Oil leakage prevention turbocharger

A technology for turbochargers and oil leakage prevention, which is applied to machines/engines, parts of pumping devices for elastic fluids, non-variable pumps, etc. Low pressure at the outlet, oil leakage into the compressor, etc., to achieve the effect of convenient adjustment and prevention of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

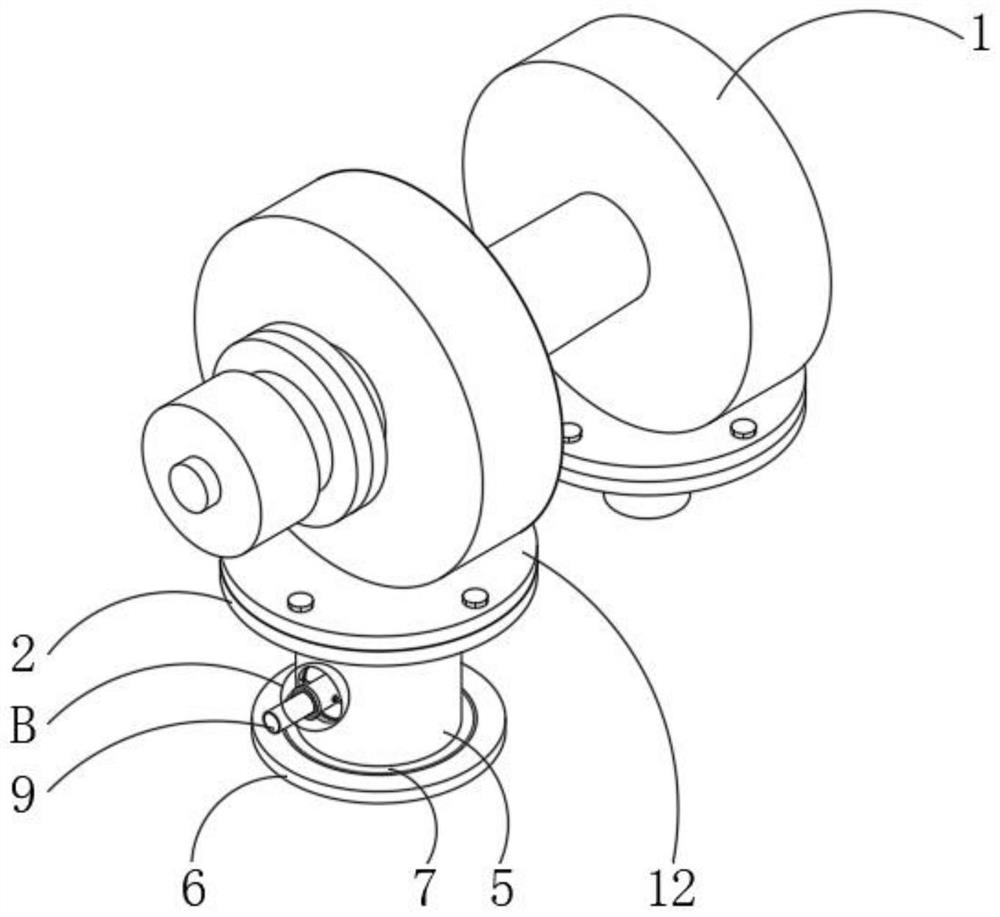

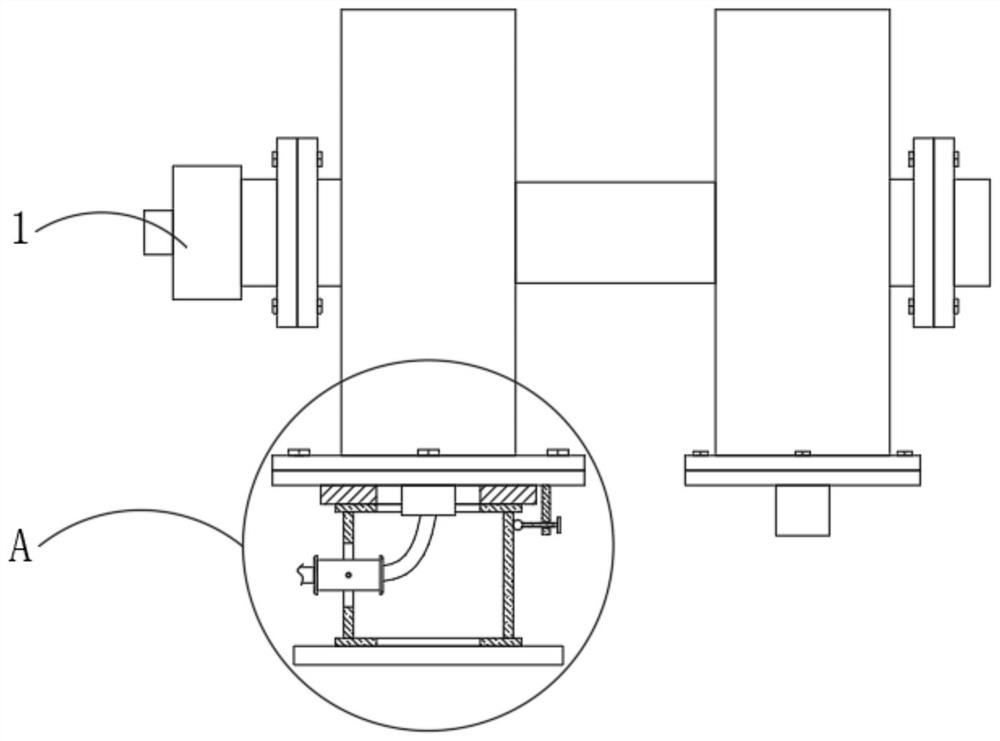

[0029] see Figure 1-6 , the present invention provides a technical solution: an oil-leakage-proof turbocharger, comprising a turbocharger body 1, a first flange 2 is provided at the bottom of one side of the turbocharger body 1, and the first method The bottom of the flange 2 is fixedly installed with a first plate body 3, and one side of the bottom of the turbocharger body 1 is fixedly installed with a second flange 12 that is compatible with the first flange 2. The first flange 2 is bolted to the second flange 12 through bolts, the intake pipe 8 communicates with the bottom of the turbocharger body 1 through the first flange 2 and the second flange 12, and the first flange 2 and The second flange 12 is used to connect and fix the first plate body 3 with the turbocharger body 1; by setting the intake pipe 8, the hose 9 communicates with the turbocharger body 1 through the intake pipe 8;

