Method for preparing nano iron/carbon compound material by kitchen waste

A technology of food waste and composite materials, which is applied in the field of treatment and disposal of food waste, can solve the problems of lack of treatment technology, difficulty in recycling, and large amount of waste, and achieve the effects of avoiding sewage, good application prospects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for preparing iron / carbon nanocomposites from food waste, specifically comprising the following steps:

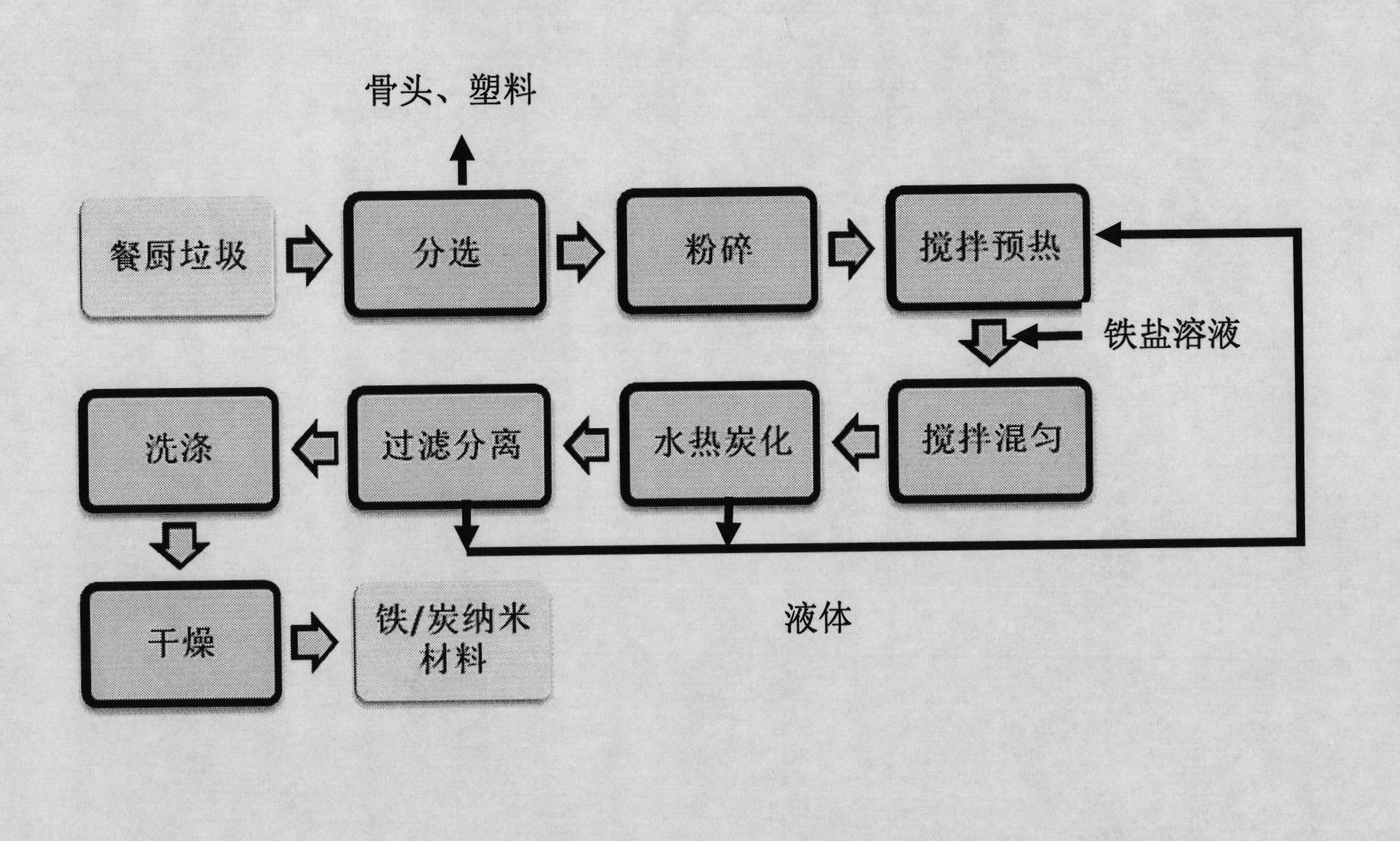

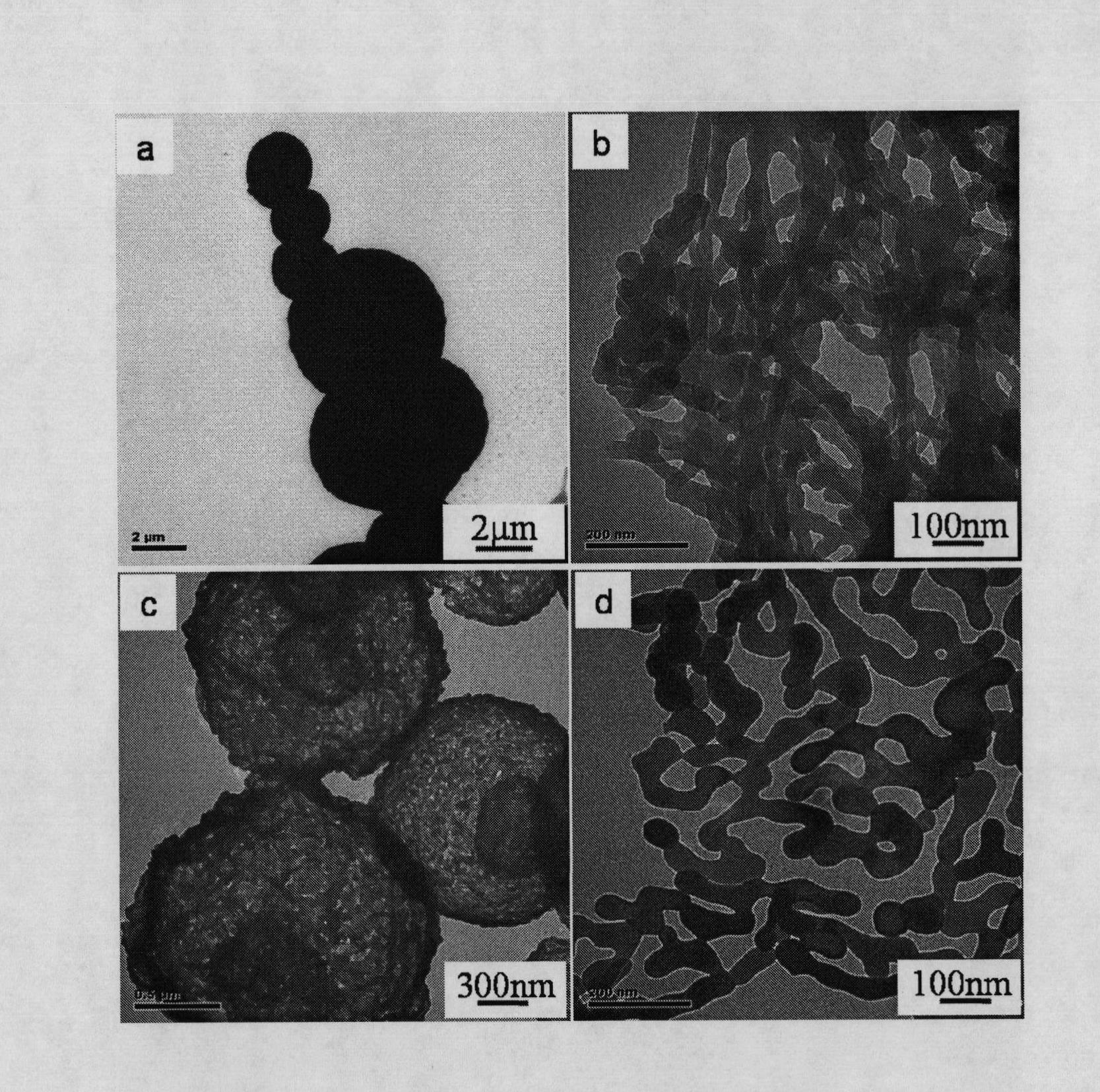

[0016] according to figure 1 As shown in the process flow, select 40 grams of food waste raw materials from which plastic and bones have been removed, crush them into a paste, add 20 ml of deionized water, stir rapidly for 30 minutes under the condition of heating in a water bath (80°C), and then slowly add 10 ml of nitric acid Iron (0.4 mol / L) solution, continue stirring for 10 minutes. Transfer the mixed solution into a 100ml sealed bomb, raise the temperature to 180°C and keep it warm for 18 hours, stop heating and cool down quickly, transfer the mixed solution, separate it by pressure filtration, return the liquid to the preheating system, and wash the solid product repeatedly with deionized water Three times, after filtering, dry at 80°C for 24 hours, grind to obtain 3.5 grams of iron-carbon composite nanomaterials, carry out electron microscope analys...

Embodiment 2

[0018] A method for preparing iron / carbon nanocomposites from food waste, specifically comprising the following steps:

