Green and efficient red mud carbon dioxide carbonized dealkalization system and process

A carbon dioxide and red mud technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of long reaction time, non-continuous operation, low efficiency, etc., and promote the process of carbonization reaction , Significant environmental and social benefits, and the effect of improving the dealkalization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

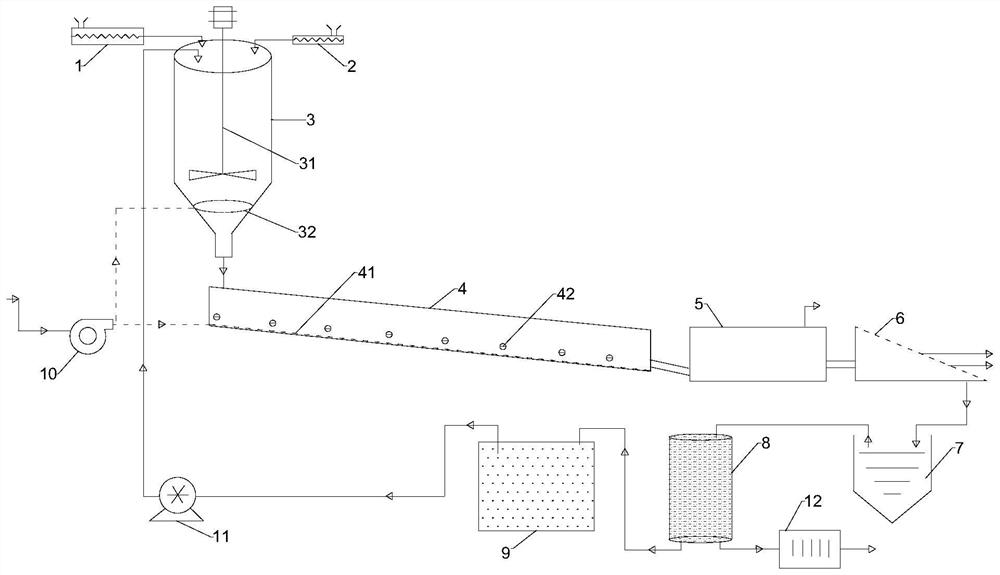

[0057] A green and efficient red mud carbon dioxide carbonization dealkalization process comprises the following steps:

[0058] S1. Preparation of red mud slurry: After the red mud collected from the red mud yard is crushed, it is fed into the red mud slurry mixing tank 3 at a uniform speed by the feeder 1. At the same time, water is added according to a certain water-solid ratio, and the agitator 31 Stir and mix, so that the fully stirred red mud slurry in the red mud slurry mixing tank 3 and the CO injected into the bottom of the red mud slurry mixing tank 3 2 A pre-carbonization reaction occurs to obtain slurry A.

[0059] S2, carbonization dealkalization: the slurry A in the red mud slurry mixing tank 3 enters the carbonization reactor 4 through the bottom outlet, and the slurry A flows from a high place to a low place under the action of gravity in the carbonation reactor 4, and is mixed with The CO fed into the bottom of the carbonization reactor 4 2 A carbonation rea...

Embodiment 2

[0065]The difference from Example 1 is that the mass ratio of red mud and water added in step S1 is 1:6, and CaO is added as a reaction aid for carbonization and dealkalization of red mud, and the mass ratio of CaO to red mud is 0.05:1 ; Stirrer 31 stirring speed is 200r / min; CO 2 Gas source selection CO 2 Concentration of more than 30% of the cement industry waste gas; the inclination angle of the carbonization reactor 4 in step S2 is 20°; the ultrasonic power of the ultrasonic generator 42 is 700W; the iron remover 5 in the step S3 selects the permanent magnetic iron remover 5; dehydration in the step S4 The mesh numbers of the two layers of sieve 6 are selected as 100 mesh and 400 mesh respectively. The dealkalized red mud product A1 is used as raw material for preparing unburned bricks, and the dealkalized red mud product A2 is used for organic fillers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com