Preparation process of enhanced plastic pipeline material

A technology of plastic pipe and preparation process, which is applied in the field of plastic pipe materials, can solve the problems that the overall toughness and impact resistance of pipes cannot be effectively improved, and achieve the effect of promoting toughening ability, promoting improvement, and increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

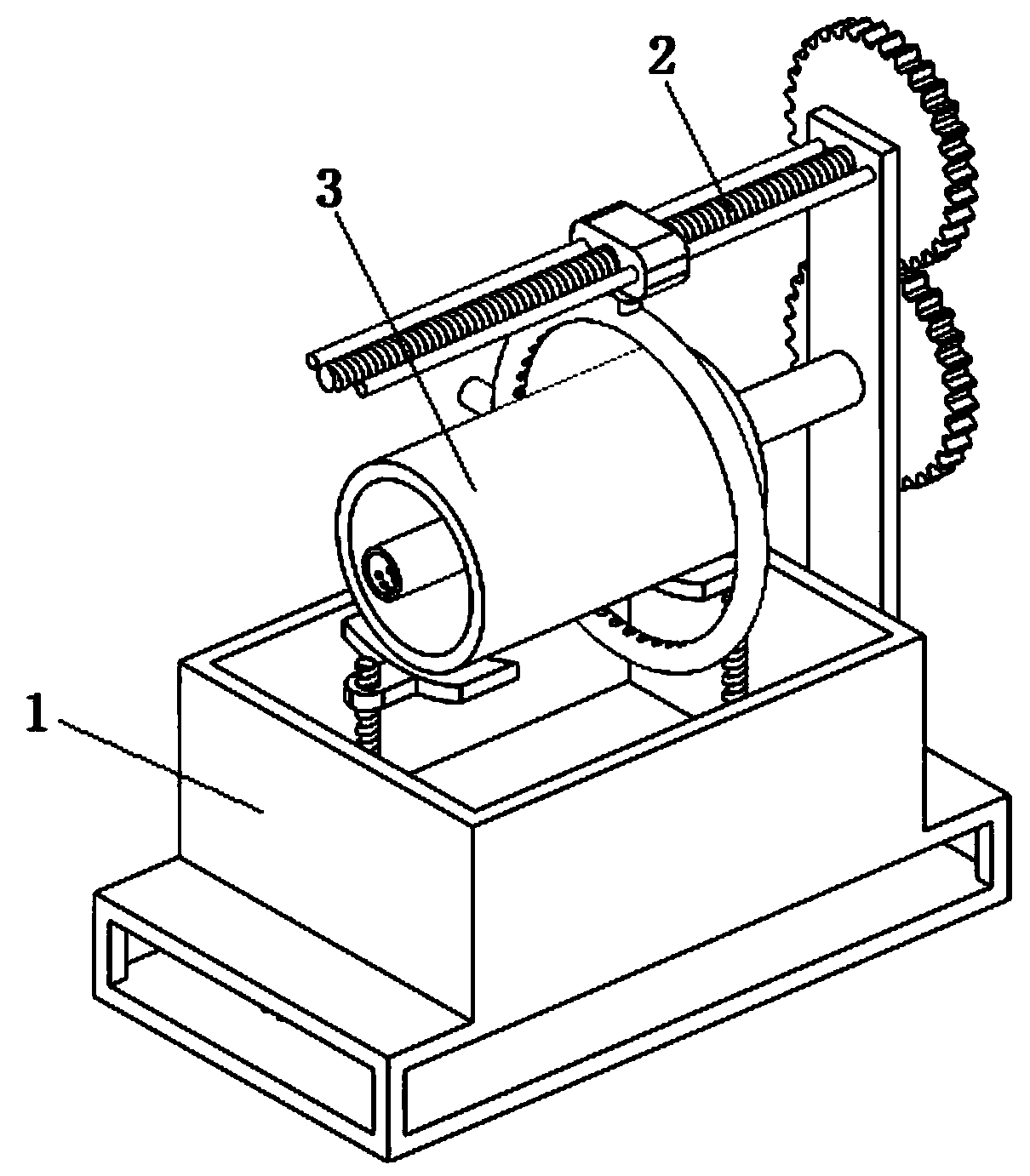

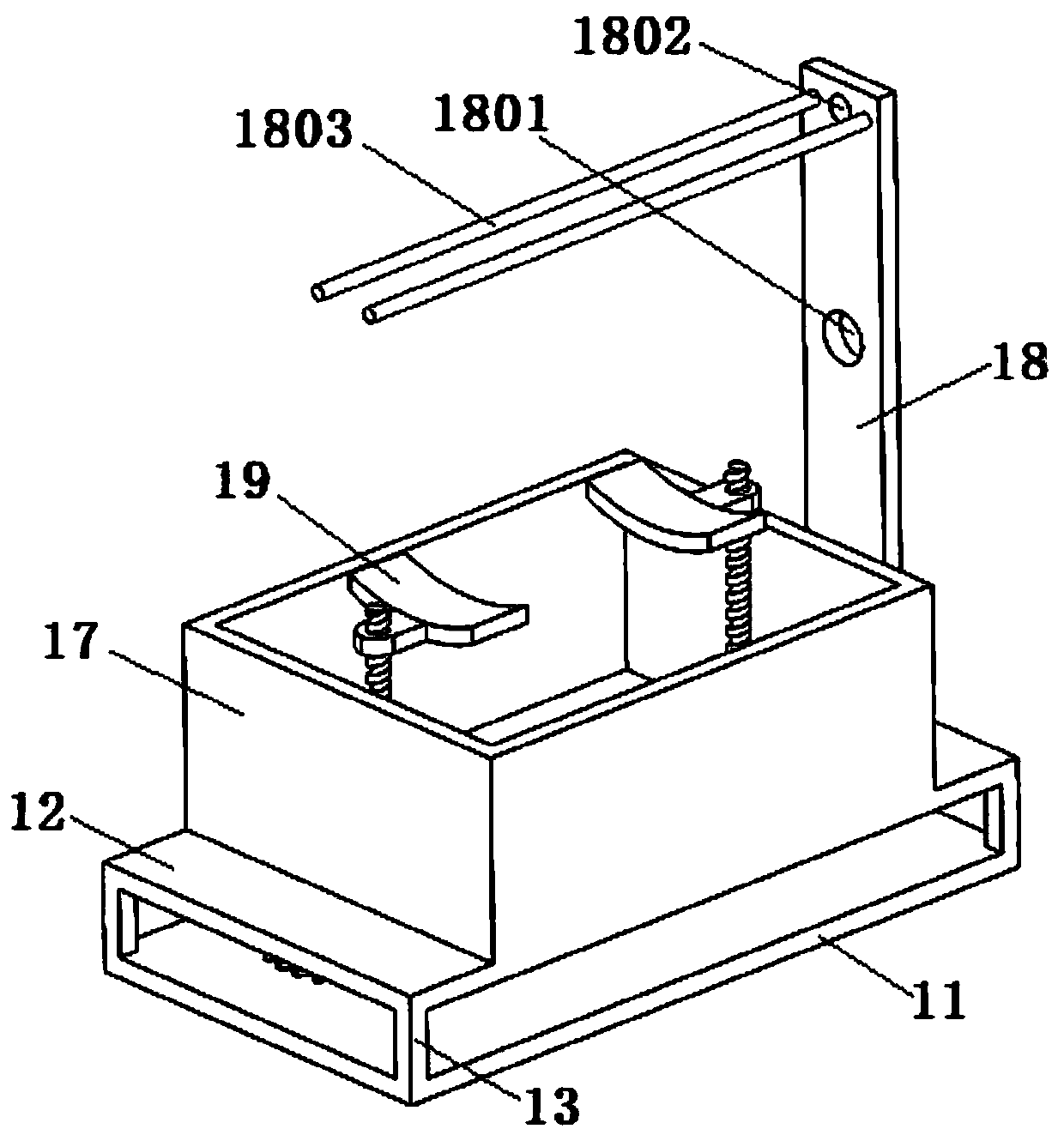

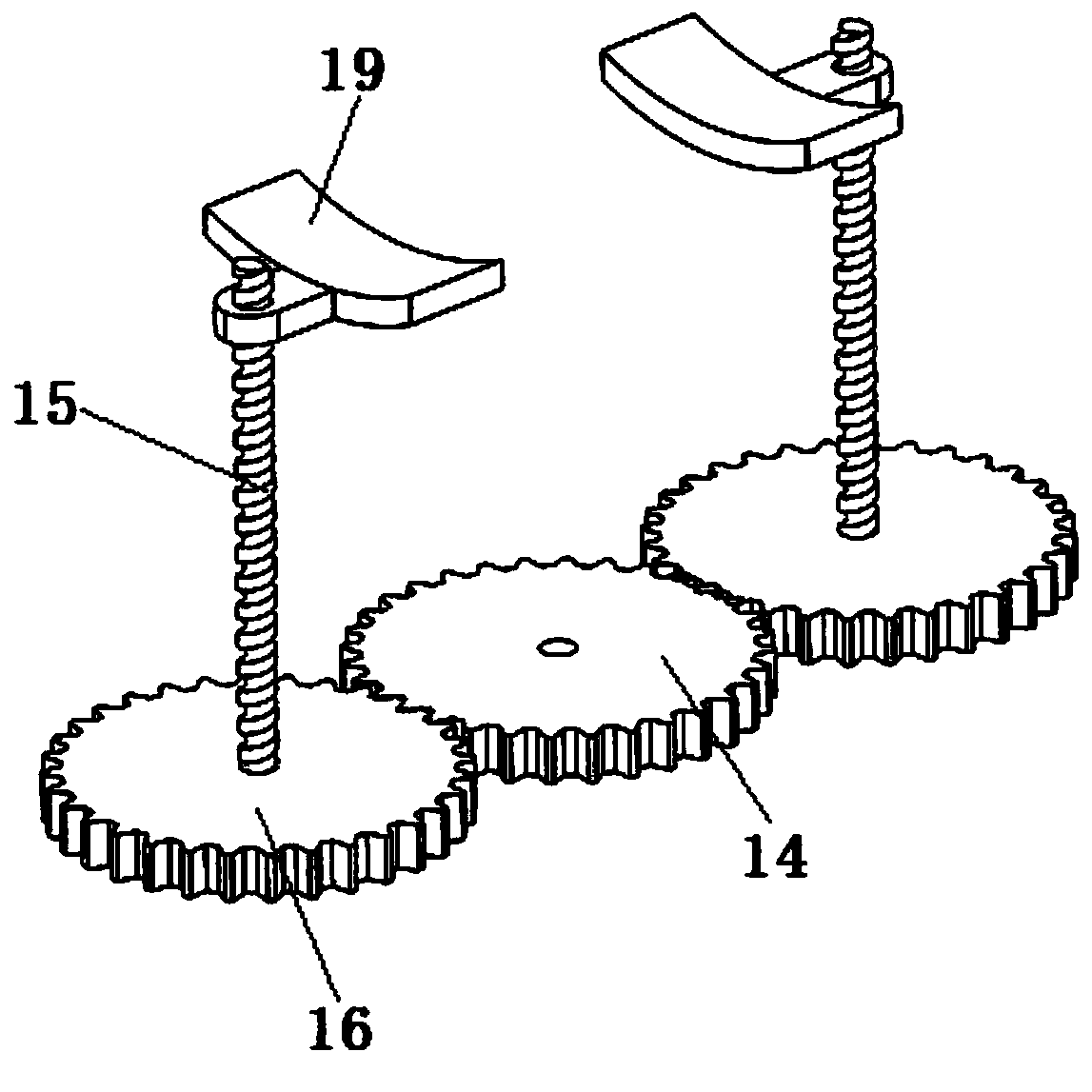

Image

Examples

preparation example Construction

[0039] A preparation process for reinforced plastic pipe material, comprising the steps of:

[0040] Step S1, material preparation: according to the following parts by weight: 90-100 parts of polyvinyl chloride resin, 4-5 parts of chlorinated polyvinyl chloride, 3-4 parts of reinforcing filler, 2-3 parts of stabilizer, 0.3-0.5 parts of stearic acid , 0.4-0.5 parts of liquid paraffin to prepare the raw materials;

[0041] The stabilizer is an organotin stabilizer or a calcium-zinc composite stabilizer;

[0042] The reinforcing filler is prepared by the following method:

