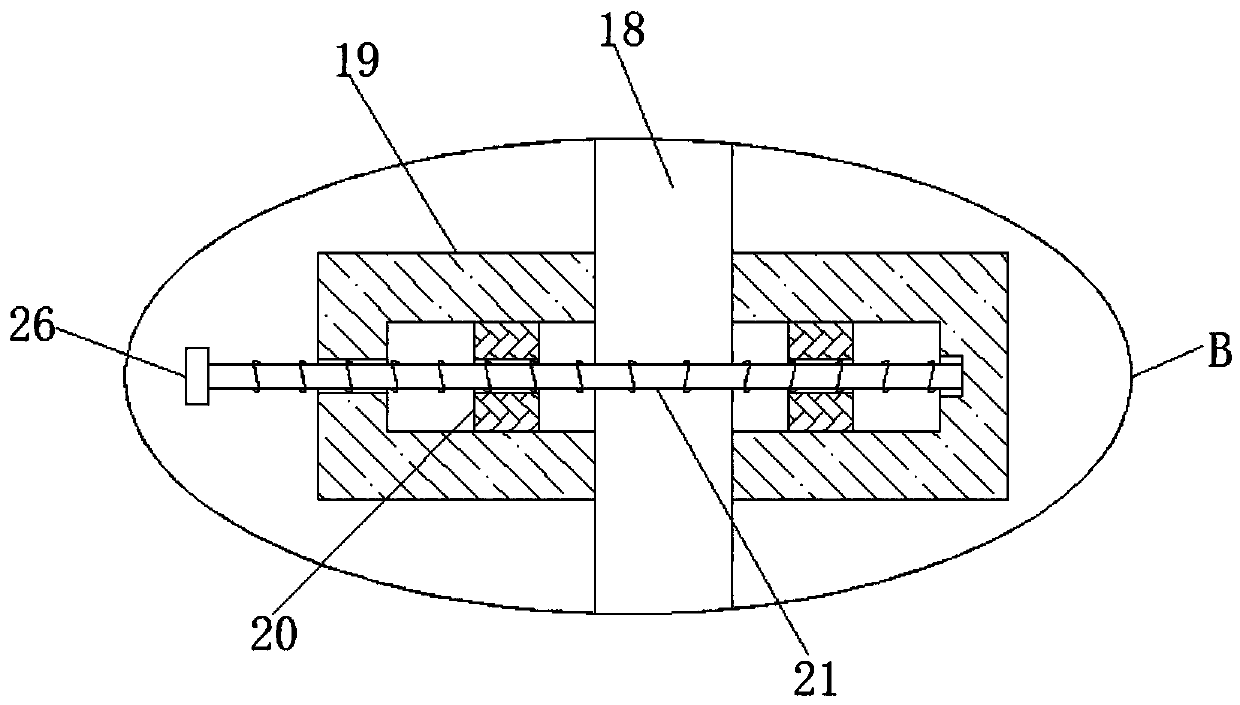

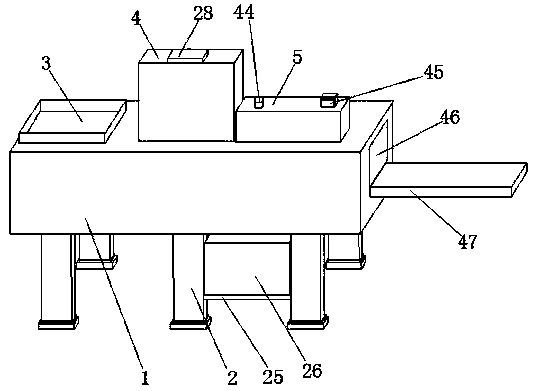

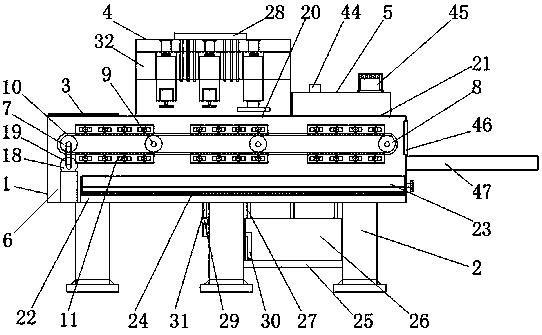

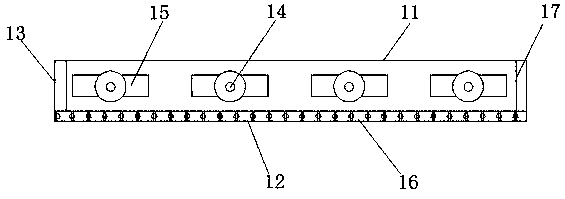

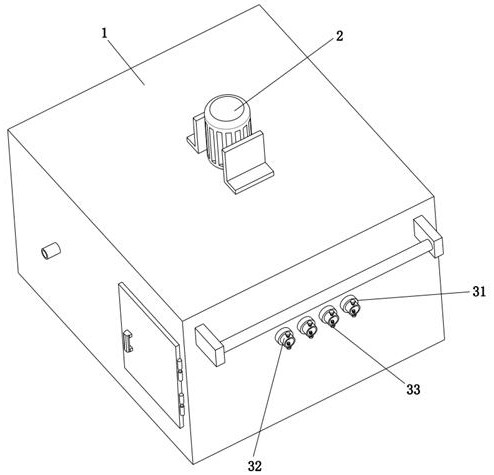

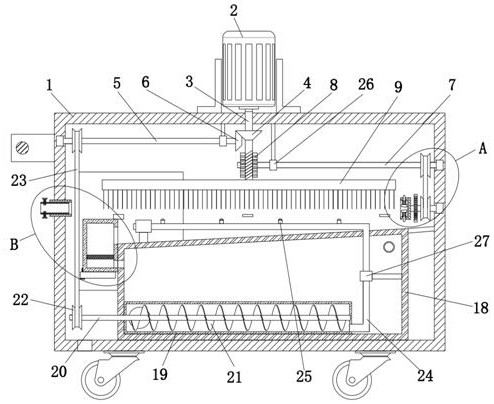

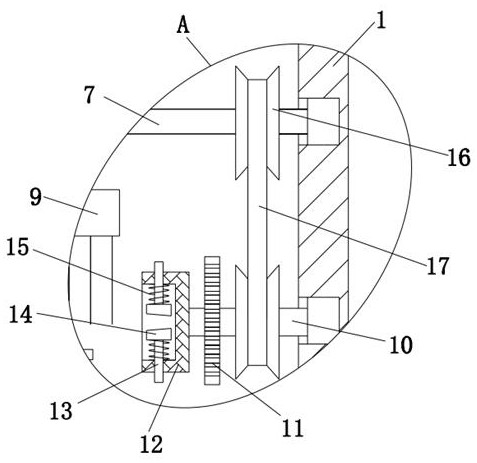

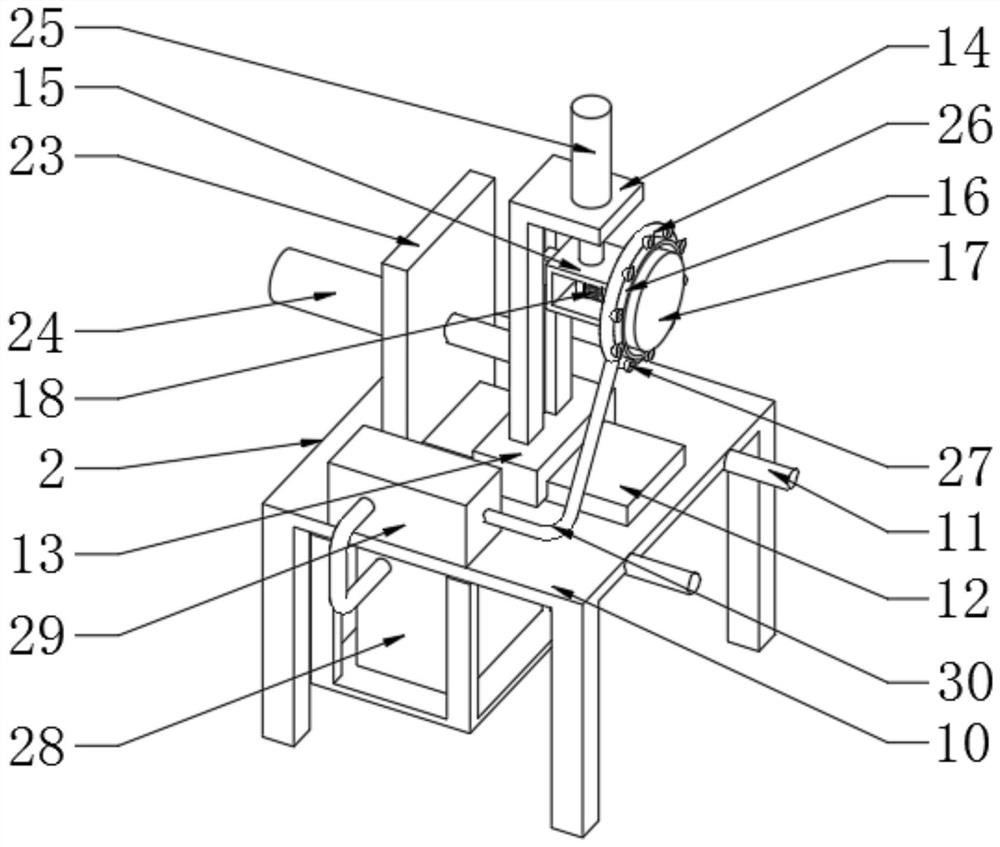

Drilling machine for machining bridge-cutoff aluminum alloy doors and windows

PendingCN109590507AStop exactly toAccurately pinpointMeasurement/indication equipmentsLarge fixed membersWater resourcesAlloy

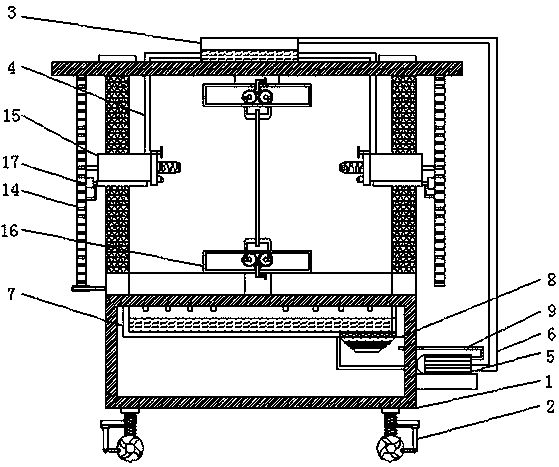

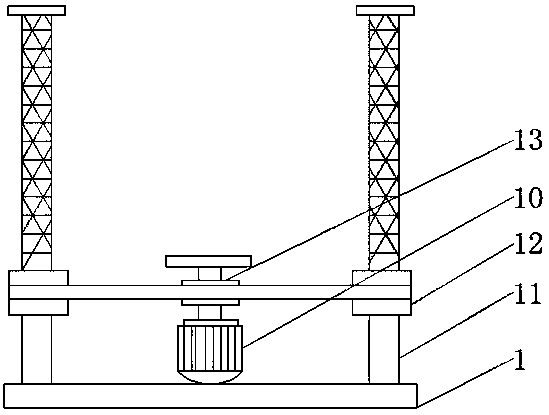

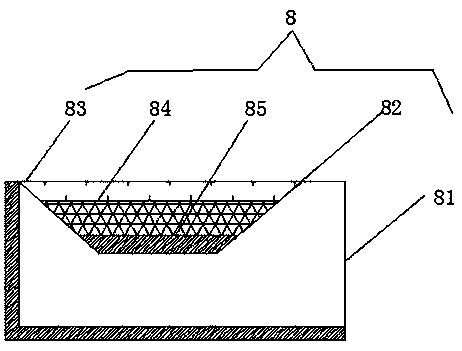

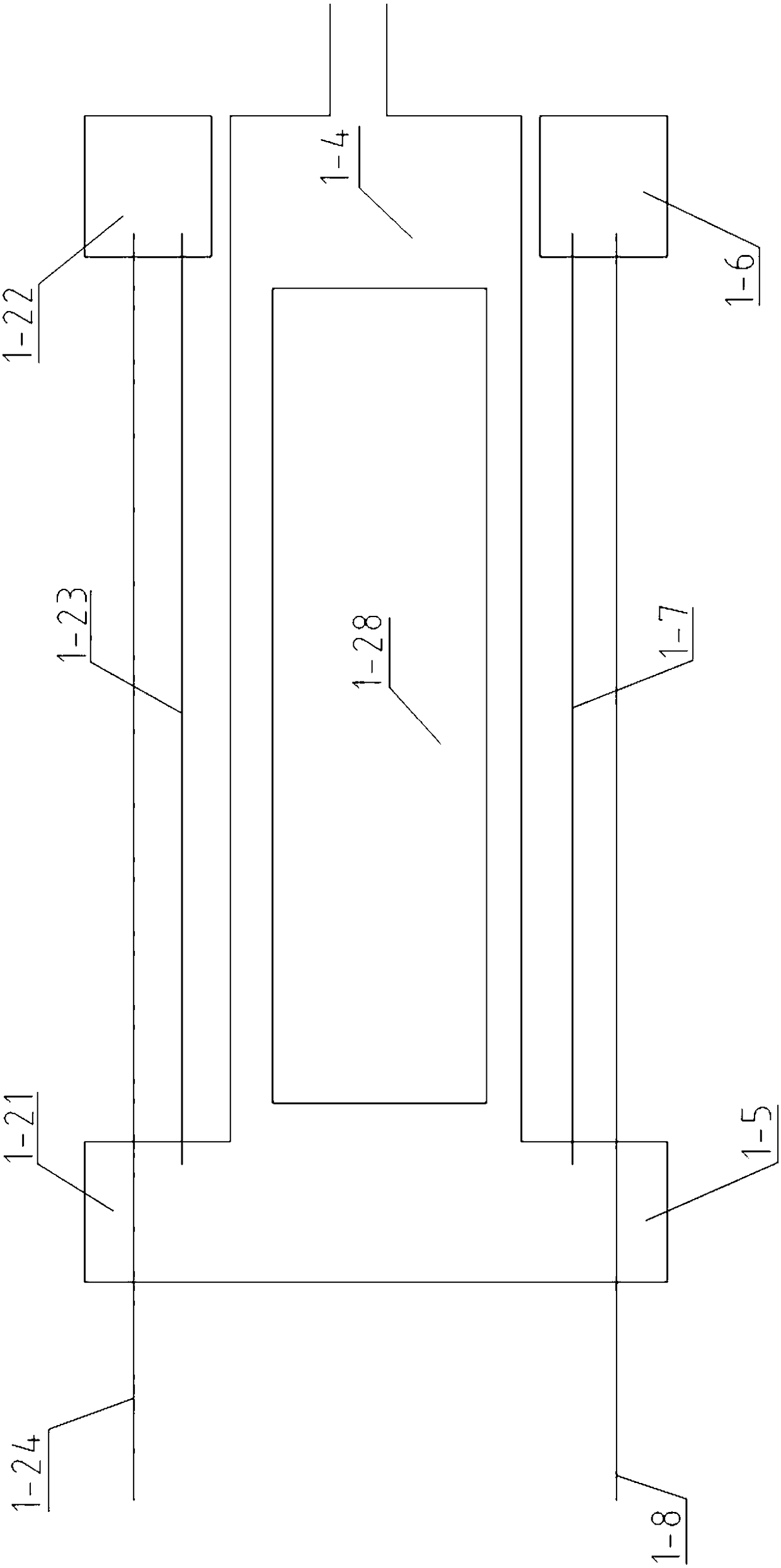

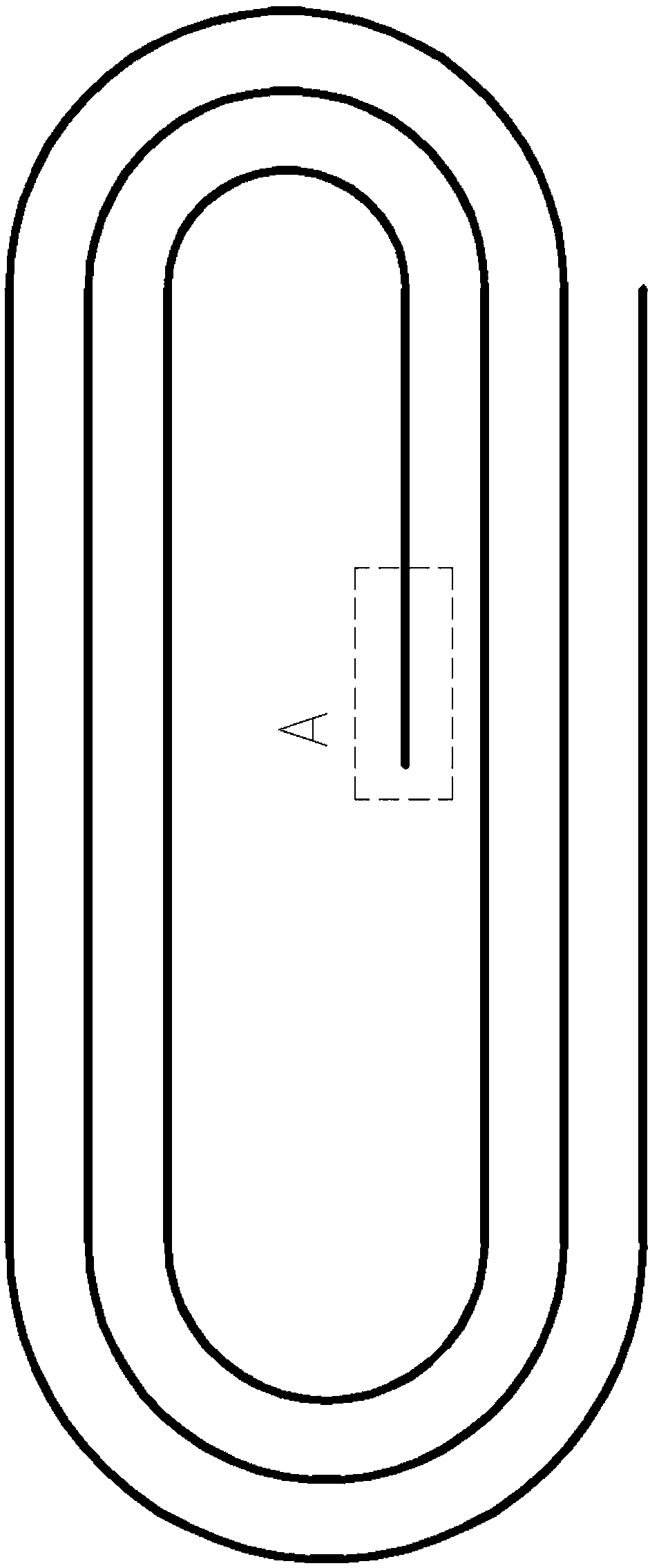

The invention provides a drilling machine for machining bridge-cutoff aluminum alloy doors and windows, and relates to the technical field of machining. The drilling machine for machining the bridge-cutoff aluminum alloy doors and windows comprises a machine body, wherein a moving device is fixedly arranged at the bottom of the machine body, the moving device comprises spring columns, and transverse plates are fixedly arranged on the outer surface of the spring columns, sliding grooves are arranged in the lower surfaces of the transverse plates, and clamping rods are connected to the inner wall of the sliding grooves in a sliding mode, wheels are movably installed at the bottoms of the spring columns, and a water tank is fixedly arranged at the top of the machine body, the left side of thewater tank is communicated with a first water pipe, and the right side of the machine body is fixedly provided with a water pump. According to the drilling machine for the bridge-cutoff aluminum alloy doors and windows, water is used for eliminating and collecting dust, and the drill bits are subjected to heat dissipation by water, the health of an operator is protected, and the service life of the drill bits is prolonged, meanwhile, the water resources are recycled by the aid of a filtering device, and the environment-friendly theme of the current society is attached.

