Preparation method and application of superhydrophobic non-woven material prepared from P(DVB (Divinyl Benzene)-VTES(Vinyl Triethoxysilane))

A non-woven fabric and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of secondary pollution and long processing time, and achieve easy operation and control, simple and easy preparation methods, The effect of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

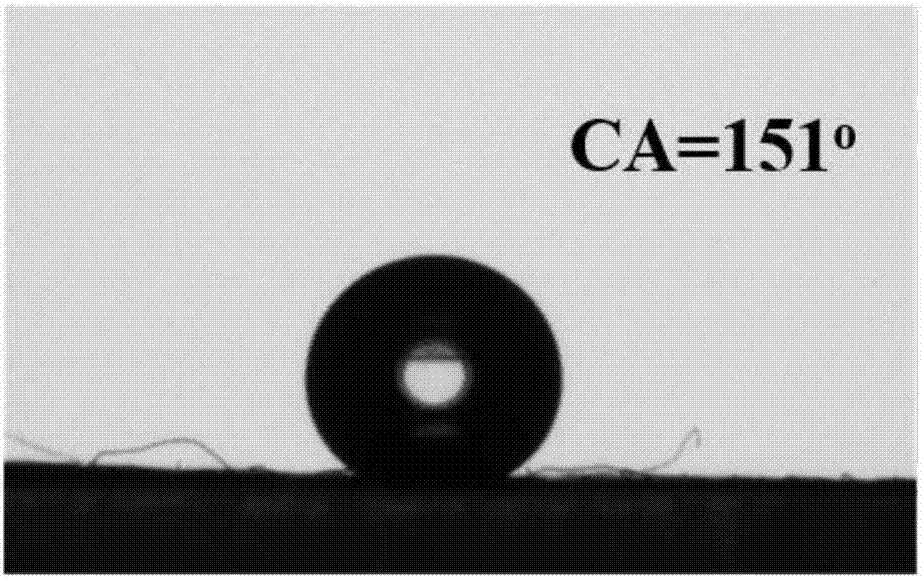

Embodiment 1

[0026] With non-woven fabric as the carrier, DVB and VTES as the hydrophobic modifier, through the solvothermal method. Take 1.5mL DVB and 0.5mL VTES into a 50mL autoclave, add 33ml of ethyl acetate, and 2% of the total monomer mass catalyst AIBN, after fully dissolved, put them in a 100°C oven for solvothermal for 10h ; After natural cooling, take out the modified non-woven fabric, clean it with absolute ethanol, and then place it in a 0.1mol L -1 Stand still in the ethanol solution of ammonia water at 25°C for 60min, and finally dry in an oven at 50°C.

