Coating method of alignment liquid and preparation method of array substrate

A coating method and an alignment liquid technology are applied in the fields of array substrate preparation and coating method, which can solve the problems of light leakage from the ear of a display panel, difficult control of the coating diffusion of the alignment liquid, etc., so as to reduce the phenomenon of light leakage from the ear and have a good application prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

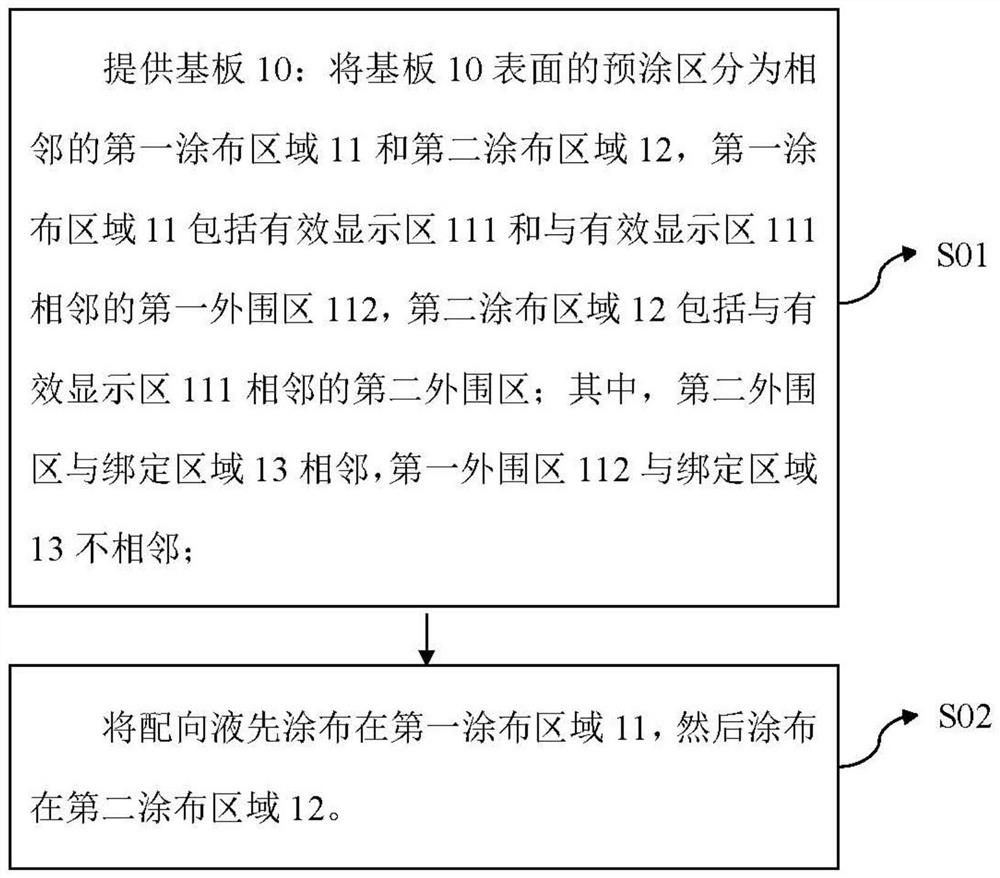

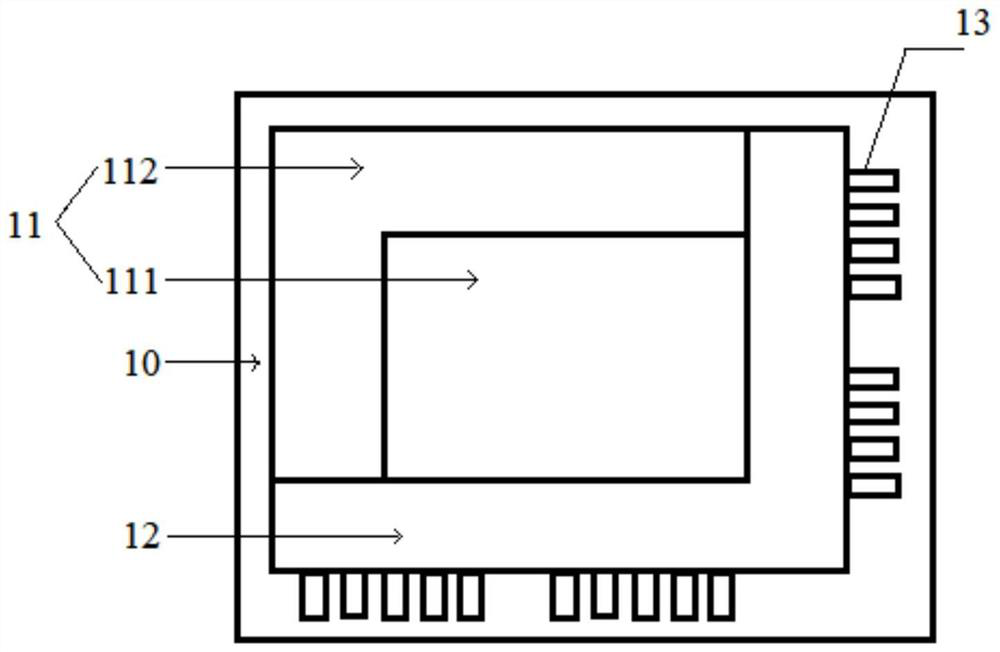

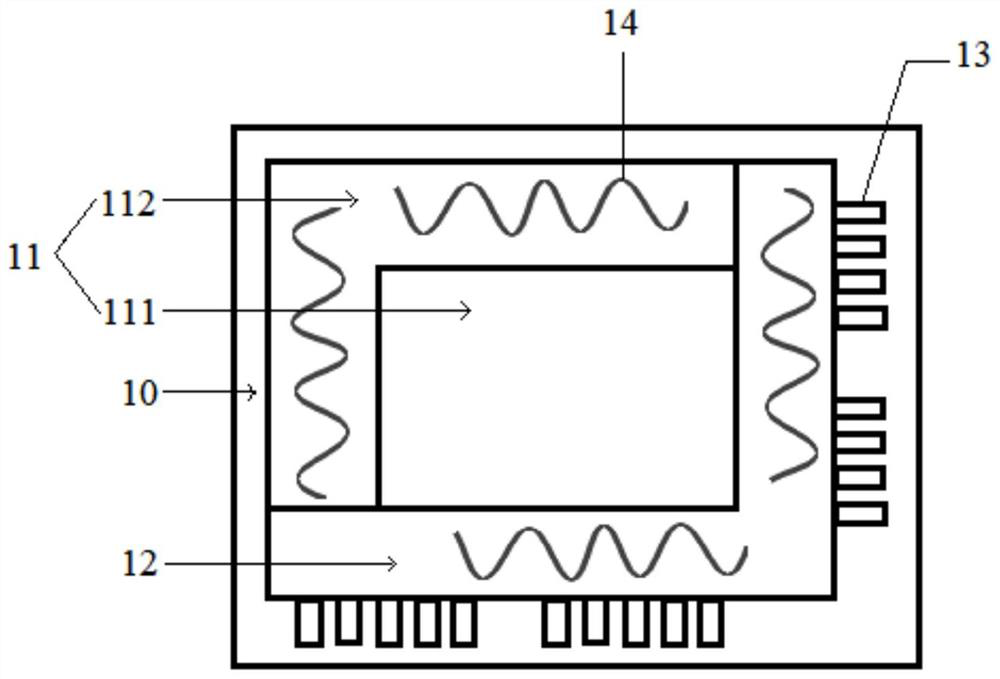

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present application more clear, the present application will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

[0032] In this application, the term "and / or", which describes the relationship between related objects, means that there can be three relationships, for example, A and / or B, which can mean that A exists alone, A and B exist at the same time, and B exists alone Happening. where A and B can be singular or plural. The character " / " generally indicates that the associated objects are an "or" relationship.

[0033] It should be understood that, in various embodiments of the present application, the size of the sequence numbers of the above-mentioned processes does not imply the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com