Innocent treatment method of waste incineration flying ash

A waste incineration fly ash and harmless treatment technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of restricting the resource utilization of residues, the limitation of slag resource utilization, and the limited effect of dioxin removal , to achieve the effect of increasing resource utilization, realizing harmless treatment, and increasing the air permeability of the material layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

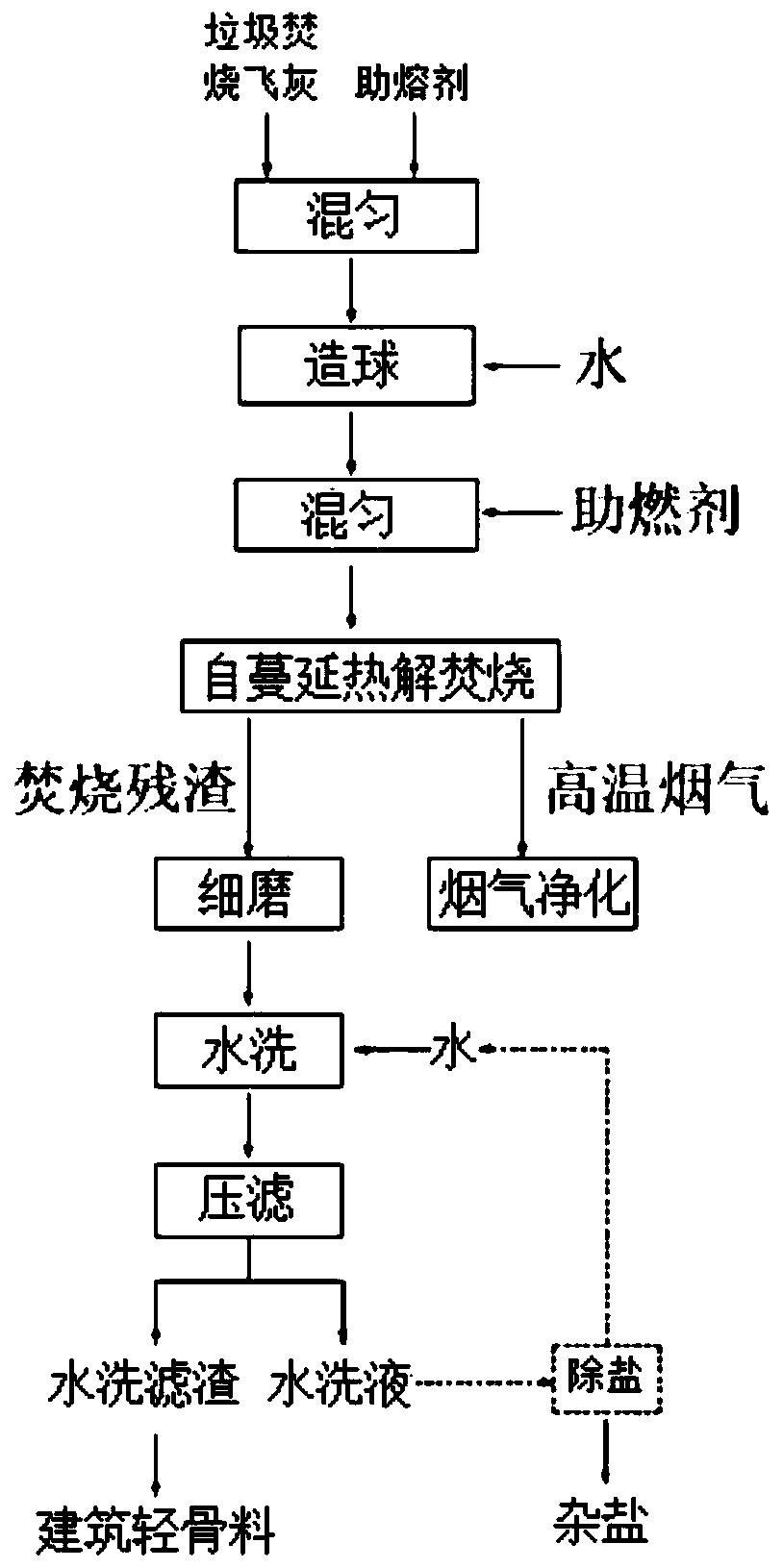

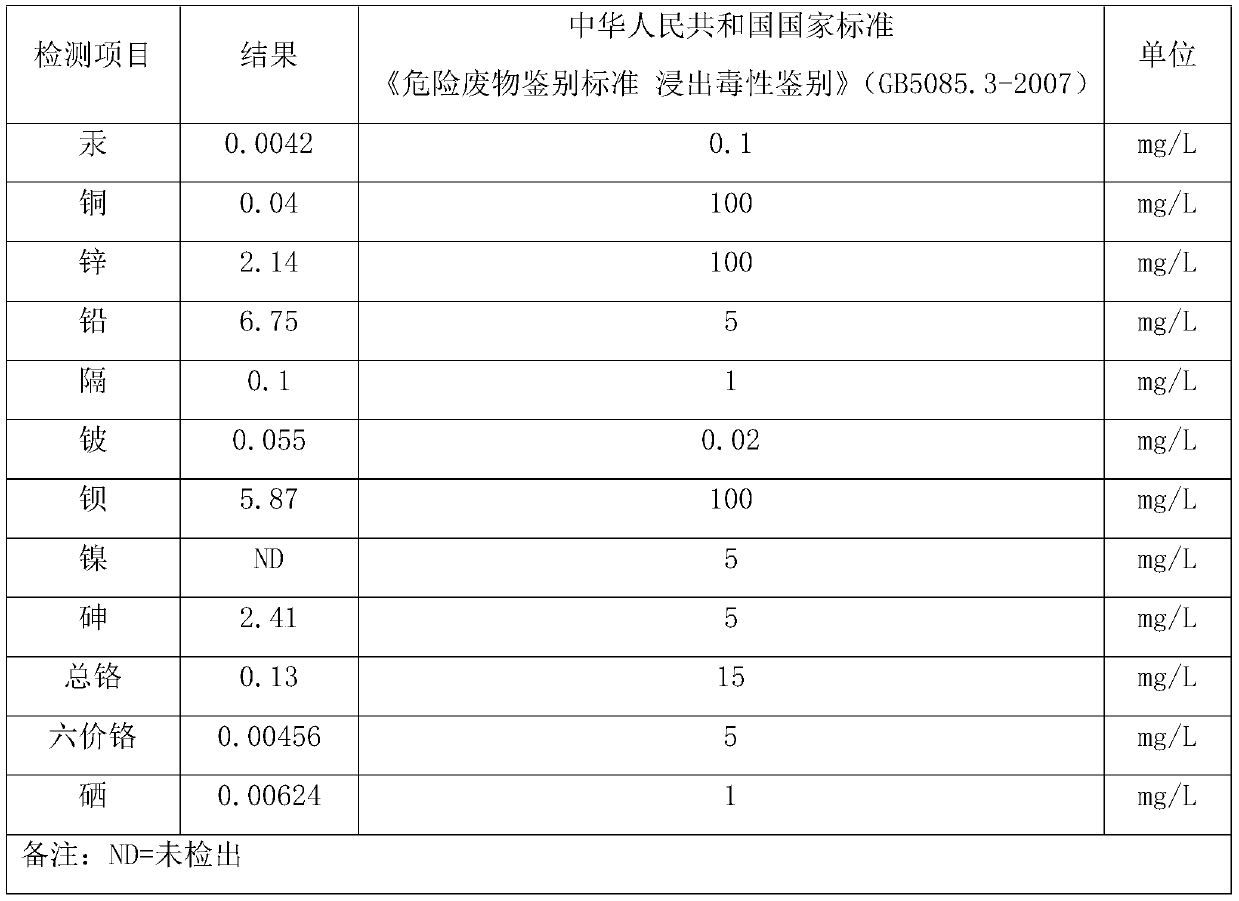

[0027] Embodiment 1, a method for harmless treatment of waste incineration fly ash, which includes the following steps.

[0028] S1, pretreatment, mix 100kg of waste incineration fly ash with 15kg of glass powder, and mix well. The mixed waste incineration fly ash and flux mixture is sent to the disc pelletizer for granulation. By controlling the rotation speed, inclination angle and water spray volume of the pelletizing disc, the fly ash pellets with uniform particle size are produced. Fly ash pellets with a particle size of 8-10 mm are screened out through a stainless steel screen, and the fly ash pellets smaller than 8 mm are returned to the disc pelletizer to continue forming pellets, and the fly ash pellets larger than 10 mm are broken into small particles and then returned to the pelletizer. The disc pelletizer continues to pelletize. Then, the pelletized fly ash pellets and coconut shell charcoal are uniformly mixed in a cylinder mixer according to the dry basis mass r...

Embodiment 2

[0048] Embodiment 2, a method for harmless treatment of waste incineration fly ash, which includes the following steps.

