Cleaning and processing machinery equipment for peanut harvesting

A technology for processing machinery and peanut harvesting, which is applied to excavating harvesters, harvesters, agricultural machinery and implements, etc. It can solve the problems of large water consumption, water waste, and excessive soil, and achieve the goal of recycling water resources and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

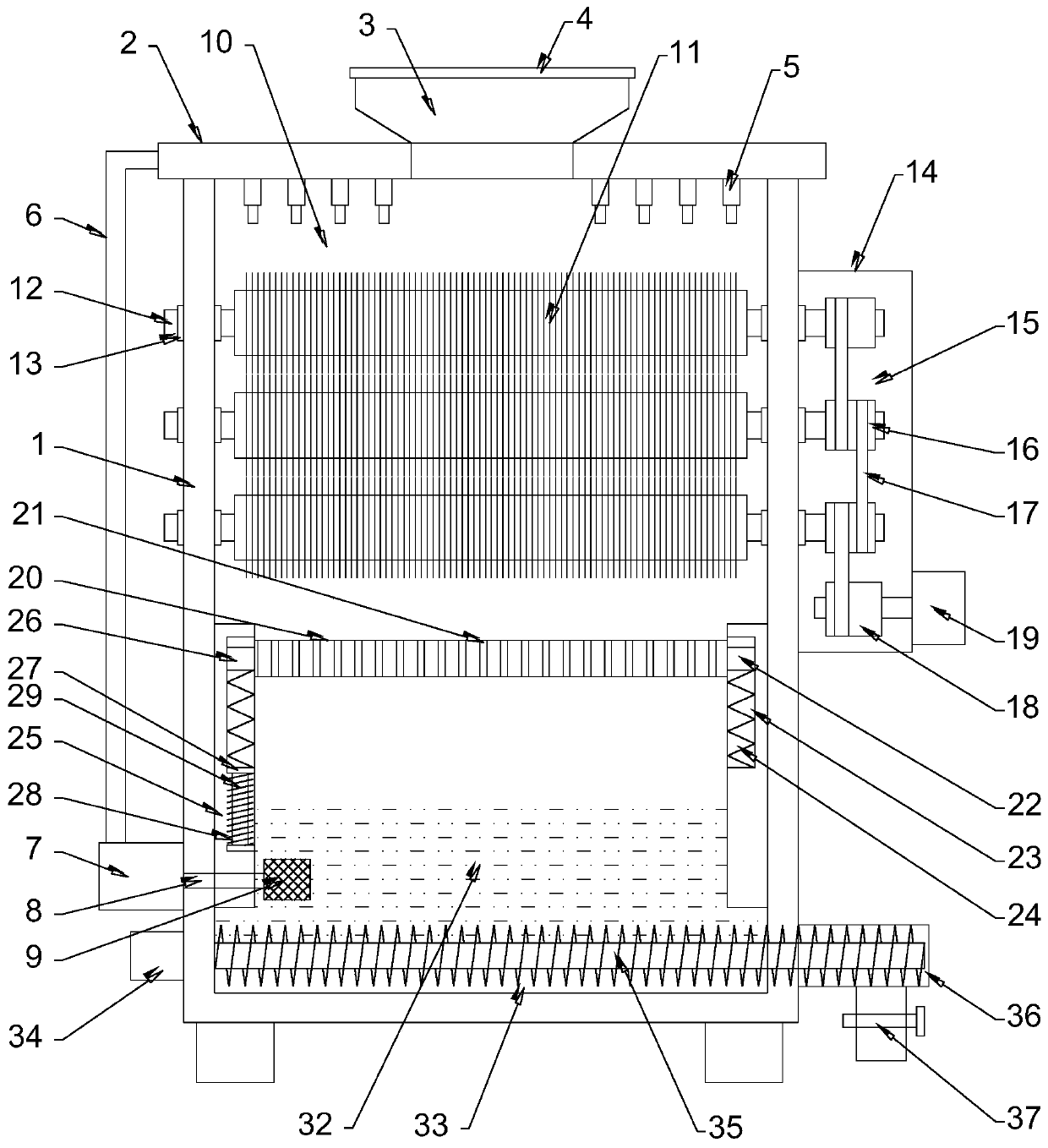

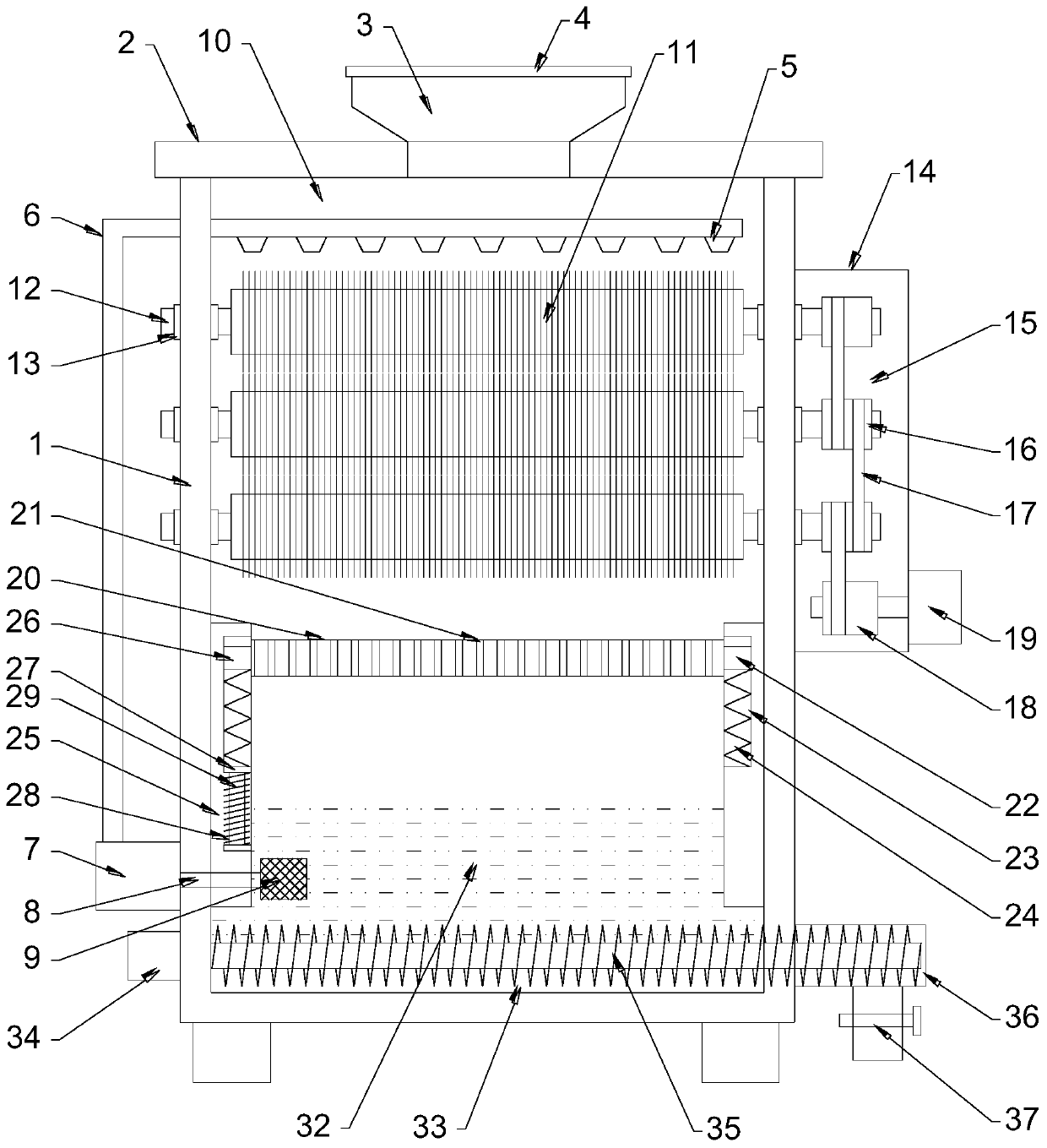

[0027] See Figure 1 ~ Figure 2 , A cleaning and processing mechanical equipment for peanut harvesting, comprising a box body 1, a water spray nozzle 5, a brush roller 11, a sieve plate 20, and a water storage tank 32. A box cover 2 is installed on the top of the box body 1, and the upper end of the box cover 2 A feed hopper 3 is connected in the middle, and the feed hopper 3 communicates with the inside of the box body 1. The top of the feed hopper 3 is hinged with a cover plate 4, and the cover plate 4 is provided with a handle for easy opening to facilitate the opening and closing of the cover plate 4. , The cover 4 has a good waterproof effect;

[0028] A number of water spray nozzles 5 are installed on the inner wall of the box cover 2, and the water spray nozzles 5 face the cleaning cavity 10 inside the box body 1. The water spray nozzles 5 communicate with the water storage cavity inside the box cover 2, and the inside of the box cover 2 stores The water cavity is connecte...

