Process for comprehensively recovering heat energy and exchanging heat

A process and heat energy technology, applied in the field of waste heat recovery and utilization process, can solve problems such as insufficient waste heat, low comprehensive utilization rate of heat energy, and threat to stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

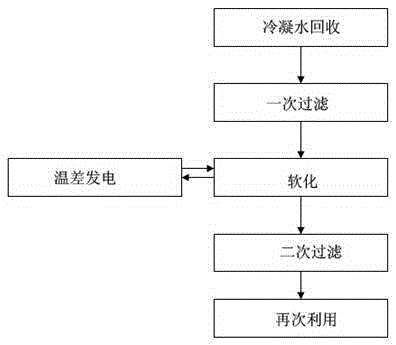

[0019] Such as figure 1 A heat exchange process for comprehensive recovery of heat energy shown includes the following steps:

[0020] The first step is condensed water recovery. The condensed water produced after heating the pipelines, tank farms and other equipment is recovered through the collection tank. When recovering, according to the temperature of the condensed water, the condensed water with a temperature difference of 10°C is collected separately. cans for recycling;

[0021] In the second step, one-time filtration, the condensed water in each collection tank is passed through the filter device respectively, and the solid particle impurities in the condensed water are filtered;

[0022] The third step is softening, passing the filtered condensed water into the softening water device for softening treatment, and collecting and storing the softened condensed water through the softening tank again;

[0023] The fourth step is secondary filtration. The softened conden...

Embodiment 2

[0029] Such as figure 1 A heat exchange process for comprehensive recovery of heat energy shown includes the following steps:

[0030] The first step is condensed water recovery. The condensed water produced after heating the pipelines, tank farms and other equipment is recovered through the collection tank. When recovering, according to the temperature of the condensed water, the condensed water with a temperature difference of 20°C is collected separately. cans for recycling;

[0031] In the second step, one-time filtration, the condensed water in each collection tank is passed through the filter device respectively, and the solid particle impurities in the condensed water are filtered;

[0032] The third step is softening, passing the filtered condensed water into the softening water device for softening treatment, and collecting and storing the softened condensed water through the softening tank again;

[0033] The fourth step is secondary filtration. The softened conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com