[0019] according to figure 1 As shown in the process flow, select 80 grams of food waste raw materials from which plastics and bones have been removed, crush them into a paste, add 50 ml of deionized water, stir rapidly at 90°C for 30 minutes under the condition of heating in a water bath, and then slowly add 20 ml of ferric chloride (0.4 mol / L) solution and continued to stir for 10 minutes. Transfer the mixed solution into a 100ml sealed bomb, raise the temperature to 180°C and keep it for 20 hours, stop heating and cool down quickly, transfer the mixed solution, press filter and separate, the liquid returns to the preheating system, and the solid product is washed repeatedly with deionized water Three times, dry at 80°C for 24 hours, grind to obtain 5.60 grams of iron-carbon composite nanomaterials, and carry out electron microscope analysis to the morpho...

Embodiment 3

[0021] A method for preparing iron / carbon nanocomposites from food waste, specifically comprising the following steps:

[0022] according to figure 1 As shown in the process flow, select 80 grams of food waste raw materials from which plastic and bones have been removed, crush them into a paste, add 60 ml of deionized water, and stir rapidly for 35 minutes under the condition of heating in a water bath (90°C), then slowly add 10 ml of sulfuric acid Iron (0.8 mol / L) solution, continue stirring for 15 minutes. Transfer the mixed solution into a 200ml sealed bomb, raise the temperature to 180°C and keep it for 15 hours, stop heating and cool down quickly, transfer the mixed solution, separate it by pressure filtration, return the liquid to the preheating system, and wash the solid product repeatedly with deionized water Three times, dry at 80°C for 24 hours, grind to obtain 6.14 grams of iron-carbon composite nanomaterials, carry out electron microscope analysis to the morpholog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com