Low-intensity groove concrete produced by using red brick construction wastes and construction technology of low-intensity groove concrete

A construction waste and concrete technology, applied in construction, infrastructure engineering, roads, etc., can solve the problems of unfavorable manual excavation and the difficulty of effective compaction of backfill materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

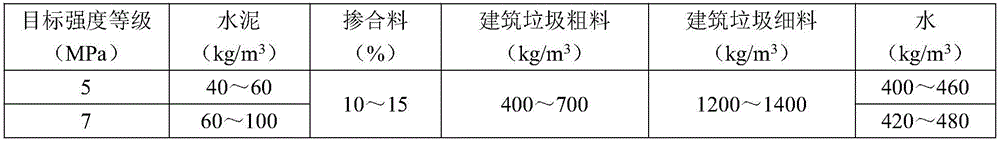

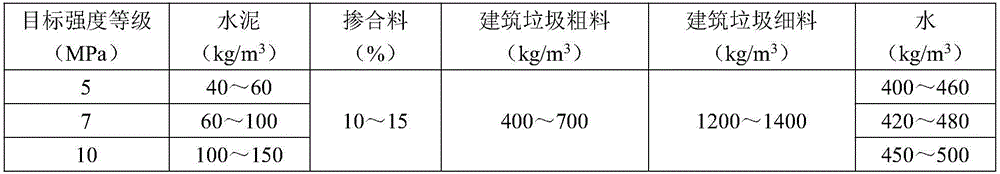

[0083] Due to pipeline protection and narrow building boundaries, large-scale compaction machines cannot be used for backfilling construction of road trenches in a certain city, and the project requires excavation in the later stage. The low-strength trench concrete that utilizes the production of red brick construction waste provided by the invention is used as the backfill material, and the specific implementation method is as follows:

[0084] Construction materials: The cement used is ordinary Portland cement with a strength grade of 42.5R; the recycled construction waste aggregate is produced by a recycling plant, and the moisture content of the recycled coarse material is 3%, and the moisture content of the recycled fine material is 3%, which meets the above recycling requirements. Aggregate technical requirements; fly ash is Class F Class I, with a moisture content of 2%, and its quality complies with national technical standards; water is potable tap water.

[0085] co...

Embodiment 2

[0094] A road in a certain city has a subsidence of the pavement and needs to be backfilled. The low-strength trench concrete produced by the invention using construction waste containing red bricks is used as the backfill material. The specific implementation is as follows:

[0095] Construction materials: The cement used is ordinary Portland cement with a strength grade of 42.5R; the recycled construction waste aggregate is produced by a recycling plant, and the moisture content of the recycled coarse material is 4%, and the moisture content of the recycled fine material is 4%. Aggregate technical requirements; fly ash is class F class Ⅲ, moisture content is 5%, and its quality is in line with national technical standards; water is potable tap water.

[0096] construction process:

[0097] S1. Clean up the foundation pit: remove the debris, floating soil and other sundries in the foundation pit, and tamp and level it, and cut the edge parts neatly.

[0098] S2. Construction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com