Food box device capable of preserving heat through excess heat of cooking oil fume

A food box and oil fume technology, which is applied in heating devices, household heating, household heating, etc., can solve the problems of poor insulation effect of insulation barrels and insulation boxes, poor utilization in winter, and unfavorable environmental protection. , to achieve the effects of increasing waste recycling costs, compact structure, and unique and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

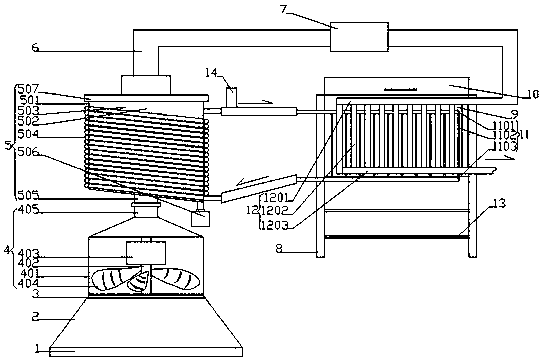

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] like figure 1 As shown in , a device for heat preservation of a food box using kitchen oil fume waste heat includes a wind cover 2, the large end of the wind cover 2 is clamped to the oil storage tank 1, the upper small end is connected to the fan cylinder 401, and the lower end of the fan cylinder 401 is A filter screen 3 is set between the small end of the wind cover 2, and the fan outlet 405 is movably connected to the inlet pipe 505 of the air filter 5, and the outlet pipe of the air filter 5 is connected to one end of the heating pipe 12 of the food box through the pipeline 6, and the spiral pipe The two ends of 504 are respectively connected to the two ends of the heat preservation pipe 11, and the heating pipe 12 and the heat preservation pipe 11 are all arranged in the interlayer of the tank body 9, and the tank body 9 is fixedly connected to the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com