Owner:杭州佧斯家居设计有限公司

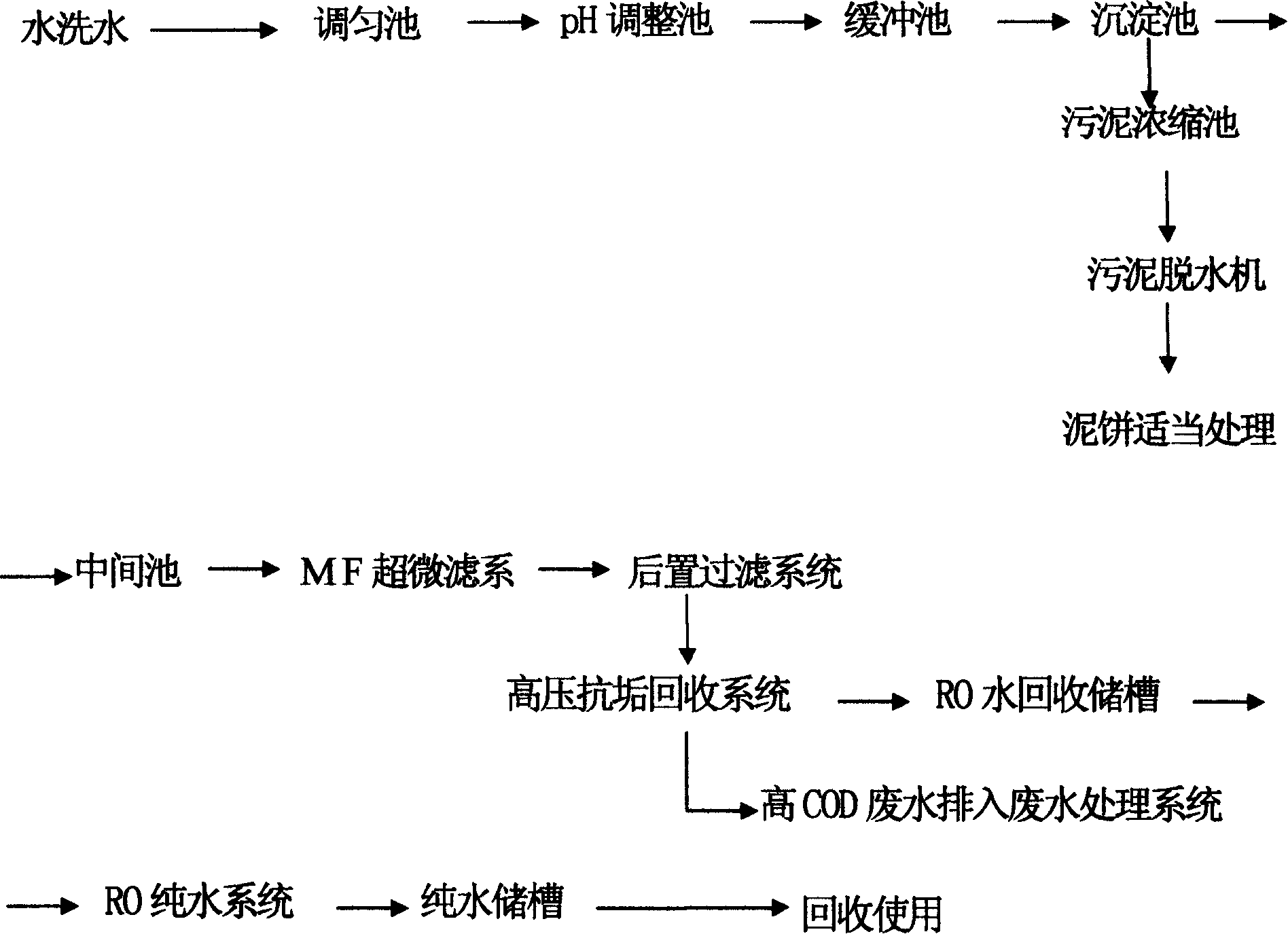

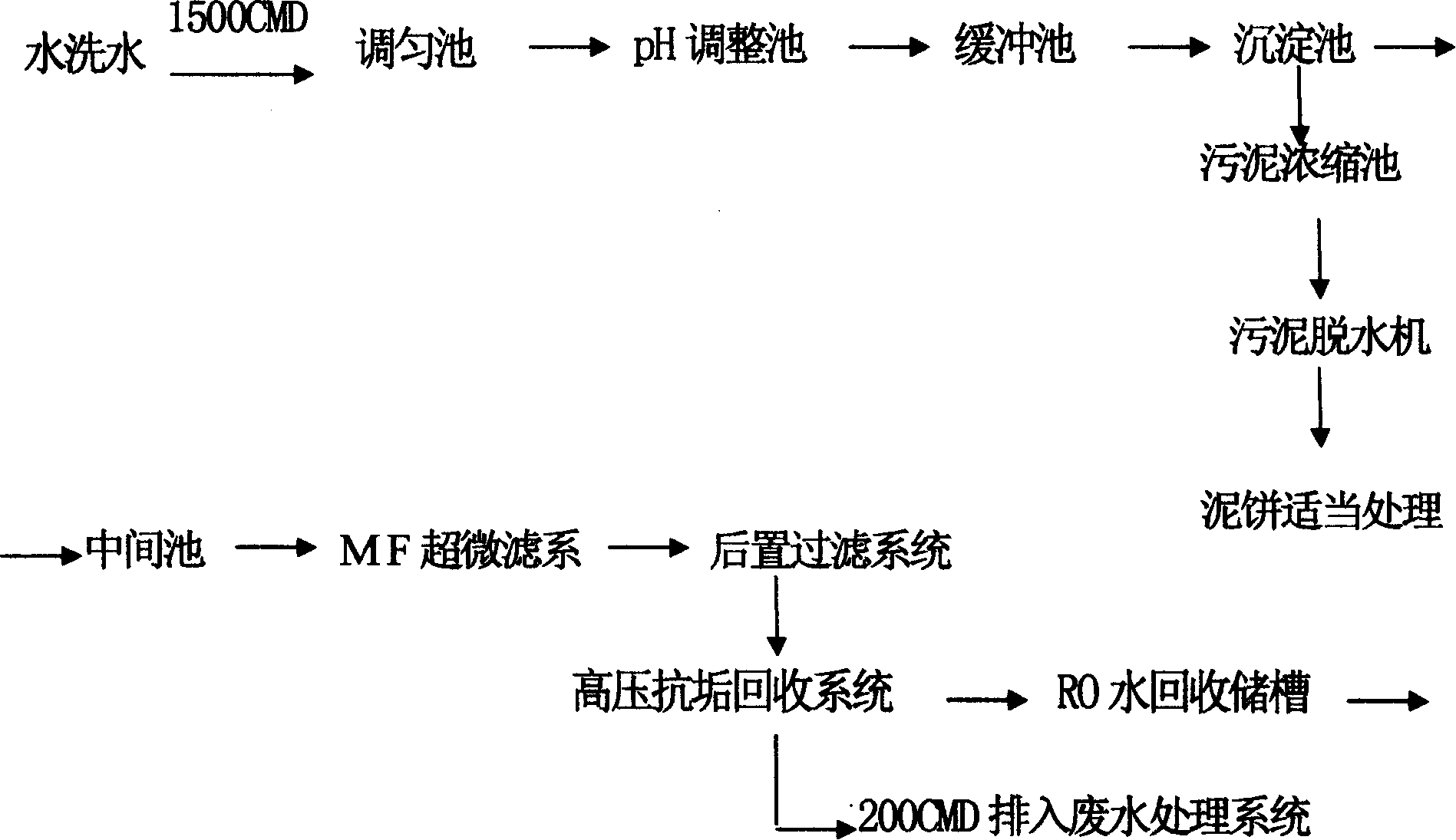

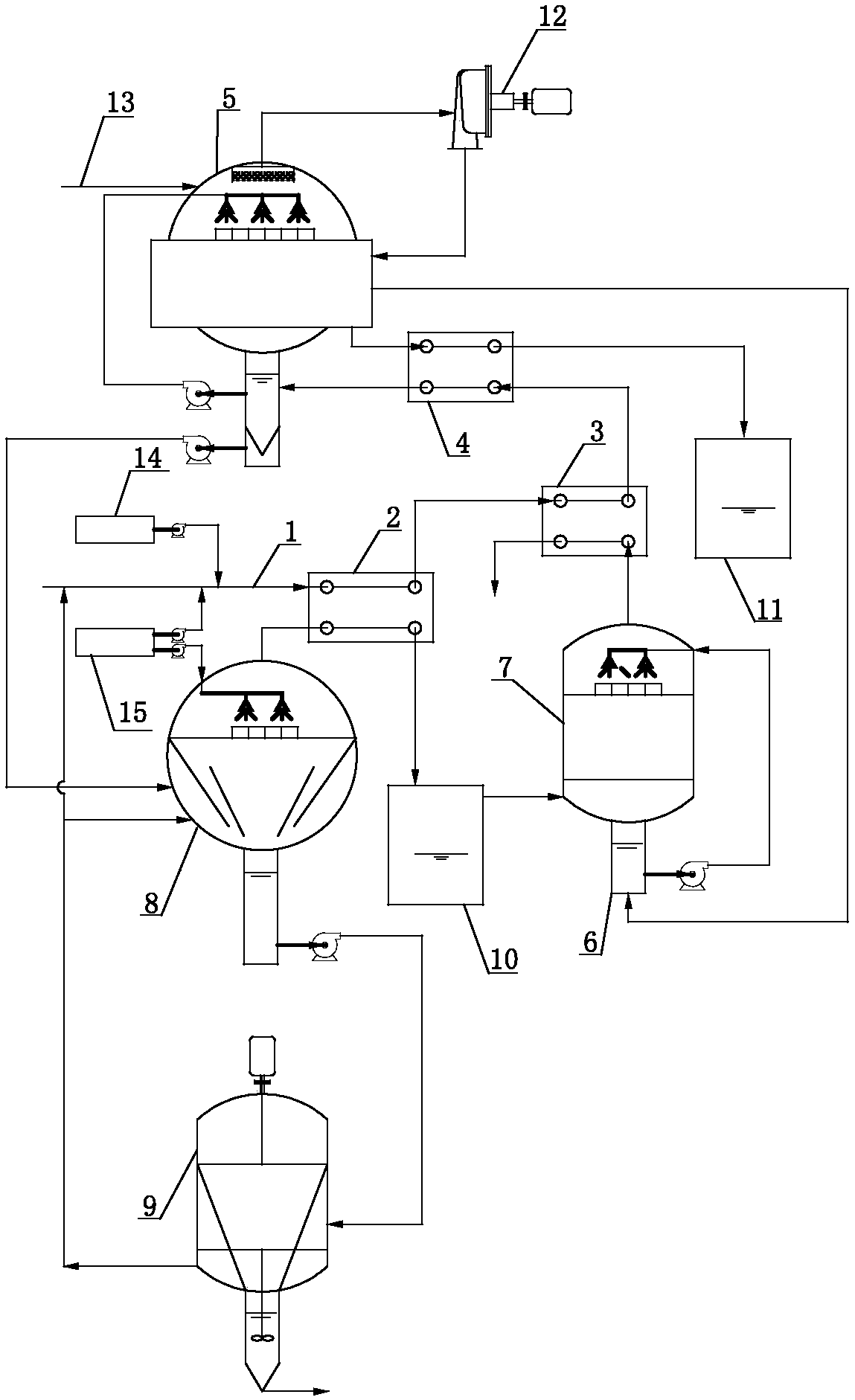

Circuit-board waste-water reutilizing process of reducing waste

ActiveCN101070211AHigh recovery rateWater recyclingWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentBreadboardPre treatment

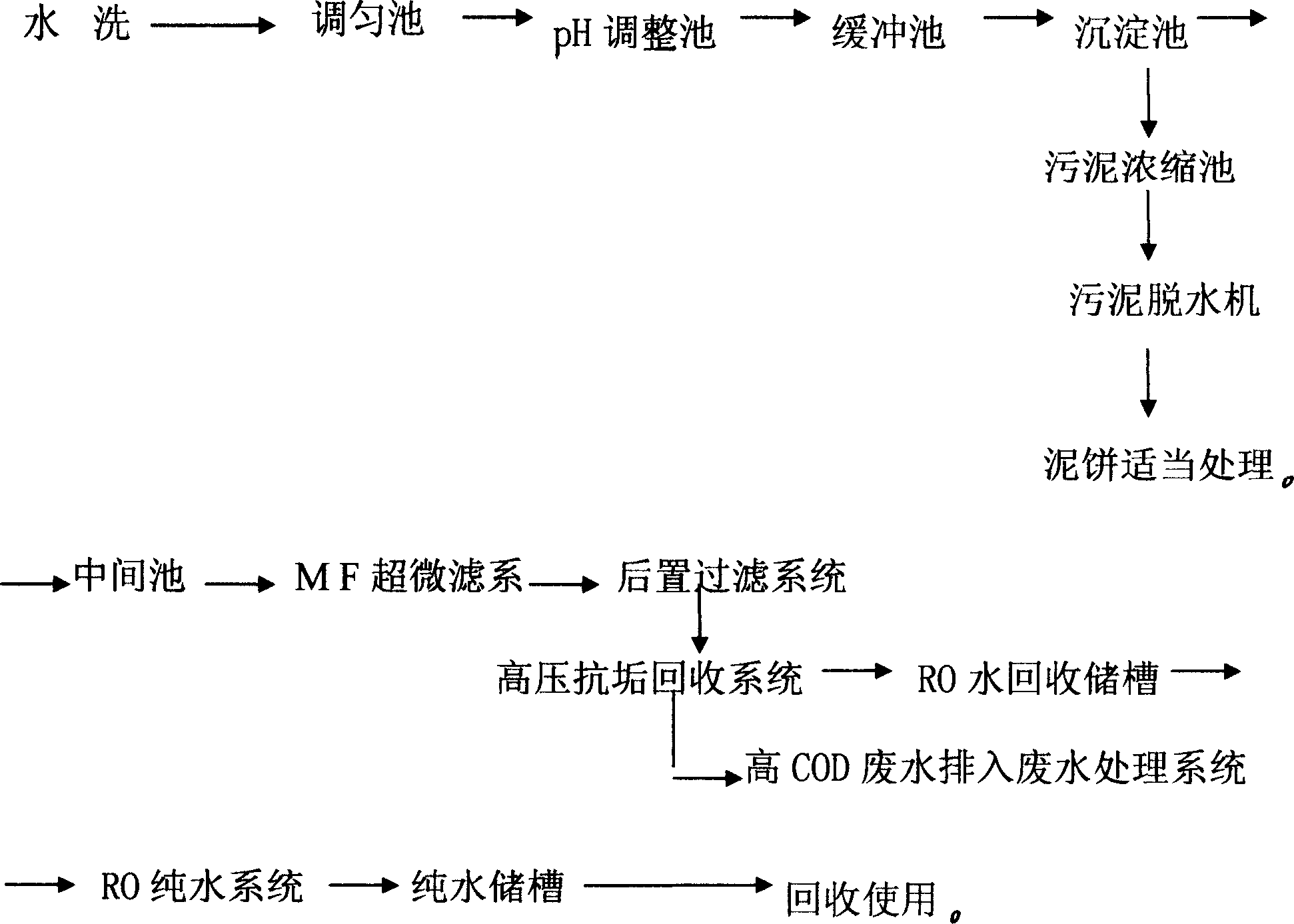

The aim of this invention is to fill up above described blank and supplies a breadboard wastewater reclaiming craft. The aim is accomplished by follows technical proposal: partly introduce each wastewater department of breadboard workshop to mixing pool, through precipitation, then takes pretreatment filtration by microfilter and ultrafilter, then pass recovery system, the water quality can reach standard that conductivity less than 20us / sq cm, and has no particle that greater than 10 micrometer, PH is neutrality, can reclaim to workshop for water of productive using; flow tank sludge after dewatering is disposed by other departments.; high COD wastewater through this system can reach discharging standard; acid and alkali department, water washing, and complexation wastewater after precipitation is introduced to mixing pool, sludge after dewatering is disposed by other departments.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

