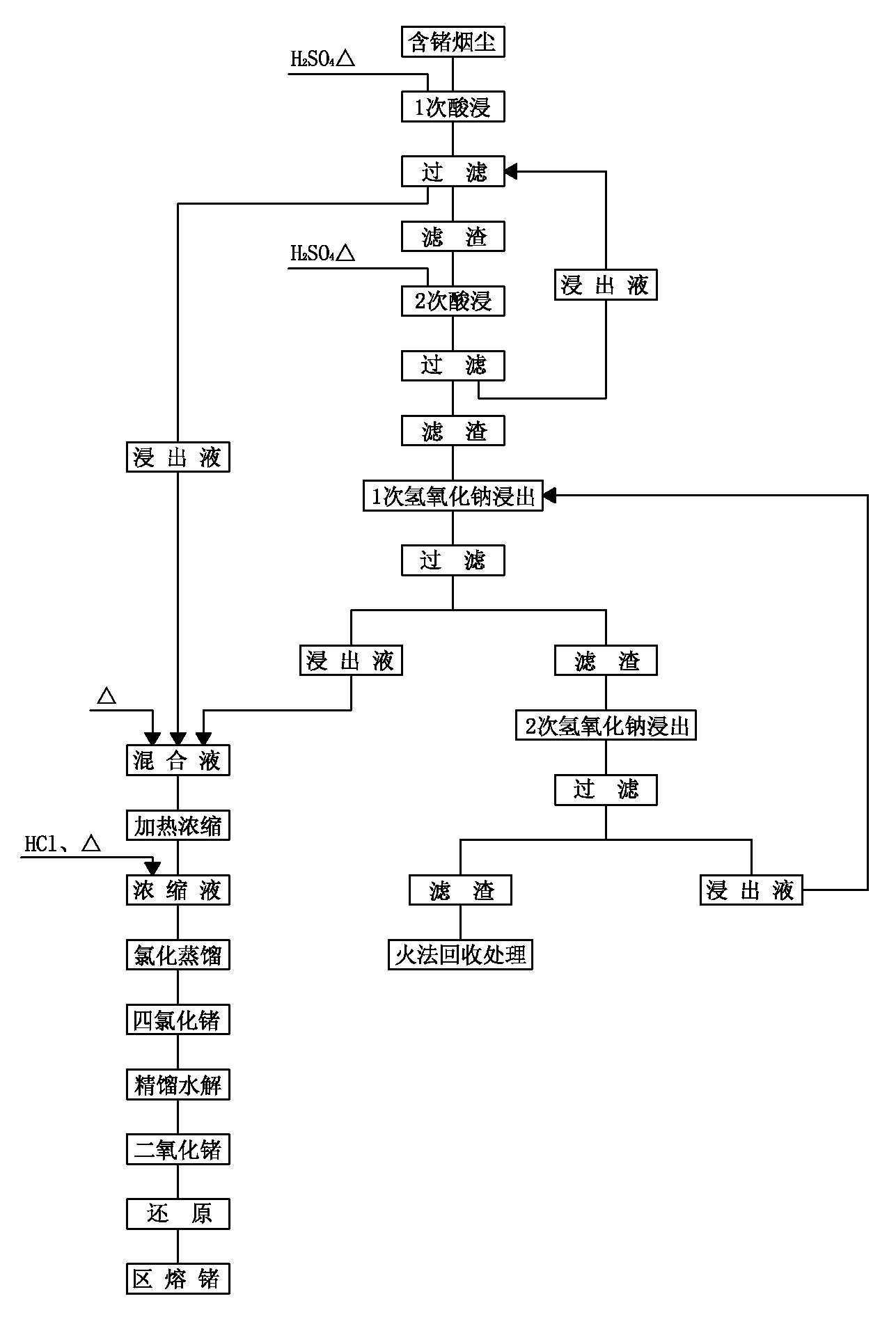

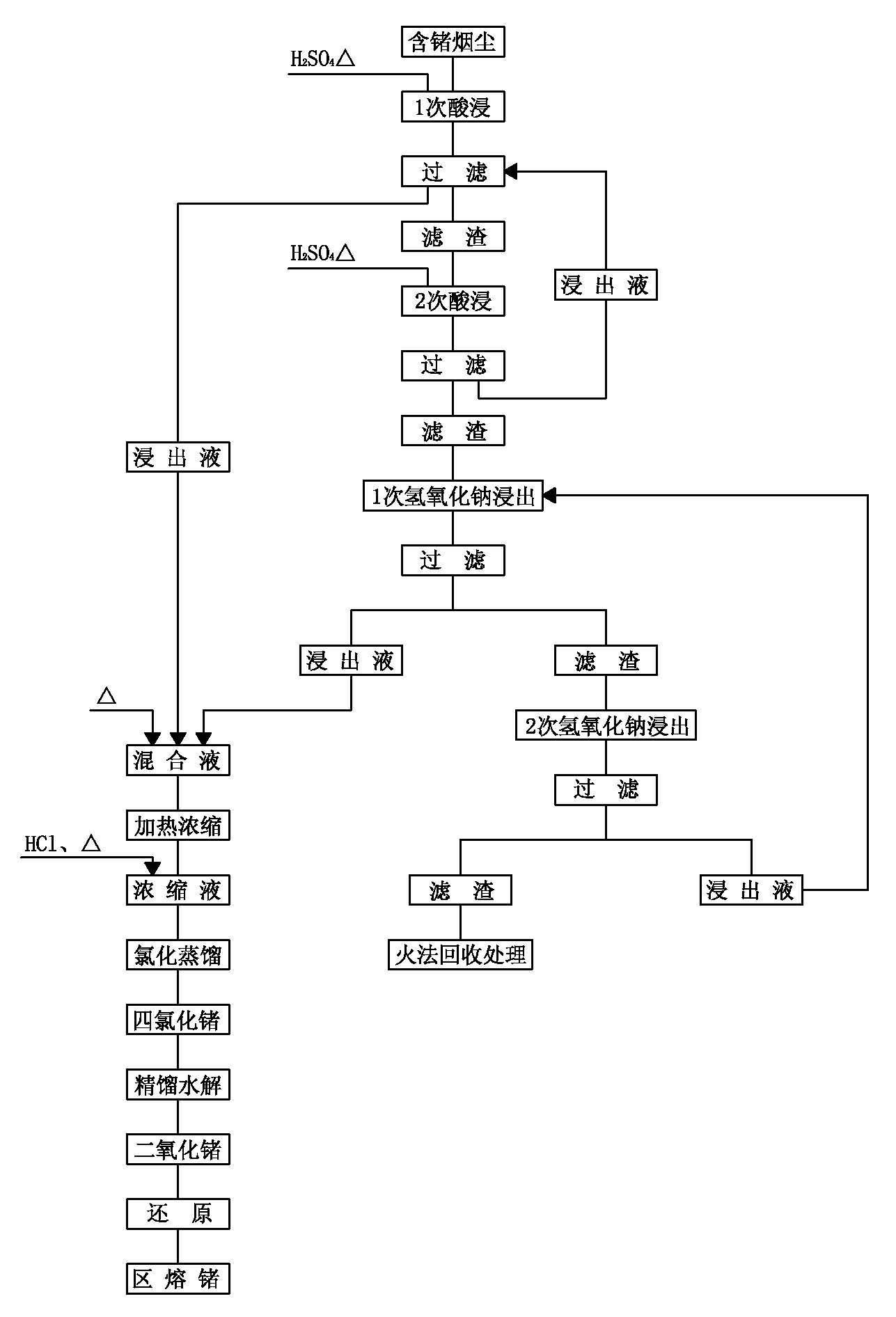

Method for recovering germanium from germanium-containing smoke dust

A germanium fume and fume technology, applied in the field of hydrometallurgy, can solve the problems of low recovery rate of germanium, low recovery rate, large acid consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Take 250g of germanium-containing fume in a 3000ml beaker. The germanium content of the fume is 1.33%, and the germanium metal of the fume is 3.325g. Add 125mL of water and 37.5g of industrial sulfuric acid, stir evenly to form a paste, heat to 65°C, and place Make the soot aging reaction for 1h. Then add 750mL of water, place it on a temperature-controlled electric furnace, start a mechanical stirrer, set the stirring speed at 115 rpm, heat up to 85°C, and stir for leaching for 1.5h. After leaching, vacuum filter, wash the filter residue with 50mL of boiling water, the washing liquid and the filtrate are combined into the leachate to obtain 860mL of the leachate, and the filter residue is transferred to the original beaker.

[0043] The second step: add 37.5g of industrial sulfuric acid to the filter residue obtained in the first step, stir evenly to form a paste, heat to 65°C, and let the smoke and dust mature for 1 hour. Then add 750mL of water, put it on th...

Embodiment 2

[0052] Step 1: Take 250g of germanium-containing fumes in a 3000ml beaker. The germanium content of the fumes is 5.43%, and the germanium metal of the fumes is 13.575g. Add 125mL of water and 50.0g of industrial sulfuric acid. Make the soot aging reaction for 1.5h. Then add 1000mL of water, place it on a temperature-controlled electric