Continuous reactor suitable for ion liquid catalyst and its use

A technology of ionic liquids and catalysts, applied in chemical methods for reacting liquids with liquids, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of few reports and achieve reduction Effects of energy consumption, environmental protection, and reduction of solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Though the continuous reactor in example 1 has only 1 unit, raw material and catalyzer are continuous feed, and reaction is uninterrupted; Although the batch reactor in comparative example 1 also can realize that catalyst is used repeatedly, Feeding and discharging are intermittent.

[0027] Examples 1-5 describe the preparation of docosyl benzene, tetracosyl toluene, hexadecyl naphthalene, dodecyl diphenyl ether and other alkyl-substituted aromatic compounds with 1+1 unit reactor instance.

[0028] If the three-way valve 9 is in the B state from the beginning to the end, then the catalyzer is only used once, and is not recycled (instance 1-4). When the time of the three-way valve 9 being in the A state and the B state is 5:1, the catalyzer is recycled 5 times , or the service time of the catalyst is 5 times (instance 5) when not circulating. Using the catalyst injection system of the present invention, the catalyst concentration in the reactor remained constant in al...

Embodiment 6

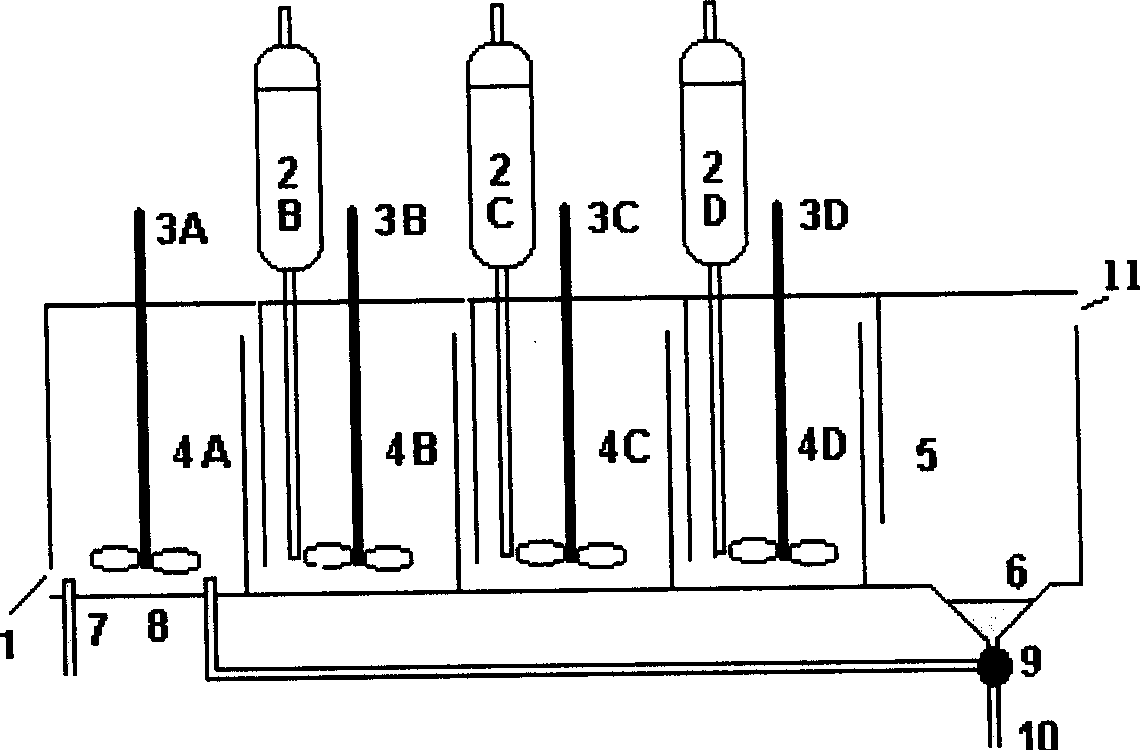

[0029] Example 6 describes the example of preparing tetracosylbenzene with 4+1 unit reactor. The catalyst circulation mode is the same as in Example 5.

Embodiment 1

[0030] Embodiment 1 Preparation of docosylbenzene

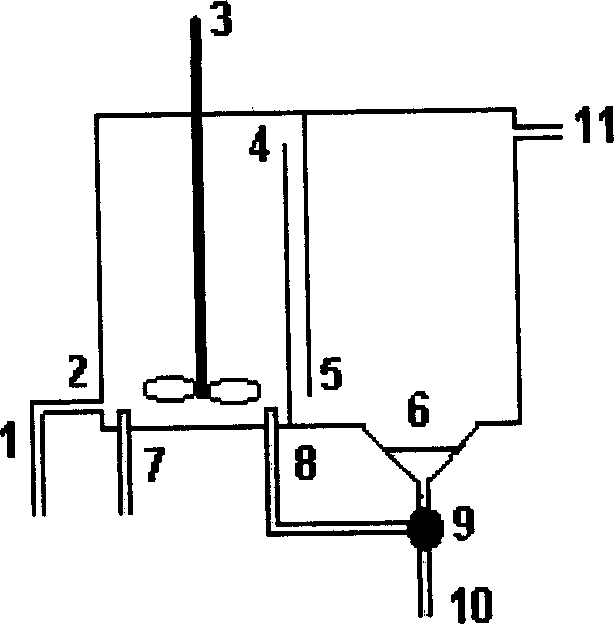

[0031] use figure 1 The shown 1+1 formula unit reactor produces long-chain alkylbenzene. The raw material is a mixture of benzene and an α-olefin with an average carbon number of 22 (NERATEN 20-24, Agrefur Corporation, an average molecular weight of 294). Concrete steps are as follows: 18g of ionic liquid type alkylation catalyst (RA101, Beijing Xingpu Fine Chemical Technology Development Company) is fed from catalyst inlet ( figure 1 , 7) into the reaction section ( figure 1 . figure 1 , 1) into the reaction section ( figure 1 , 2), when the liquid level height of the material is equal to the overflow port height, the effective volume of the reaction section is regarded as 20 liters. Reaction section temperature: 80°C, settling section temperature: 120°C. After 1 hour, the raw material was replenished from 1 at a flow rate of 20 L / h, and the catalyst was injected from 7 at a rate of 18 g / h. The reacted material automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com