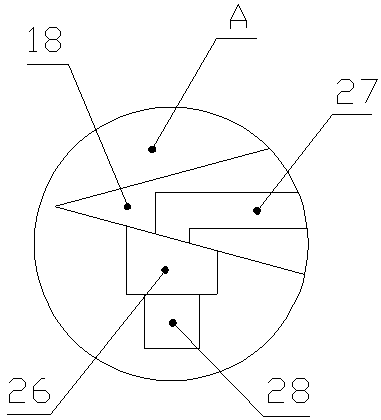

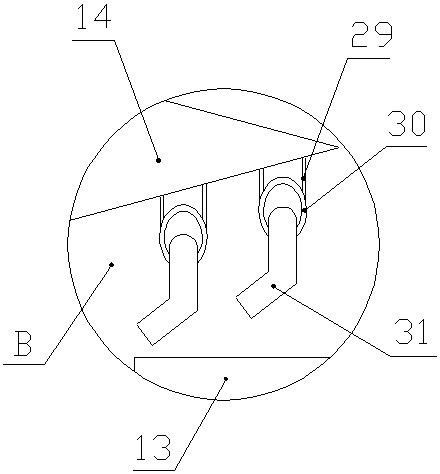

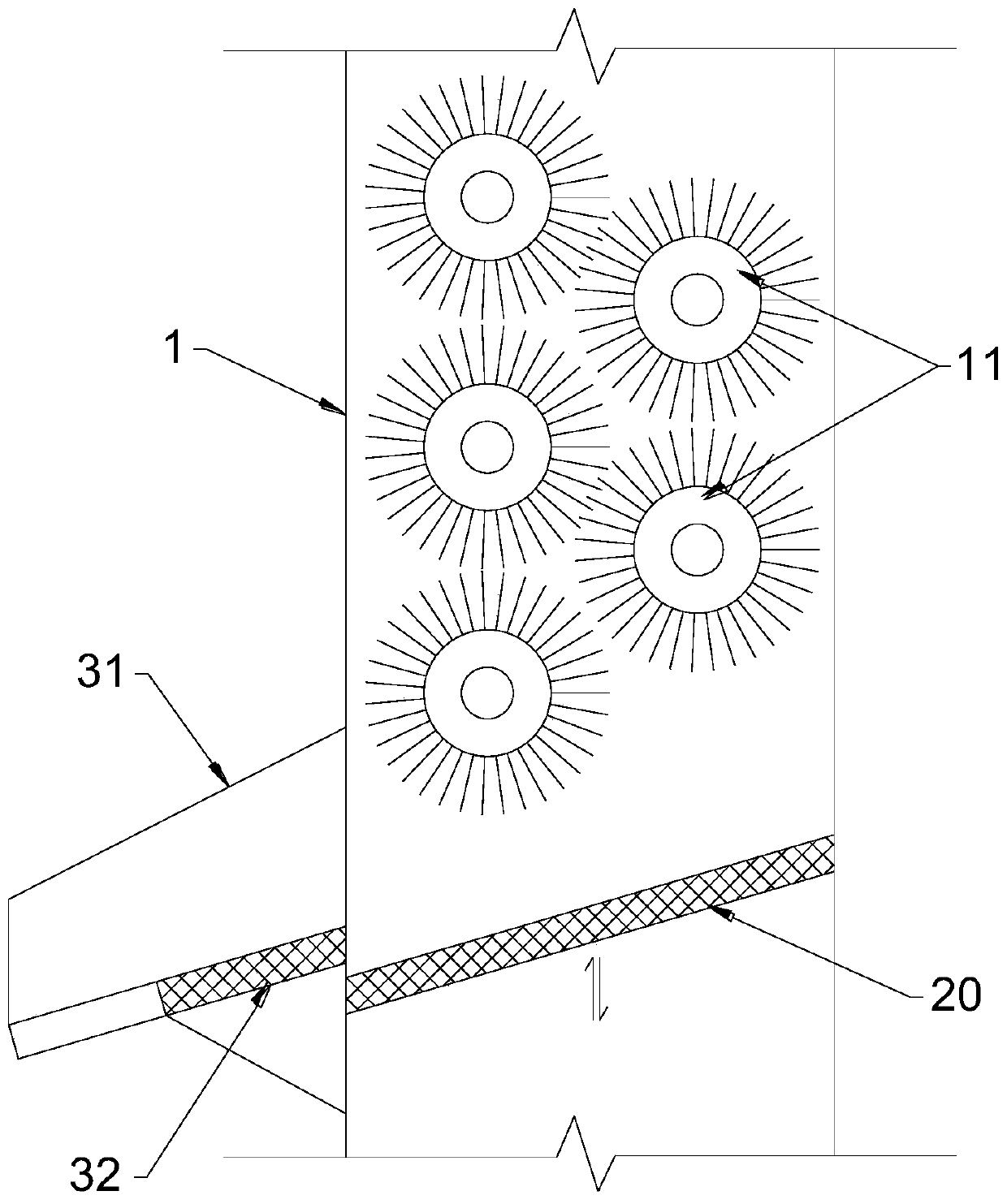

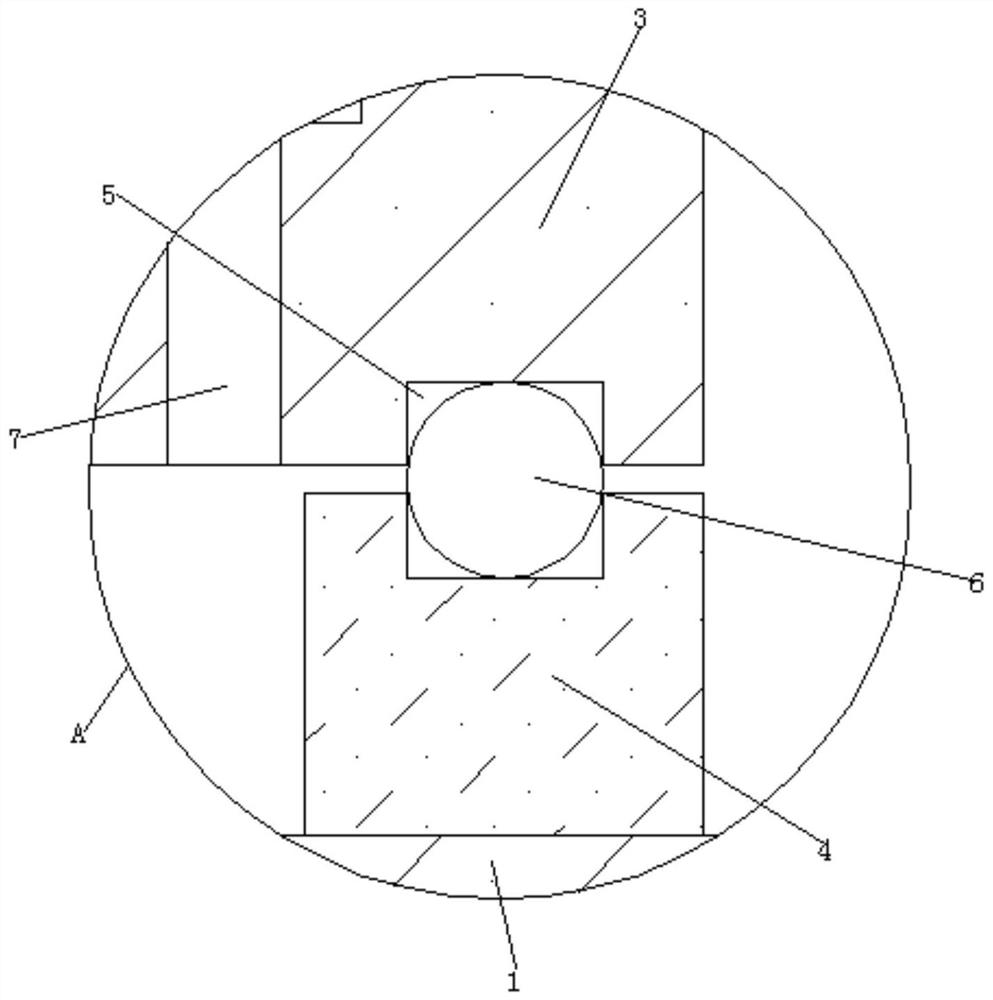

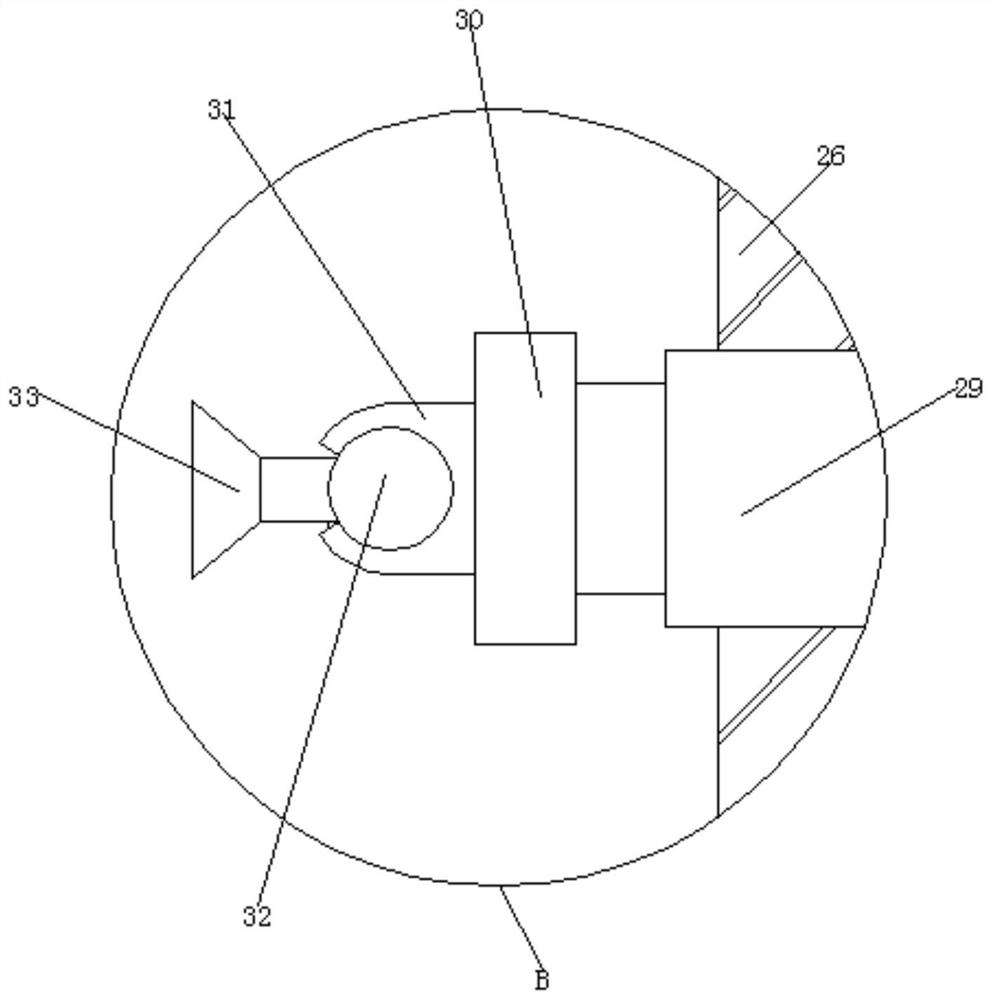

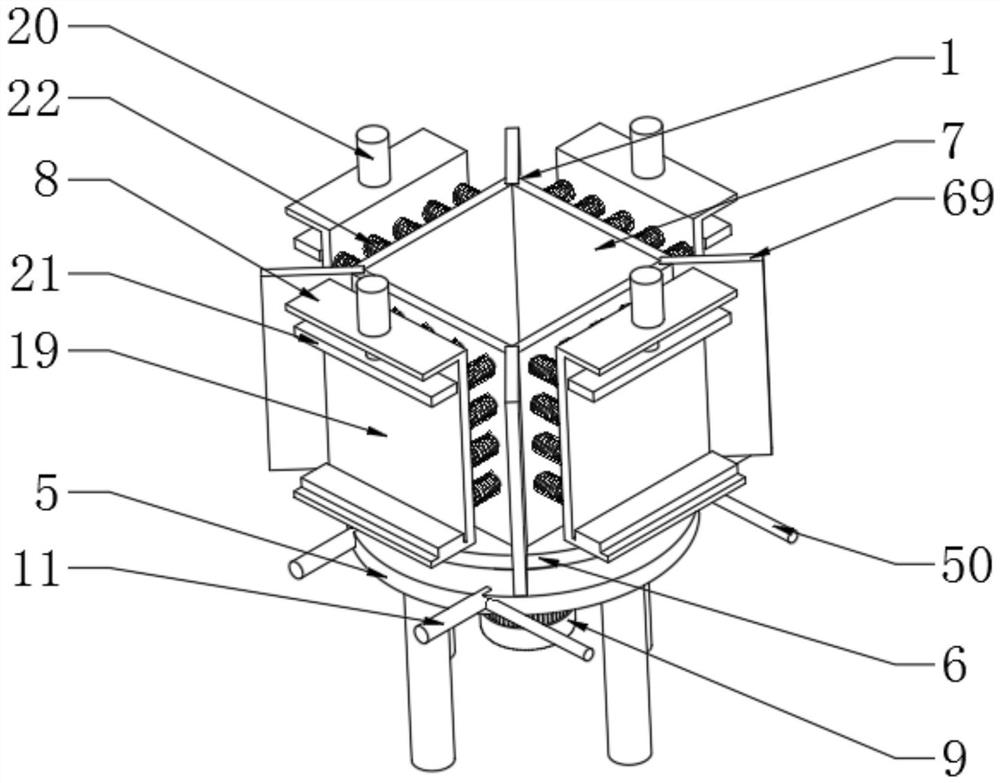

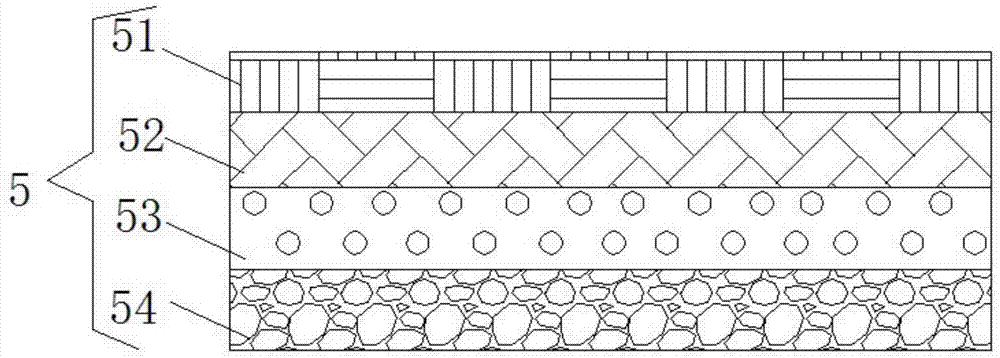

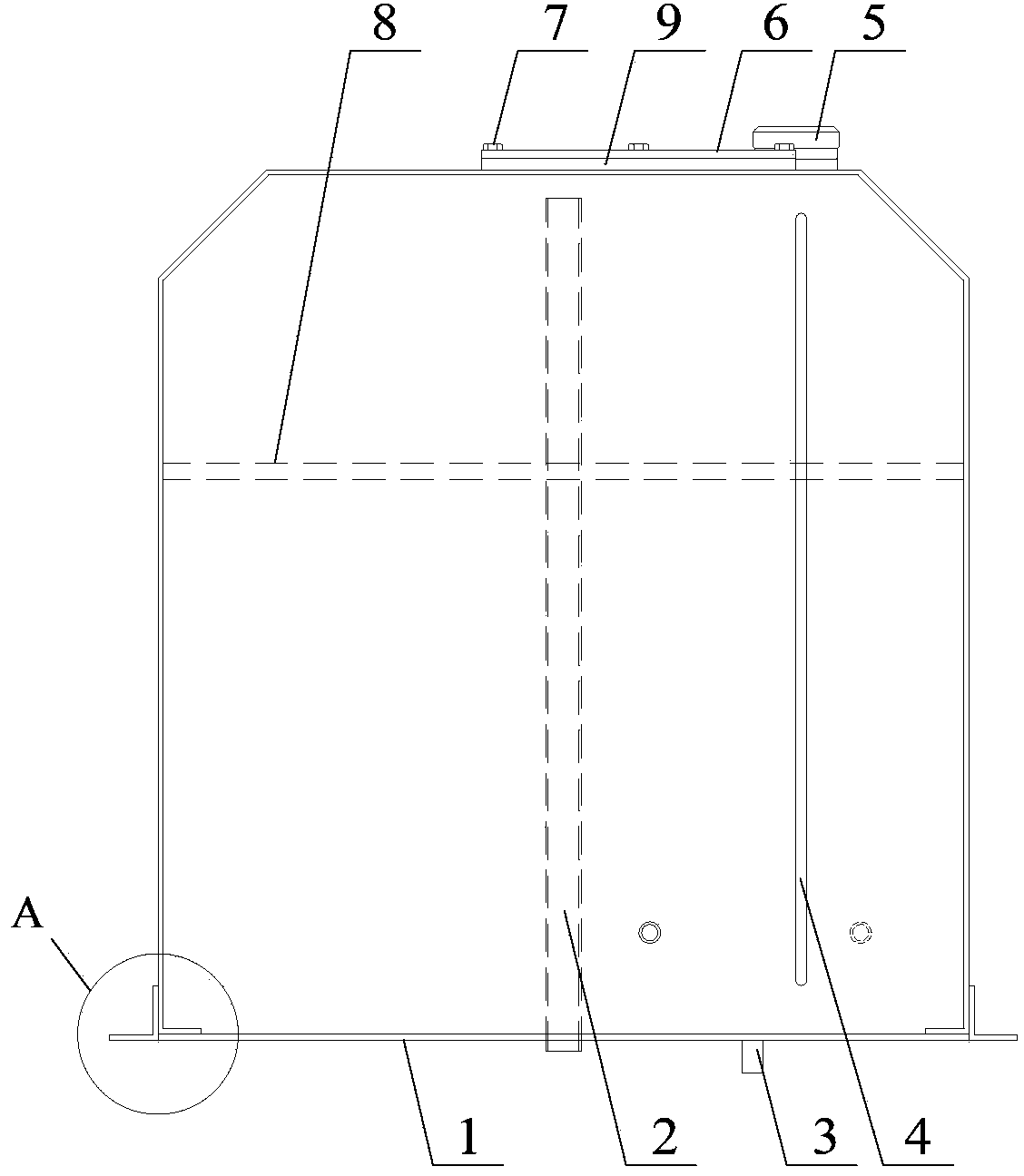

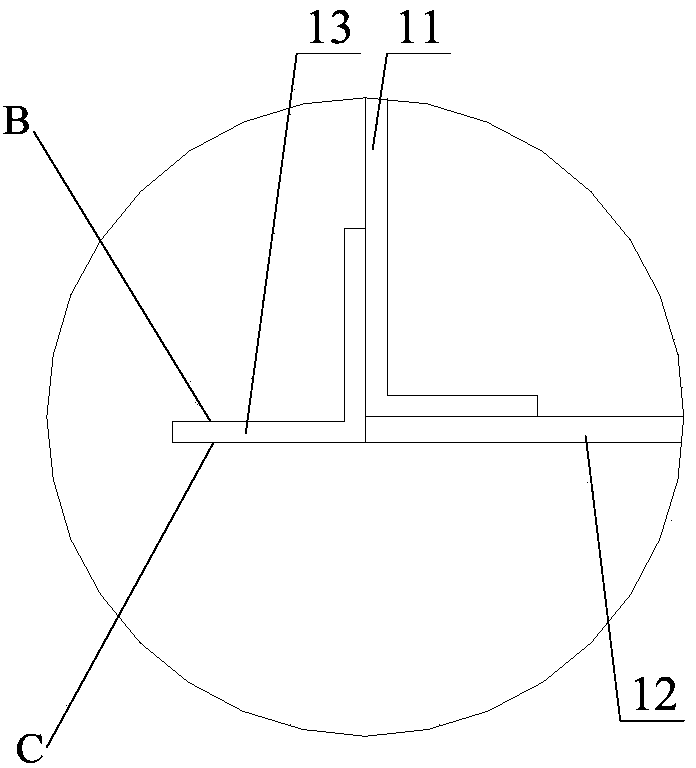

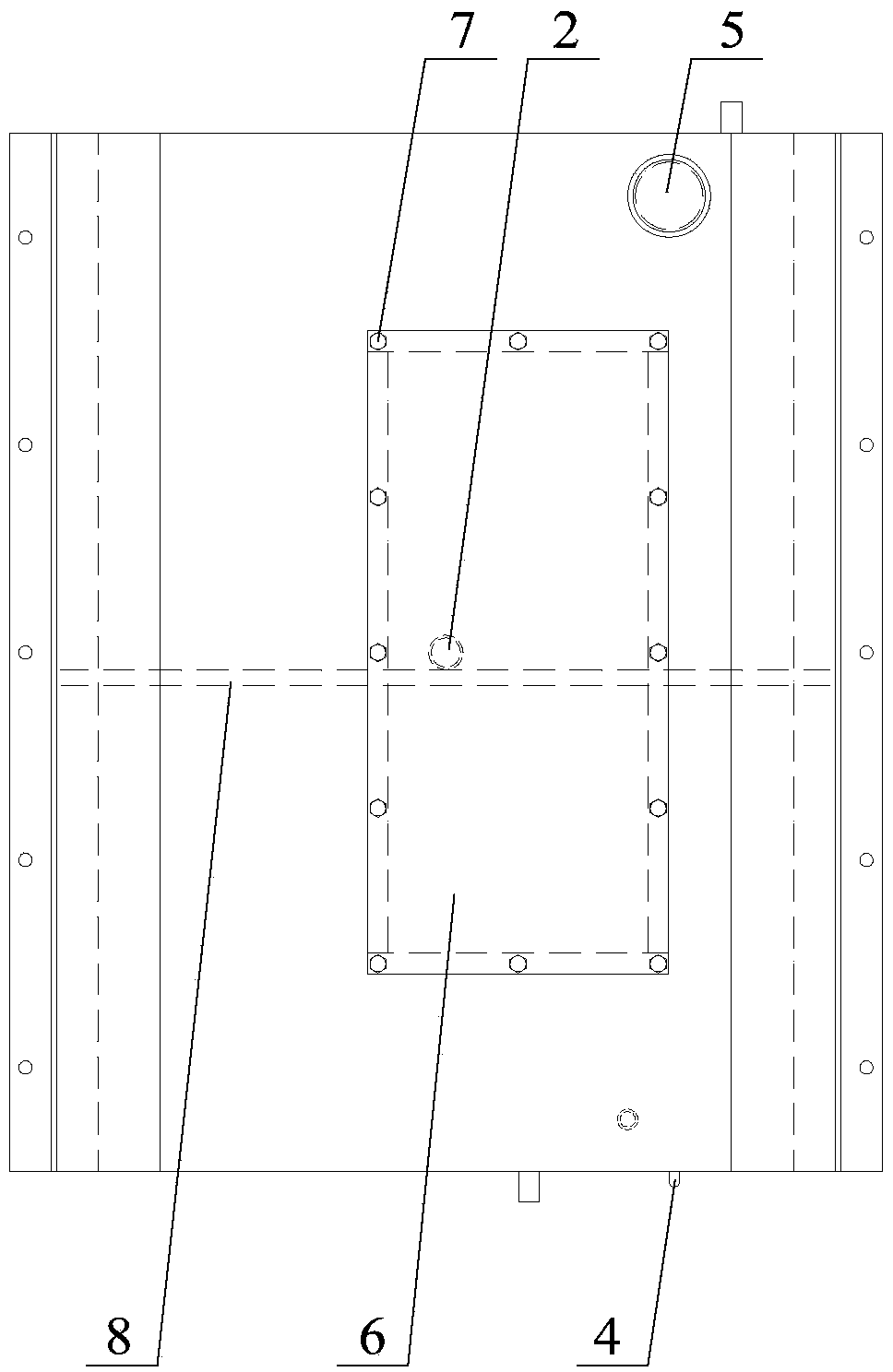

Water washing mechanism for stone processing system

InactiveCN109092753AFully washedWater recyclingUsing liquid separation agentCleaning using liquidsSurface mountingArchitectural engineering

The invention discloses a water washing mechanism for a stone processing system, comprising a crusher shell, a through groove is formed in the top of the crusher shell, a water guide pipe matched withthe through groove is inserted in the through groove, and the water guiding pipe is in movable connection with the through groove. One end of the water guide pipe fixedly communicates with a water guide plate, and a plurality of evenly distributed nozzles are mounted on the lower surface of the water guide plate. The water guide plate is located in the inner cavity of the crusher shell, and the outer side wall of the water guide pipe is symmetrically fixedly connected with a sliding rod and a protruding rod. A position, corresponding to the sliding rod, at the inner wall of the through grooveis fixedly connected with a sleeve matched with the sliding rod, and one end, away from the water guide pipe, of the sliding rod is inserted in the sleeve and fixedly connected with a spring, the sliding rod is in slidable connection with the sleeve, and the other end of the spring is fixedly connected to the bottom in the sleeve. The water washing mechanism disclosed by the invention makes stonewashing more fully in a processing process, and water after washing can be recycled to avoid waste of water resources.

Owner:安龙县喜莱莹建材装饰有限公司

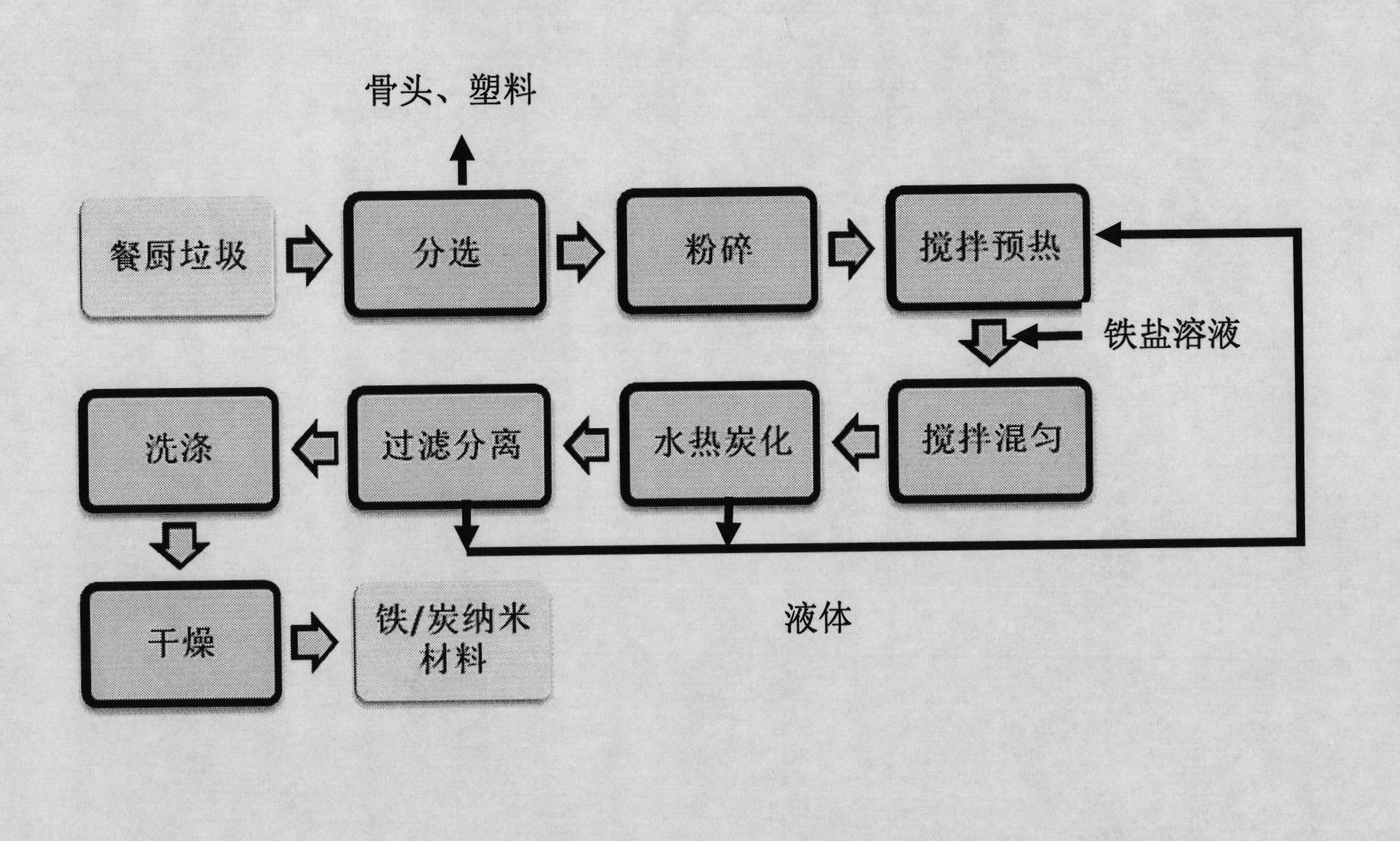

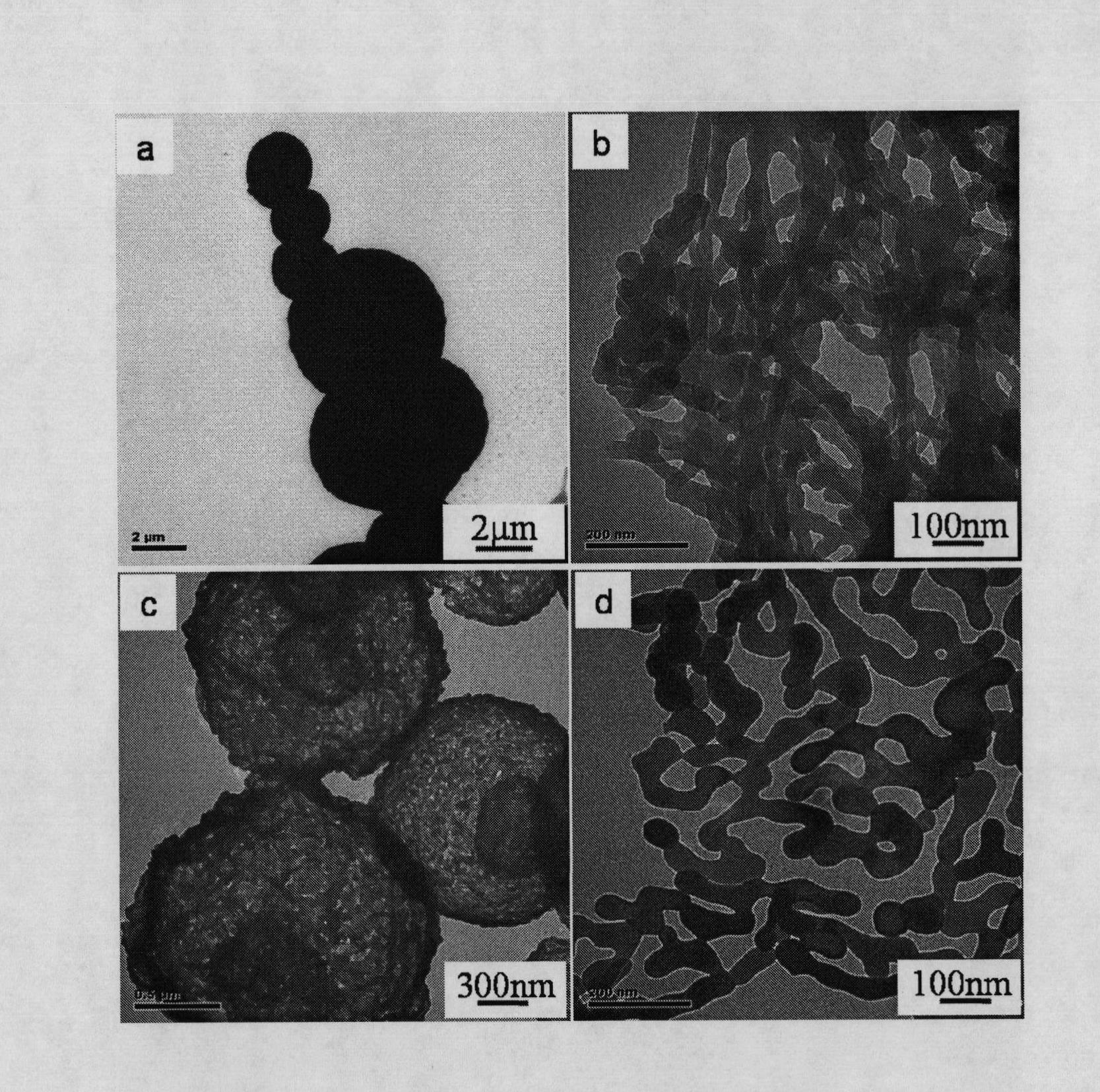

Method for preparing nano iron/carbon compound material by kitchen waste

InactiveCN102527695AEffective control of diffusionAvoid it happening againSolid waste disposalCarbon compositesNanowire

For the current situations of large waste quantity, shortage of treatment technology and difficult regeneration and recycling, the invention provides a method for preparing a nano iron / carbon compound material by utilizing kitchen waste as a raw material. The method is characterized by comprising the following steps of: carrying out pasting pretreatment on the kitchen waste in a sealed container, adding a catalyst and an auxiliary agent, implementing hydro-thermal treatment under certain conditions, and by hydrolysis, dewatering, decarboxylation, polymerization and aromatization reaction, finally synthesizing iron / carbon complex containing a large amount of nano wires and microsphere structures. According to the method, the operation is simple and convenient, the production cost is low, the stable and reliable effects are achieved, the source of the raw material is wide, the price of the auxiliary raw material is low, the large-scale production is easy, and the economic benefit is obvious. A synthesized product has good catalysis and absorption performances and has a wide industrialized application prospect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

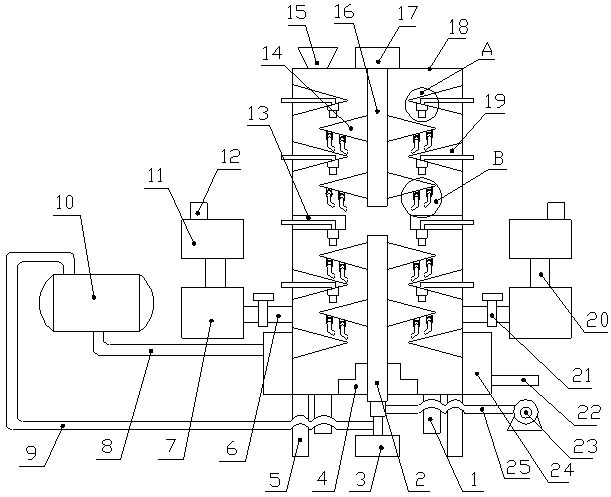

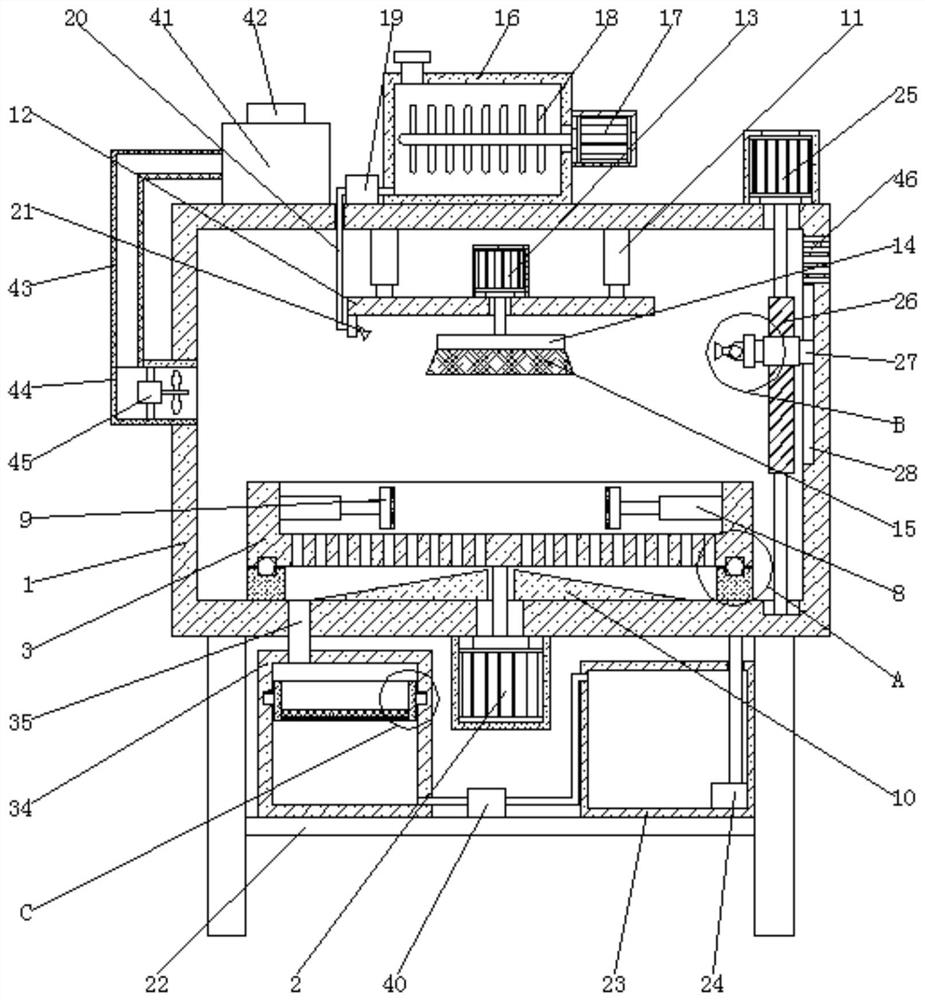

Limestone powder calcining furnace

The invention discloses a limestone powder calcining furnace which comprises a furnace body, wherein the left side and the middle of the upper surface of the furnace body are connected with a feedinghopper and a motor B respectively; a motor A is arranged below the furnace body; output shafts of the motor A and the motor B are respectively connected with a stirring shaft A and a stirring shaft B;stirring blades are connected to the stirring shaft A and the stirring shaft B; high-temperature belts are connected to the middle of the inner side wall of the furnace body; the upper and lower parts of the inner side wall of the furnace body are connected with guide plates; the lower surfaces of the guide plates and the high-temperature belts are connected with material blowing devices; the lower surfaces of the stirring blades are connected with poking devices; the outer side of the stirring shaft A is connected with a discharge tower through a bearing; the outer side of the lower part ofthe furnace body is sleeved by a cooling sleeve; the lower part of the right side of the cooling sleeve is connected with a liquid inlet pipe; the upper part of the left side of the cooling sleeve isconnected with the inlet end of a steam drum through a liquid outlet pipe; the outlet end of the steam drum is connected with the stirring shaft A through a steam pipe; and the left side and the rightside of the lower surface of the furnace body are connected with discharge tubes. The limestone powder calcining furnace has the advantages of thorough calcination, wall adhesion prevention, high discharge efficiency, energy conservation and environment protection.