[0030] The bottom of the first plate 3 is embedded with the first turntable bearing 4,...

Embodiment 2

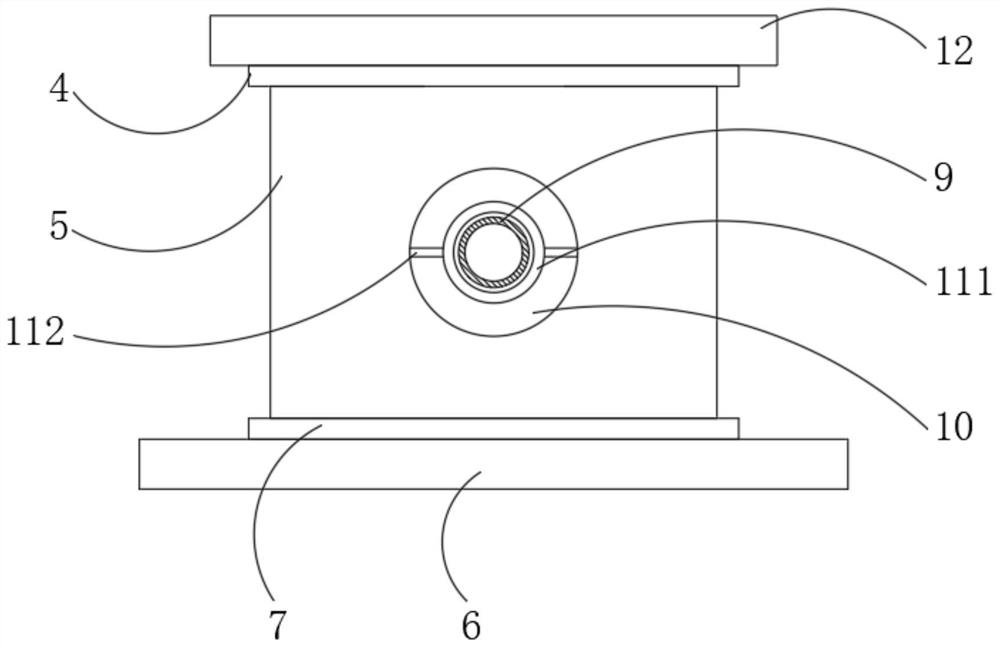

[0035] see Figure 1-6 The difference between this embodiment 2 and embodiment 1 is that: the guide assembly 11 includes a tube body 111, the tube body 111 is located in the inner cavity of the through groove 10, and the centers of the front and rear sides of the tube body 111 are rotatably installed with support rods 112 , the end of the strut 112 away from the tube body 111 is slidably connected to the inner wall of the through groove 10, and the end of the hose 9 away from the intake pipe 8 slides through the tube body 111 and extends to the outside of the tube body 111; by setting the strut 112 and the chute 13. When the hose 9 shakes or moves under force, the hose 9 drives one end of the tube body 111 to tilt or droop, and the hose 9 can also drive the tube body 111 to rotate, and the tube body 111 passes through the support rod 112 in the chute 13 Rotate, so that the hose 9 is limited, and at the same time, the tube body 111 can move flexibly in a small range when it is un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com