Circuit-board waste-water reutilizing process of reducing waste

A circuit board and waste water technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of waste reduction and reuse of waste water without circuit boards, and achieve High recovery rate, low operating cost, and the effect of recycling water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

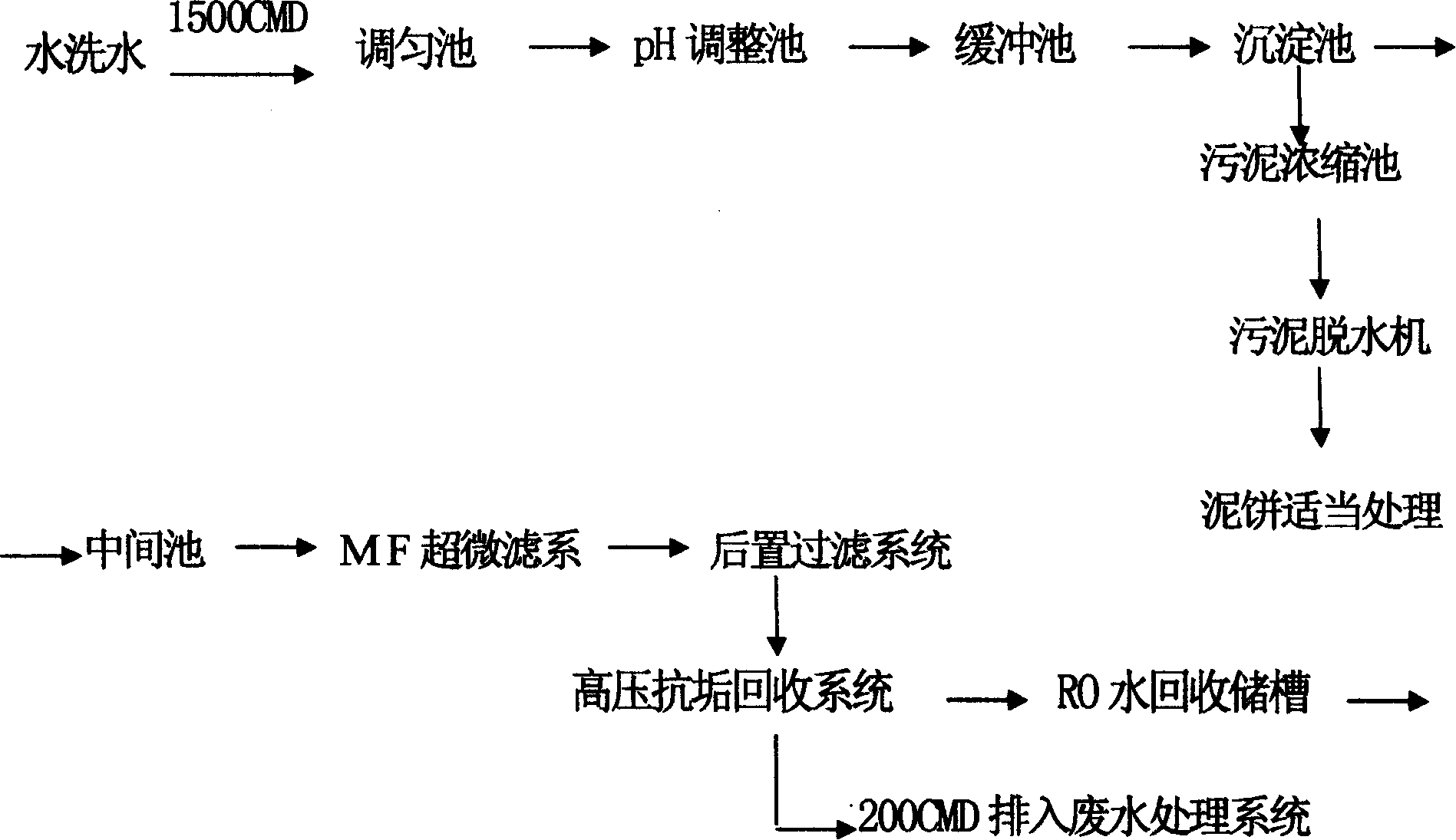

[0025] Below in conjunction with technology, take 1500CMD as an example to further illustrate the present invention:

[0026]

[0027]