Owner:河南越尔环保科技有限公司

Green and efficient red mud carbon dioxide carbonized dealkalization system and process

ActiveCN112624538AAchieve continuous operationImprove dealkalization rateSludge treatmentNature of treatment waterHigh concentrationWater storage tank

The invention relates to a green and efficient red mud carbon dioxide carbonized dealkalization system and process. The dealkalization system comprises a red mud slurry stirring tank, a carbonization reactor, a de-ironing separator, a dewatering screen, an ion separator and a water storage tank which are connected in sequence, the dealkalization process comprises the following steps: carrying out pre-carbonization reaction on the prepared red mud slurry and CO2 introduced into the bottom of a red mud slurry stirring tank; introducing CO2 into the carbonization reactor to carry out carbonization and dealkalization, and carrying out ultrasonic treatment on the slurry at the same time; carrying out iron removal and dehydration / screening on the obtained slurry to obtain a filtrate and a dealkalized red mud product with low water content; and precipitating the filtrate, separating by an ion separator to obtain a concentrated solution containing high-concentration carbonate and a low-concentration circulating solution, drying the concentrated solution to obtain carbonate, and recycling the low-concentration circulating solution as circulating water. According to the method, continuous efficient red mud carbonization dealkalization in the whole process is achieved, no harmful substances are generated in the reaction process, the dealkalized red mud is subjected to graded separation, carbonate products are efficiently recycled, and water resources are recycled.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

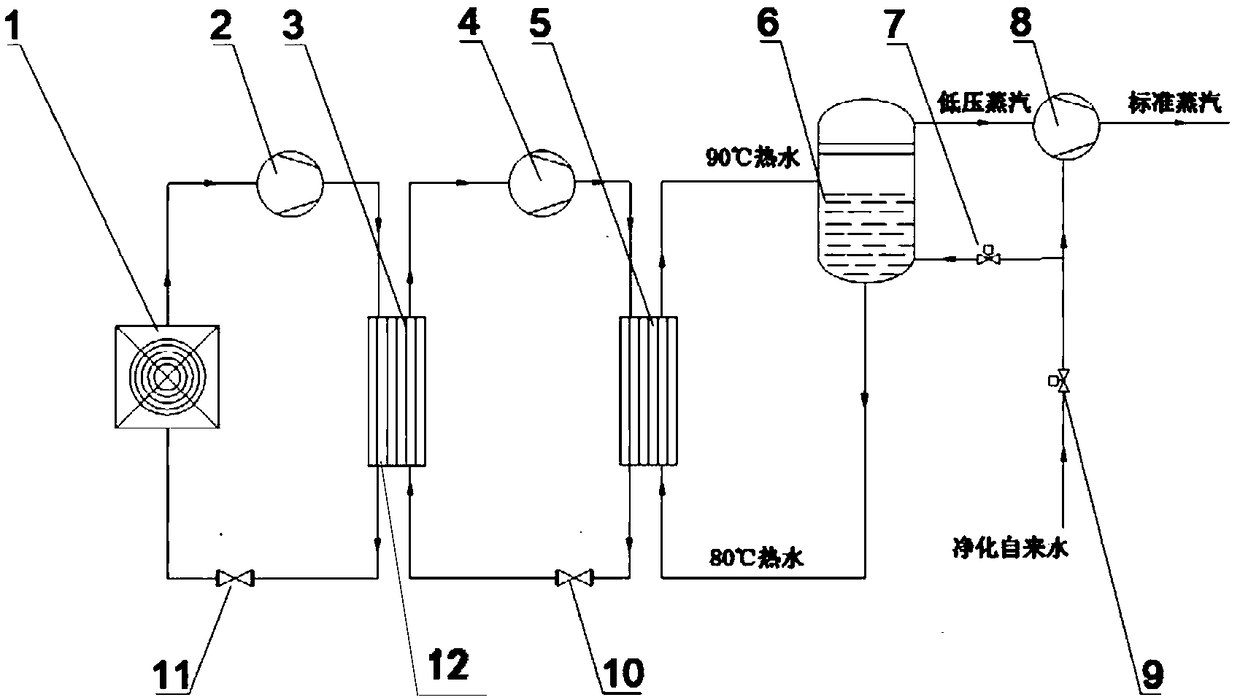

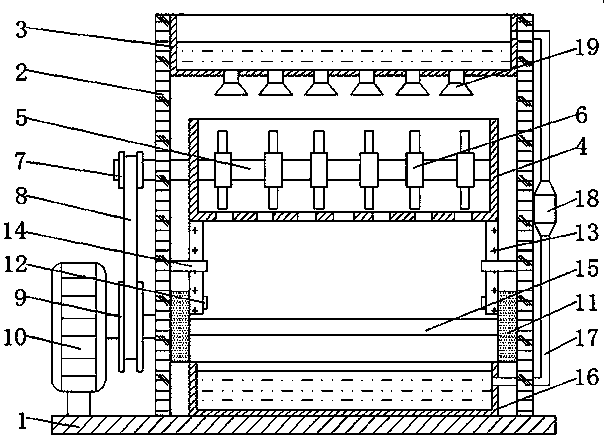

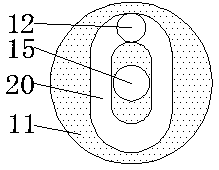

Air energy boiler steam supply system

InactiveCN109323234AReduce consumptionEnergy savingFluid heatersHeat pumpsHeat pump water heaterEngineering

The invention provides an air energy boiler steam supply system. The air energy boiler steam supply system comprises a laminated air energy heat pump water heater system and a hot water flash evaporation recompression steam generation system; the laminated air energy heat pump water heater system comprises a low-temperature-stage heat pump unit and a high-temperature-stage heat pump unit, whereinthe low-temperature-stage heat pump unit is connected with the high-temperature-stage heat pump unit; and the high-temperature-stage heat pump unit is connected with the hot water flash evaporation recompression steam generation system. The laminated air energy heat pump water heater system is used for absorbing air energy in air; and the absorbed air energy is used for generating steam by the hotwater flash evaporation recompression steam generation system. The air energy is used for heating running water, and is finally used for generating steam; and a lot of air energy in the air is effectively used, so that the consumption of high-quality energy is reduced, the use of a coal-fired boiler is effectively prevented, the smoke emission of the coal-fired boiler is eliminated, and the effects of energy conservation and environmental protection are achieved.

Owner:上海诺通新能源科技有限公司

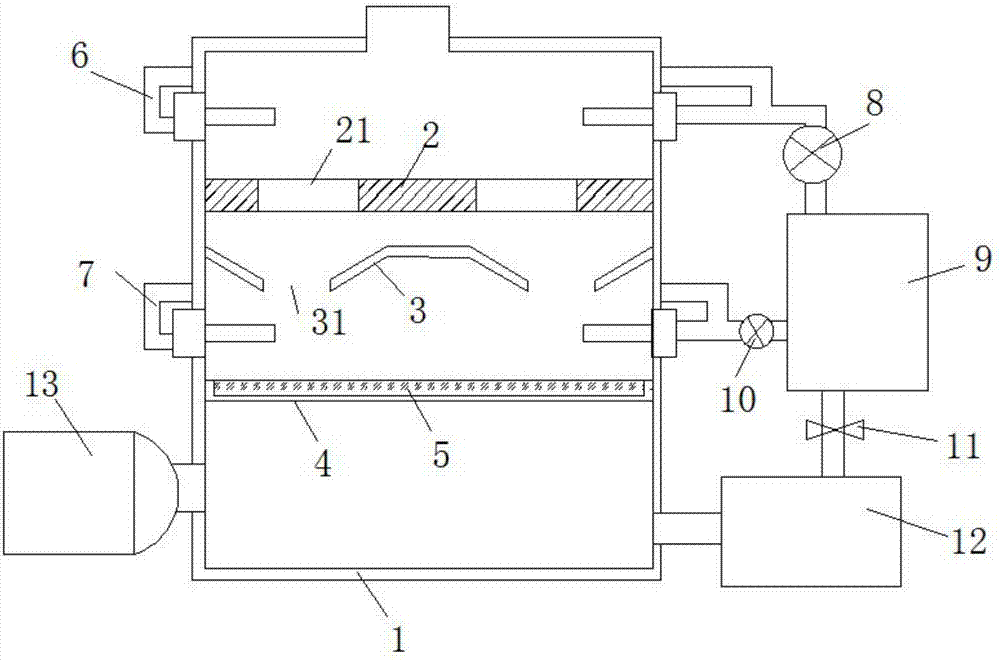

Steam sterilization device

The invention discloses a steam sterilization device which comprises a sterilization chamber, a water tank, a cooling device and a steam pipeline, wherein the steam pipeline is communicated with the sterilization chamber and the water tank respectively; a heating device for generating steam and a purifying device are arranged on the water tank; a condensed water discharge pipeline is arranged on the cooling device and is connected with the water tank. By adopting the steam sterilization device, a water resource can be circulated while an object to be sterilized is sterilized, thus being environment-friendly and energy-saving.

Owner:JIANGSU GUOTAI ENVIRONMENTAL MONITORING CO CHANGSHU BRANCH

Willowleaf swallowwort rhizome washing device wide in application range

The invention discloses a willowleaf swallowwort rhizome washing device wide in application range. The willowleaf swallowwort rhizome washing device wide in application range comprises a base. One side of the top of the base is fixedly provided with a motor. The motor is connected with a rotating shaft of a second sliding wheel through a rotating shaft of the motor. The second sliding wheel is rotationally connected with a first sliding wheel through a conveyor belt. One end of a stirring rod is fixedly sleeved with the first sliding wheel. The other end of the stirring rod sequentially penetrates supporting plat and one side of a washing box and extends into an inner cavity of the washing box to be rotationally connected with the other side of the washing box. The stirring rod is providedwith stirring blades. According to the willowleaf swallowwort rhizome washing device wide in application range, in the spraying process, willowleaf swallowwort rhizomes are stirred and shaken up anddown at the same time, the willowleaf swallowwort rhizomes are vibrated so that the willowleaf swallowwort rhizomes can be washed completely, manual washing is not needed, hand scratching is avoided,and water resources are circulated and saved; and after washing, stirring and vibrating continue to be carried out, the willowleaf swallowwort rhizomes can be dewatered, the processing procedures of the willowleaf swallowwort rhizomes are simplified, and the willowleaf swallowwort rhizome processing efficiency is improved.

Owner:扬州起航机械有限公司

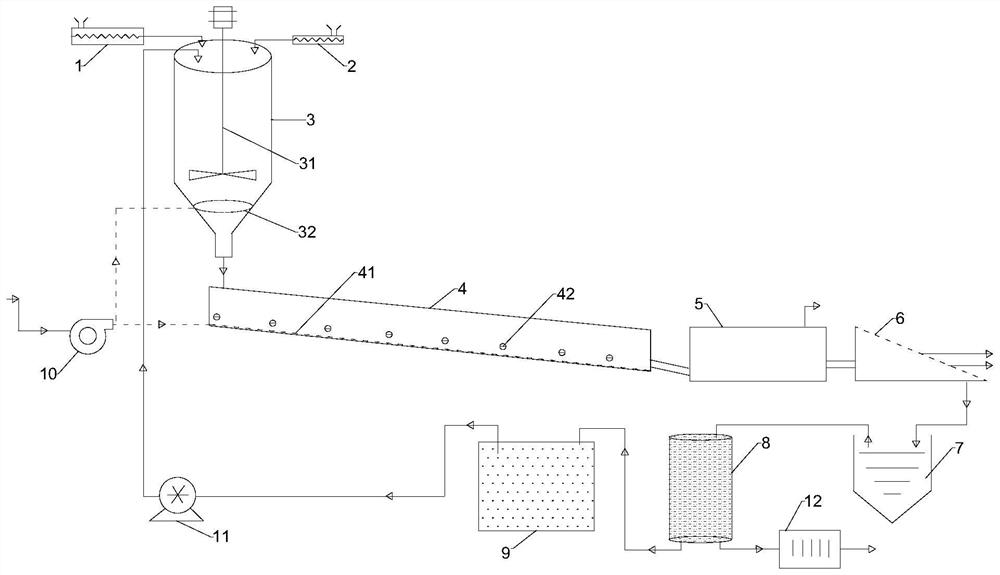

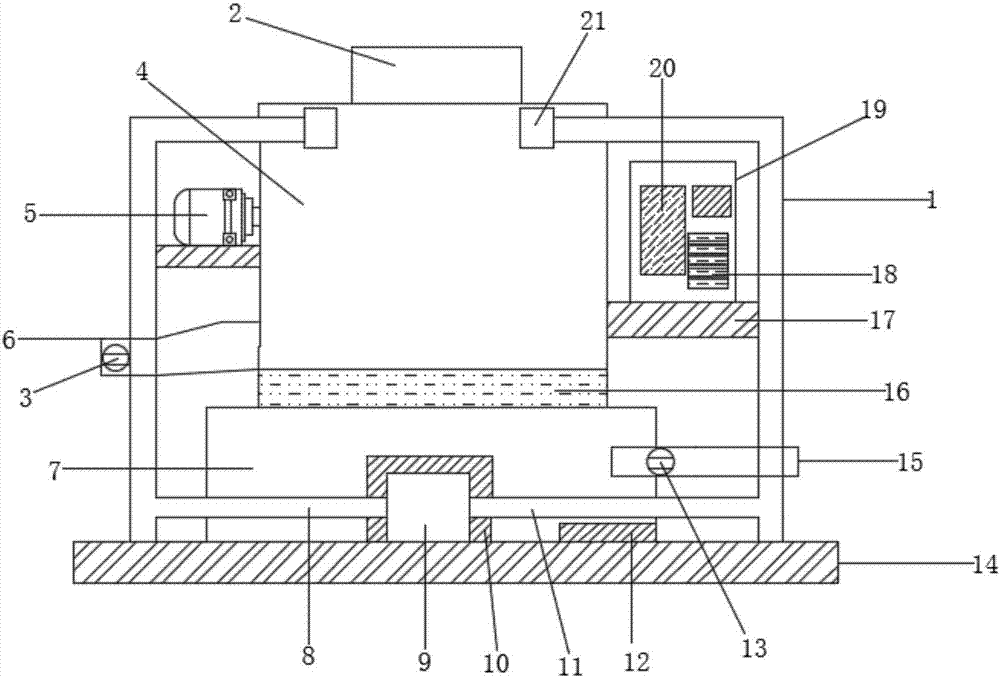

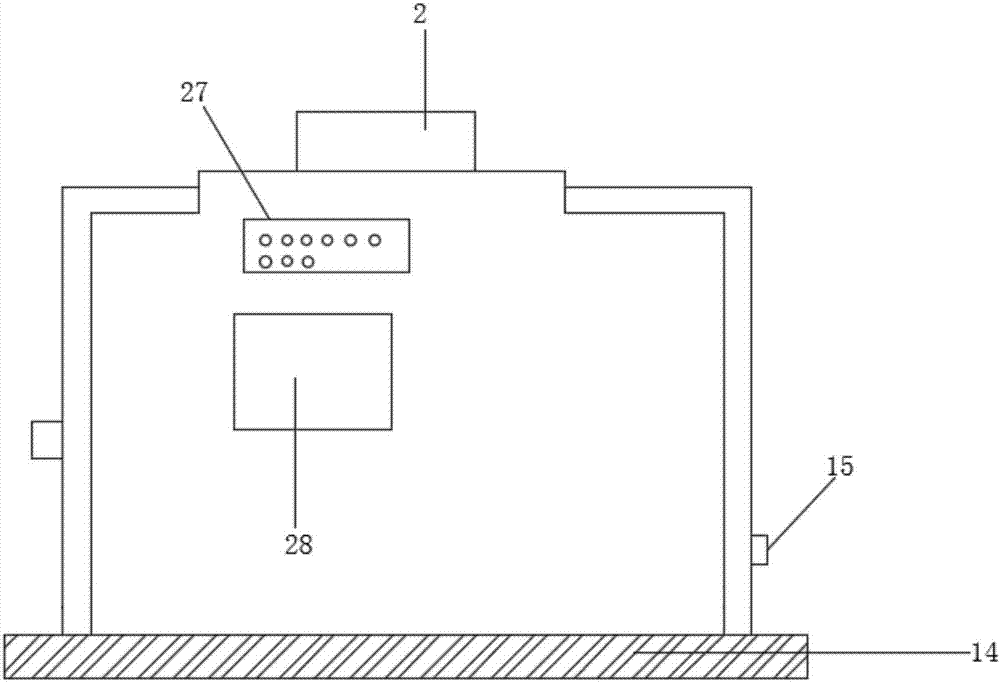

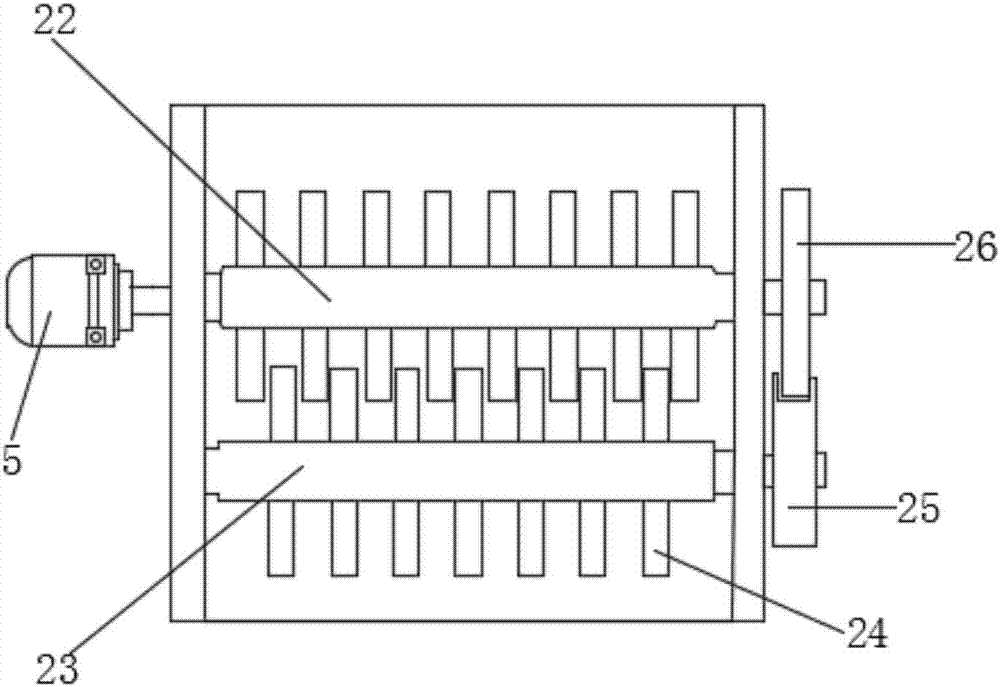

Feed pulverizer with cleaning function

InactiveCN107511233AEasy post-processingRegular cleaningFeeding-stuffHollow article cleaningWater storage tankWater resources

The invention discloses a feed pulverizer with a cleaning function. The feed pulverizer comprises a machine body, a pulverizing chamber and a water storage tank, wherein a display screen is arranged on the front surface of the machine body; the pulverizing chamber is arranged at the middle part position of the machine body; a control box is arranged on the right side of the pulverizing chamber; a storage battery and a timer are arranged inside the control box; the water storage tank is arranged on a bottom plate at the bottom of the machine body; a filter net is arranged between the pulverizing chamber and the water storage tank; a water pump is arranged inside the water storage tank; and the water pump extends into the pulverizing chamber through a first water conveying pipeline and a second water conveying pipeline. The feed pulverizer can uniformly pulverize feeds entering the pulverizer, so that a worker can observe data of the pulverizer more directly, and use the pulverizer more conveniently; the inside of the machine body can be regularly cleaned; later treatment of people is facilitated, the working burden of people is relieved, and the working efficiency of people is improved; and furthermore, water resources are cyclically used, so that water is saved; and the natural environment is protected.

Owner:杜鑫

High-nitrate wastewater treatment apparatus and high-nitrate wastewater treatment process

ActiveCN109626684AProcess environmental protectionNo secondary pollutionGas treatmentWater contaminantsThermodynamicsNitrate salts

The invention relates to a wastewater treatment process, particularly to a high-nitrate wastewater treatment apparatus and a high-nitrate wastewater treatment process. According to the high-nitrate wastewater treatment apparatus, a raw water input pipeline is sequentially connected to a nitric acid steam heat exchanger, a tail gas heat exchanger, a condensed water heat exchanger and an MVR evaporator; the MVR gas discharge port of the MVR evaporator is connected to a tail gas absorbent tank, the tail gas absorbent tank is connected to a tail gas absorption tower, and the gas discharge port onthe top portion of the tail gas absorption tower is connected to the heat source inlet of the tail gas heat exchanger; the concentrated liquid outlet of the MVR evaporator is connected to the inlet ofa nitric acid recovery device, the concentrated liquid discharge port of the nitric acid recovery device is connected to a crystallizer, the nitric acid steam discharge port on the top portion of thenitric acid recovery device is connected to the heat source inlet of the nitric acid steam heat exchanger, and the heat source outlet of the nitric acid steam heat exchanger is connected to a concentrated nitric acid tank; and the condensed water outlet of the MVR evaporator is connected to the heat source inlet of the condensed water heat exchanger. According to the present invention, after theraw water is treated by the apparatus and the process, the effluent can be recycled, and the crystal and the tail gas are harmlessly treated.

