Slurrying and visbreaking method for improving liquidity of dewatered sludge

A technology for dewatering sludge and fluidity, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of complex equipment structure, cumbersome pulping operation, and high pulping energy consumption, To achieve the effect of simple installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

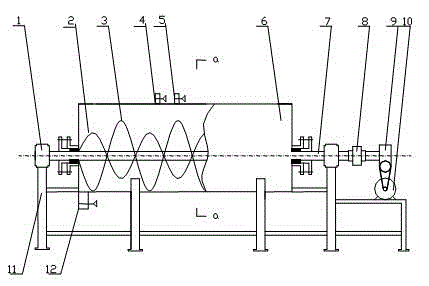

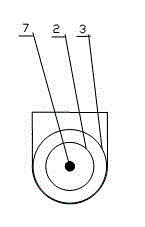

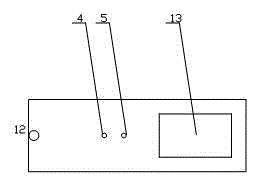

[0028] Such as Figure 1-3 As shown, the dewatered sludge pulping device is composed of: 1 bearing and bearing support, 2 inner ribbon of agitator, 3 outer ribbon of agitator, 4 inlet of salt solution, 5 inlet of alkali solution, 6 main tank Body, 7 shafts, 8 couplings, 9 transmissions, 10 motors, 11 brackets, 12 discharge ports, 13 feed ports. Wherein, the feeding port 13 is used for putting in the initial material at one time, and the volume of the material contained in the main tank body 6 should be controlled to be no higher than the upper edge of the outer ribbon 3 of the agitator. When dosing, the powdered inorganic salt and alkaline substance can be put into the main tank 6 from the feed port 13, or it can be prepared into a concentrated solution in an external container, and the peristaltic pump is connected to the salt solution drug inlet 4 and the alkali solution is fed. Medicine mouth 5 carries out continuous medicine feeding. The agitator is composed of a stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com