Supercritical steam collision material thermal decomposition condensation reduction device

A thermal decomposition and supercritical technology, applied in steam distillation, evaporation, separation methods, etc., can solve the problems of bulky equipment, high investment cost, complex process, etc., to achieve a wide range of applications, solve pollution problems, and expand heat exchange area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

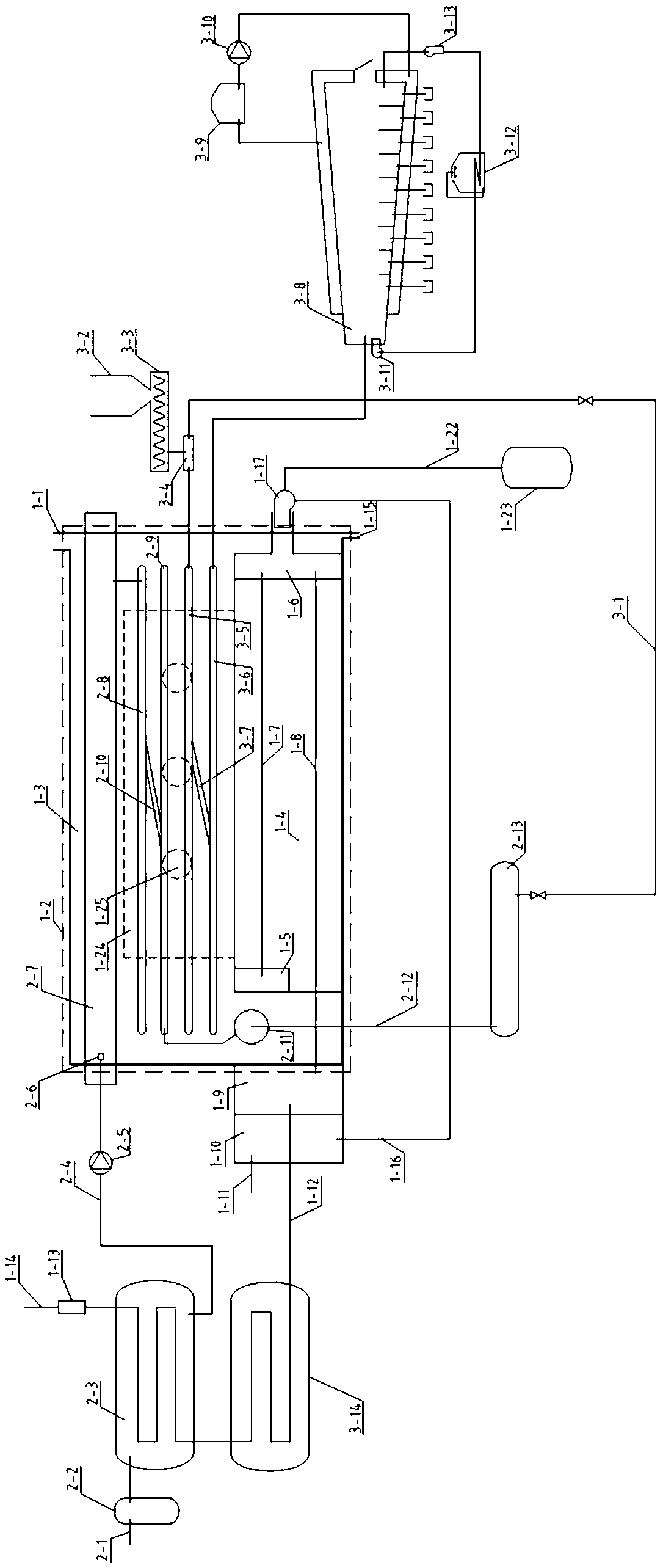

[0067] In the present invention, after the steam generated by the steam generator in the furnace body collides with various substances in the thermal decomposition coil in the furnace body, the moisture in the substance is pyrolyzed to achieve a supercritical effect in an instant and quickly converted into gas, which enters the condensation reduction bed , solid-liquid separation, according to the floating distance and the specific gravity of the different components of the material, the location of the sedimentation is different, and the classification is collected.