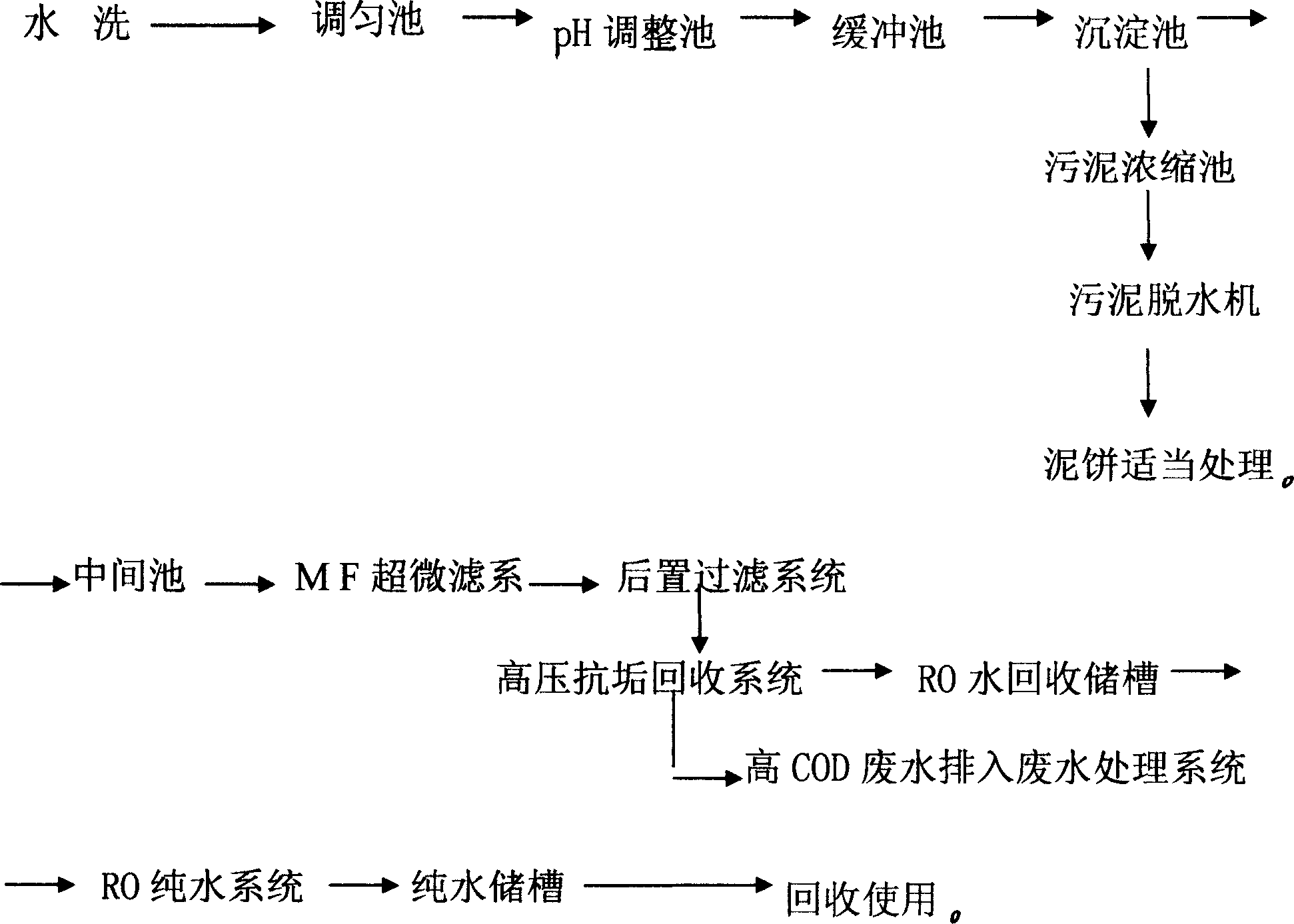

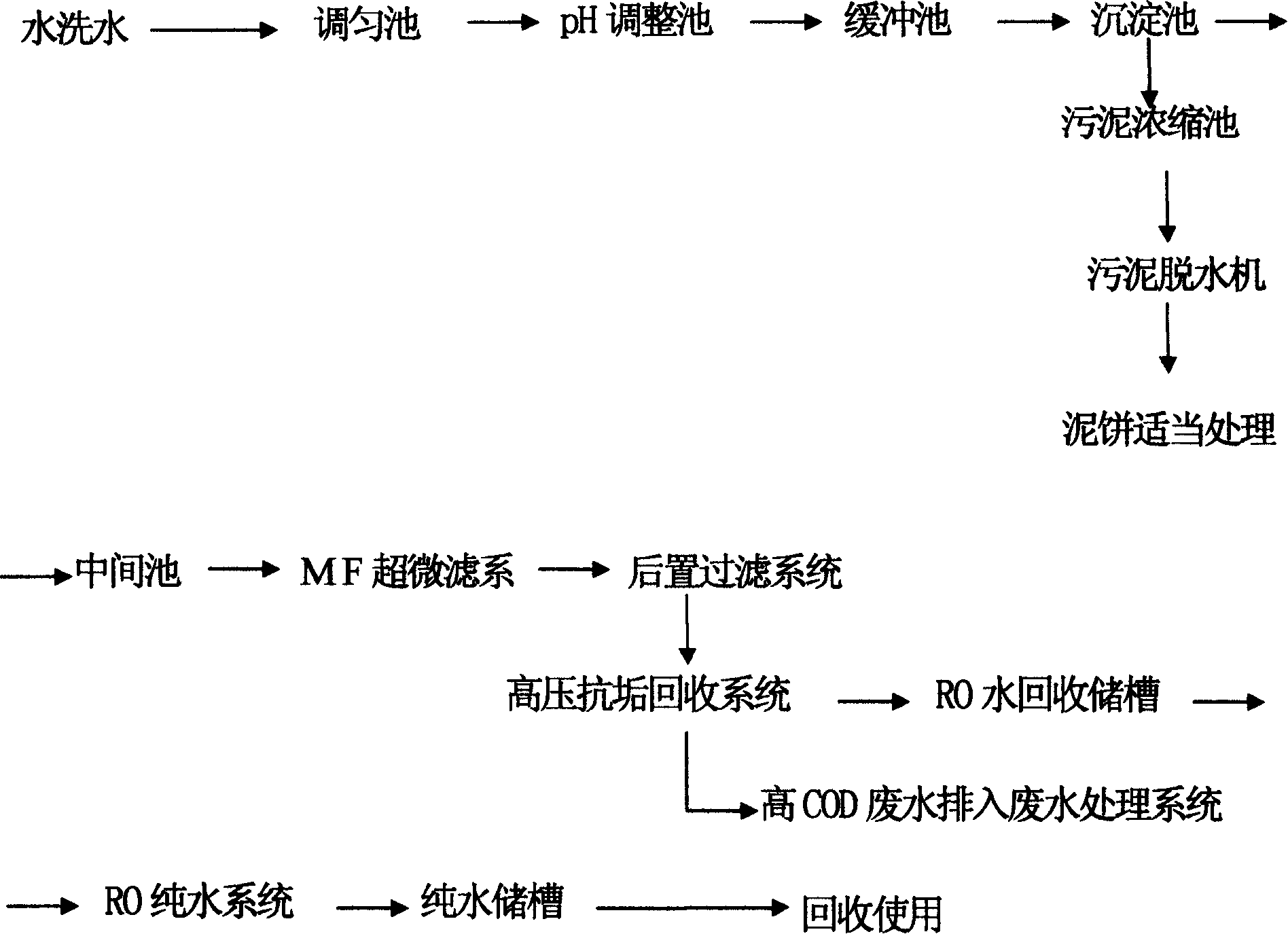

[0028] The waste water from the circuit board workshop is introduced into the mixing pool separately, enters the pH adjustment pool to adjust the pH value, and then enters the buffer pool. After sedimentation in the sedimentation tank, it enters the intermediate pool and is pre-treated and filtered by microfilters and ultrafilters, and then passes through the recovery system. , the quality of the effluent can reach a conductivity of less than 20us / cm 2 , the water quality does not contain particles larger than 10 microns, the PH is neutral, and can be reused in the workshop as production water; the sludge in the sedimentation tank is dehydrated and treated outsourced; the high-COD wastewater is discharged through the wastewater treatment system to meet the standard; acid-base system, water washing , and complex wastewater is introduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com