Owner:CHINA PETROLEUM & CHEM CORP

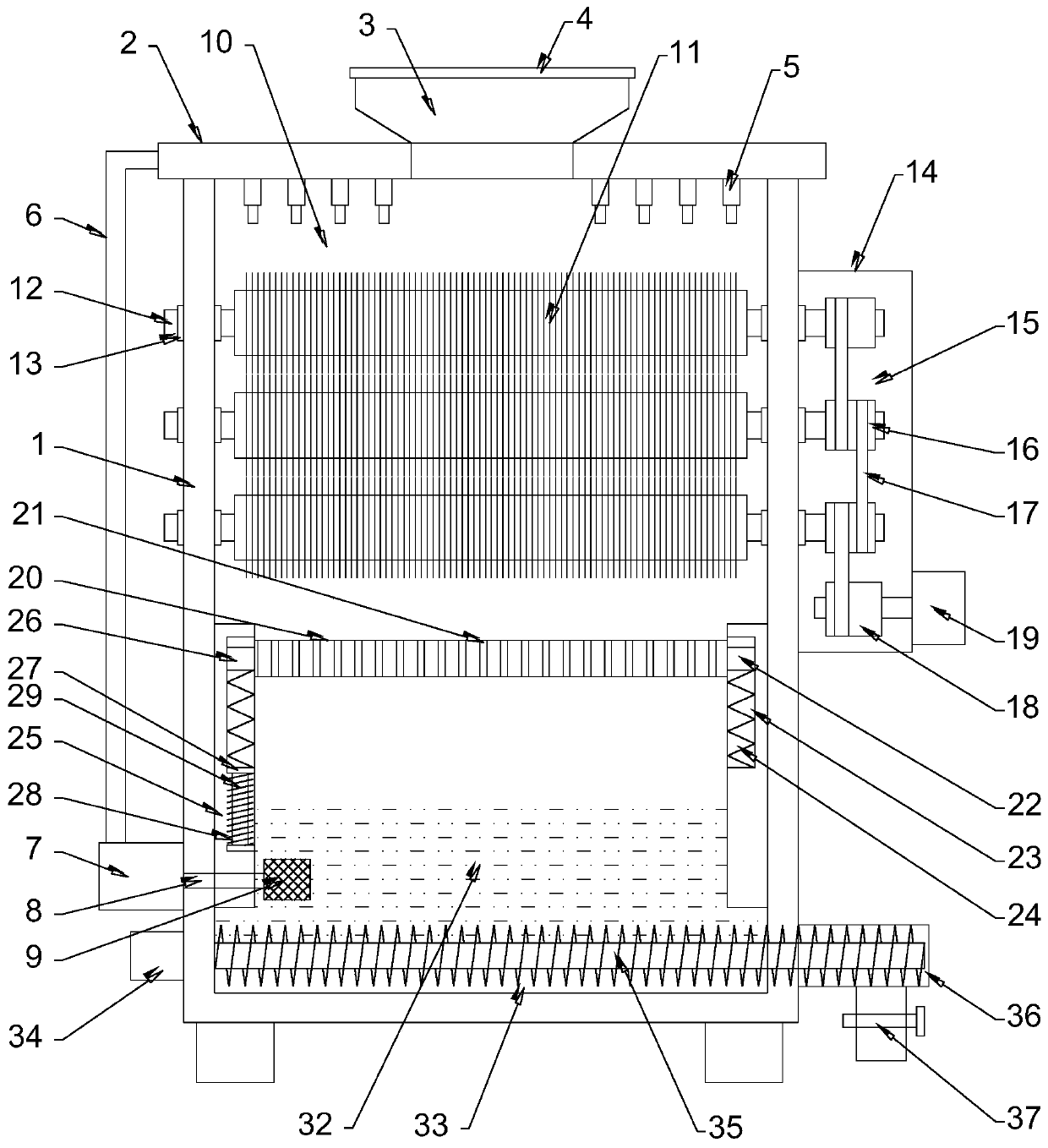

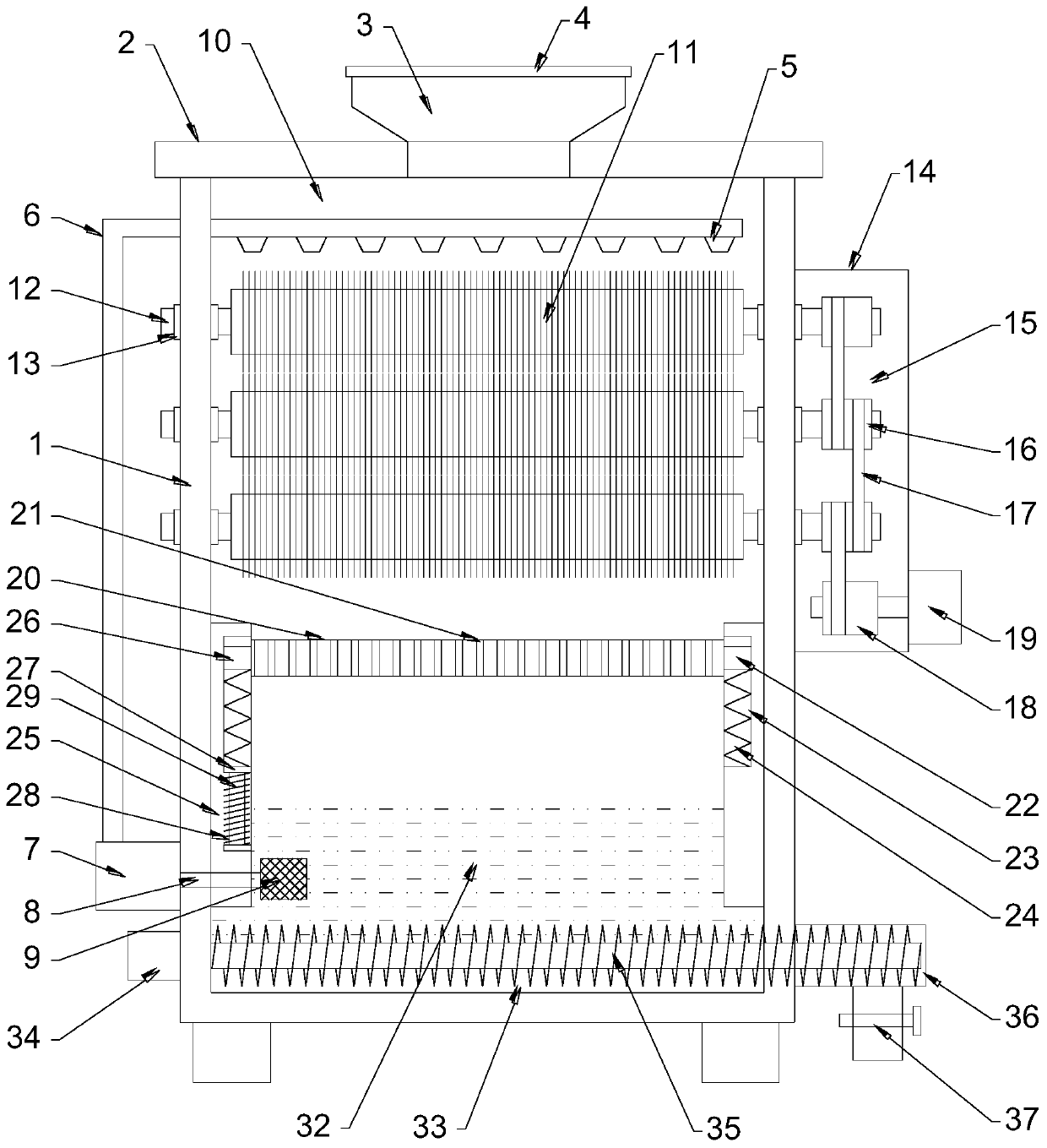

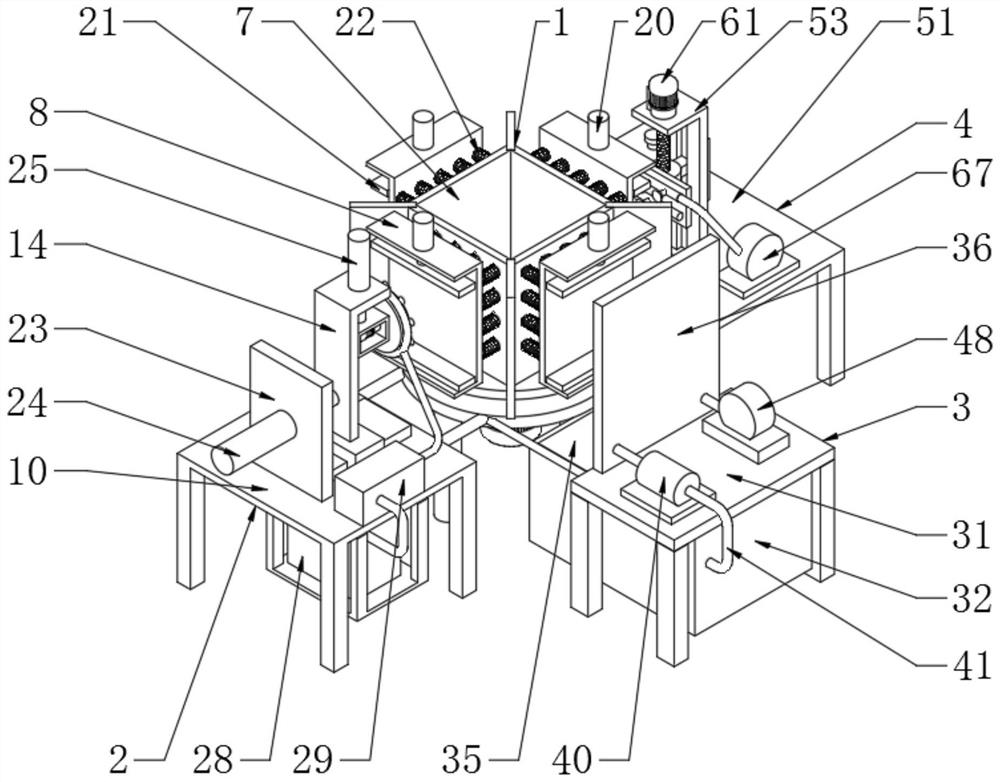

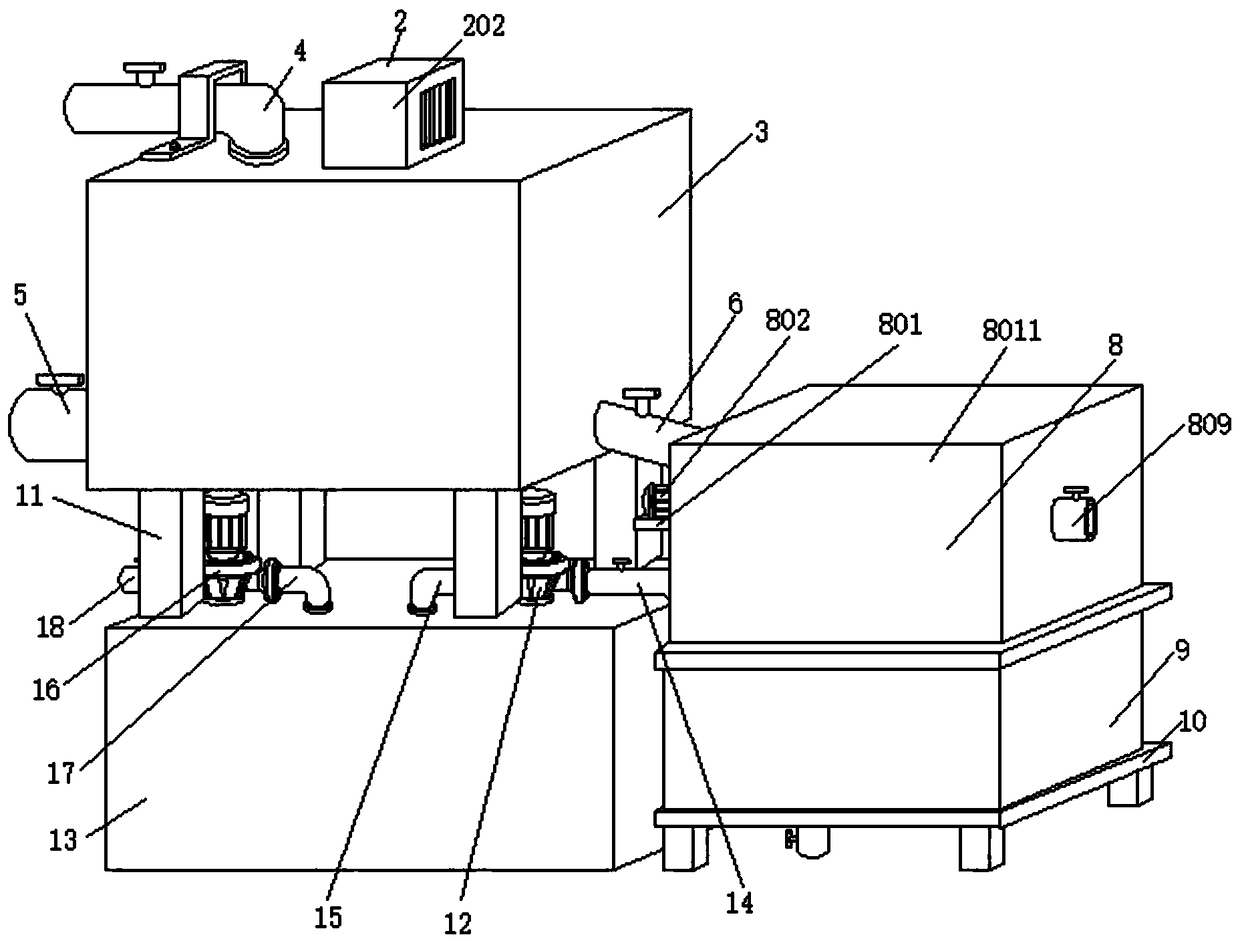

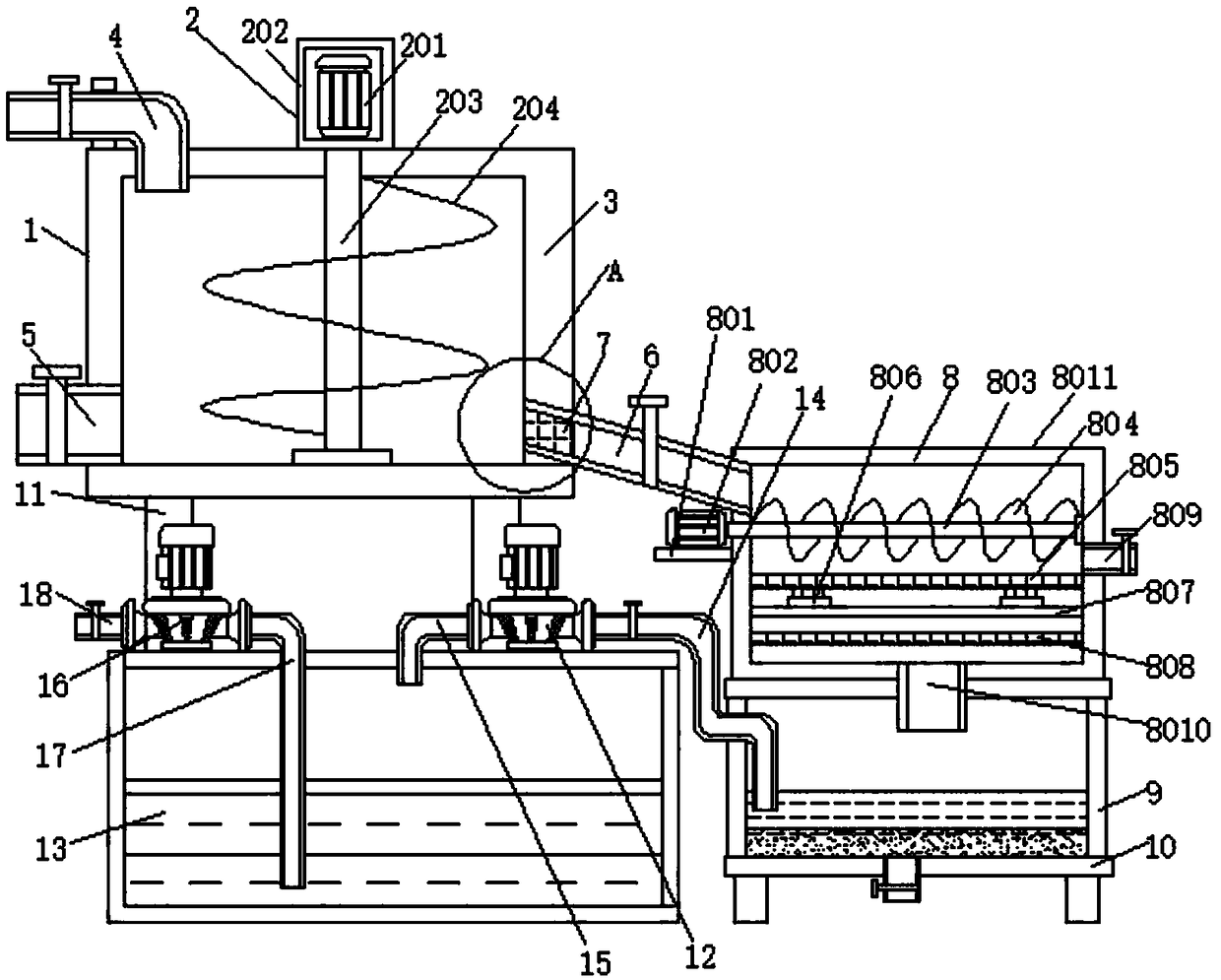

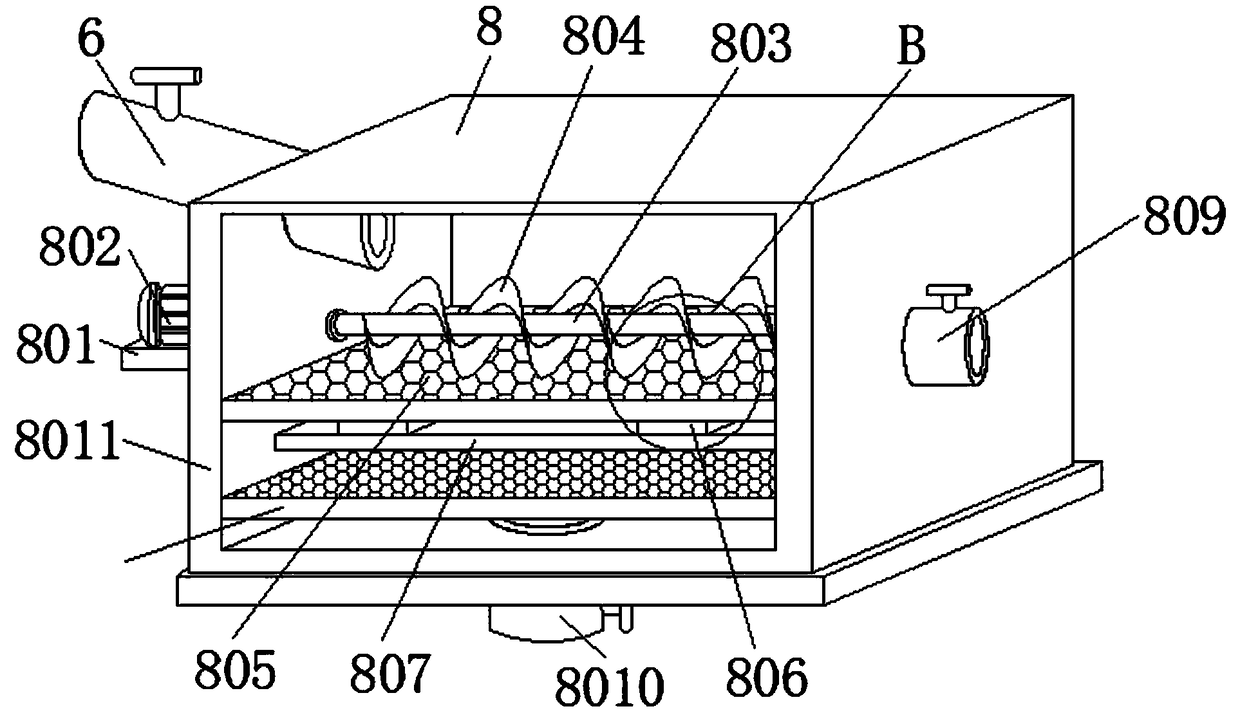

Cleaning and processing machinery equipment for peanut harvesting

InactiveCN110214530AImprove screening efficiencyDischarge in timeDigger harvestersWater storageWater resources

The invention discloses cleaning and processing machinery equipment for peanut harvesting, which belongs to the technical field of agricultural and sideline products processing machinery, and solves the problems of lack of mechanical equipment for cleaning picked peanuts and unclear dirt attached to the surface of peanuts. The technical key points include that the equipment comprises a box body, water spray nozzles, brush rollers, a screening plate and a water storage groove, wherein a box cover is mounted at the top of the box body; a feed hopper is connected to the middle of the upper end ofthe box cover; a cleaning cavity is formed in the box body; a plurality of the water spray nozzles are arranged in the cleaning cavity; a plurality of brush rollers are alternately arranged from topto bottom along the cleaning cavity of the box body; and the washing of the water spray nozzles is matched, so that the peanut surface passing between two adjacent brush rollers is conveniently scrubbed, and the soil attached to the peanut surface is cleaned; and secondly, the screening plate which continuously vibrates up and down under the action of a vibration exciter is matched, so that the peanut screening efficiency is improved, and the cleaned peanut is further favorably discharged in time, and in the whole cleaning process, water resources are recycled, and energy is saved and environment is protected.

