Recycling device of oiliness plastic bag

A recycling device and plastic bag technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of high recycling cost, white pollution, environmental hazards, etc., and achieve the effect of low price and high recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

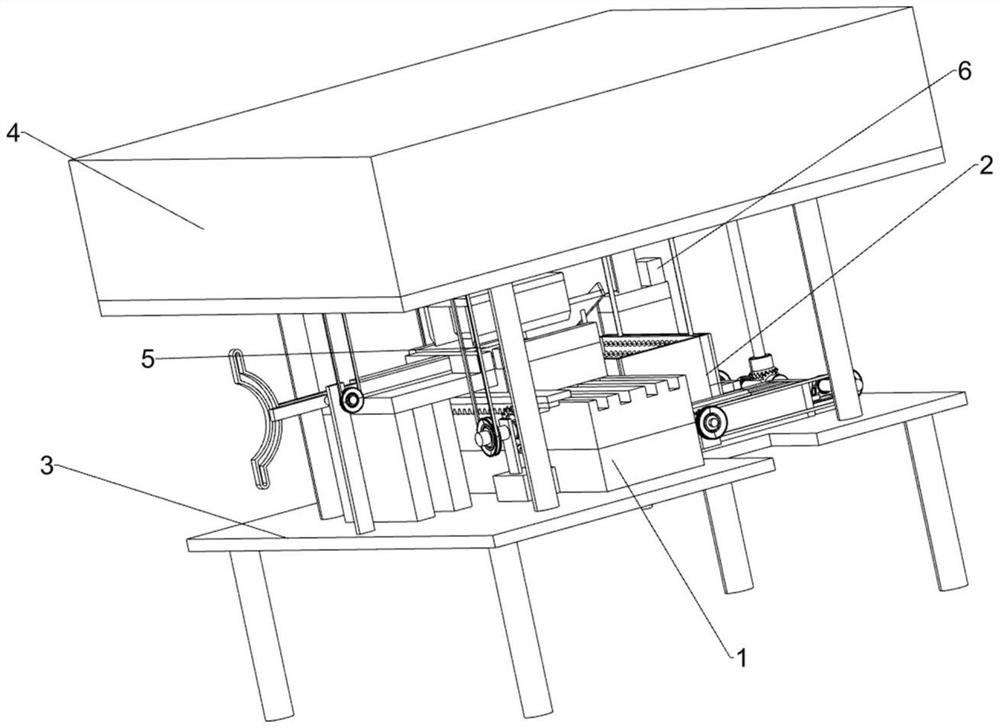

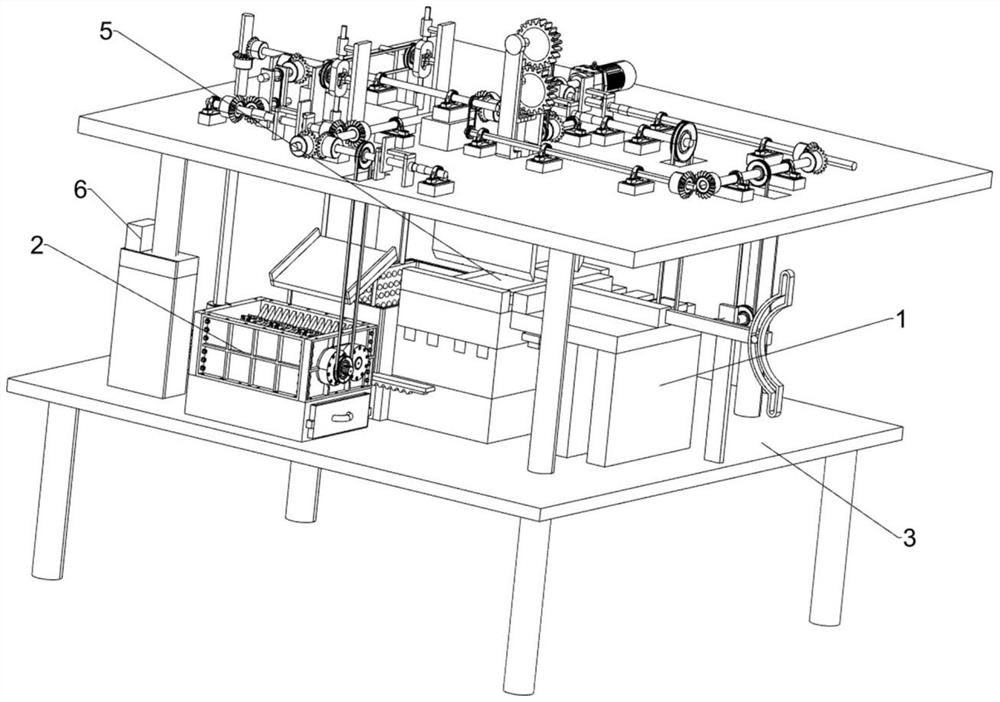

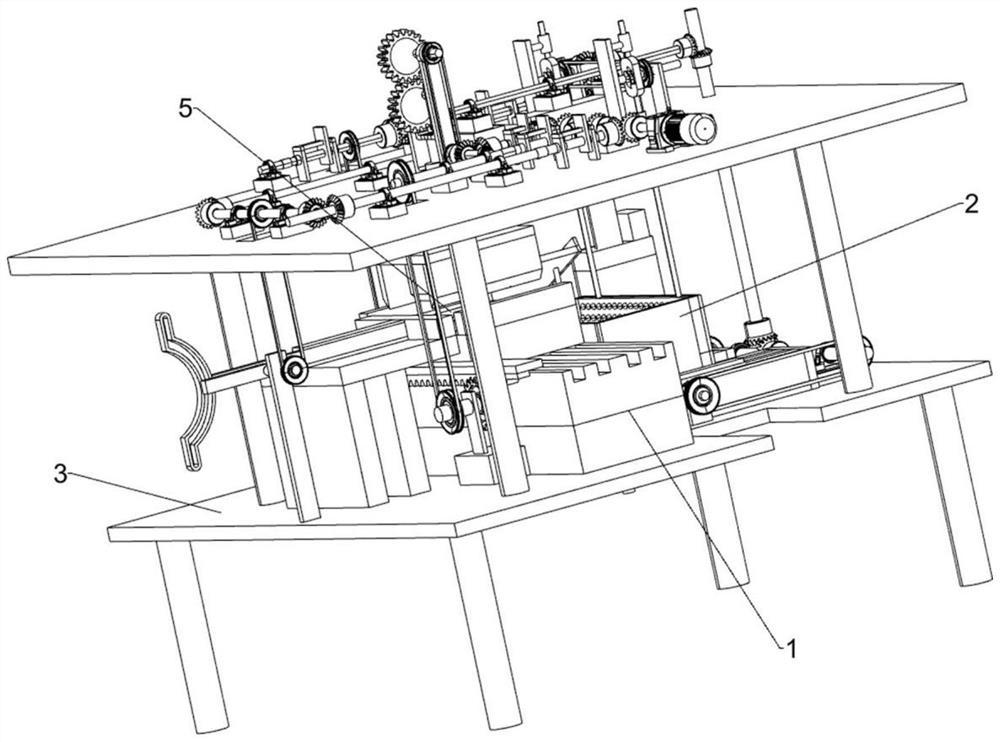

[0034] A recovery device for oily plastic bags, such as Figure 1-11 As shown, it includes a transport cutting mechanism 1, an oil removal, separation and crushing mechanism 2, a workbench 3, a device protection case 4, a plastic bag 5 and a control display; the workbench 3 is provided with a transportation and cutting mechanism 1 and an oil removal, separation and crushing mechanism 2 ; The upper part of the workbench 3 is connected with the device protection shell 4; the transport cutting mechanism 1 is connected with the plastic bag 5; the workbench 3 is connected with the control display screen.

[0035] A device protection case 4 is arranged above the device to protect the device. When in use, the plastic bag 5 is stacked on the transport cutting mechanism 1 on the workbench 3, and the device is controlled through the control display screen to control the drive. Transport the cutting mechanism 1 to the corresponding position, through the cutting process of the plastic bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com