furnace, start a mechanical stirrer, set the stirring speed at 115 rpm, heat up to 85°C, and stir for leaching for 2.0h. After leaching, vacuum filter, wash the filter residue with 50mL of boiling water, the washing liquid and the filtrate are combined into the leachate to obtain 1040mL of the leachate, and the filter residue is transferred to the original beaker.

[0053] In the second step, 50.0 g of industrial sulfuric acid is added to the filter residue obtained in the first step, stirred evenly to form a paste, heated to 65° C., and left to allow the soot to mature for 1.5 hours. Then add 1000mL of water, put it on the electric furnace, st...

Embodiment 3

[0062] Step 1: Take 250g of germanium-containing fume in a 3000ml beaker. The germanium content of the fume is 9.17%, and the germanium metal of the fume is 22.925g. Add 125mL of water and 62.5g of industrial sulfuric acid. Stir to form a paste, heat to 70°C, and place Make the soot aging reaction for 2h. Then add 1250mL of water, place it on a temperature-controlled electric furnace, start a mechanical stirrer, set the stirring speed at 115 rpm, heat up to 85°C, and stir for leaching for 2.5h. After leaching, vacuum filter, wash the filter residue with 50mL of boiling water, the washing liquid and the filtrate are combined into the leachate to obtain 1260mL of the leachate, and the filter residue is transferred to the original beaker.

[0063] The second step: add 62.5g of industrial sulfuric acid to the filter residue obtained in the first step, stir evenly to form a paste, heat to 70°C, and let the soot mature for 2 hours. Then add 1250mL of water, put it on the electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com