Nickel cobaltate nano material as well as preparation method and application thereof

A nanomaterial, nickel cobalt oxide technology, applied in nanotechnology, chemical instruments and methods, nickel compounds and other directions, can solve the problems of single structure and morphology, can not meet the needs of applications, weak catalytic activity, etc., achieves low preparation cost, The effect of high recycling rate and poor recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

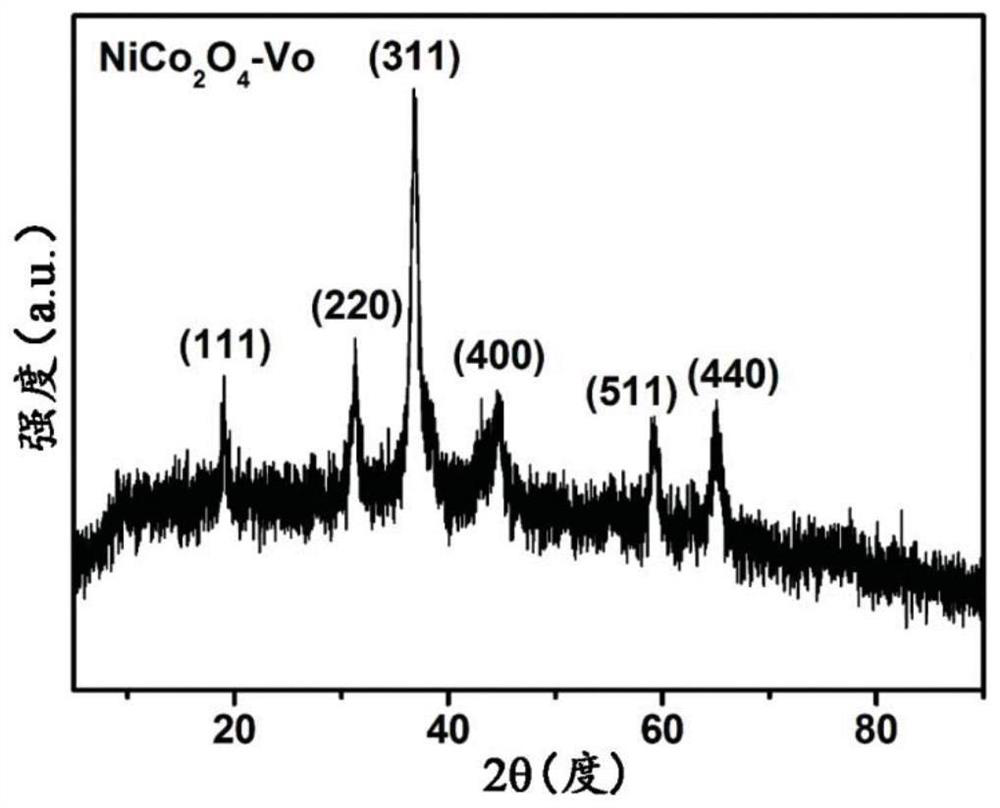

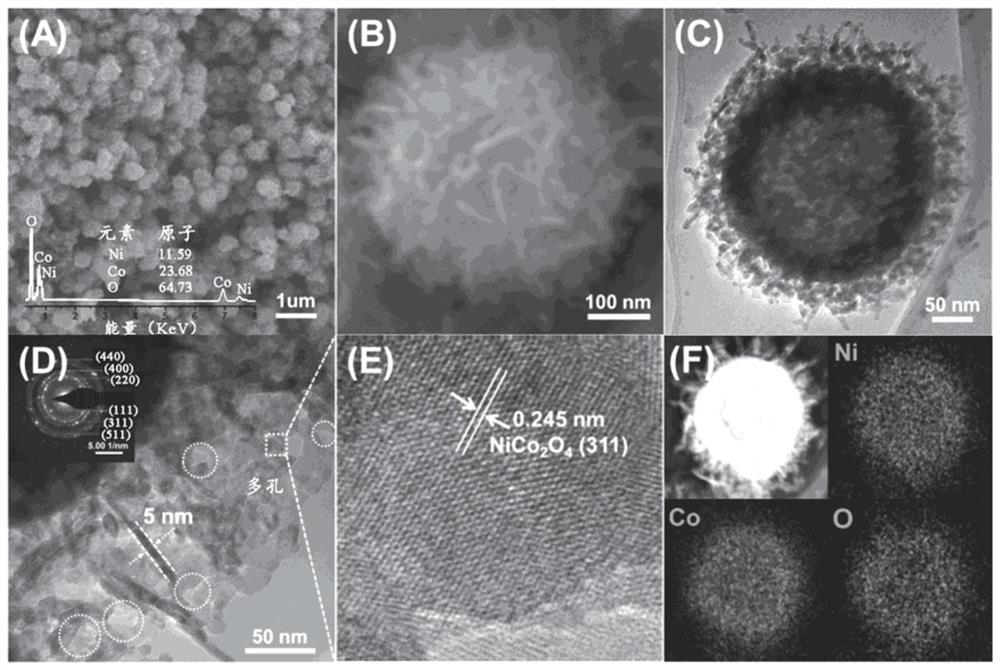

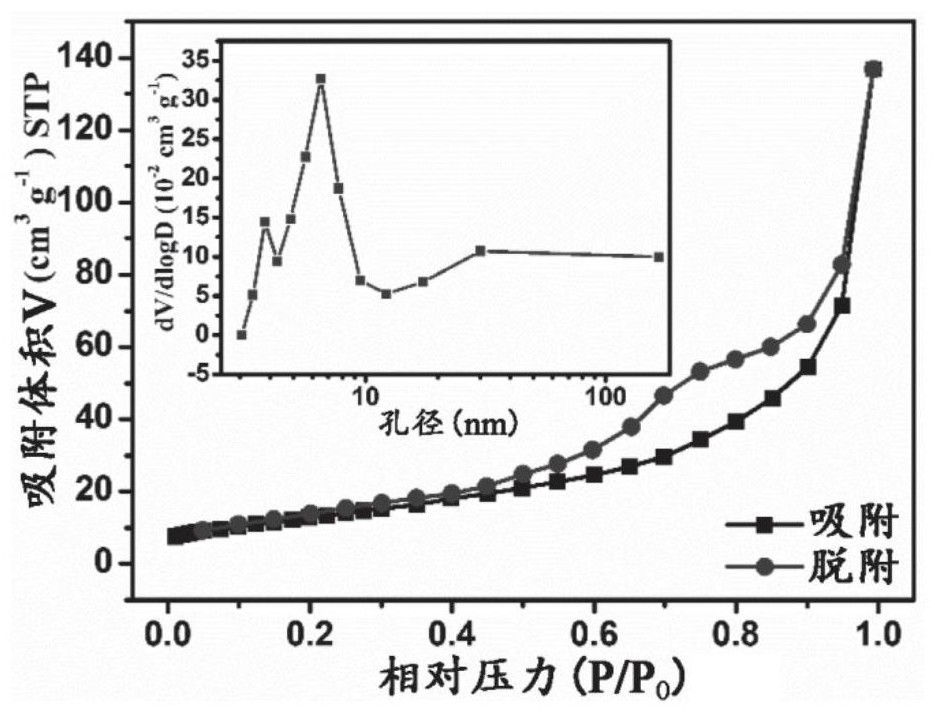

[0065] Example 1 Preparation of hollow porous nickel cobaltate nanomaterials with oxygen-rich vacancy defects

[0066] Preparation of Ni-Co-glycerol precursor

[0067] Nickel nitrate hexahydrate and cobalt nitrate hexahydrate were dissolved in a polytetrafluoroethylene reactor (50 ml) filled with isopropanol, and then glycerol and water were added to form a mixed solution. In the mixed solution, the quality of cobalt nitrate hexahydrate is 64mg, the quality of nickel nitrate hexahydrate is 32mg, the volume of isopropanol is 35ml, the volume of glycerol is 5ml, and the volume of water is 1ml. Then place the polytetrafluoroethylene reactor in a homogeneous reactor for heating, make the mixed solution react at a temperature of 190° C. for 12 hours at a stirring speed of 15 r / min, cool the obtained product at room temperature, and then The product was centrifuged, washed once with ethanol and water, and then dried at 105 °C to obtain the Ni-Co-glycerol precursor.

[0068] NiC...

Embodiment 2

[0070] Example 2 Preparation of hollow porous nickel cobaltate nanomaterials with oxygen-rich vacancy defects

[0071] Preparation of Ni-Co-glycerol precursor