Owner:唐鑫

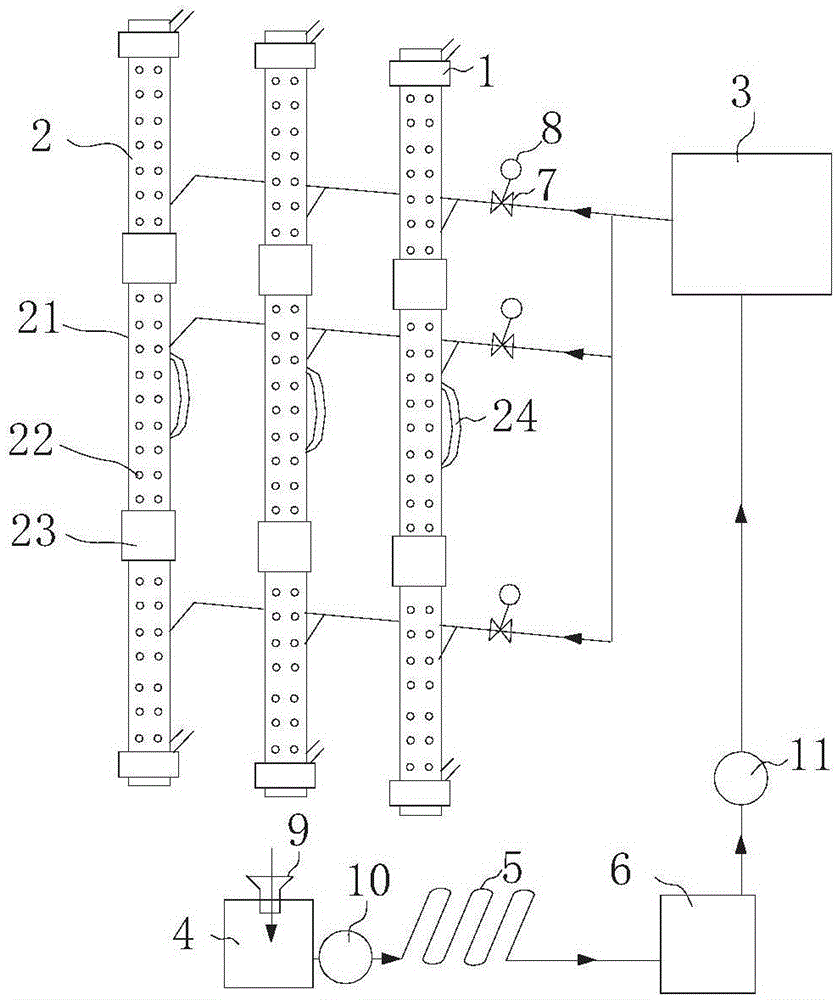

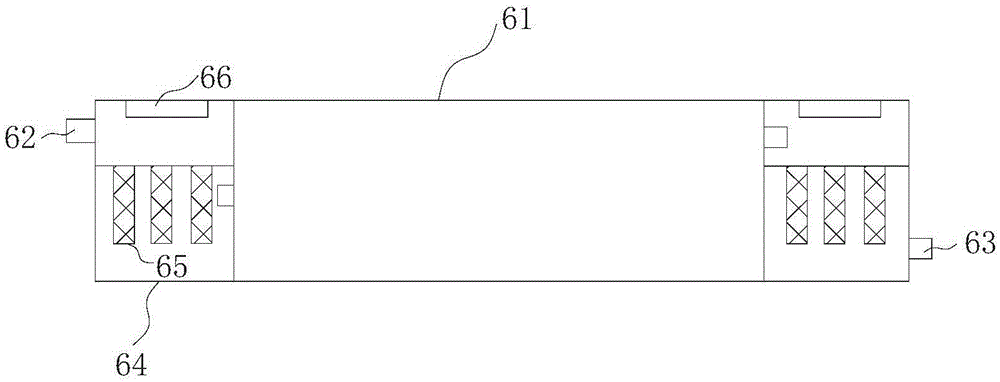

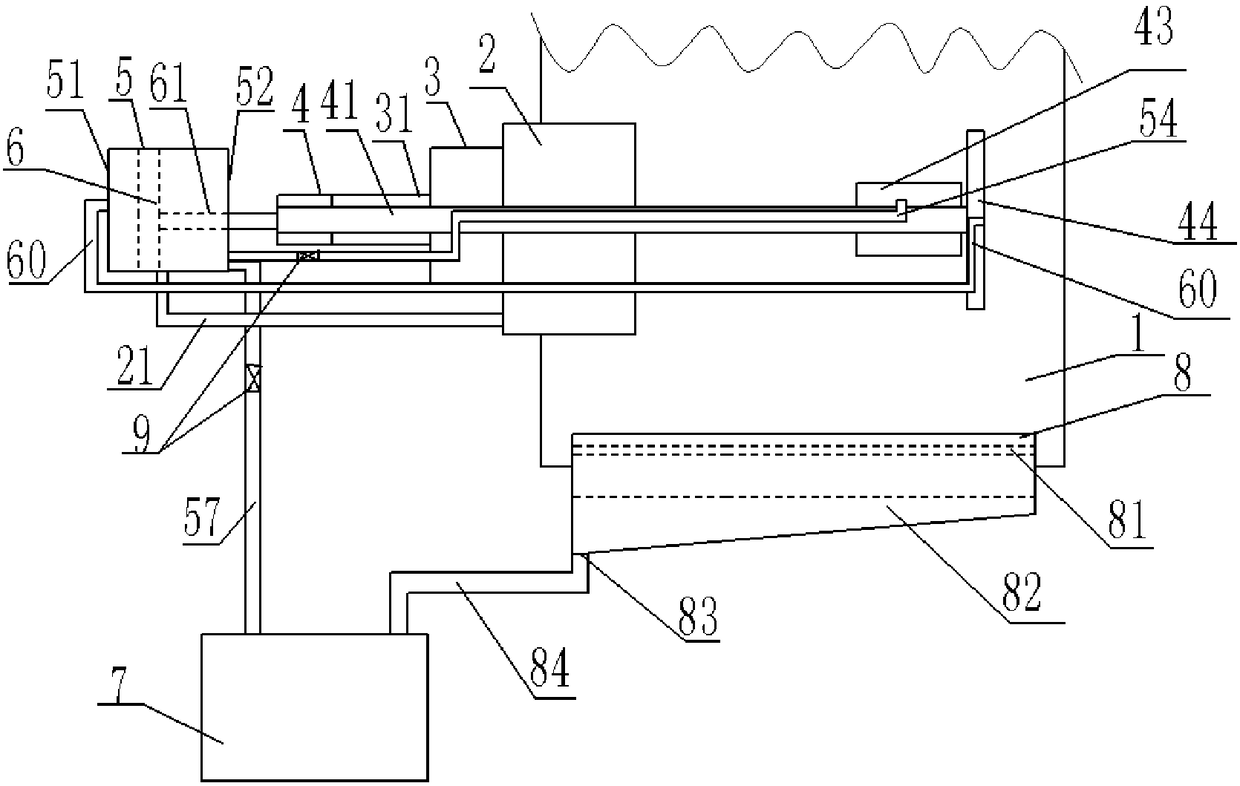

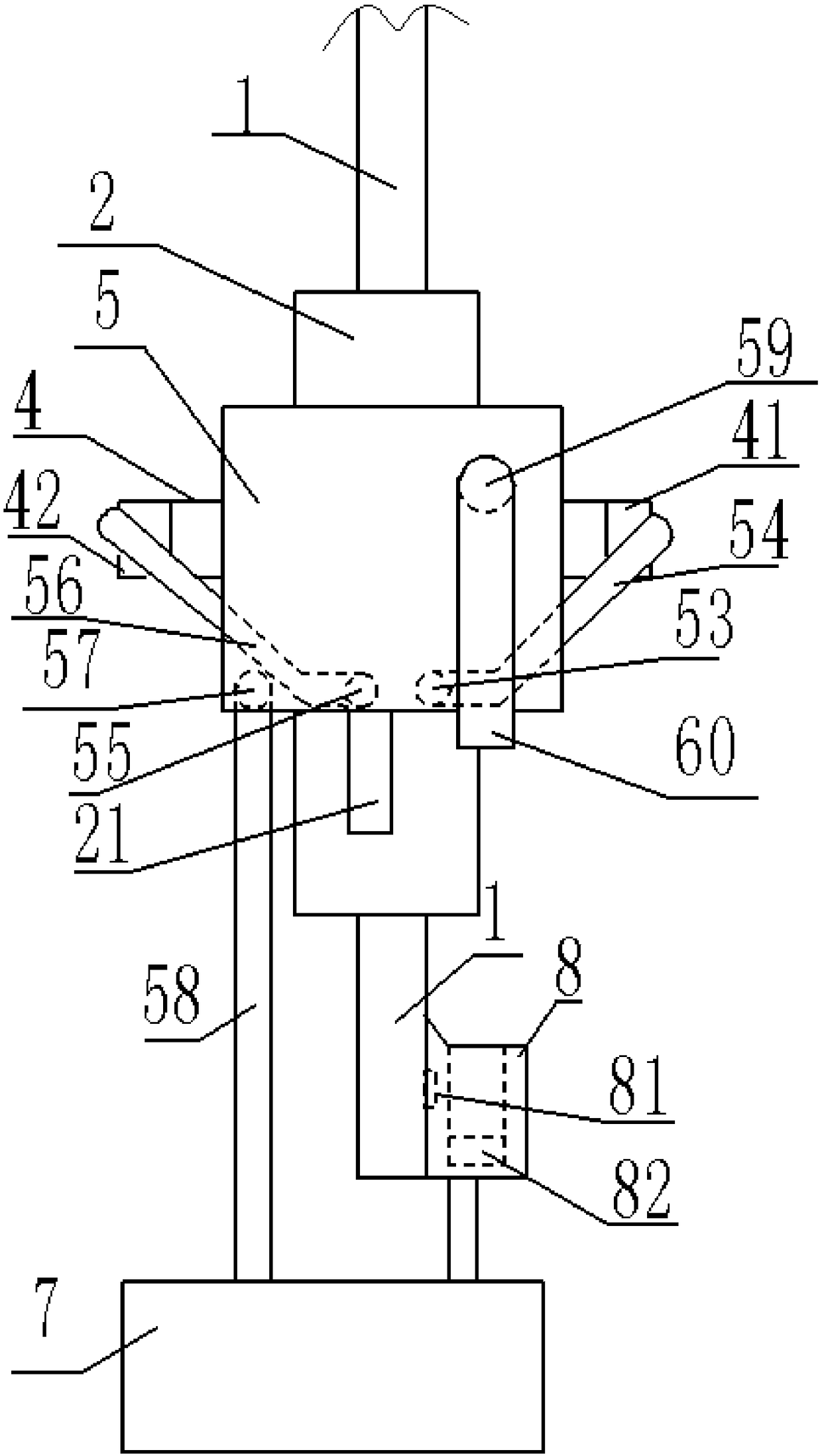

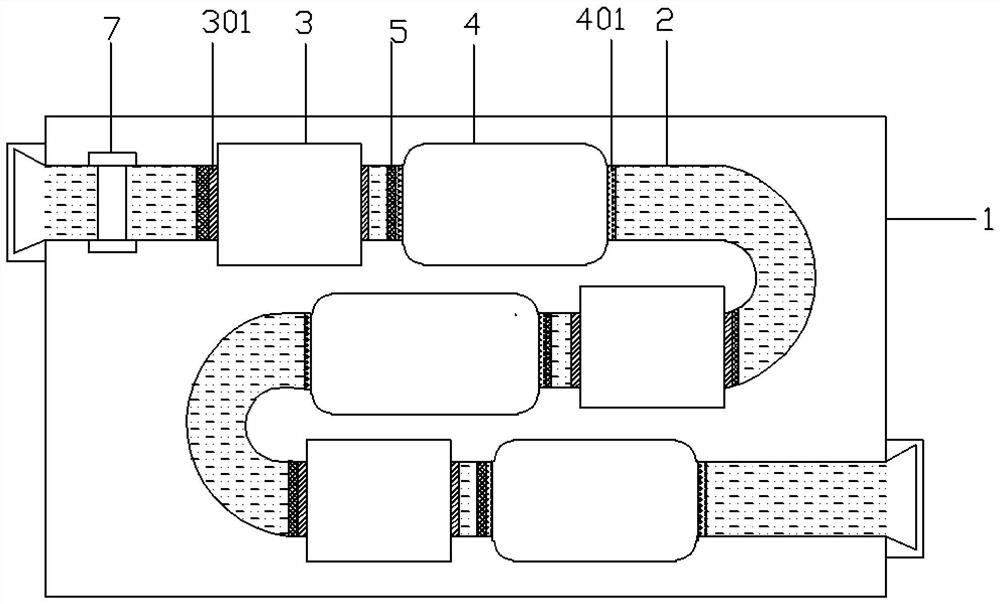

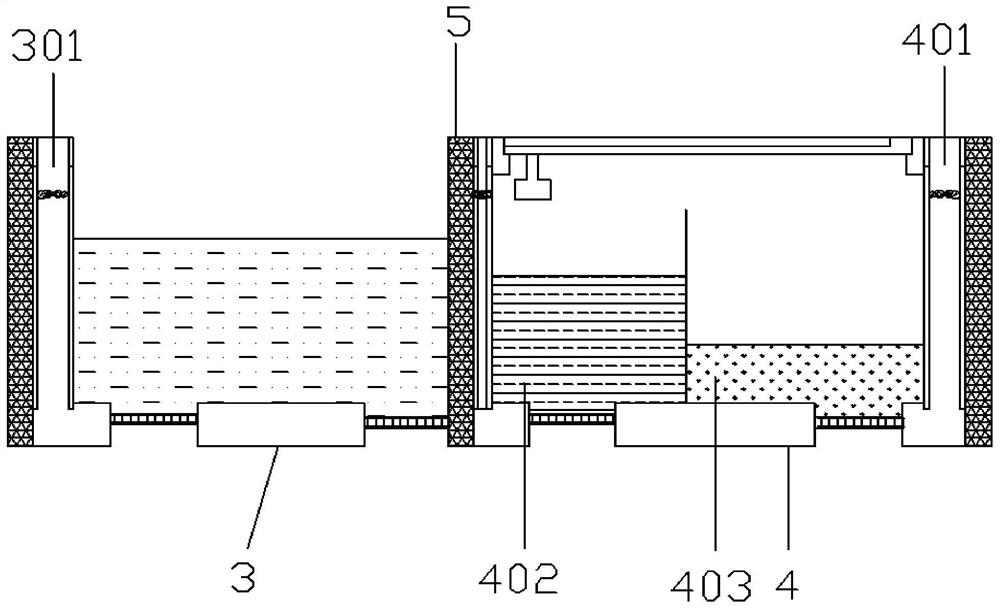

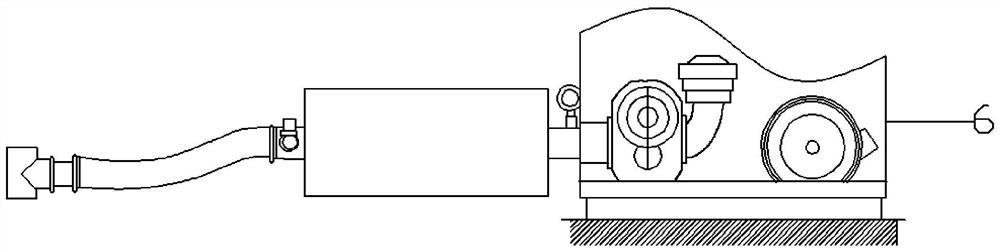

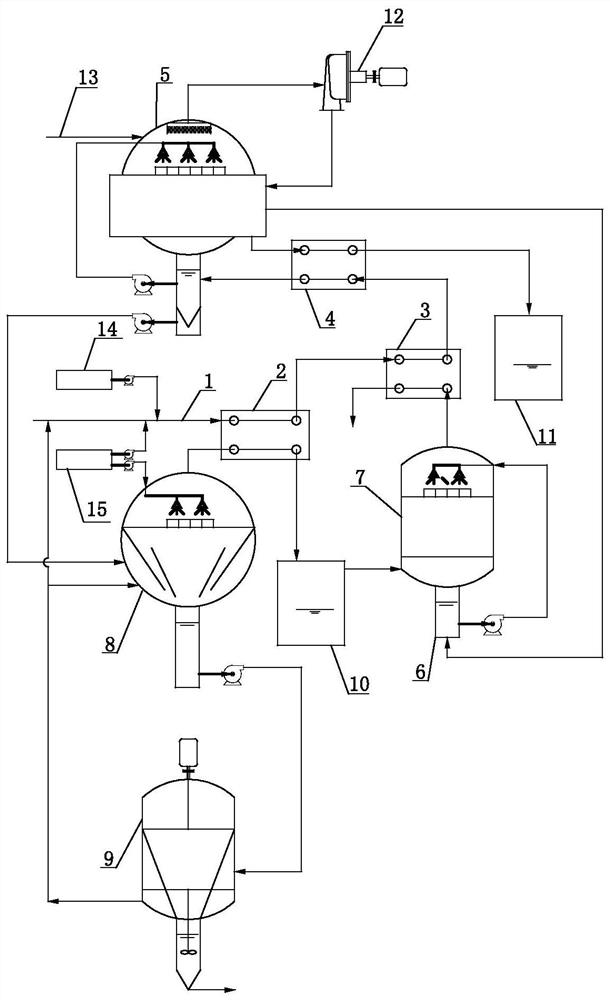

Water circulation shower system

ActiveCN105078332AImprove comfortWater recyclingFatty/oily/floating substances removal devicesSewerage structuresWater circulationEngineering

The invention discloses a water circulation shower system, comprising a shower room, an underground collecting basin, a coiled pipe laid under floor of the shower room, and a water treatment system. The shower room is internally fixedly provided with a shower hose through a fixing support. The shower hose and the fixing support are rotatably connected. The shower hose is arranged vertically and the pipe wall is provided with blowholes. The shower hose is at least divided into two segments of independent sub-shower hoses from high to low, and each sub-shower hose is provided with a water inlet port connected with a water source. The entrance of the collecting basin is connected with a floor drain on the floor of the shower room. The coiled pipe comprises a water inlet and a water outlet. The water inlet is connected with the outlet of the collecting basin through a water pump. The water treatment system is used to receive effluent from the coiled pipe and supply water for a water resource. The water treatment system is a clustered A2O water treatment device, and comprises a plurality of tubular A2O treatment units, and series-parallel connection of the A2O treatment units can be switched over through pipelines. The shower room is configured with the water treatment device, and can collect, purify, and reuse shower wastewater, so as to save water resource.

Owner:ZHEJIANG HUMANITIES LANDSCAPE CO LTD

Cleaning device for two sides of glass

The invention discloses a cleaning device for the two sides of glass. The cleaning device comprises a clamping mechanism, an air cylinder is arranged on the clamping mechanism, a telescopic rod of theair cylinder is connected with a connecting rod, a brushing component is arranged on the connecting rod, a cleaning brush and a scraper are arranged on the brushing component, the scraper is connected to the end of the brushing component, a chamber is formed in the left side of the connecting rod, a piston is arranged in the chamber, a piston rod of the piston is fixed on the connecting rod, a water inlet is formed in the bottom of the side wall of the chamber, the water inlet is connected with a water inlet pipe, a water storage mechanism is arranged below the chamber, the water inlet pipe is connected with the water storage mechanism, water outlets are formed in the bottom of the side wall and are connected with water outlet pipes, the other ends of the water outlet pipes are connectedwith the cleaning brush, a water tank is arranged on the bottom of the glass, a water filtering part is arranged on the bottom of the water tank, a water return port is formed in the bottom of the water tank, and a water pipe is connected between the water return port and the water storage mechanism. The cleaning device can simultaneously clean the two sides of the glass and can also remove residual water stains on the glass, the cleaning degree is high, and the time is saved.

Owner:CHONGQING MINGYOU STEEL PROD MFG CO LTD

Efficient cleaning device for agricultural machine

PendingCN112495904APlay a supporting roleSpray evenlyDrying gas arrangementsCleaning using toolsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural machine cleaning, and particularly relates to an efficient cleaning device for an agricultural machine. The efficient cleaning device comprises a shell and a filter frame, and the bottom of the shell is fixedly connected with a first fixed shell. A cleaning liquid storage tank, a brush, a water tank and a heater are arranged, thus a cleaning agent is put into the cleaning liquid storage tank, a stirring paddle is driven by a third motor to mix and stir the cleaning agent, so that the cleaning agent is uniformly mixed with water, andcleaning liquid is sprayed to the machine through a first pump, so that the machine is conveniently brushed. A second motor drives a rotating plate, so that the rotating plate drives the brush to rotate, the brush cleans the surface of the machine, the cleaning efficiency is improved, a fourth motor drives a threaded column to rotate, a threaded cylinder drives a fixed pipe to move, the fixed pipedrives a second spray head to clean the whole machine, and the cleaning effect is improved. Hot air in a heating box is blown into the shell through a draught fan, and therefore the machine can be dried conveniently.

Owner:襄阳金美科林农业开发有限公司

Supercritical steam collision material thermal decomposition condensation reduction device

InactiveCN108704597AIncrease the heat exchange areaHigh thermal efficiencyEvaporator accessoriesLiquid solutions solvent extractionCombustion chamberCooling tower

The invention discloses a supercritical steam collision material thermal decomposition condensation reduction device, which is mainly composed of a molten salt bath, a combustion chamber, a flue gas tank, an air preheating tank, a combustion engine, a fuel tank, a waste heat recovery tank, a high pressure plunger pump, a high pressure spraying device, a steam generator, a first steam coil a secondsteam coil, a steam header, a sub-cylinder, a steam collider, a first material thermal decomposition coil, a second material thermal decomposition coil, a condensation reduction bed, a conveyor, a first wind turbine, a second wind turbine, a delivery pipe, a first cooling tower, a second cooling tower and the like. The advantages of the supercritical steam collision material thermal decompositioncondensation reduction device include: 1. superheated steam is produced instantaneously, and the heat efficiency is very high; 2. steam temperature and pressure can be adjusted alone; 3. multi-stagewaste heat recovery can be made, and smoke exhaust temperature is low; 4. any limescale and sewage can't be generated, and no exhaust gas can be discharged; 5. in material thermal decomposition, the supercritical steam collision material thermal decomposition condensation reduction device is energy-saving and efficient, and the decomposition is adequate; 6. the device has multiple use, and the industrial process is integrated.