[0049]S1, pretreatment, mix 100kg waste incineration fly ash with 12kg glass powder, and mix well. The mixed waste incineration fly ash and flux mixture is sent to the disc pelletizer for granulation. By controlling the rotation speed, inclination angle and water spray volume of the pelletizing disc, the fly ash pellets with uniform particle size are produced. Fly ash pellets with a particle size of 8-10 mm are screened out through a stainless steel screen, and the fly ash pellets smaller than 8 mm are returned to the disc pelletizer to continue forming pellets, and the fly ash pellets larger than 10 mm are broken into small particles and then returned to the pelletizer. The disc pelletizer continues to pelletize. Then, the pelletized fly ash pellets and coconut shell charcoal are mixed evenly in a cylinder mixer according to the dry basis mass ratio of 1:...

Embodiment 3

[0068] Embodiment 3, a method for harmless treatment of waste incineration fly ash, which includes the following steps.

[0069] S1, pretreatment, mix 100kg waste incineration fly ash with 10kg flux, and mix well. The mixed waste incineration fly ash and flux mixture is sent to the disc pelletizer for granulation. By controlling the rotation speed, inclination angle and water spray volume of the pelletizing disc, the fly ash pellets with uniform particle size are produced. Fly ash pellets with a particle size of 8-10 mm are screened out through a stainless steel screen, and the fly ash pellets smaller than 8 mm are returned to the disc pelletizer to continue forming pellets, and the fly ash pellets larger than 10 mm are broken into small particles and then returned to the pelletizer. The disc pelletizer continues to pelletize. Then, the pelletized fly ash pellets and coconut shell charcoal are mixed evenly in a cylinder mixer according to the mass ratio of 1:0.10 on a dry bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com