High-nitrate wastewater treatment apparatus and high-nitrate wastewater treatment process

A treatment device, nitrate technology, applied in the direction of return water treatment, water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problem of high total nitrogen concentration in sewage, high salt content in waste water, large amount of carbon source dosage, etc. No secondary pollution, low operating cost, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A rare earth wastewater, water volume 100m 3 / h, the salt content is about 3%, the total nitrogen concentration is 4000mg / L, and the COD is 400mg / L.

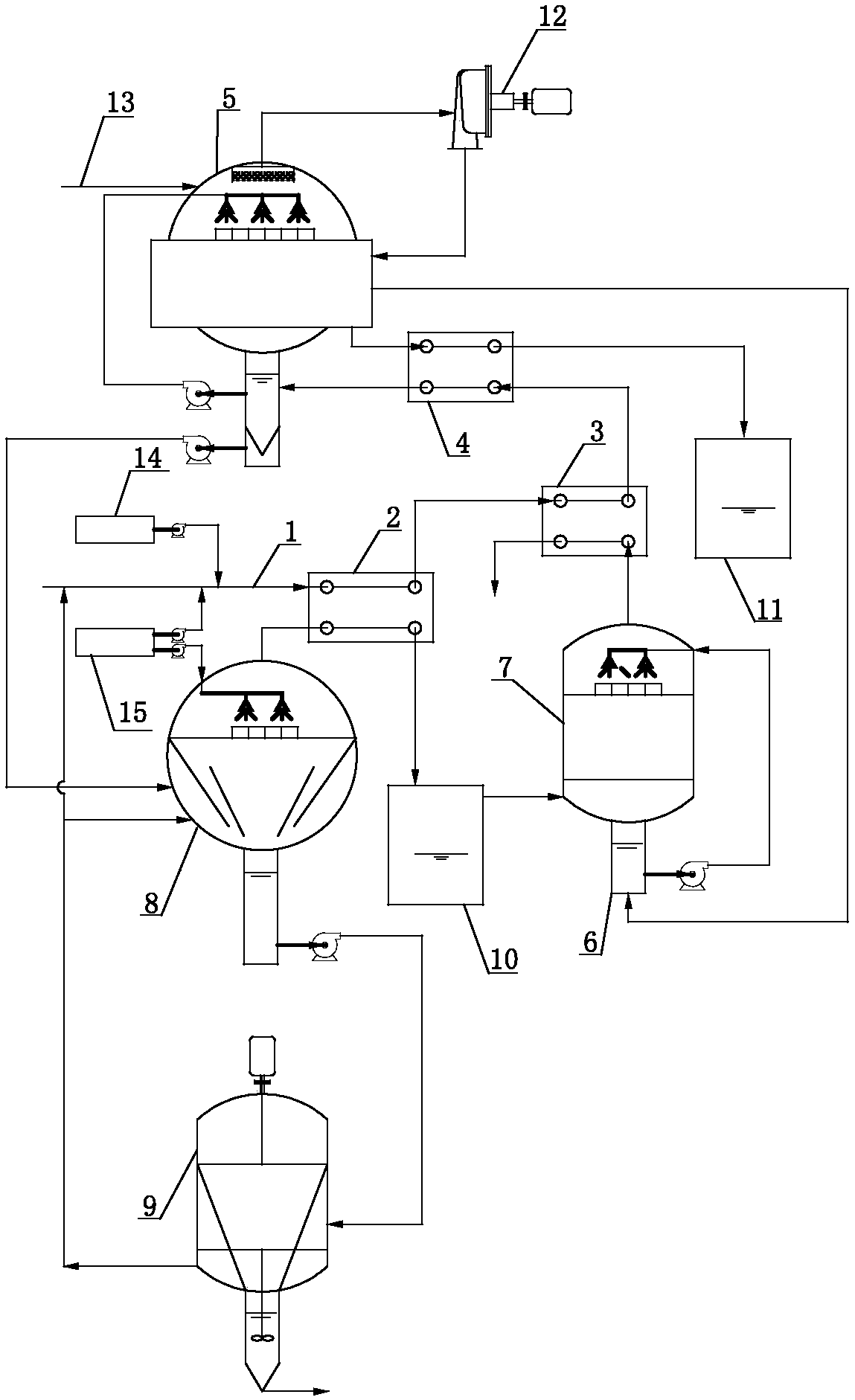

[0047] a. After the pH of the raw water is adjusted to neutral, it is preheated by the nitric acid steam heat exchanger 2, tail gas heat exchanger 3, and condensed water heat exchanger 4, and then enters the MVR evaporator 5 for evaporation and concentration. The condensed water generated during the concentration process enters the condensation The water heat exchanger 4 preheats the raw water and enters the condensed water tank 11 for recovery to obtain condensed water of 90m 3 / h, COD35mg / L; The remaining concentrated solution enters the nitric acid recovery device 8, and in the nitric acid recovery device 8, adding concentrated sulfuric acid with a mass concentration of 98% reacts with the concentrated solution, controls the reaction temperature at 85.5 ± 0.5 ° C, and the reaction time is 15 minutes. In the process, t...

Embodiment 2

[0052] A rare earth wastewater, water volume 50m 3 / h, the salt content is about 6%, the total nitrogen concentration is 12000mg / L, and the COD is 300mg / L.

[0053] a. After the pH of the raw water is adjusted to neutral, it is preheated by the nitric acid steam heat exchanger 2, tail gas heat exchanger 3, and condensed water heat exchanger 4, and then enters the MVR evaporator 5 for evaporation and concentration. The condensed water generated during the concentration process enters the condensation The water heat exchanger 4 preheats the raw water and enters the condensed water tank 11 for recovery to obtain condensed water 44m 3 / h, COD10mg / L; The remaining concentrated solution enters the nitric acid recovery device 8, and in the nitric acid recovery device 8, adding concentrated sulfuric acid with a mass concentration of 90% reacts with the concentrated solution, controls the reaction temperature at 88 ± 1 ° C, and the reaction time is 60 minutes. In the process, the nitr...

Embodiment 3

[0058] A rare earth wastewater, water volume 60m 3 / h, the salt content is about 3%, the total nitrogen concentration is 8000mg / L, and the COD is 300mg / L.

[0059] a. After the pH of the raw water is adjusted to neutral, it is preheated by the nitric acid steam heat exchanger 2, tail gas heat exchanger 3, and condensed water heat exchanger 4, and then enters the MVR evaporator 5 for evaporation and concentration. The condensed water generated during the concentration process enters the condensation The water heat exchanger 4 preheats the raw water and enters the condensed water tank 11 for recovery to obtain condensed water of 54m 3 / h, COD30mg / L; The remaining concentrated solution enters the nitric acid recovery device 8, and in the nitric acid recovery device 8, adding concentrated sulfuric acid with a mass concentration of 93% reacts with the concentrated solution, controls the reaction temperature at 90 ± 1 ° C, and the reaction time is 30 minutes. In the process, the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com