Ozone combined photo-excited peroxide VOCs (volatile organic chemicals) purification system and method

A peroxide and purification system technology, applied in chemical instruments and methods, separation methods, dispersion particle separation, etc., can solve problems such as catalyst poisoning and deactivation, complicated process, frequent replacement of activated carbon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

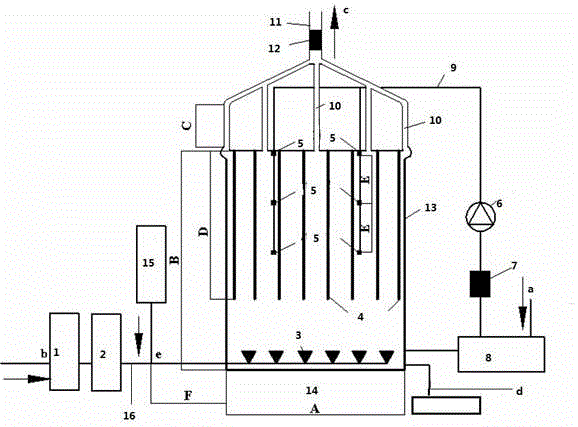

[0071] Example 1: A VOCs purification system with ozone pre-oxidation combined with light-excited peroxide:

[0072] Including dust collector 1, cooler 2, ozone generator 16, photochemical atomization bed reactor 15, gas distribution nozzle 3, circulation pump 6, particle filter device 7, feeding tower 8, spray pipe 9, total flue 11, Demister 12 and product post-treatment system;

[0073] The flue gas inlet b is connected to the dust collector 1;

[0074] The outlet of the dust collector 1 is connected to the cooler 2; the cooler 2 is connected to the gas distribution nozzle 3; the gas distribution nozzle 3 is connected to the photochemical atomization bed reactor 14 through the flue 16;

[0075] The flue gas inlet e between the cooler 2 and the gas distribution nozzle 3 is connected to the ozone generator 15;

[0076] The feeding tower 8 is connected to the particle filtering device 7, and is connected to the photochemical atomization bed reactor 14 through the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com