Space truss structure and construction method thereof

A network frame structure and space grid technology, applied in the direction of building construction, construction, etc., can solve the problems of weak overall rigidity of the steel structure network frame, increased construction difficulty, and reduced work efficiency, so as to reduce the consumption of building materials, Single construction link, lightening the effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

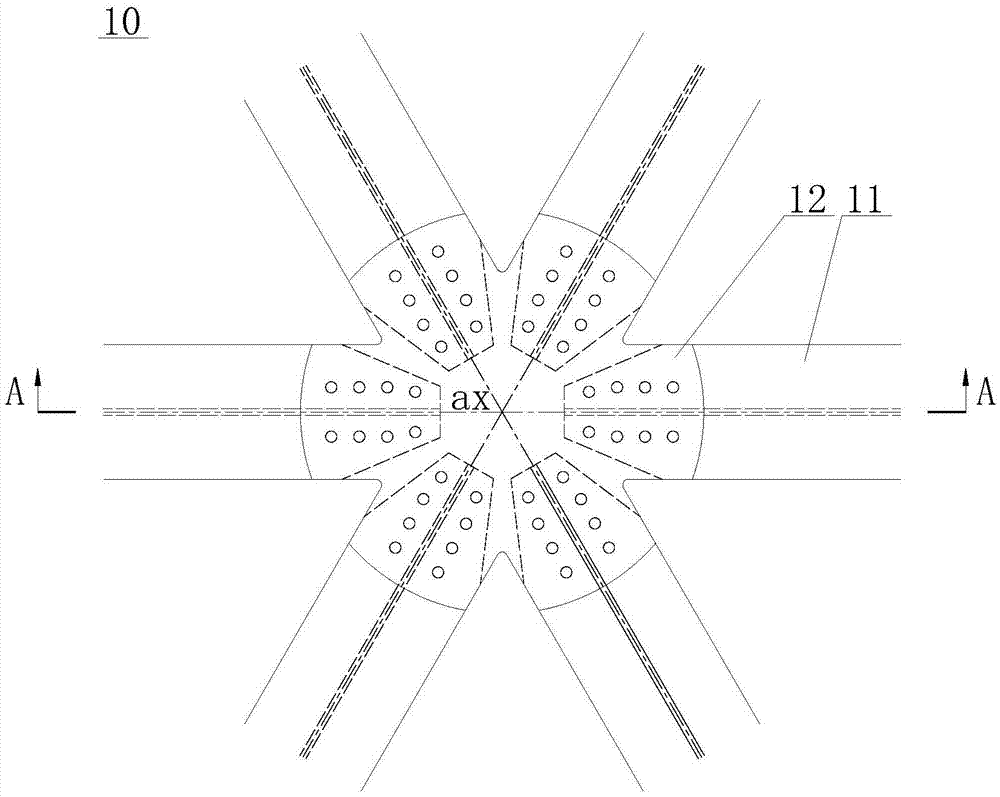

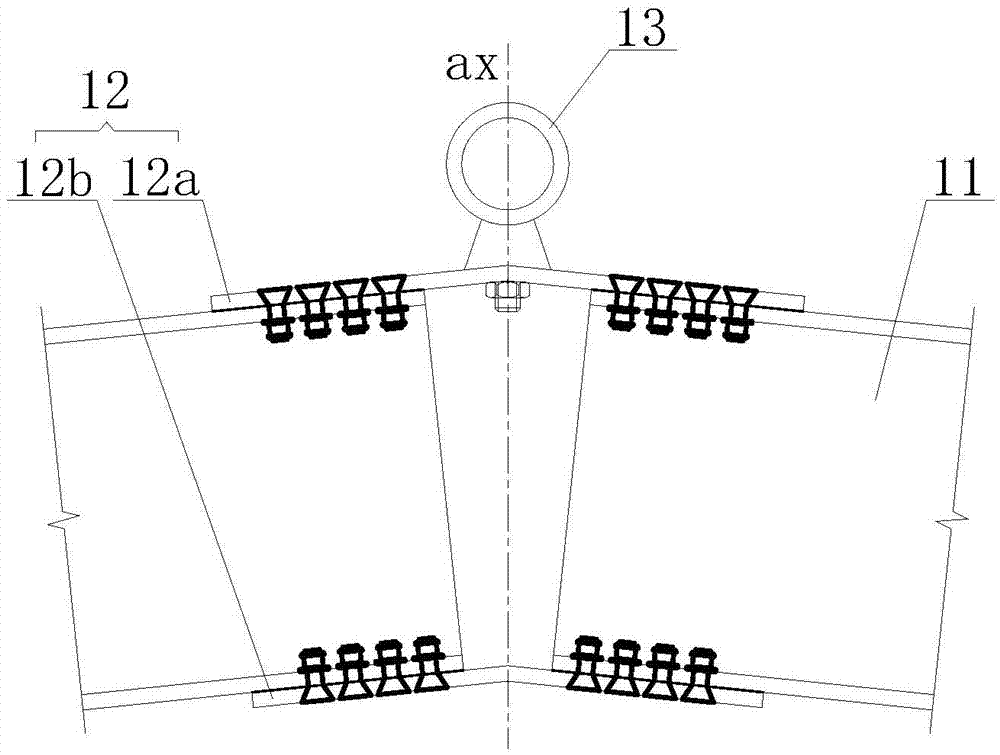

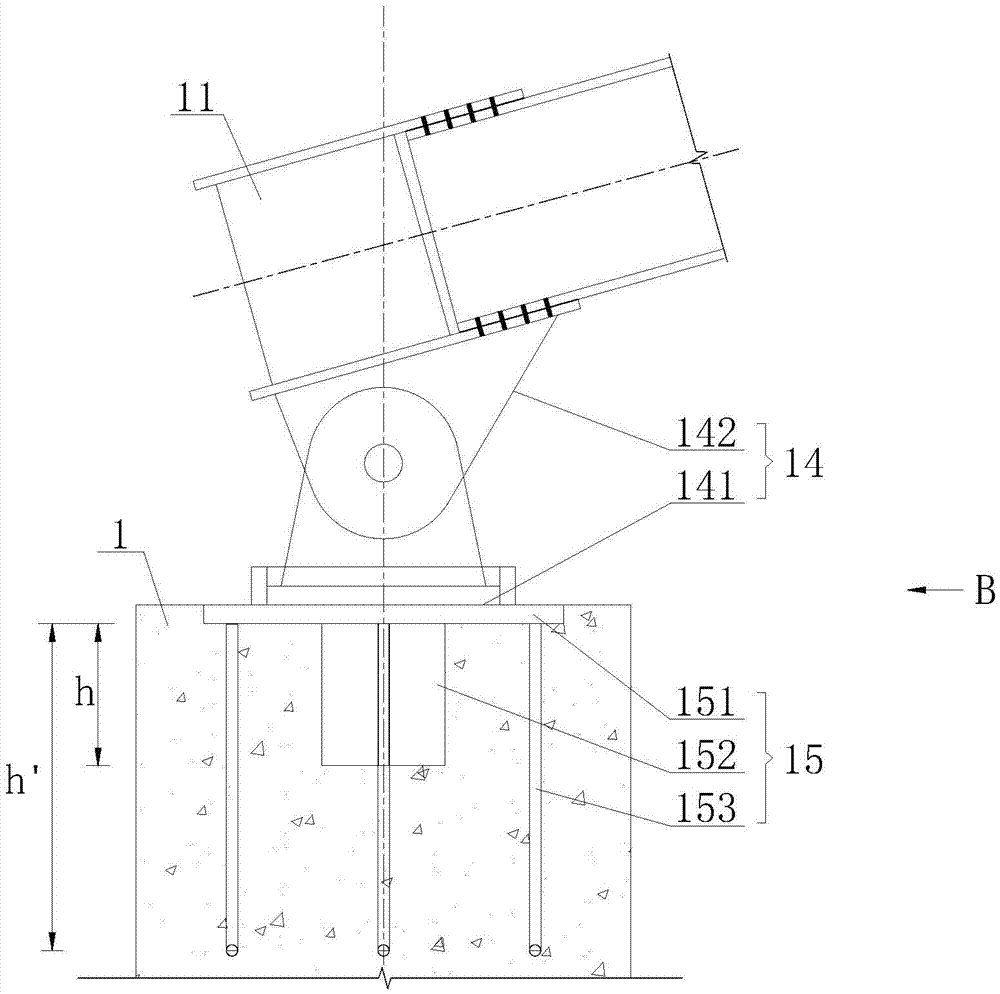

[0027] Embodiment 1: This embodiment takes the construction of the decorative grid frame on the top of an energy center building as an example, and the following is combined Figure 1 to Figure 6 Illustrate a kind of space grid structure of the present invention, it is the space grid structure that is assembled into by several grid units 10 continuously; As figure 1 and figure 2 As shown, the grid unit 10 includes several rods 11 radially distributed along its axis ax, and the converging ends of the rods 11 are fixed together by connecting plates 12, and the rods 11 are made of aluminum alloy.

[0028] Since the gas released by the energy center will corrode the traditional steel structure grid, and the long-term sun and rain will also make the traditional steel structure grid rusty, and the space grid structure of this embodiment, on the one hand, is composed of connecting plates 12 Replace the node structure of the traditional steel structure grid (welded steel plate node,...

Embodiment 2

[0036] Embodiment two: if Image 6 As shown, the difference from Embodiment 1 is that the other end of the base plate 1 of the support body 141 is provided with a connecting rod, and the connecting rod is welded on the steel column 2 of the building, so that the space grid structure can be supported on the steel column of the building. 2 on.

Embodiment 3

[0037] Example Three: Combining Figure 1 to Figure 6 Illustrate the construction method of a kind of space grid structure of the present invention, concrete steps are as follows:

[0038] 2. According to the design requirements, a number of rods 11 and connecting plates 12 are prefabricated in the factory. In order to ensure machining accuracy and improve production capacity, this embodiment adopts high-precision CNC lathes and vertical multi-axis machining centers, and is equipped with precision tools to complete the work. The cutting of the word aluminum, side plates and connecting plates 12 to ensure the processing quality and precision requirements of each component;

[0039] 2. During on-site installation and construction, it is first necessary to number each component, and correspond to and classify the design drawings one by one, so that each rod 11 in the grid unit 10 is connected to the connecting plate 12 with bolts, and the rod 11 passes through the support 14 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com