Owner:广西恒颐鑫科技有限公司

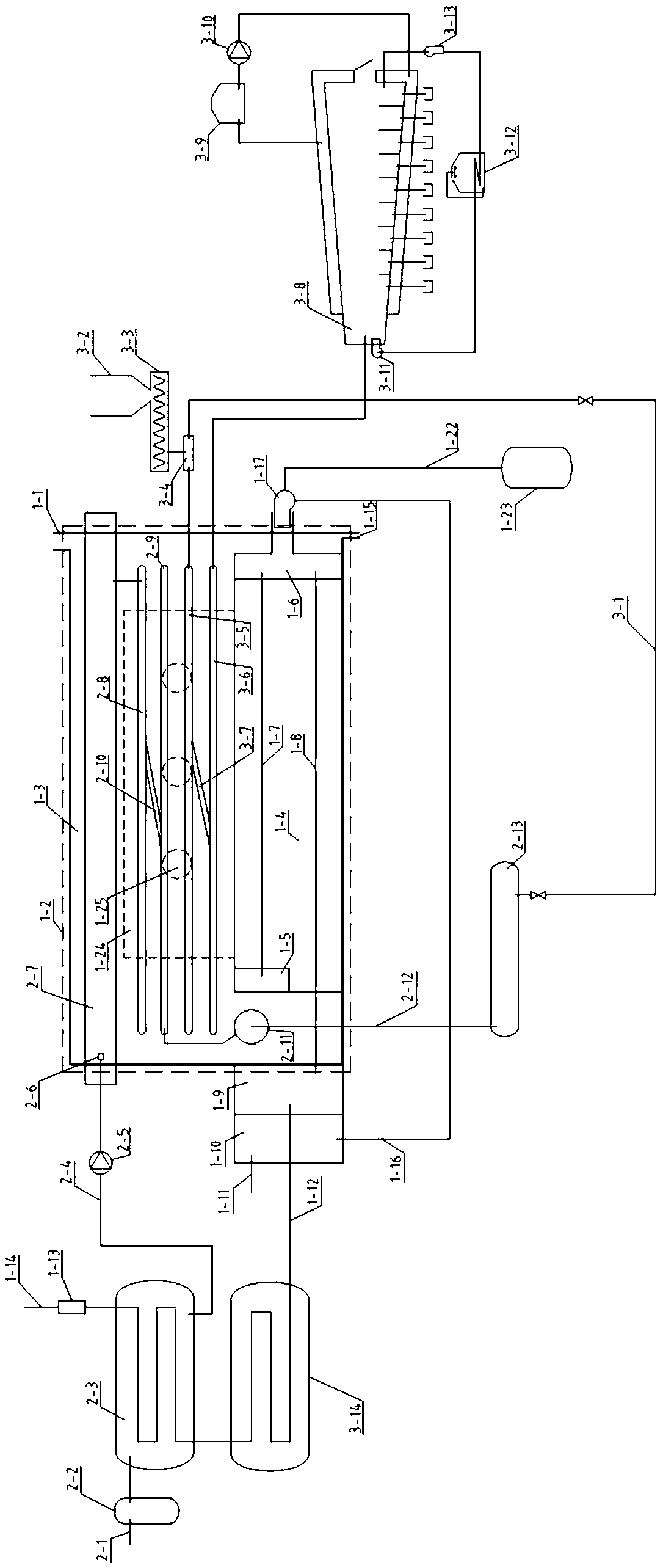

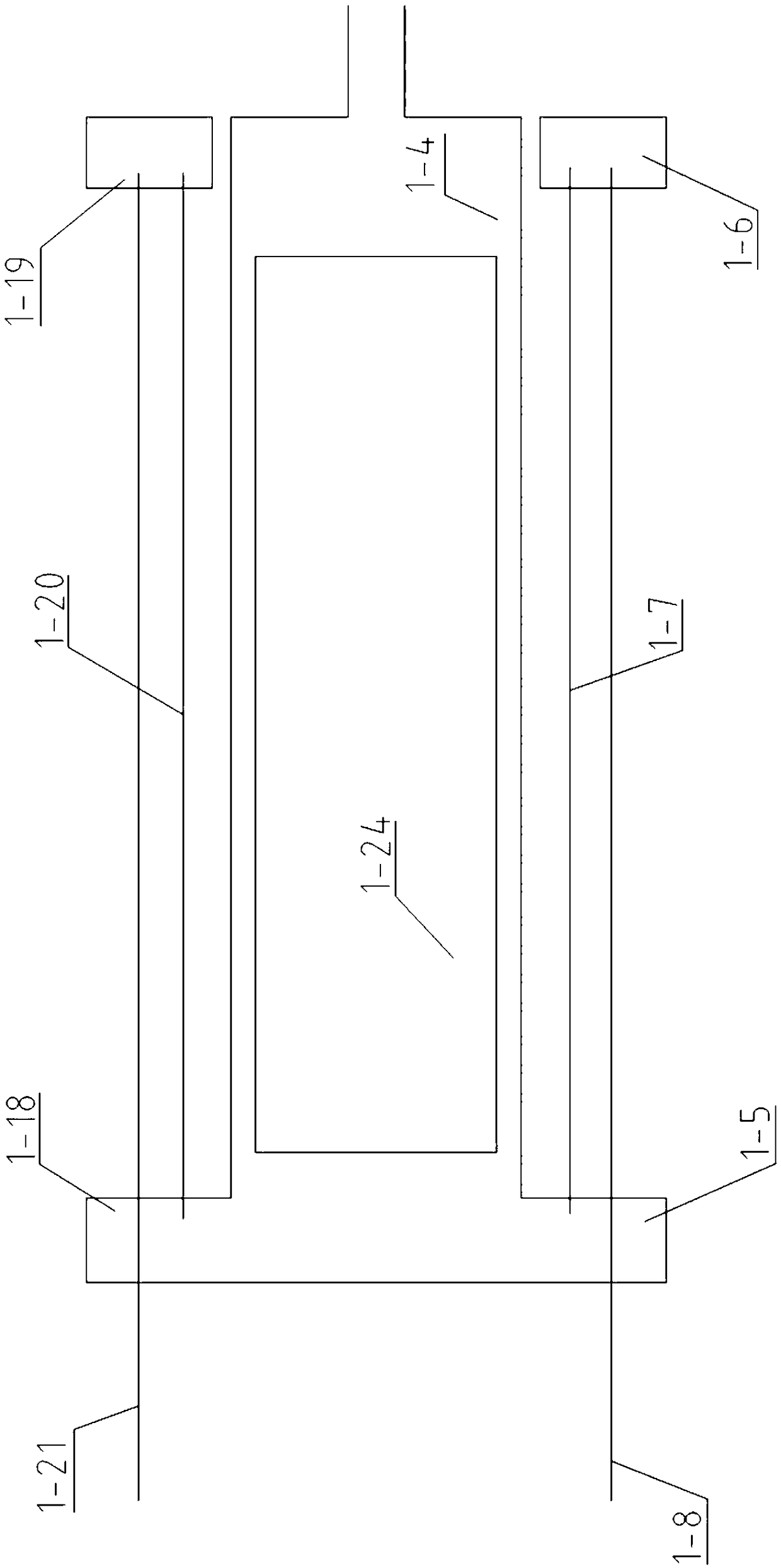

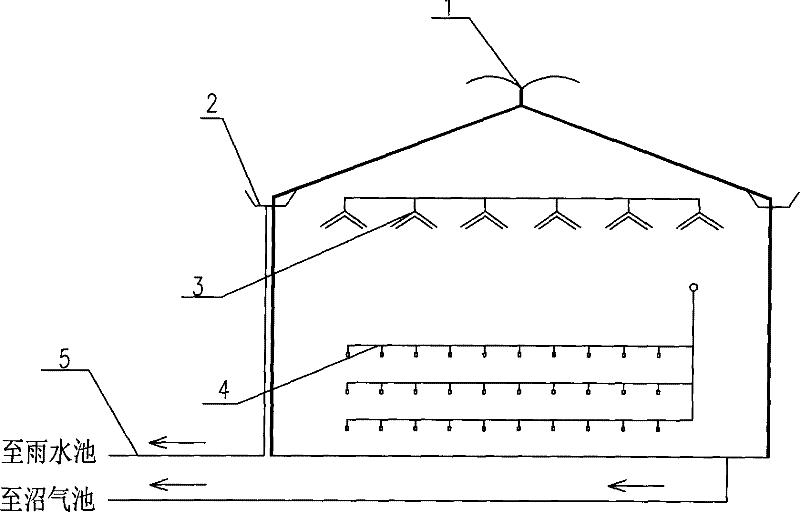

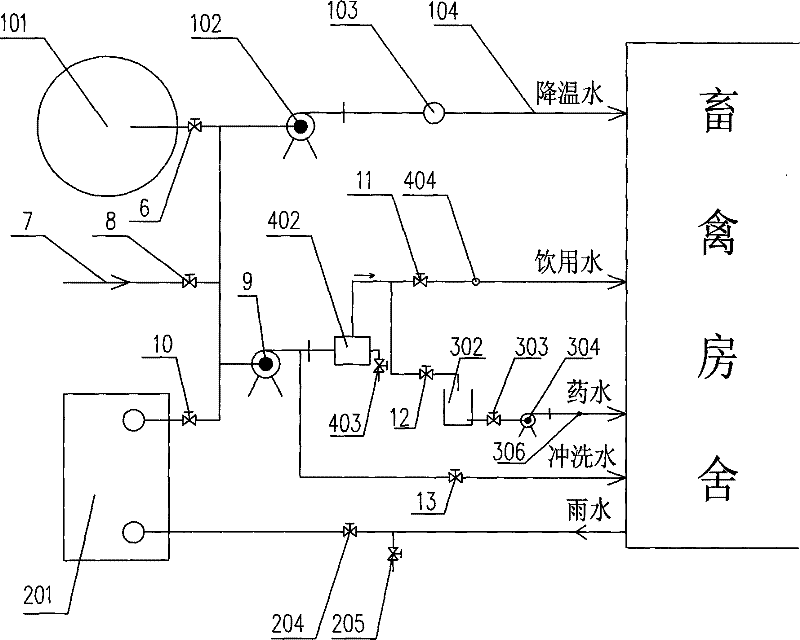

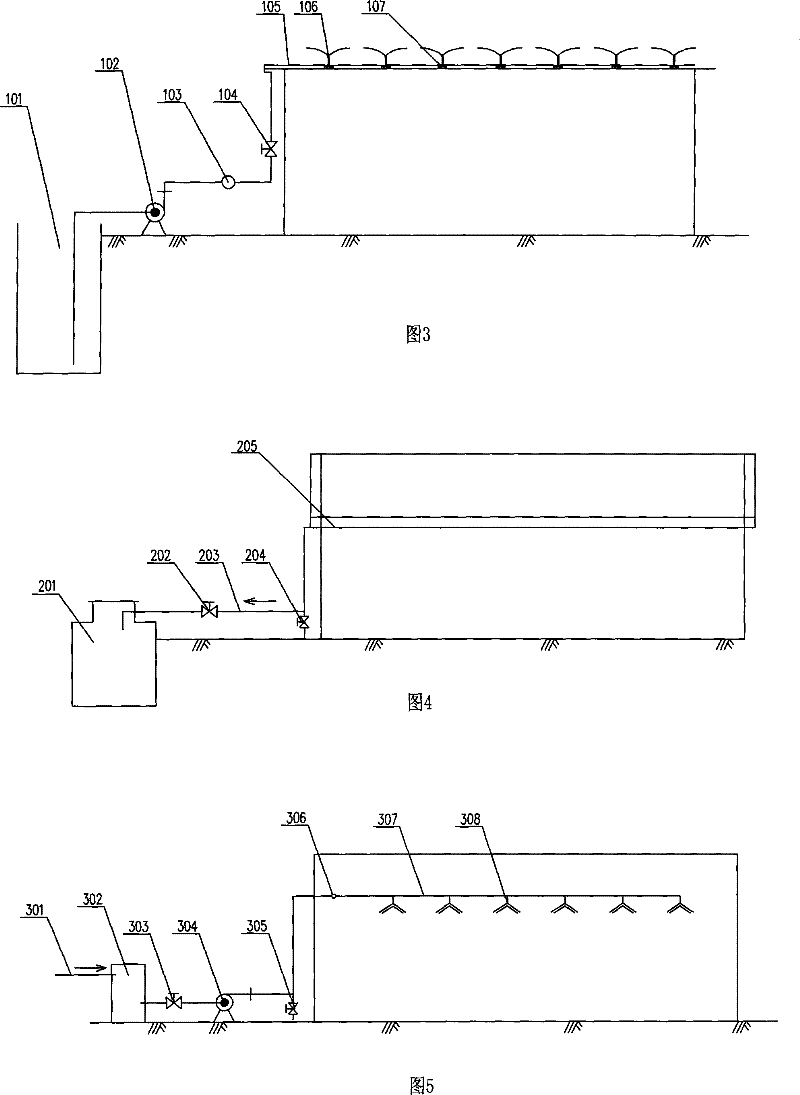

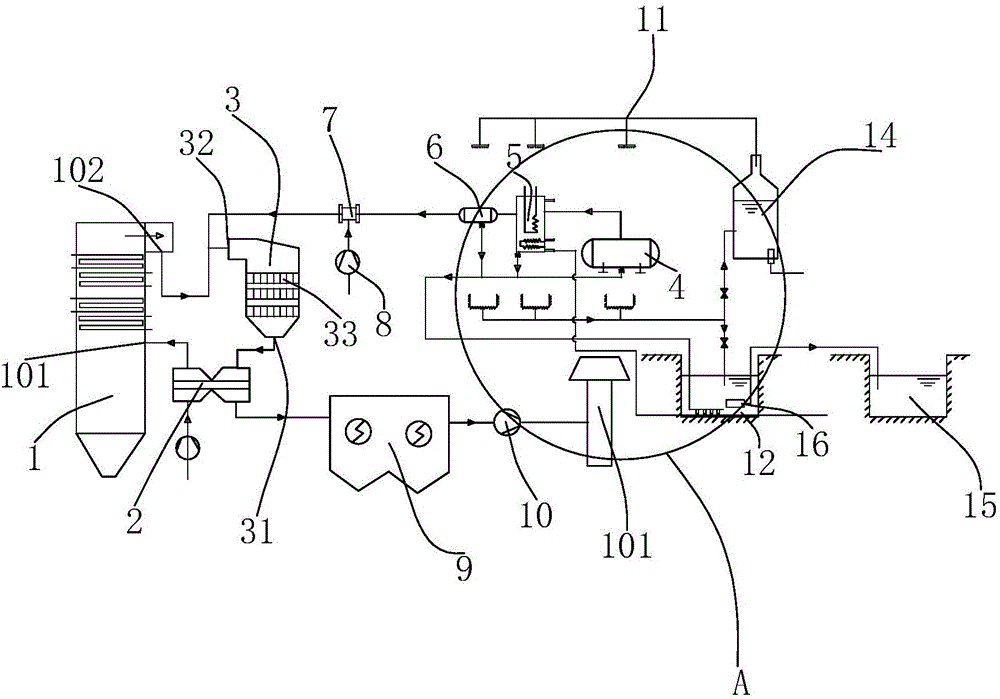

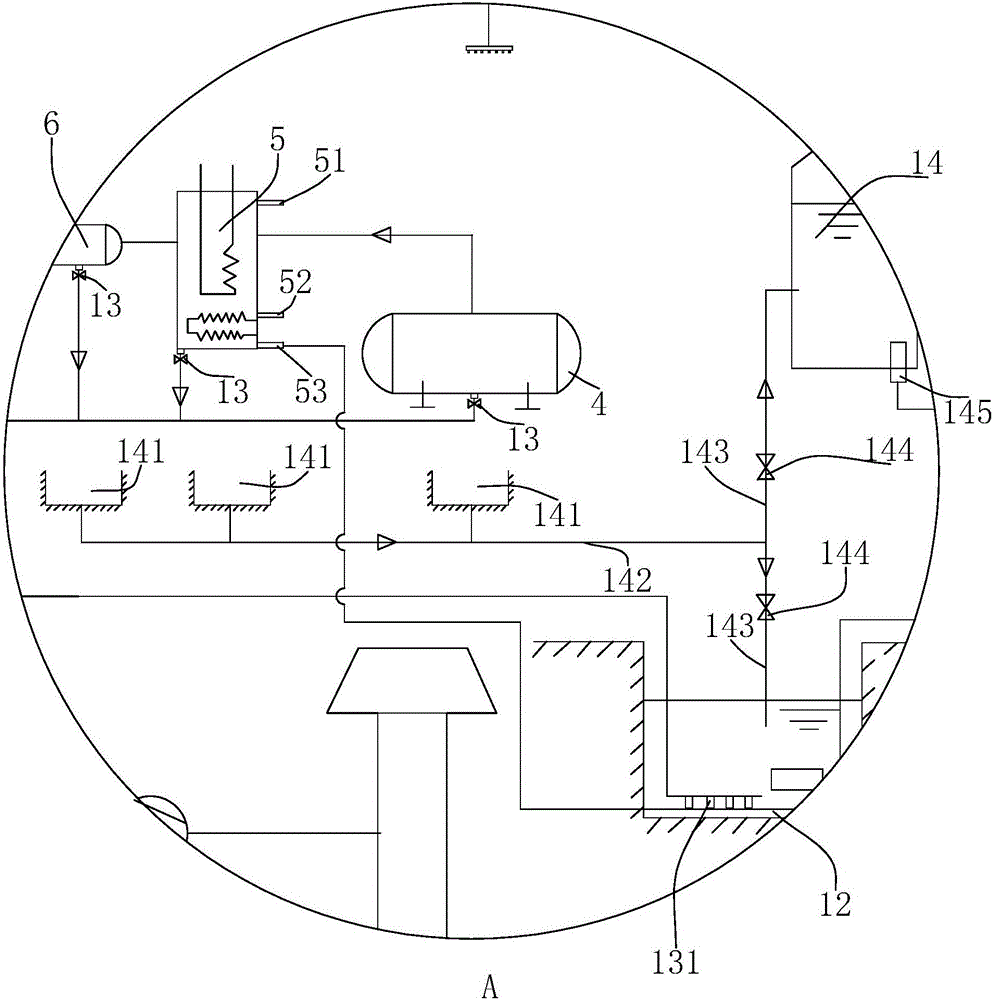

Water supply and drainage system of livestock and poultry farms

InactiveCN101248776BReasonable designConserve waterBio-organic fraction processingClimate change adaptationSlurryEngineering

The invention relates to a livestock and poultry farm water supply and drainage system, which is designed for water resource recycling of the scale livestock and poultry farm. The system consists of five parts including a cooling device, a rain water harvesting device, a medicine spraying device and a sewage disposal system. The design of the system is mainly characterized in that the system adopts well water or rain water for cooling the livestock and poultry houses, the cooling sewage and the rain water are colleted to rain water pools through rain water grooves, and the rain water or tap water is processed by a ultrafiltration membrane water processor to provide drinking water for the houses. The tap water or the rain water processed by the ultrafiltration membrane water processor is used for diluting the liquid medicine and the well water or the rain water is used for washing the livestock and poultry houses; the methane and the biogas slurry generated after the biological treatment of the house-washing sewage is used for fertilizing after being biologically treated. The water supply and drainage system is characterized in reasonable design, water conservation, water resource recycling, ecological virtuous circle and low production cost, which is applicable to the modernized management of the scale livestock and poultry farm water supply and drainage facility.

Owner:奕永庆 +2

SCR (Selective Catalytic Reduction) flue gas denitrification system

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitrification system which comprises an industrial boiler, an air pre-heater, an SCR reactor, a liquid ammonia tank, an electric precipitator, a draught fan and a spraying device, wherein an air inlet and a flue gas discharging port are formed in the industrial boiler; the air pre-heater is connected with the air inlet; a gas outlet and a gas inlet connected with the flue gas discharging port are formed in the SCR reactor; the liquid ammonia tank successively passes through a vaporizer, an ammonia buffer tank and a mixer and then is connected with the gas inlet of the SCR reactor, and an air dilution fan is connected with the mixer; the electric precipitator passes through the air pre-heater and then is connected with the gas outlet; one end of the draught fan is connected with the electric precipitator while the other end is connected with a chimney; and the spraying device is located above the liquid ammonia tank, the vaporizer and the ammonia buffer tank and is used for absorbing ammonia from air. The SCR flue gas denitrification system has the advantages and effects that the SCR reactor can remove oxynitride; when the spraying device is used for reducing the temperature, the water resource is recycled; and the solution, which is generated after ammonia is removed by the spraying device, also can be neutralized with dilute sulphuric acid, and finally, an ammonia fertilizer can be acquired.

Owner:浙江友通环境科技有限公司

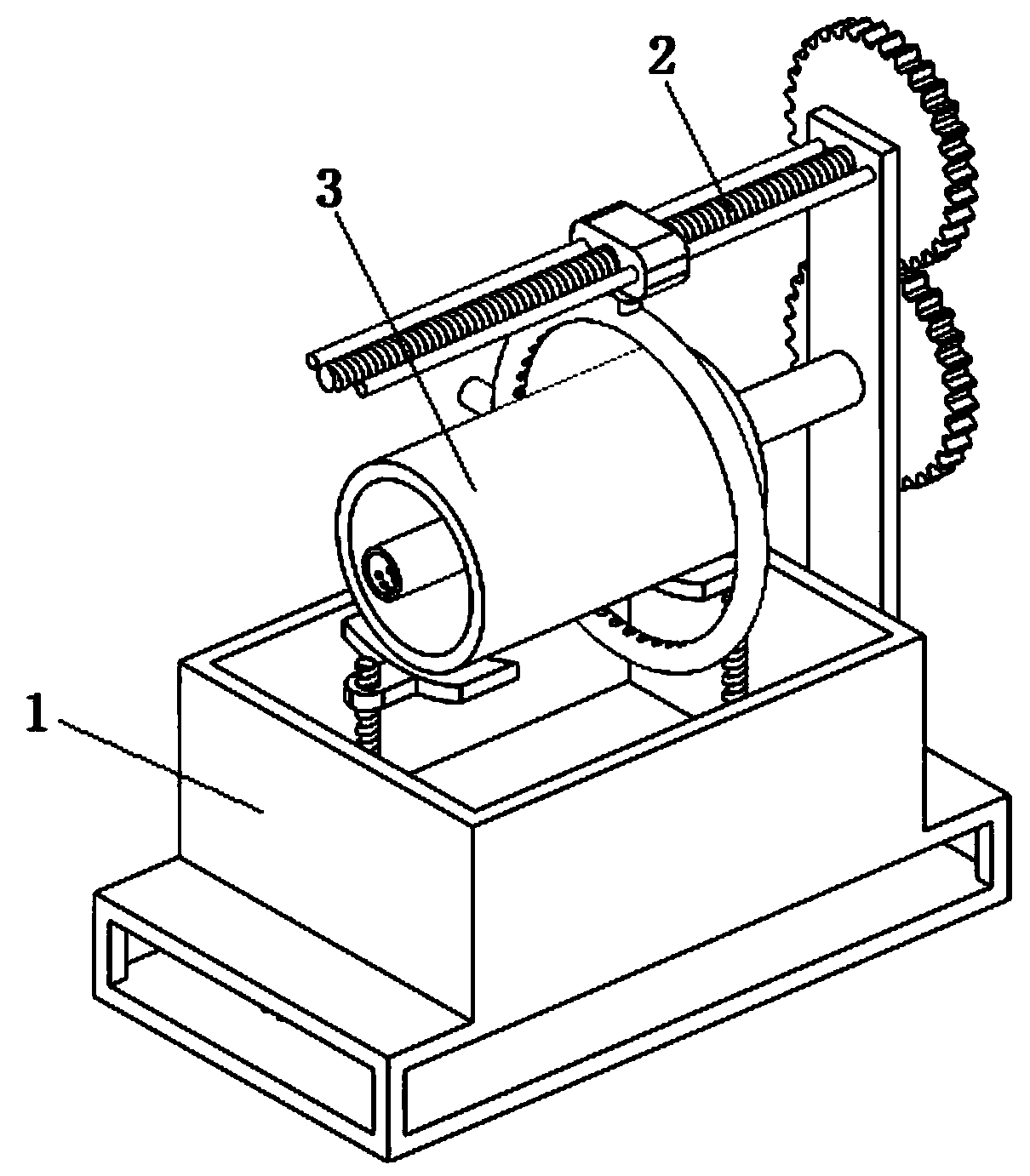

Polishing device for metal material surface machining

InactiveCN110303394AReduce surface temperatureReduce splashGrinding feedersGrinding work supportsWater resourcesEngineering

The invention discloses a polishing device for metal material surface machining. Each clamping piece is arranged to comprise a moving base, elastic plates, first servo electric cylinders, clamping plates, chains and protective plates, wherein by adjusting the extending and retracting lengths of the first servo electric cylinders, the clamping piece can clamp, fix and separate the metal materials of different types, so that use is convenient and rapid. By arranging a water storage box, backflow pipes, a water pump, a first water conveying pipe, a second water conveying pipe, a water storage disk and water dropping pipes, water dropping can be conducted in the metal material polishing process, splashing chips are reduced, and the metal material surface temperature can be lowered; the water resource is recycled, so that the resource is saved; by arranging cleaning cloth, the polished metal material can be cleaned, convenience and rapidness are achieved; by arranging an air blower and airinlet, the polished and cleaned metal material can be blown and cooled, convenience and rapidness are achieved, and the safety of work personnel can be effectively guaranteed.

Owner:赖成凤

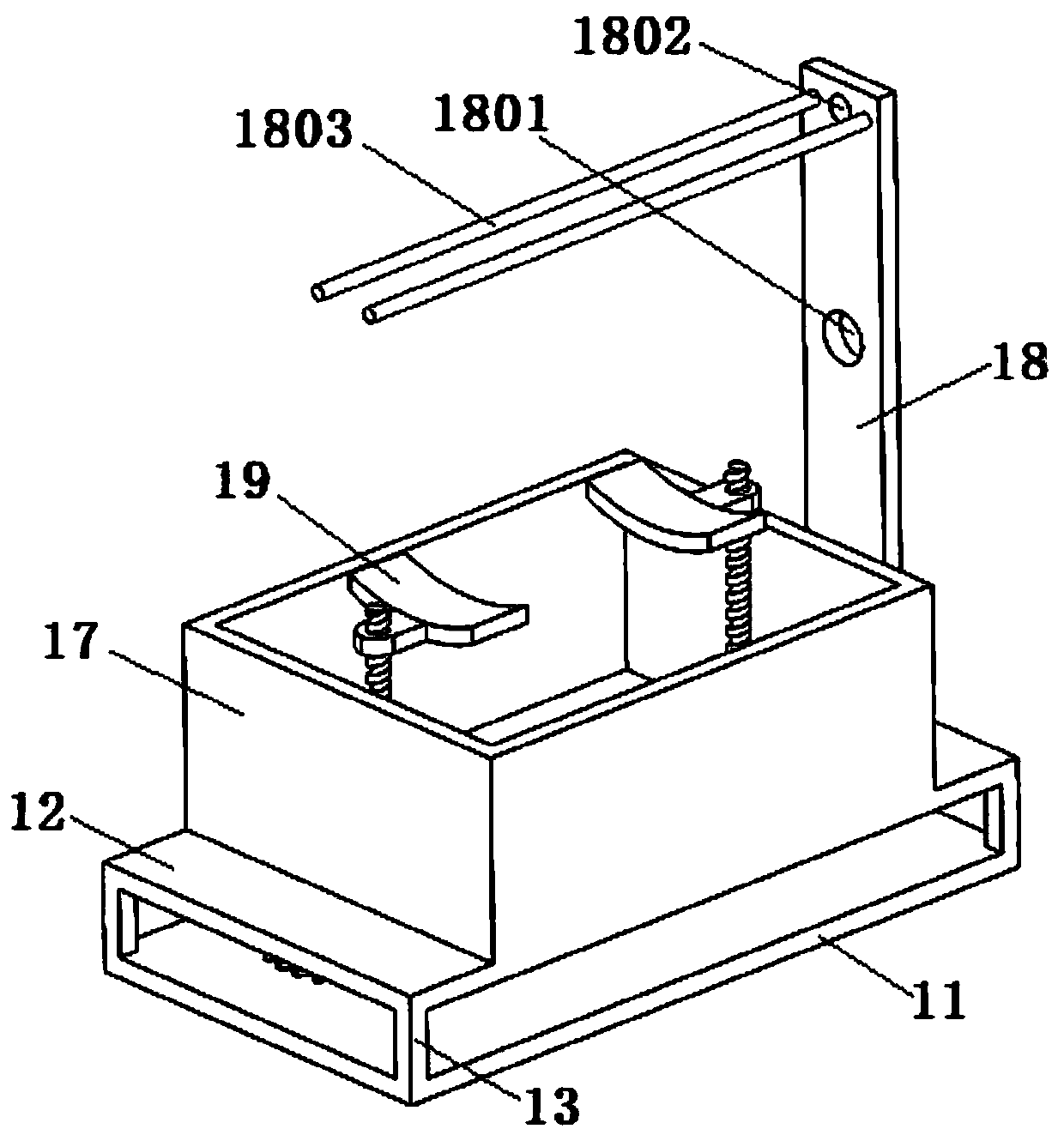

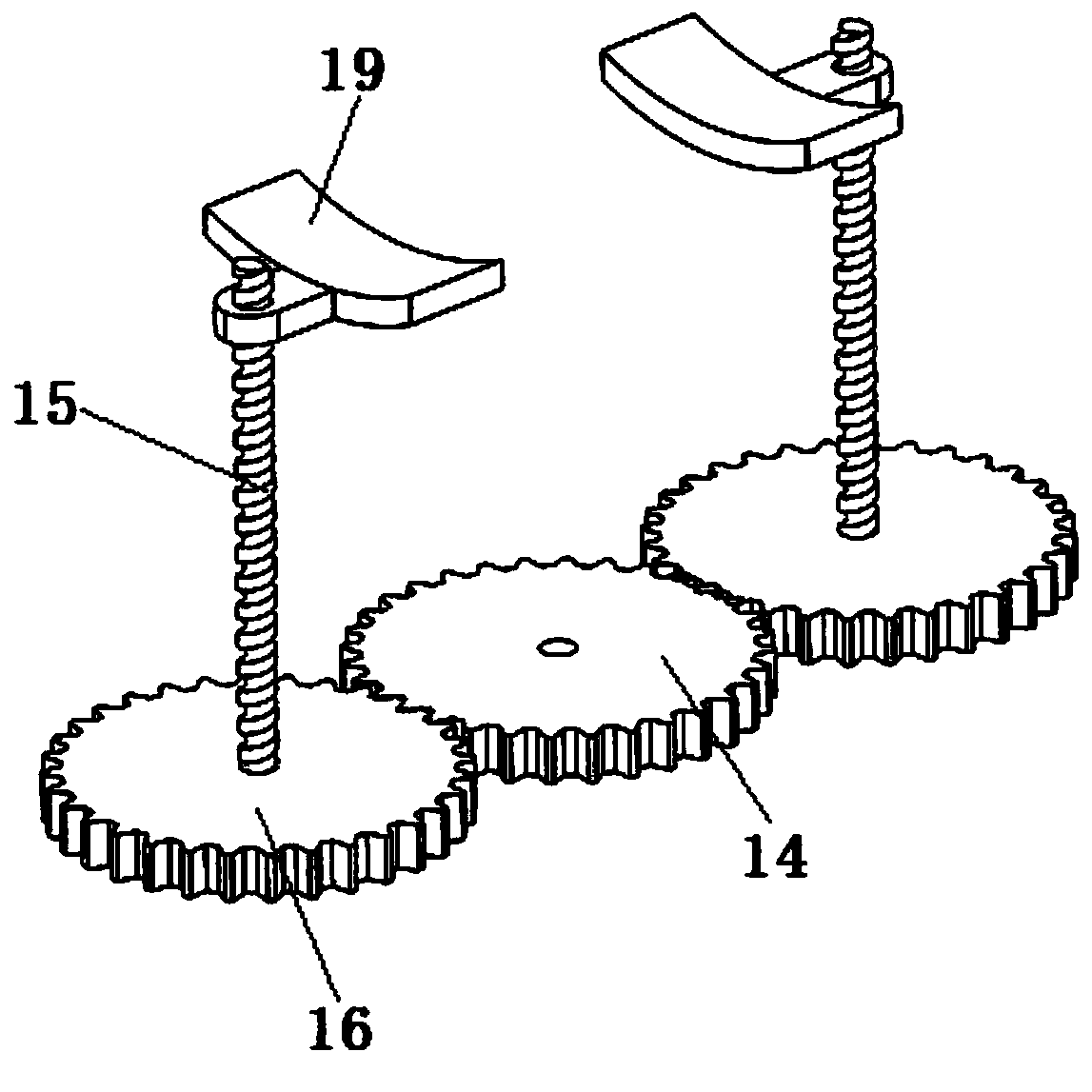

Portable steel bar rust removal device for bridge deck pavement

InactiveCN113681421ARealize the recycling effectReasonable structural designGrinding drivesGrinding machinesElectric machineBridge deck

The invention discloses a portable steel bar rust removal device for bridge deck pavement, and relates to the technical field of steel bar rust removal equipment. Aiming at the problems of an existing portable steel bar rust removal device for bridge deck pavement, the following scheme is provided, the portable steel bar rust removal device comprises a box body, wherein a motor is fixedly installed at the top of the box body, a worm is fixedly connected to an output shaft of the motor, a cleaning brush is fixedly connected to the bottom end of the worm, a driving bevel gear is fixedly connected to the worm, a first transverse shaft is rotationally connected to the inner wall of one side of the box body, a driven bevel gear is fixedly connected to the first transverse shaft, and the driving bevel gear is meshed with the driven bevel gear. The portable steel bar rust removal device is reasonable in structural design, easy to operate and convenient to move, the device can be easily moved according to specific use scenes, water resources are saved and can be recycled, the production cost is low, rust removal can be carried out on a plurality of steel bars at the same time, the rust removal effect is good, and the working efficiency is high.

