Efficient production and manufacturing method and equipment for lyocell fibers

A manufacturing method and fiber technology, applied in the field of high-efficiency production and manufacturing of lyocell fibers, can solve the problems of less production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

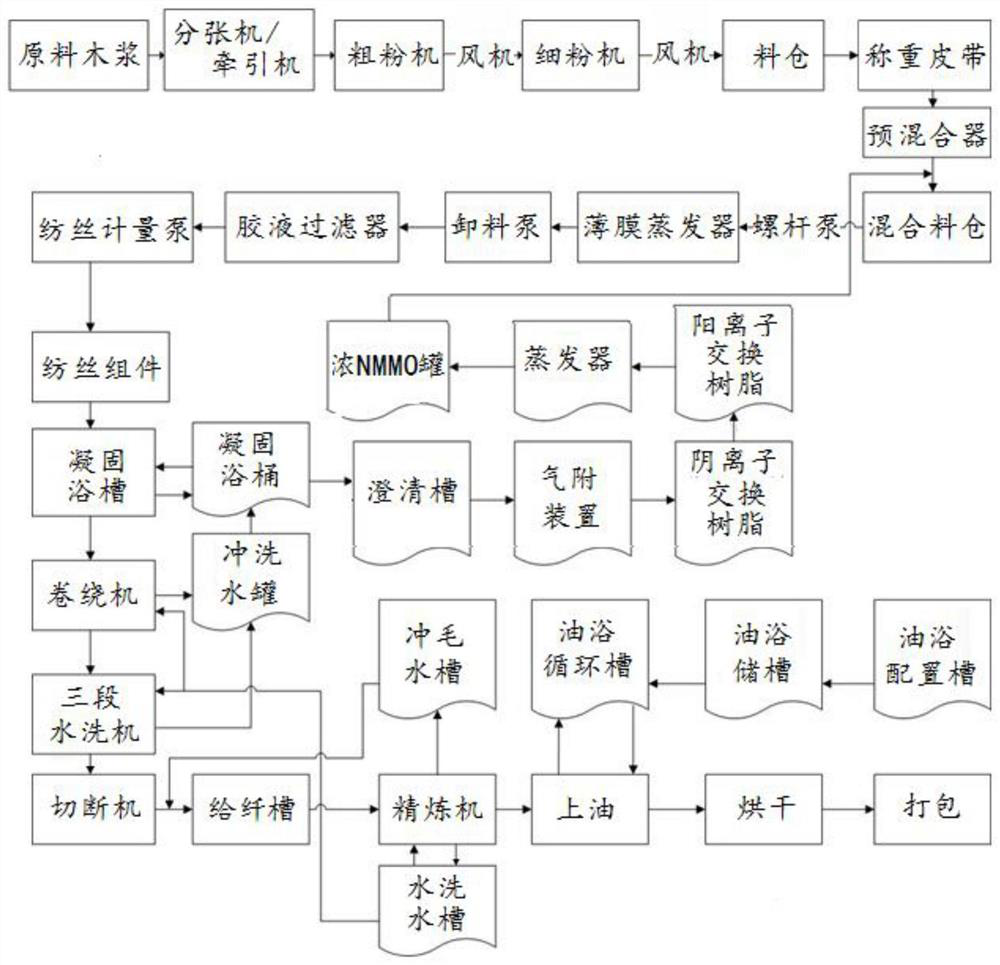

[0036] Embodiment 1: as figure 1As shown, a high-efficiency production and manufacturing equipment for lyocell fiber, the splitter or tractor is connected to the coarse powder machine, the coarse powder machine is connected to the fine powder machine through the fan, the fine powder machine is connected to the silo, and the silo is connected to the weighing belt device , the weighing belt device is connected to the premixer, the premixer is connected to the mixing silo, the mixing silo is connected to the thin film evaporator through the screw pump, the evaporator is connected to the discharge pump, the discharge pump is connected to the glue filter, and the glue filter is connected Spinning metering pump, the spinning metering pump is connected to the spinning assembly, the spinning assembly is connected to the coagulation bath, the coagulation bath is respectively connected to the coagulation bath and the winding machine, the coagulation bath is respectively connected to the ...

Embodiment 2

[0038] Embodiment 2: as figure 1 As shown, a high-efficiency manufacturing method of lyocell fiber has developed a set of mature and reliable lyocell fiber production technology, which reduces production costs and investment costs, promotes the localization process of lyocell fine fibers, and then effectively Promote the development of new fiber materials in China.

[0039] Step 1), solvent selection:

[0040] Due to the rigid molecular chains and intramolecular and intermolecular hydrogen bond networks of cellulose make it insoluble in water and traditional organic solvents, the choice of solvent is very important for the preparation of cellulose fibers.

[0041] Diethylene glycol reacts with ammonia to generate morpholine, which is then methylated and hydrogen peroxide (H 2 o 2 ) oxidation, an aliphatic cyclic tertiary amine oxide (namely NMMO) can be obtained. Due to the strong polarity of the N-O bond, it can break the hydrogen bonds between cellulose molecules, form h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com