[0043] (1) Dry the nano-calcium carbonate in a vacuum oven at 100°C and -0.05MPa for 30 minutes, seal it for use;

[0044] (2) Prepare an acetone solution with a mass fraction of 60%, adjust the pH value to 4.9-5.2 with acetic anhydride, add silane coupling agent KH-590 at room temperature and stir at a constant speed and dissolve it; silane coupling agent KH-590 The addition amount is 5% of acetone solutio...

Embodiment 1

[0063] A preparation process for reinforced plastic pipe material, comprising the steps of:

[0064] Step S1, material preparation: according to the following parts by weight: 90 parts of polyvinyl chloride resin, 4 parts of chlorinated polyvinyl chloride, 3 parts of reinforcing filler, 2 parts of stabilizer, 0.3 part of stearic acid, and 0.4 part of liquid paraffin, prepare the raw materials;

[0065] Step S2, mixing: mix the raw materials in a high-speed mixer, first mix at 500r / min, wait until the mixing temperature reaches 110°C, then turn to 200r / min and mix at a low speed until the temperature reaches 45°C, to obtain a blend;

[0066] Step S3, melting: using a plastic extruder to melt the blended material, and outputting the molten material outward;

[0067] Step S4, extruding: extruding the molten material into shape, and outputting the formed tube blank;

[0068] Step S5, setting the shape: sizing the extruded tube blank, and outputting the formed product;

[0069] S...

Embodiment 2

[0071] A preparation process for reinforced plastic pipe material, comprising the steps of:

[0072] Step S1, material preparation: According to the following parts by weight: 95 parts of polyvinyl chloride resin, 4.5 parts of chlorinated polyvinyl chloride, 3.5 parts of reinforcing filler, 2.5 parts of stabilizer, 0.4 part of stearic acid, and 0.45 part of liquid paraffin, prepare the raw materials;

[0073] Step S2, mixing: mix each raw material in a high-speed mixer, firstly mix at 500r / min, wait until the mixing temperature reaches 115°C, then turn to 200r / min and mix at a low speed until the temperature reaches 48°C to obtain a blend;

[0074] Step S3, melting: using a plastic extruder to melt the blended material, and outputting the molten material outward;

[0075] Step S4, extruding: extruding the molten material into shape, and outputting the formed tube blank;

[0076] Step S5, setting the shape: sizing the extruded tube blank, and outputting the formed product;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com