Owner:江苏融道复合材料产业技术研究院有限公司

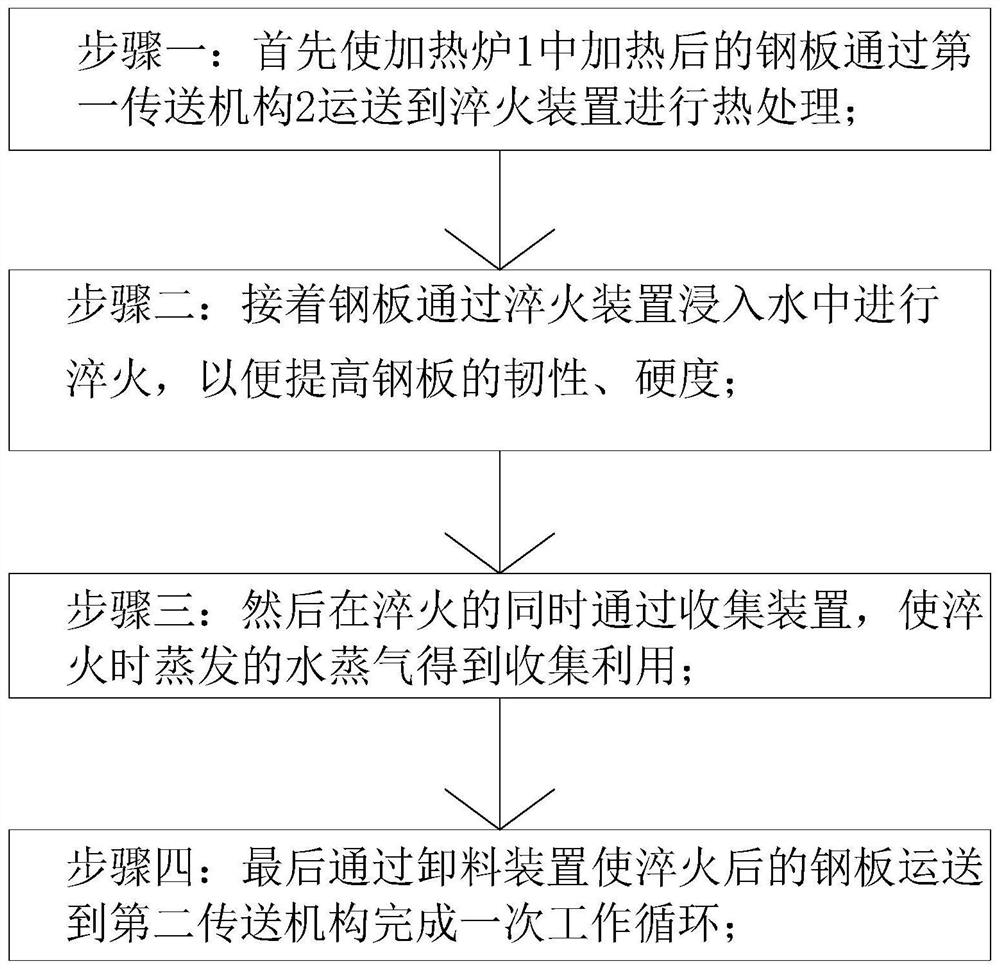

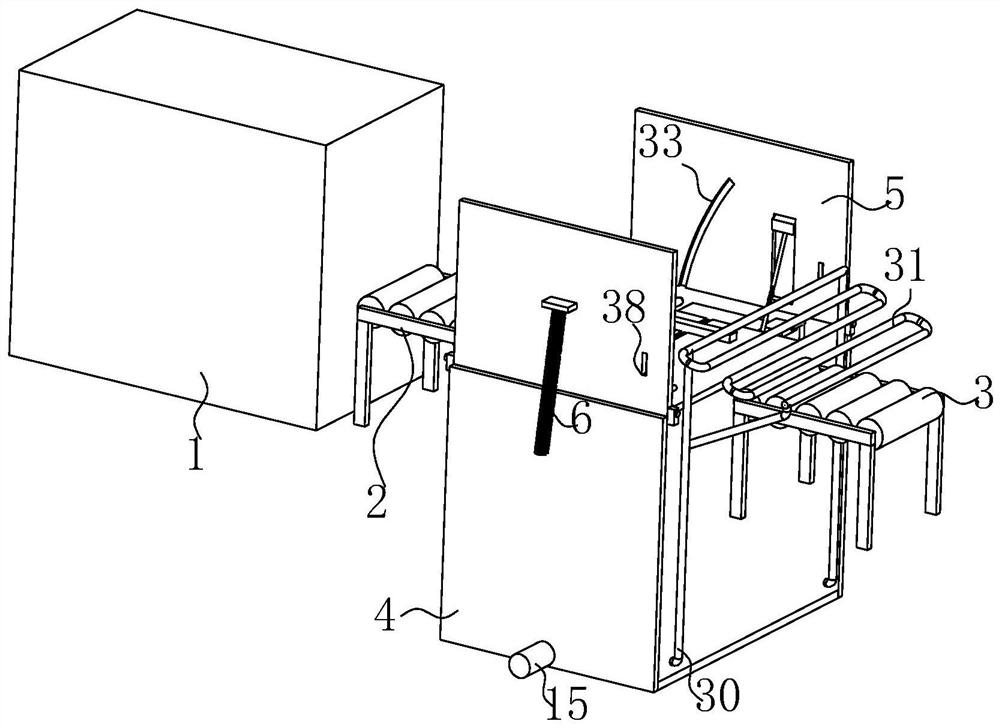

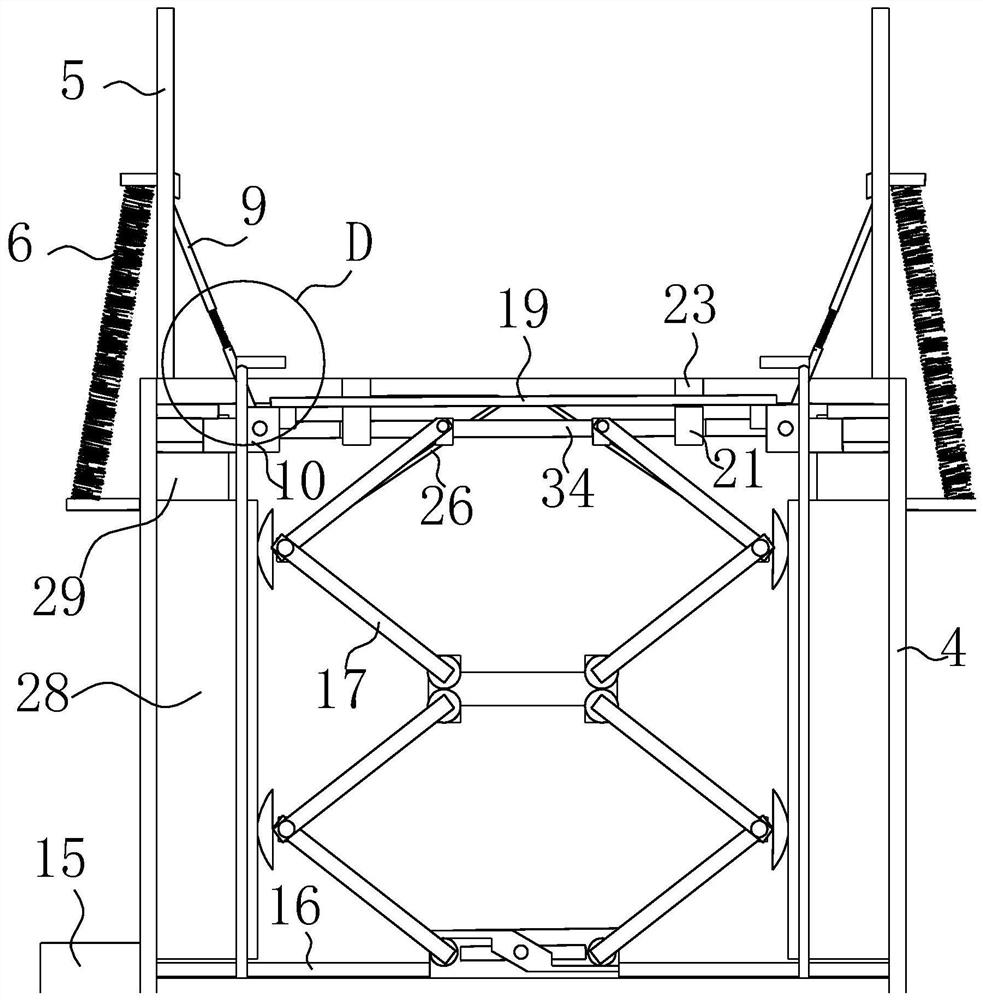

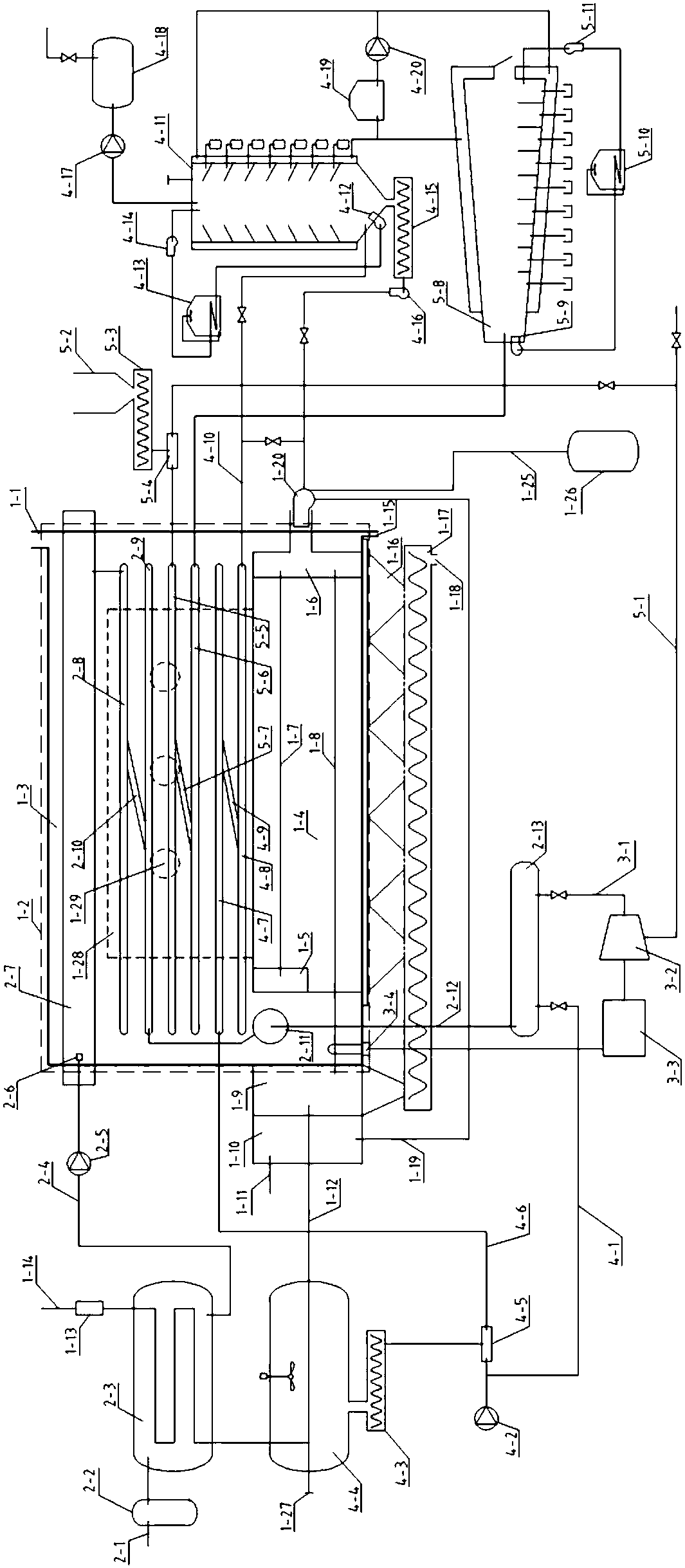

High-performance engineering steel plate welding heat treatment process

ActiveCN112695160AReduce churnIncrease corrosion rateFurnace typesProcess efficiency improvementPhysicsSteel plates

The invention discloses the technical field of heat treatment, and particularly relates to a high-performance engineering steel plate welding heat treatment process. A quenching device is included, the quenching device comprises a quenching box, and the quenching box is located between a first conveying mechanism and a second conveying mechanism. Sealing devices used for sealing the quenching box are symmetrically arranged on the upper end face of the quenching box, a lifting device used for quenching a steel plate is arranged in the center in the quenching box, a clamping device used for stabilizing the steel plate is arranged on the lifting device, and collecting devices used for collecting water vapor are arranged on the two sides of the lifting device. An unloading device for unloading the quenched steel plate is arranged on the left side of the upper end of the lifting device. By means of the device, water vapor can be fully collected when the steel plate is subjected to heat treatment, and rapid loss of heat of the quenched steel plate can be reduced. Meanwhile, the water vapor can flow into the quenching box when reacting into water, and therefore water resources can be recycled, and acceleration of the rusting speed of other steel materials in a plant due to the water vapor is avoided.

Owner:湖北纽睿德防务科技有限公司

Supercritical cogeneration device

InactiveCN108506050AIncrease the heat exchange areaHigh thermal efficiencyCombustion technology mitigationSteam superheatersCooling towerCombustion chamber

The invention discloses a supercritical cogeneration device. The supercritical cogeneration device mainly comprises a fused salt tank, a combustion chamber, a smoke tank, an air preheating box, an ashconveyer, a burner, a waste heat recovery water tank, a high-pressure plunger pump, a high-pressure spraying device, a steam generator, a steam coil pipe, a steam collection box, a steam manifold, asteam turbine, an electric generator, an electric heater, a steam collision device, a water gas coil pipe, a matter thermal decomposition coil pipe, a cyclone separating column, a condensation reduction bed, a conveyer, a fan, a cooling tower and the like. The supercritical cogeneration device has the advantages that overheat steam is generated instantly, and the heat efficiency is very high; thetemperature and pressure of steam are adjustable; waste heat recovery is carried out in a multistage manner, and the exhaust gas temperature is low; no scale is formed, no sewage is drained out, and no exhaust gas is emitted; according to the matter thermal decomposition function, high efficiency and energy saving are achieved, and decomposition is complete; water gas is generated at the top speedcontinuously; and one machine is used in multiple ways, and cogeneration and industrial technology integration are achieved.

Owner:广西汽能壹号节能技术有限公司

Preparation process of enhanced plastic pipeline material

The invention discloses a preparation process of an enhanced plastic pipeline material. The preparation process comprises the following steps that S1, materials are prepared; S2, material mixing is conducted, S3, melting is conducted, specifically, a blended material is molten by using a plastic extruder, and the molten material is output outwards; S4, extruding is conducted, specifically, the molten material is extruded and formed, and a formed pipe blank is output; S5, setting is conducted, specifically, the diameter of the extruded pipe blank is fixed; and S6, cooling is conducted, specifically, the formed product is cooled through a pipe forming cooling spraying device. According to the preparation process, polyvinyl chloride is adopted as a pipe base material, the base material is subjected to toughening and enhancing treatment through reinforcing filler, so that the obtained pipe has excellent mechanical property and corrosion resistance, meanwhile, the specially-made pipe forming cooling spraying device is adopted for cooling the formed pipe, so that the pipe can be uniformly cooled, the quality of a plastic pipeline is guaranteed, the recycling purpose of a water resourcecan be further achieved, and the process is simple and feasible, and has a wide application range.

Owner:安徽超星新材料科技有限公司

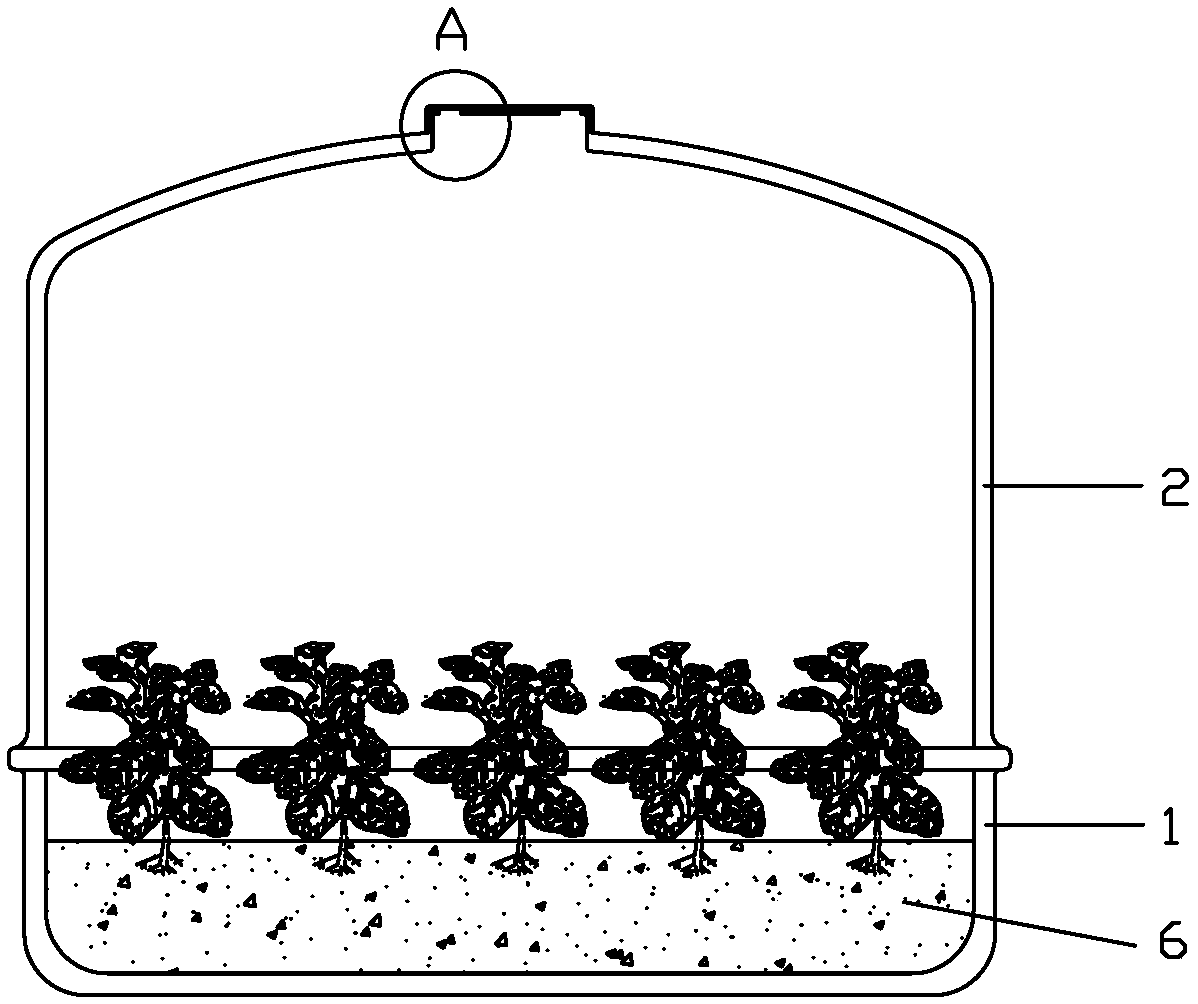

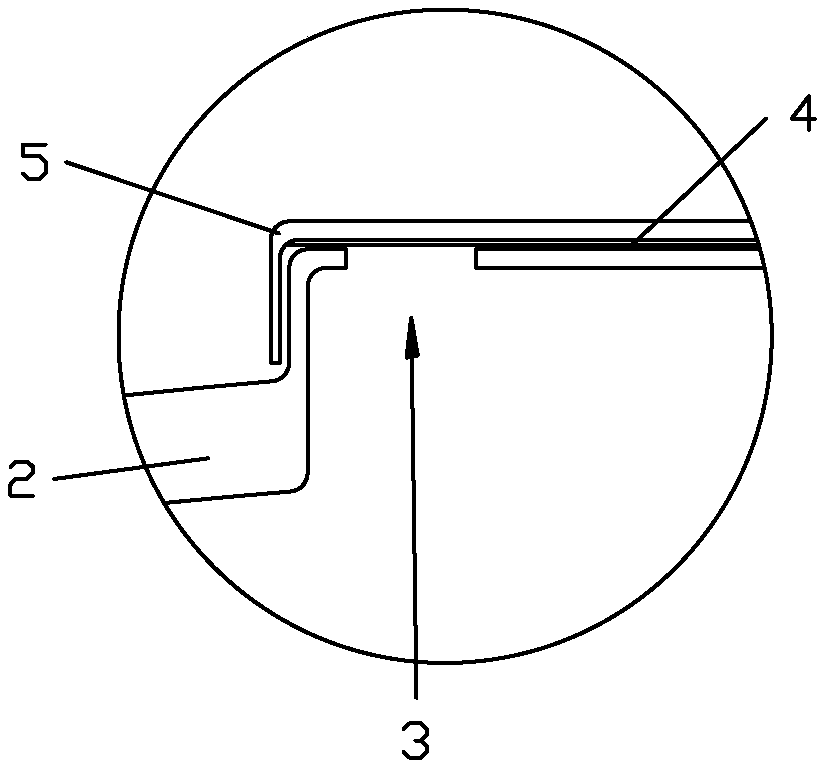

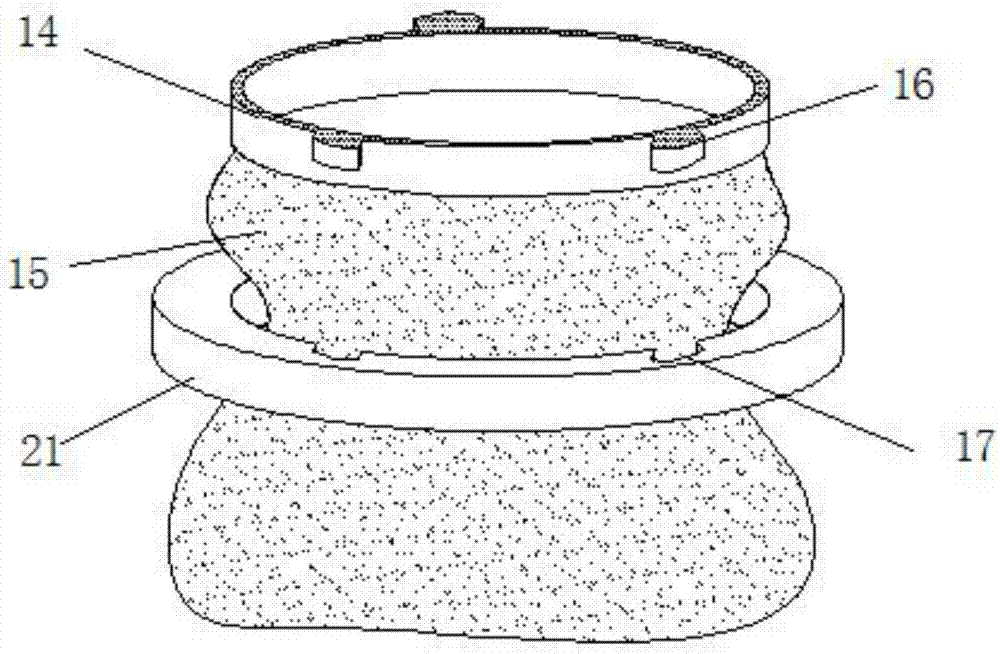

Anoectochilus roxburghii closed type cultivation container and substrate cultivation method thereof

ActiveCN108142268AReduce the chance of plant contaminationReduce light source wasteAgriculture gas emission reductionCultivating equipmentsFertilizerAnoectochilus roxburghii

The invention discloses an anoectochilus roxburghii closed type cultivation container and a substrate cultivation method thereof. Anoectochilus roxburghii plants can grow in a closed mode in the cultivation container for 5-6 months, in the whole growth process, watering, fertilizer applying and other management measures are not needed, and only the growth and health condition of the plants need tobe inspected and observed. The anoectochilus roxburghii closed type cultivation container and the substrate cultivation method thereof have the advantages that not only the chance of plant infectioncan be reduced and the spread range of germs can be controlled, but also the time, the labor and the cost are saved, and the cultivation container is conductive to large-scale promotion.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

Aluminum profile surface treatment method

PendingCN113680627AImprove work efficiencyImprove polishing effectSpraying apparatusPretreated surfacesSpray driedDust control

The invention discloses an aluminum profile surface treatment method. A material conveying mechanism, a polishing mechanism, a cleaning mechanism and a spraying mechanism are included, the polishing mechanism is located at the left side of the material conveying mechanism, the cleaning mechanism is located at the front side of the material conveying mechanism, and the spraying mechanism is located at the right side of the material conveying mechanism. The method is scientific and reasonable in structure and safe and convenient to use, by arranging the material conveying mechanism, the polishing mechanism, the cleaning mechanism, the spraying mechanism and other parts, the material conveying mechanism drives an aluminum profile to rotate, so that the aluminum profile sequentially passes through the polishing mechanism, the cleaning mechanism and the spraying mechanism, and the polishing mechanism, the cleaning mechanism and the spraying mechanism can sequentially conduct polishing dust removal, cleaning drying and spraying drying treatment on the aluminum profile; and the aluminum profile does not need to be mounted, dismounted and carried repeatedly, the operation is very simple and convenient, and the working efficiency is greatly improved.

Owner:陈毅珊

Printing and dyeing dust collector

PendingCN107419465AImprove dust removal effectEasy to collectTextile treatment machine arrangementsTextile treatment cleaning apparatusEngineeringMechanical engineering

The invention discloses a printing and dyeing dust collector which comprises a collector body. A net plate is mounted on the upper portion of an inner cavity of the collector body, placement holes are formed in the net plate, fixing grooves are arranged in the placement holes, a fixing ring is placed in each placement hole, fixing blocks corresponding to the fixing grooves are arranged in the side face of the fixing ring, and a net bag is fixedly arranged on the lower end face of each fixing ring; a filter plate is arranged in the middle of the inner cavity of the collector body, filter holes are formed in the lower end of the filter plate, a filter tank is arranged in the lower portion of the filter plate, a filter unit is arranged in the filter tank, the filter unit includes a bamboo charcoal filter net, a sand and gravel layer, filter beads and a filter gauze layer, the sand and gravel layer is attached to the lower end face of the bamboo charcoal filter, the filter beads are arranged on the lower surface of the sand and gravel layer, and the filter gauze layer is arranged on lower ends of the filter beads. The printing and dyeing dust collector is good in filter effect, low in cost, environment friendly and high in operation efficiency.

Owner:张家港市双盈印染有限公司

Water tank of concrete pump truck and concrete pump truck applying same

ActiveCN103410327APrevent overflowImprove work efficiencyBuilding material handlingWater flowConcrete pump

The invention discloses a water tank of a concrete pump truck. The water tank of the concrete pump truck comprises a tank body casing and a liquid limiting pipe, wherein a water supply port is arranged at the top of the tank body casing, the water inlet end of the liquid limiting pipe is higher than the water outlet end of the liquid limiting pipe, the water inlet end is located inside the tank body casing, the water outlet end is located outside the tank body casing, the liquid limiting pipe is in sealing connection with the tank body casing, and the inner cavity of the tank body casing is communicated with the outside through the liquid limiting pipe. The liquid limiting pipe is installed on the tank body casing, the situation that water overflows from the water supply port is effectively avoided, an operator can perform other work when the water is filled into the inner cavity of the tank body casing, and the work efficiency is improved. when the water flows out of the liquid limiting pipe, overflowed water is timely recovered, and then the operator stops filling the water into the inner cavity of the tank body casing. By means of the water tank, the situation that the overflowed water from the water supply port cannot be recovered while the work efficiency of the operator is improved. The invention further discloses the concrete pump truck including the water tank.

Owner:HUALING XINGMA AUTOMOBILE GRP

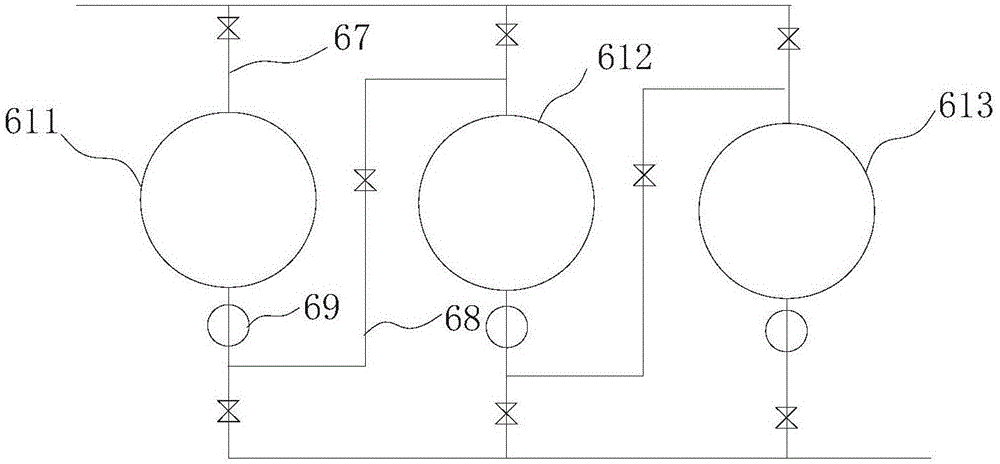

A device for removing residual pesticides and hormones in aquaculture

ActiveCN109077010BEffective filteringEfficient decompositionPisciculture and aquariaWater resourcesZoology

Owner:苏州千层茧农业科技有限公司

Treatment device and process for high nitrate wastewater

ActiveCN109626684BProcess environmental protectionNo secondary pollutionGas treatmentWater contaminantsNitrate saltsEngineering

The invention relates to a waste water treatment process, in particular to a high nitrate waste water treatment device and a process thereof. In the device, the raw water input pipeline is sequentially connected to the nitric acid steam heat exchanger, tail gas heat exchanger, condensed water heat exchanger, and MVR evaporator; the MVR exhaust port of the MVR evaporator is connected to the tail gas absorbent tank, and the tail gas absorbent tank It is connected to the tail gas absorption tower, and the exhaust port on the top of the tail gas absorption tower is connected to the heat source inlet of the tail gas heat exchanger; the concentrated liquid outlet of the MVR evaporator is connected to the inlet of the nitric acid recovery device, and the concentrated liquid outlet of the nitric acid recovery device is connected to the crystallizer. The outlet of nitric acid steam on the top of the nitric acid recovery unit is connected to the heat source inlet of the nitric acid steam heat exchanger, and the heat source outlet of the nitric acid steam heat exchanger is connected to the concentrated nitric acid tank; the condensed water outlet of the MVR evaporator is connected to the heat source inlet of the condensed water heat exchanger . After the raw water is treated by the device and process of the invention, the effluent can be recycled, and the crystallization and tail gas can be harmlessly treated.

Owner:CHINA PETROLEUM & CHEM CORP

Residual material treating device of concrete pumping system used for super high-rise buildings

The invention discloses a residual material treating device of a concrete pumping system used for super high-rise buildings. The residual material treating device comprises a main device body. A clearwater tank is arranged on one side of the bottom of the main device body; a second water pump is installed on one side of the top of the clear water tank; the water inlet end of the second water pumpis provided with a third water pipe that penetrates to the inner bottom end of the clear water tank; one side, away from the third water pipe, of the second water pump is provided with a fourth waterpipe; the four corners of the top of the clear water tank are provided with support rods; and the tops of the support rods are provided with a storage box. According to the device in the invention, the separation effect of gravel is made better in virtue of a gravel separation mechanism, so the blockage of a water channel is prevented, and the use effect of the residual material treating device of the concrete pumping system is better; and water in a sedimentation box is introduced into the clear water tank through a first water pipe and a second water pipe in virtue of a first water pump, and then the water in the clear water tank is led out through the third water pipe and the fourth water pipe via the second water pump, so water resources are recycled and saved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com