[0072] Nickel nitrate hexahydrate and cobalt nitrate hexahydrate were dissolved in a polytetrafluoroethylene reactor (50 ml) filled with isopropanol, and then glycerol and water were added to form a mixed solution. In the mixed solution, the quality of cobalt nitrate hexahydrate is 64mg, the quality of nickel nitrate hexahydrate is 32mg, the volume of isopropanol is 35ml, the volume of glycerol is 5ml, and the volume of water is 1ml. Then place the polytetrafluoroethylene reactor in a homogeneous reactor for heating, make the mixed solution react at a temperature of 180° C. for 12 hours at a stirring speed of 15 r / min, cool the obtained product at room temperature, and then prepare the obtained The product was centrifuged, washed once with ethanol and water, and then dried at 105 °C to obtain the Ni-Co-glycerol prec...

Embodiment 3

[0075] Example 3 Preparation of hollow porous nickel cobaltate nanomaterials with oxygen-rich vacancy defects

[0076] Preparation of Ni-Co-glycerol precursor

[0077] Nickel nitrate hexahydrate and cobalt nitrate hexahydrate were dissolved in a polytetrafluoroethylene reactor (50 ml) filled with isopropanol, and then glycerol and water were added to form a mixed solution. In the mixed solution, the quality of cobalt nitrate hexahydrate is 64mg, the quality of nickel nitrate hexahydrate is 32mg, the volume of isopropanol is 35ml, the volume of glycerol is 5ml, and the volume of water is 1ml. Then place the polytetrafluoroethylene reactor in a homogeneous reactor for heating, make the mixed solution react at a temperature of 190° C. for 12 hours at a stirring speed of 15 r / min, cool the obtained product at room temperature, and then The product was centrifuged, washed once with ethanol and water, and then dried at 105 °C to obtain the Ni-Co-glycerol precursor.

[0078] NiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com