[0068] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

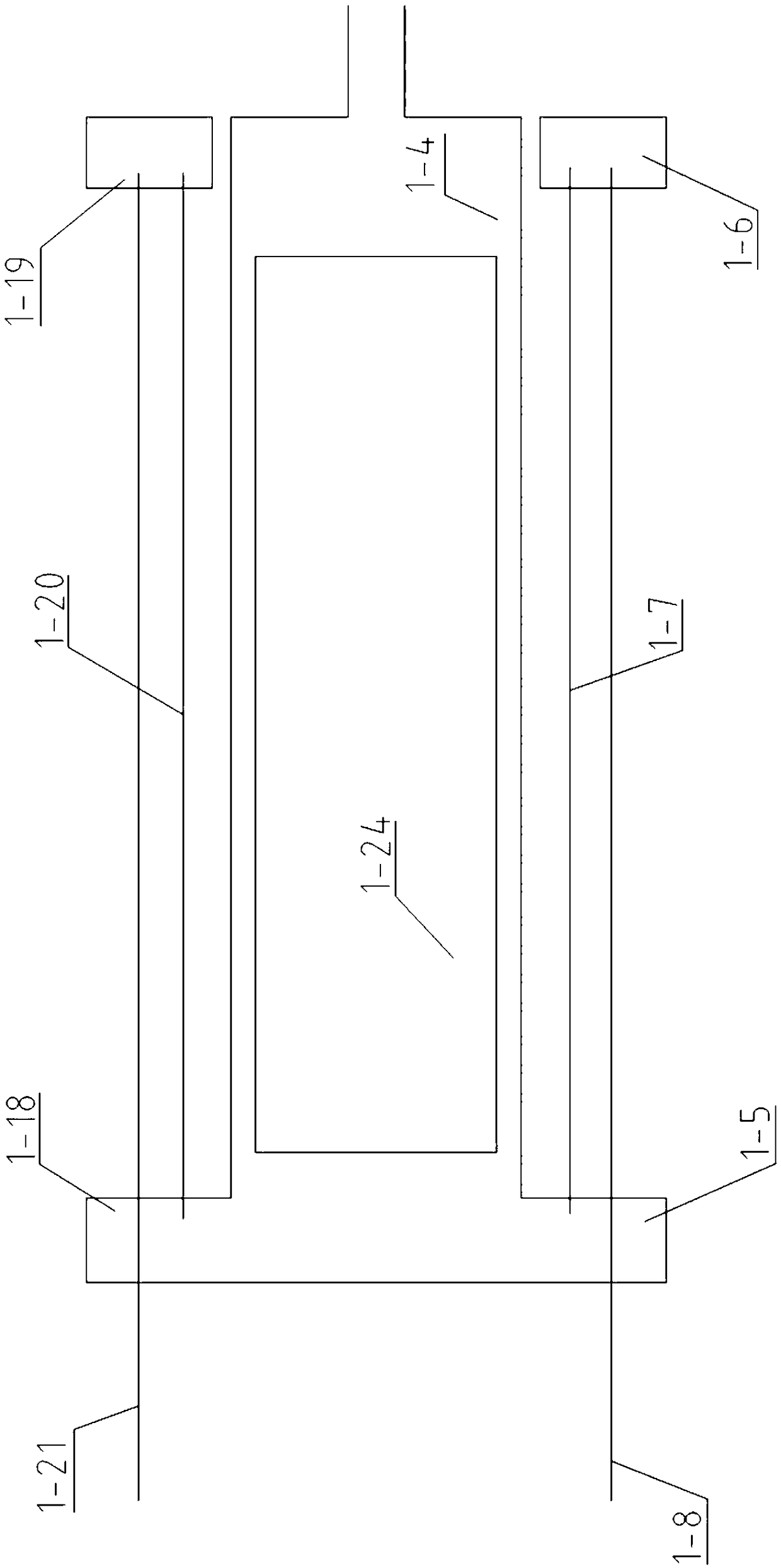

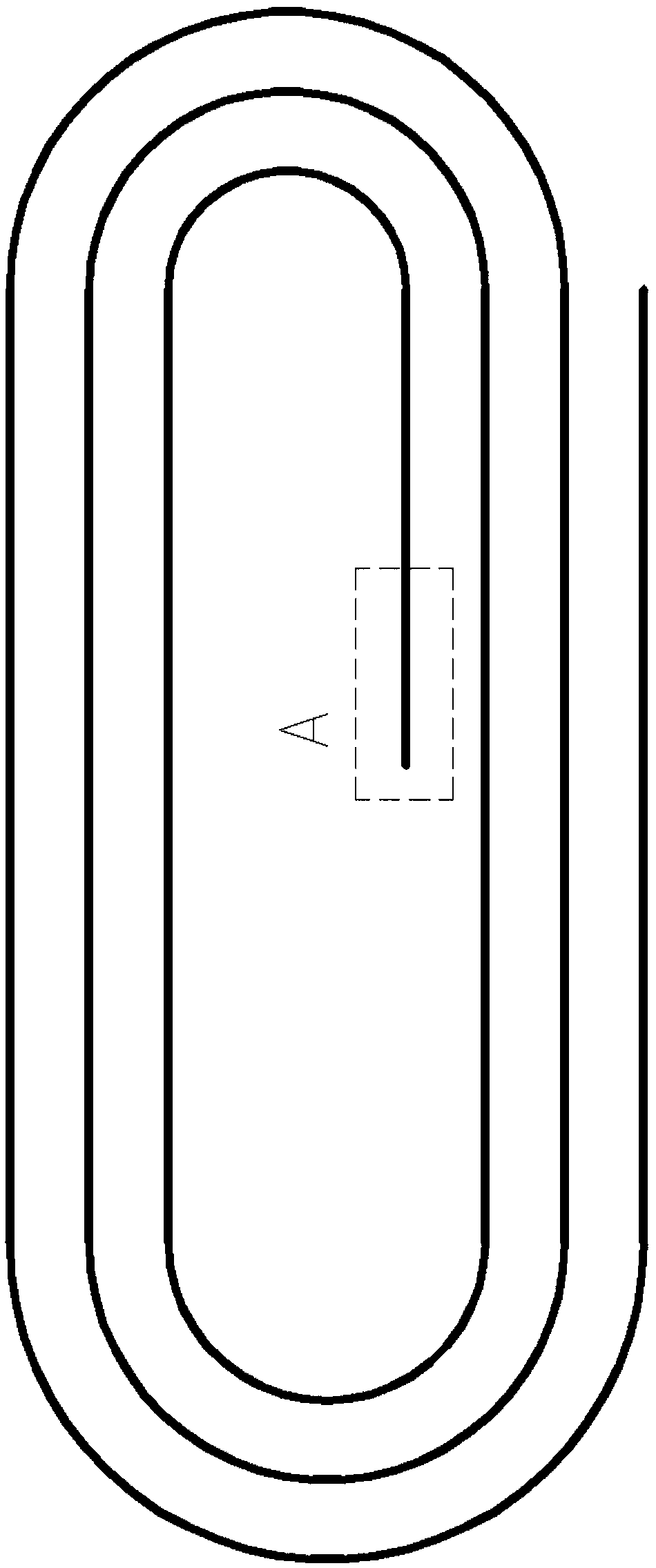

[0069] The structure of the supercritical steam collision material thermal decomposition condensation reduction device of the present invention is as follows figure 1 , figure 2 , image 3 , Figure 4 as shown,

[0070] Supercritical steam colliding material thermal decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com