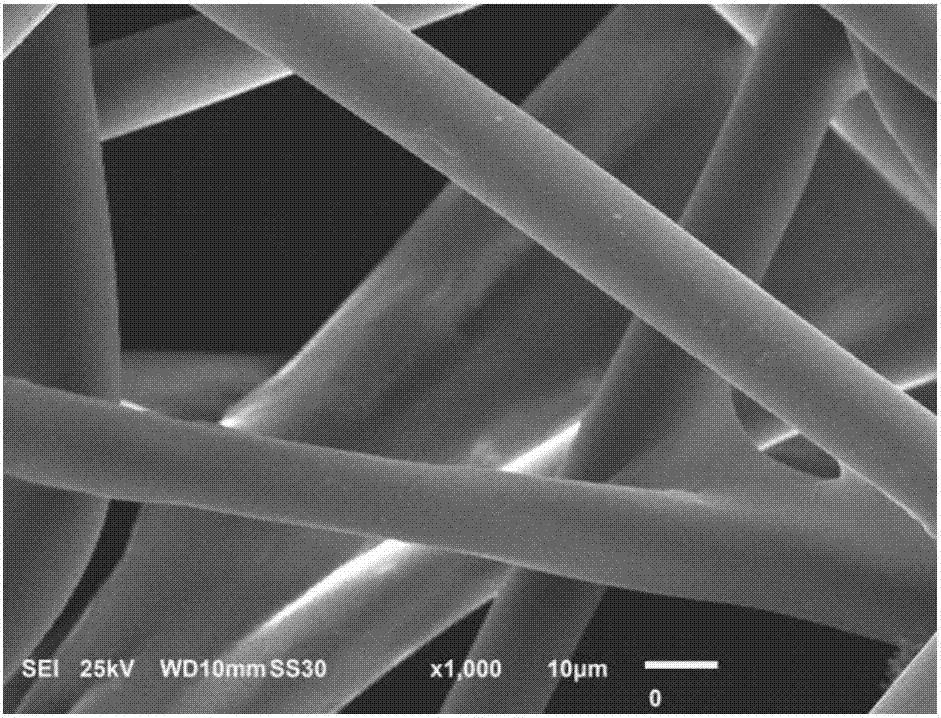

[0027] figure 1 It is a scanning electron microscope picture of an unmodified non-woven fabric. It is obvious that the non-woven fabric is made of disordered fibers, and the surface of each fiber is relatively smooth without obvious rough structure.

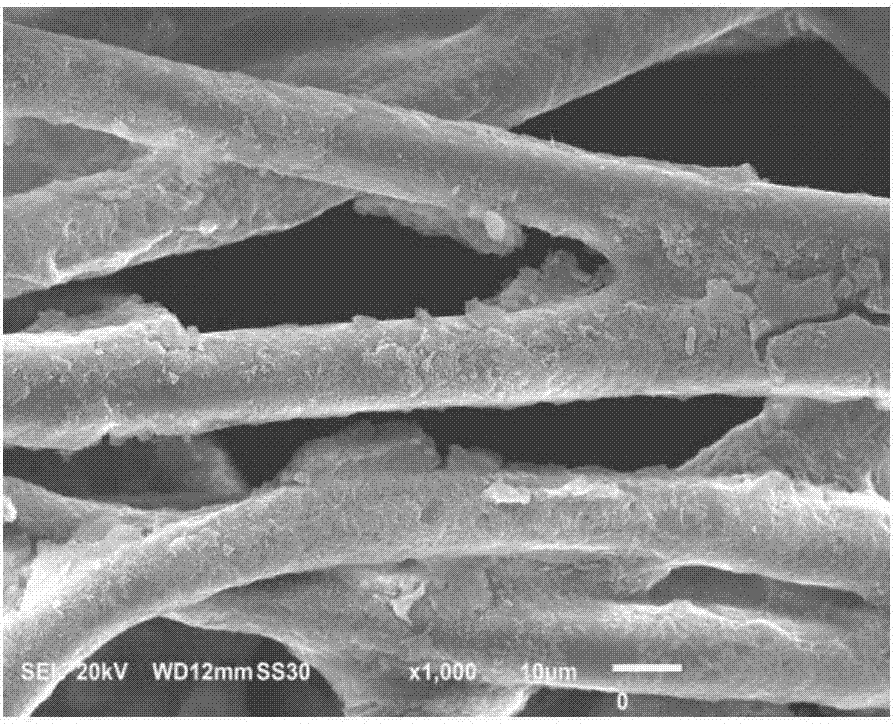

[0028] figure 2 SEM images of superhydrophobic nonwovens constructed for P(DVB-VTES), and figure 1 In comparison, the surface becomes rough obviously, and the size of the ...

Embodiment 2

[0031] With non-woven fabric as the carrier, DVB and VTES as the hydrophobic modifier, through the solvothermal method. Take 1.5mL DVB and 0.5mL VTES into a 50mL autoclave, add 33ml of ethyl acetate, and 2% of the total monomer mass catalyst AIBN, after fully dissolved, put them in a 100°C oven for solvothermal for 10h ; After natural cooling, take out the modified non-woven fabric, and clean it with absolute ethanol, then place it in 2mol L -1 Stand still in the ethanol solution of ammonia water at 25°C for 10 minutes, and finally dry in an oven at 50°C.

Embodiment 3

[0033] With non-woven fabric as the carrier, DVB and VTES as the hydrophobic modifier, through the solvothermal method. Take 1.5mL DVB and 0.5mL VTES into a 50mL autoclave, add 33ml of ethyl acetate, and 2% of the total monomer mass catalyst AIBN, after fully dissolved, put them in a 100°C oven for solvothermal for 10h ; After natural cooling, take out the modified non-woven fabric, and clean it with absolute ethanol, then place it in 2mol L -1 Stand still in the ethanol solution of ammonia water at 25°C for 10 minutes, and finally dry in an oven at 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com