Embodiment 2

[0036] See Figure 2 ~ Figure 3 , A cleaning and processing mechanical equipment for peanut harvesting, comprising a box body 1, a water spray nozzle 5, a brush roller 11, a sieve plate 20, and a water storage tank 32. A box cover 2 is installed on the top of the box body 1, and the upper end of the box cover 2 A feed hopper 3 is connected in the middle, and the feed hopper 3 communicates with the inside of the box body 1. The top of the feed hopper 3 is hinged with a cover plate 4, and the cover plate 4 is provided with a handle for easy opening to facilitate the opening and closing of the cover plate 4. , The cover 4 has a good waterproof effect;

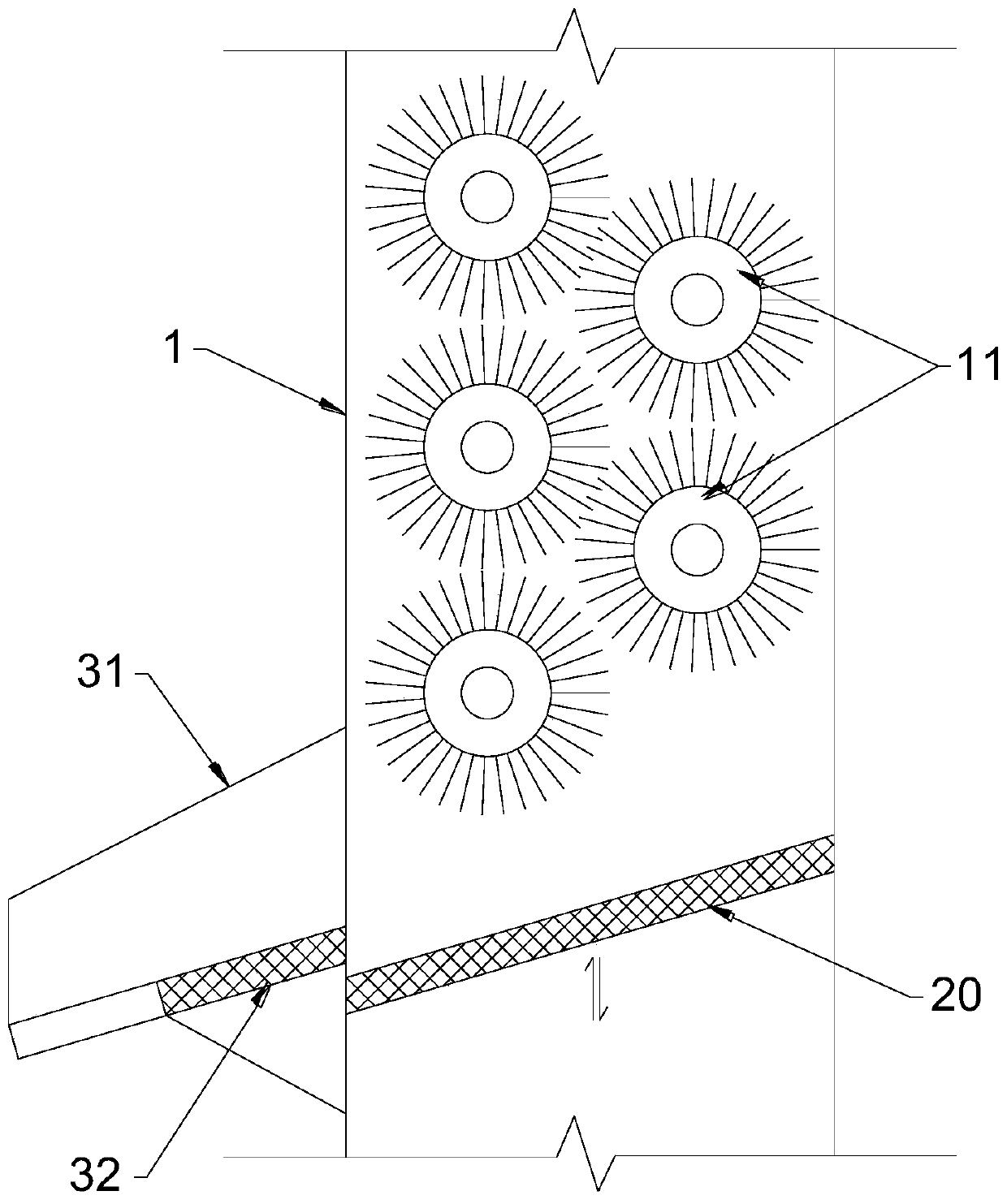

[0037] A number of brush rollers 11 are arranged in the cleaning cavity 10 of the box body 1. The brush rollers 11 are installed on the cleaning shaft 12, and the two ends of the cleaning shaft 12 are erected on the box body 1, between the cleaning shaft 12 and the box body 1. A sealing ring 13 is provided to prevent water overflow....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com